Microstructure and Properties of Glass Fiber-Reinforced Polyamide/Nylon Microcellular Foamed Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Experiment Procedure

2.3. Preparation of GF/PA Microcellular Foams

2.4. Characterization

3. Results and Discussion

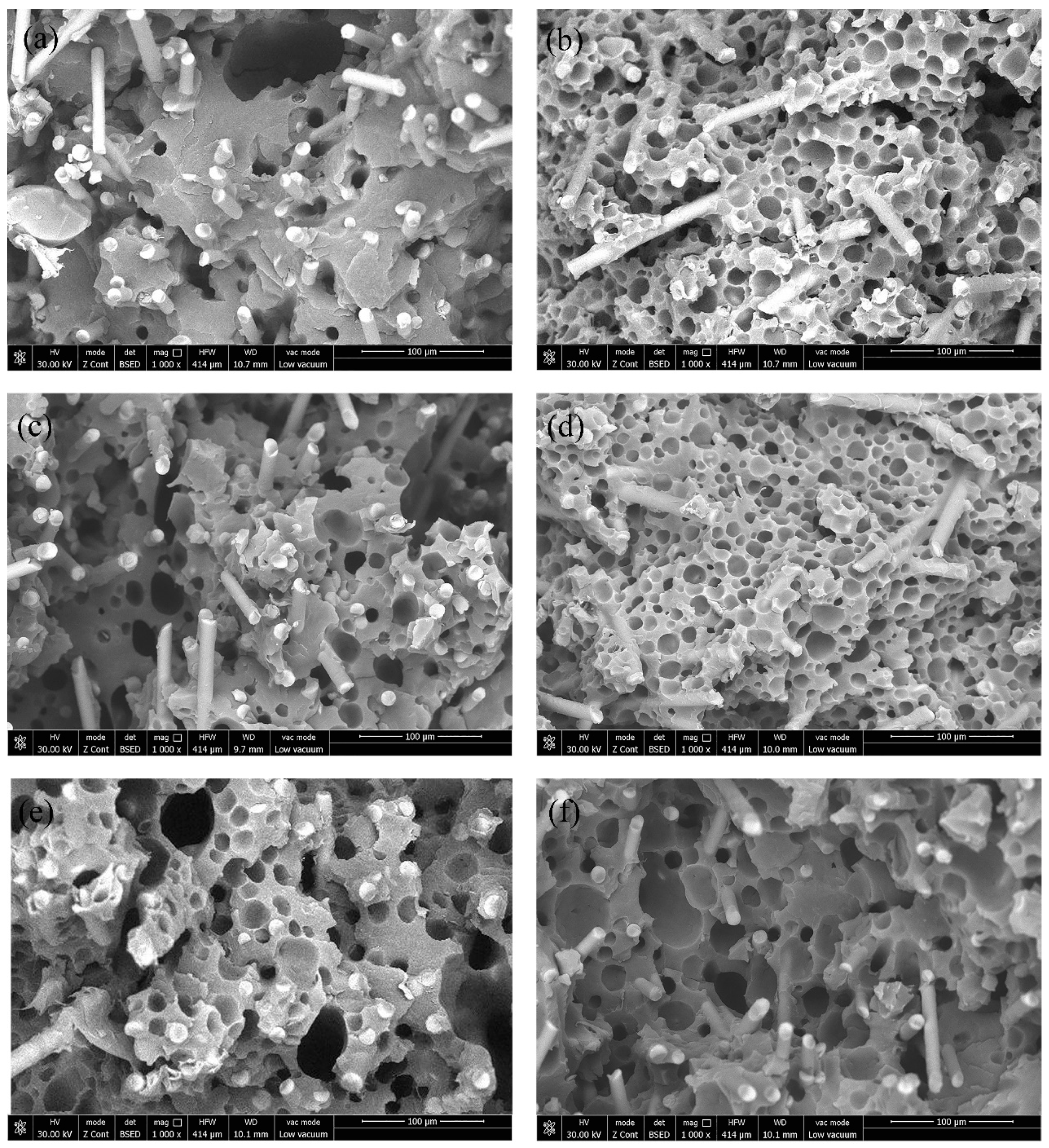

3.1. Cellular Morphology

3.2. Tensile Strength/Weight Ratios

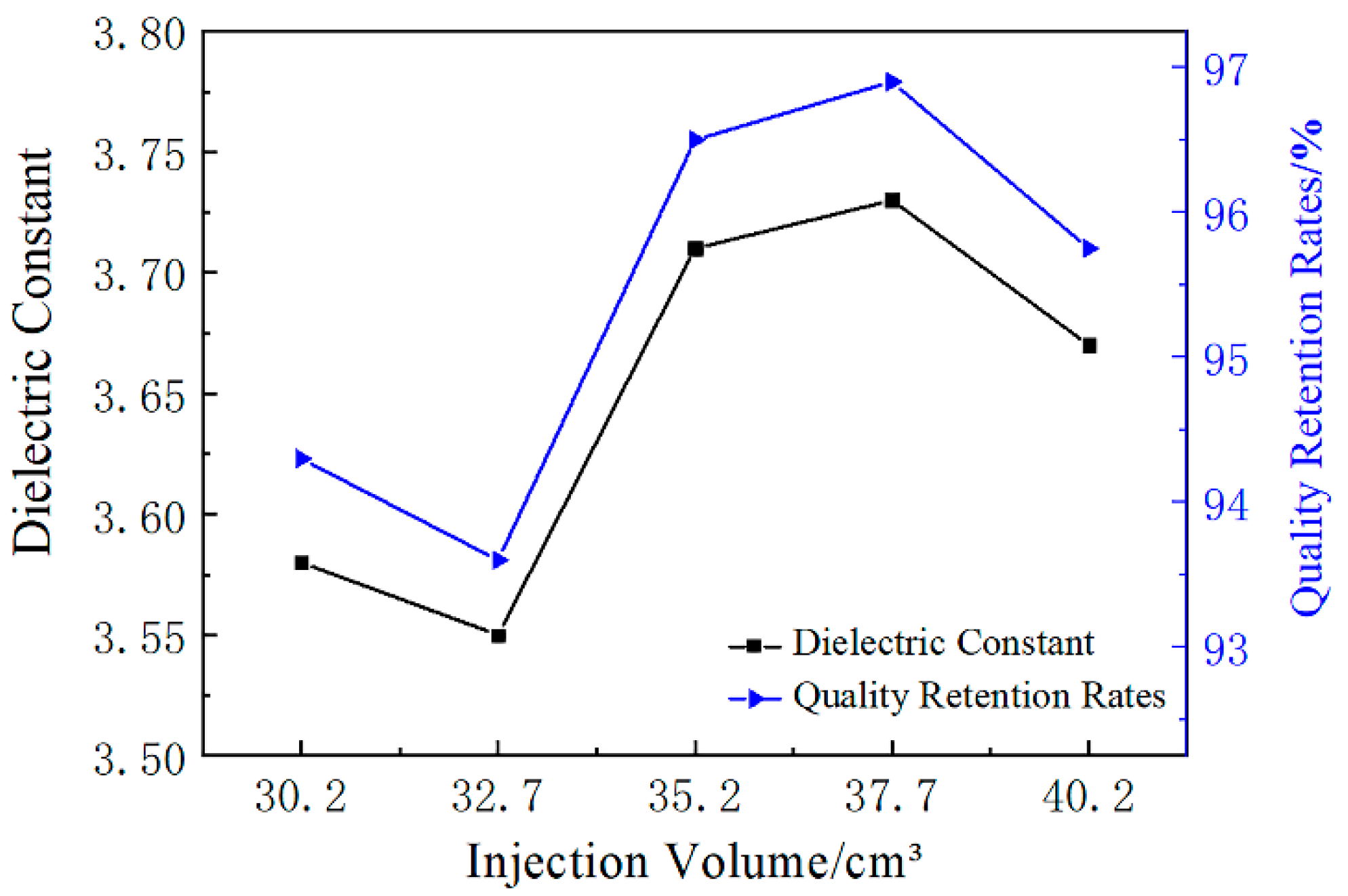

3.3. Dielectric Constant

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, J.C.; Wang, G.L.; Zhang, L.; Li, B.; Wang, C.D.; Zhao, G.Q.; Park, C.B. Lightweight and strong fibrillary PTFE reinforced polypropylene composite foams fabricated by foam injection molding. Eur. Polym. J. 2019, 119, 22–31. [Google Scholar] [CrossRef]

- Hou, J.J.; Zhao, G.Q.; Zhang, L.; Dong, G.W.; Wang, G.L. Foaming Mechanism of Polypropylene in Gas-Assisted Microcellular Injection Molding. Ind. Eng. Chem. Res. 2018, 57, 4710–4720. [Google Scholar] [CrossRef]

- Zhang, R.Z.; Chen, J.; Zhu, Y.X.; Zhang, J.; Luo, G.Q.; Cao, P.; Shen, Q.; Zhang, L.M. Correlation Between the Structure and Compressive Property of PMMA Microcellular Foams Fabricated by Supercritical CO2 Foaming Method. Polymers 2020, 12, 315. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, C.X.; Wang, C.D.; Park, C.B. Poly(vinylidene fluoride) foams: A promising low-k dielectric and heat-insulating material. J. Mater. Chem. C 2018, 6, 3065–3073. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhao, G.Q.; Dong, G.W.; Song, L.B.; Park, C.B. Lightweight, thermally insulating, and low dielectric microcellular high-impact polystyrene (HIPS) foams fabricated by high-pressure foam injection molding with mold opening. J. Mater. Chem. C 2018, 6, 12294–12305. [Google Scholar] [CrossRef]

- Xie, P.C.; Wu, G.J.; Cao, Z.D.; Han, Z.Z.; Zhang, Y.C.; An, Y.; Yang, W.M. Effect of Mold Opening Process on Microporous Structure and Properties of Microcellular Polylactide-Polylactide Nanocomposites. Polymers 2018, 10, 554. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Jiang, C.; Yu, K.S.; Mi, J.G.; Chen, S.H.; Wang, X.D. Influence of crystallization on microcellular foaming behavior of polyamide 6 in a supercritical CO2-assisted route. J. Appl. Polym. Sci. 2020, 137, e49183. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhao, G.Q.; Zhang, L.; Mu, Y.; Park, C.B. Lightweight and tough nanocellular PP/PTFE nanocomposite foams with defect-free surfaces obtained using in situ nanofibrillation and nanocellular injection molding. Chem. Eng. J. 2018, 350, 1–11. [Google Scholar] [CrossRef]

- Cho, S.H.; Kim, H.K.; Sohn, J.S.; Ryu, Y.; Cha, S.W. Effect of foaming processes on the reduction of warpage in glass fiber reinforced plastic composites. J. Mech. Sci. Technol. 2019, 33, 4227–4232. [Google Scholar] [CrossRef]

- Teixeira, D.; Giovanela, M.; Gonella, L.B.; Crespo, J.S. Influence of injection molding on the flexural strength and surface quality of long glass fiber-reinforced polyamide 6.6 composites. Mater. Des. 2015, 85, 695–706. [Google Scholar] [CrossRef]

- Ryu, Y.; Sohn, J.S.; Yun, C.S.; Cha, S.W. Shrinkage and Warpage Minimization of Glass-Fiber-Reinforced Polyamide 6 Parts by Microcellular Foam Injection Molding. Polymers 2020, 12, 889. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Sohn, J.S.; Ryu, Y.; Kim, S.W.; Cha, S.W. Warpage Reduction of Glass Fiber Reinforced Plastic Using Microcellular Foaming Process Applied Injection Molding. Polymers 2019, 11, 360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, J.; Zhao, Q.; Wang, L.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. Development of high thermal insulation and compressive strength BPP foams using mold-opening foam injection molding with in-situ fibrillated PTFE fibers. Eur. Polym. J. 2018, 98, 1–10. [Google Scholar] [CrossRef]

- Gratzl, T.; van Dijk, Y.; Schramm, N.; Kroll, L. Influence of the automotive paint shop on mechanical properties of continuous fibre-reinforced thermoplastics. Compos. Struct. 2019, 208, 557–565. [Google Scholar] [CrossRef]

- Nuruzzaman, D.M.; Iqbal, A.K.M.A.; Oumer, A.N.; Ismail, N.M.; Basri, S. Experimental investigation on the mechanical properties of glass fiber reinforced nylon. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012118. [Google Scholar] [CrossRef]

- Rudresh, B.M.; Ravikumar, B.N. Effect of Short Glass Fiber Loading on the Mechanical Behaviour of PA66/PTFE Blend Composites. Trans. Indian Inst. Met. 2017, 70, 1285–1294. [Google Scholar] [CrossRef]

- Belmonte, E.; De Monte, M.; Hoffmann, C.J.; Quaresimin, M. Damage initiation and evolution in short fiber reinforced polyamide under fatigue loading: Influence of fiber volume fraction. Compos. Part B Eng. 2017, 113, 331–341. [Google Scholar] [CrossRef]

- Cui, J.J.; Wang, S.L.; Wang, S.H.; Li, G.Y.; Wang, P.L.; Liang, C.S. The Effects of Strain Rates on Mechanical Properties and Failure Behavior of Long Glass Fiber Reinforced Thermoplastic Composites. Polymers 2019, 11, 2019. [Google Scholar] [CrossRef] [Green Version]

- Nia, A.B.; Xin, L.; Yahya, M.Y.; Ayob, A.; Nejad, A.F.; Koloor, S.S.R.; Petrů, M. Failure of Glass Fibre-Reinforced Polypropylene Metal Laminate Subjected to Close-Range Explosion. Polymers 2020, 12, 2139. [Google Scholar]

- Wang, L.; Okada, K.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Yano, H. Effect of Cellulose Nanofiber (CNF) Surface Treatment on Cellular Structures and Mechanical Properties of Polypropylene/CNF Nanocomposite Foams via Core-Back Foam Injection Molding. Polymers 2019, 11, 249. [Google Scholar] [CrossRef] [Green Version]

- Bin, W.; Dingjun, J. Effects of Chemical Foaming Injection Process on Structure and Mechanical Properties of Nylon6 Microcellular Material Reinforced by Glass Fiber. Eng. Plast. Appl. 2018, 46, 53–59. [Google Scholar]

- Llewelyn, G.; Rees, A.; Griffiths, C.A.; Scholz, S.G. Advances in microcellular injection moulding. J. Cell. Plast. 2020. Available online: https://journals.sagepub.com/doi/10.1177/0021955X20912207 (accessed on 14 October 2020).

- Wang, L.; Wakatsuki, Y.; Hikima, Y.; Ohshima, M.; Yusa, A.; Uezono, H.; Naitou, A. Preparation of Microcellular Injection-Molded Foams Using Different Types of Low-Pressure Gases via a New Foam Injection Molding Technology. Ind. Eng. Chem. Res. 2019, 58, 17824–17832. [Google Scholar] [CrossRef]

- Wang, C.; Wu, J.; She, J.; Zhang, X.; Yuan, C.; Zhao, Y.; He, J. Preparation and Properties of Supercritical N2 Microcellular Foaming PA6. Eng. Plast. Appl. 2015, 2, 64–66. [Google Scholar]

- Hwang, S.S.; Liu, S.P.; Hsu, P.P.; Yeh, J.M.; Yang, J.P.; Chang, K.C.; Chu, S.N. Effect of organoclay and preparation methods on the mechanical/thermal properties of microcellular injection molded polyamide 6-clay nanocomposites. Int. Commun. Heat Mass 2011, 38, 1219–1225. [Google Scholar] [CrossRef]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight High-Performance Polymer Composite for Automotive Applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef] [Green Version]

- Roch, A.; Kehret, L.; Huber, T.; Henning, F.; Elsner, P. Investigations on injection molded, glass-fiber reinforced polyamide 6 integral foams using breathing mold technology. AIP Conf. Proc. 2015, 1664, 110013. [Google Scholar]

- Huang, R.; Liu, Z. Recent research and development of low dielectric constant materials. Micronanoelectron. Technol. 2003, 40, 11–14. [Google Scholar]

- Wenguan, Z.; Xishun, W. Main Mechanical Properties of Foamed Plastics and Its Mechanical Model. Plast. Sci. Technol. 2003, 6, 17–19. [Google Scholar]

- Zhu, Y.X.; Luo, G.Q.; Zhang, R.Z.; Cao, P.; Liu, Q.W.; Zhang, J.; Sun, Y.; Li, J.S.; Shen, Q.; Zhang, L.M. Numerical simulation of static mechanical properties of PMMA microcellular foams. Compos. Sci. Technol. 2020, 192, 108110. [Google Scholar] [CrossRef]

- Leung, S.N.; Li, H.B.; Park, C.B. Impact of approximating the initial bubble pressure on cell nucleation in polymeric foaming processes. J. Appl. Polym. Sci. 2007, 104, 902–908. [Google Scholar] [CrossRef]

- Xu, J. Microcellular Injection Molding; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Kastner, C.; Steinbichler, G.; Kahlen, S.; Jerabek, M. Influence of process parameters on mechanical properties of physically foamed, fiber reinforced polypropylene parts. J. Appl. Polym. Sci. 2019, 136, 47275. [Google Scholar]

- Kastner, C.; Steinbichler, G.; Kahlen, S.; Jerabek, M.; Lummerstorfer, T. Nonlinear influences of process parameters on mechanical properties of physically foamed, fiber-reinforced polypropylene parts. J. Appl. Polym. Sci. 2020, 137, e49569. [Google Scholar] [CrossRef]

- Dajiong, F.; Zhenhua, L.; Qi, W.; Gang, S.; Bo, Y.; Wenge, Z.; Zhongfu, L. The Effect of Nucleation Agents and Mold Temperature on Properties of Injection Molded Polypropylene Foams. Plast. Sci. Technol. 2019, 47, 60–64. [Google Scholar]

- Xie, X.; Yang, C.; Qi, X.; Yang, J.; Zhou, Z.; Wang, Y. Constructing polymeric interlayer with dual effects toward high dielectric constant and low dielectric loss. Chem. Eng. J. 2019, 366, 378–389. [Google Scholar] [CrossRef]

| Level | Factor A Injection Rate/% | Factor B Temperature/°C | Factor C Injection Volume/cm3 |

|---|---|---|---|

| 1 | 20-20 | 240 | 30.2 |

| 2 | 50-50 | 250 | 32.7 |

| 3 | 80-80 | 260 | 35.2 |

| 4 | 50-80 | 270 | 37.7 |

| 5 | 100-100 | 280 | 40.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wu, G.; Xie, P.; Gao, X.; Yang, W. Microstructure and Properties of Glass Fiber-Reinforced Polyamide/Nylon Microcellular Foamed Composites. Polymers 2020, 12, 2368. https://doi.org/10.3390/polym12102368

Wang X, Wu G, Xie P, Gao X, Yang W. Microstructure and Properties of Glass Fiber-Reinforced Polyamide/Nylon Microcellular Foamed Composites. Polymers. 2020; 12(10):2368. https://doi.org/10.3390/polym12102368

Chicago/Turabian StyleWang, Xiulei, Gaojian Wu, Pengcheng Xie, Xiaodong Gao, and Weimin Yang. 2020. "Microstructure and Properties of Glass Fiber-Reinforced Polyamide/Nylon Microcellular Foamed Composites" Polymers 12, no. 10: 2368. https://doi.org/10.3390/polym12102368