A Method of Adding Binder by High-Pressure Spraying to Improve the Biomass Densification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Moisture Content Determination

2.2.2. Experimental Equipment

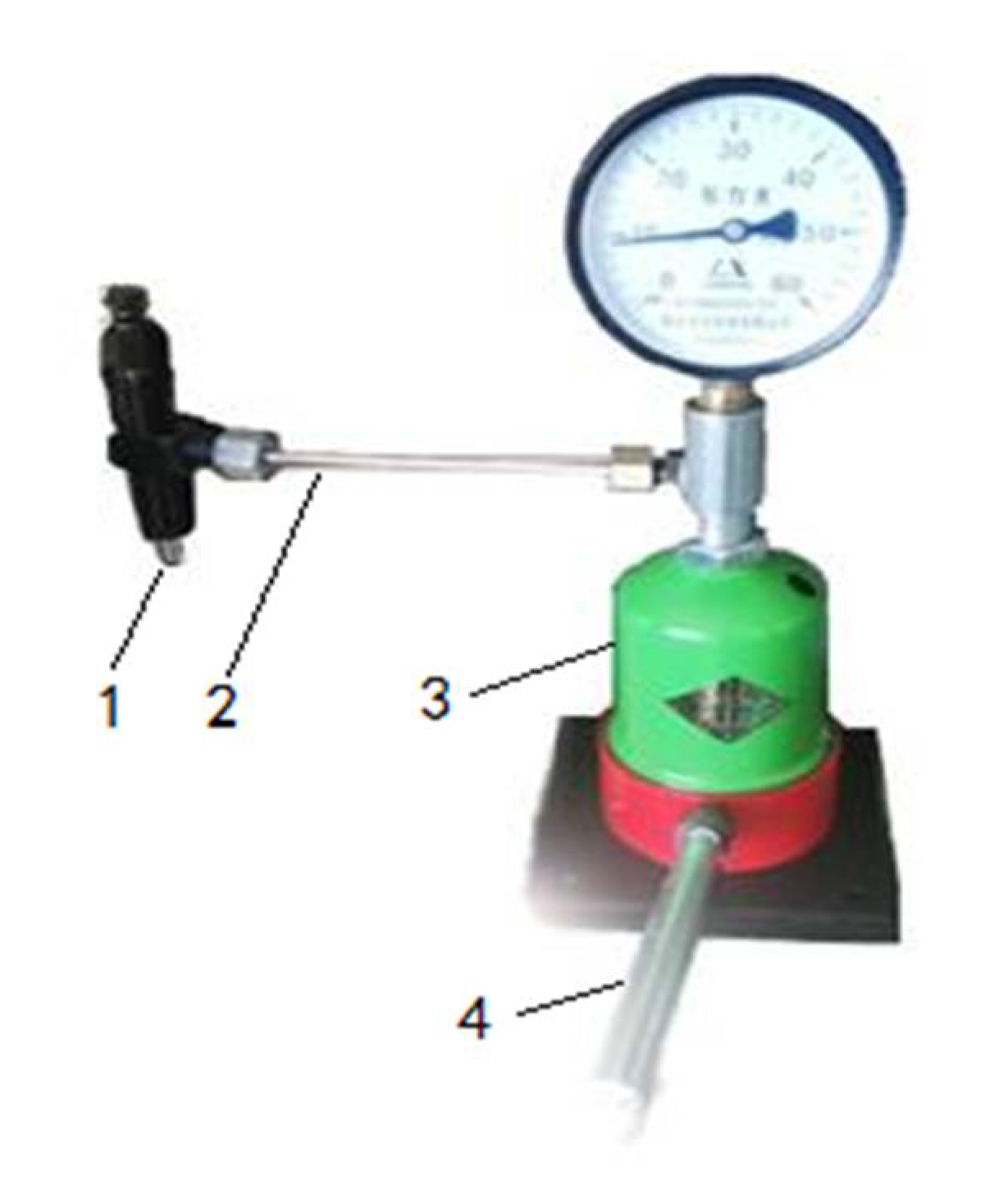

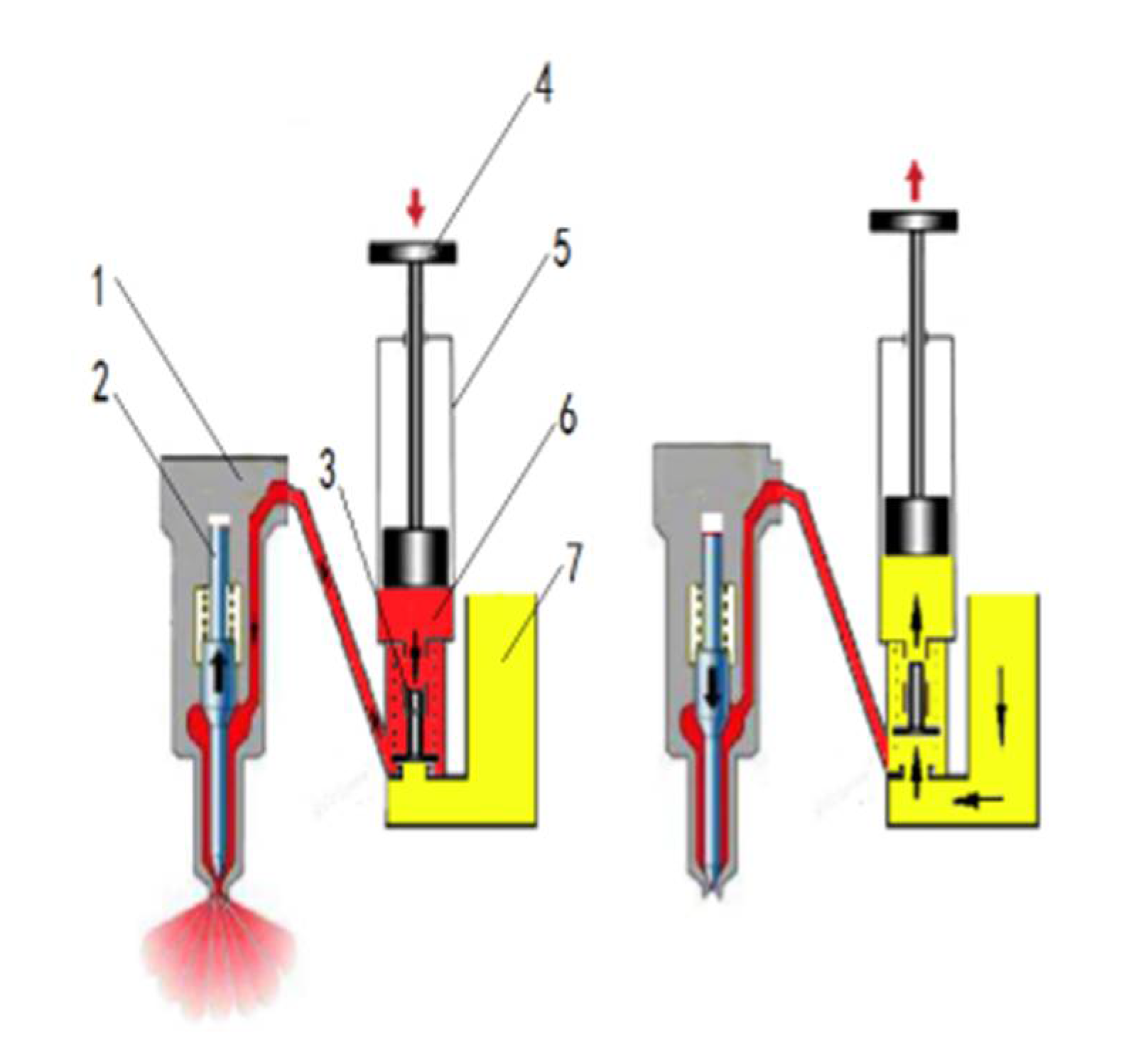

- A high-pressure spraying device (model: XZ-PJ602L13, Shanghai, China)(pressure gauge, exit pressure: 10 MPa). In this test, compared with the 4 MPa sprayer in the previous study, the 10 MPa high-pressure sprayer (Figure 1) was used for spraying. It consists of a sprayer (1) (nozzle diameter: 0.6 mm), and a hand pressure pump (3) (height: 33 cm), which are connected by tubing (2). Under normal conditions (Figure 2), the needle valve (2) is closed under the spring pressure. When the piston (4) is pressed, liquid under the piston (4) is pressurized. The high -pressure liquid (6) enters the sprayer through the one-way valve and tubing; then, the needle valve (2) overcomes the spring pressure and rises under the push of the high-pressure liquid (6). Afterwards, the binder is sprayed from the nozzle hole at the tip of the needle valve (2). Under high pressure, the liquid binder will spray out as a mist. The schematic diagram is shown in Figure 2.

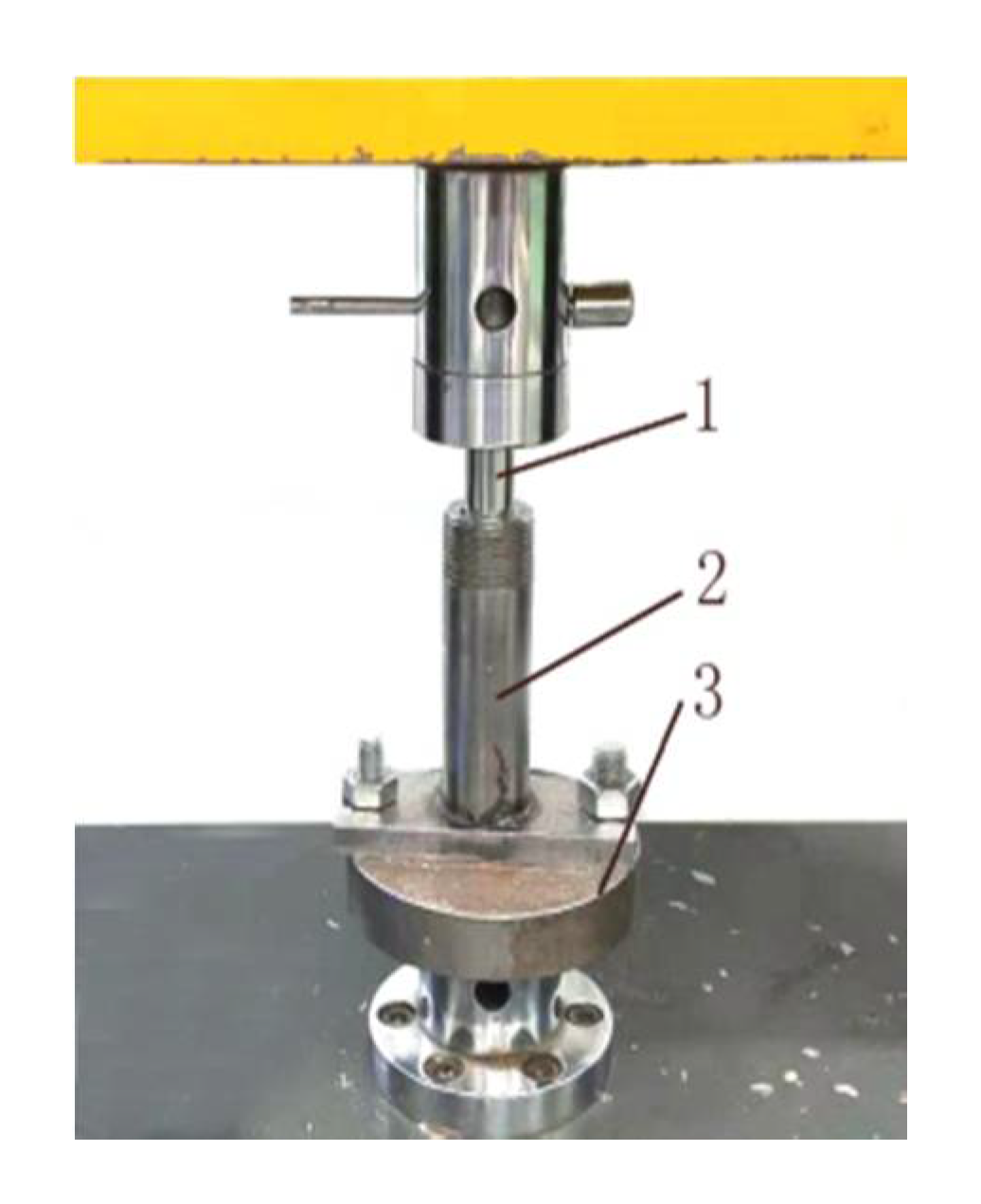

- Plunger and die (inner diameter: 16 mm; length: 125 mm). This test used following compaction apparatus for densification (Figure 3). During densification, the plunger exerted pressure on the raw materials in the die to densify the biomass raw materials.

- Microcomputer-controlled electronic universal testing machine (Model: 4050, Reger, Shenzhen, China), electronic balance(Model: SF-400A, Shanghai, China) (accuracy: 0.01 g), moisture tester (model: SC69-02, Shanghai, China), vernier caliper(precision: 0.01 mm), etc.

2.2.3. Pretreatment of Sawdust and Binder

2.2.4. Pretest—the Effect of High-pressure Spraying Method at Low Pressure Compaction

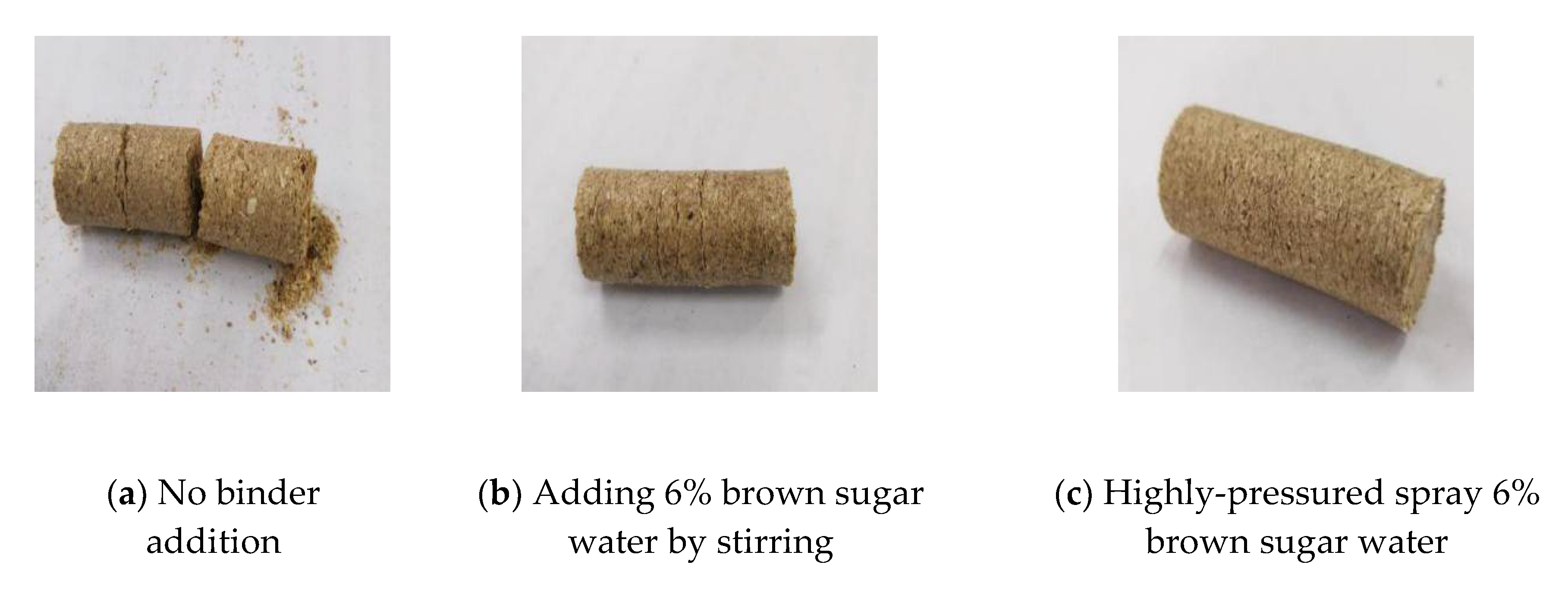

- Test method. At a pressure of 14.9 MPa, adding 6% binder was taken as an example. The densification test was carried out on three groups of samples including no binder addition, 6% brown sugar water addition by stirring and 6% brown sugar water addition by highly-pressured spraying. Each set of tests was repeated 3 times, and the average value was calculated to compare the densification effect. The pretest aims to verify the feasibility of the high-pressure spraying method: that is, whether this method promotes the densification of biomass.

- Evaluation index.

- Densification effect. At the same compaction pressure, the experiments under different densification conditions were compared. The evaluation criteria were whether the sawdust can be densified into pellets and the surface quality of the pellets after densification.

- Relaxation density.

2.2.5. The Effect of the High-Pressure Spraying Method at High Pressure Compaction

- The table L16 (2 × 42) was used to design a three-factor mixed level orthogonal test (Table 1).

- 2.

- Evaluation index:

- Relaxation density.

- Compressive strength.

2.2.6. Statistical Software

3. Results and Discussion

3.1. Densification Experiment under Low Compaction Pressure

3.2. Densification Experiment under High Compaction Pressure

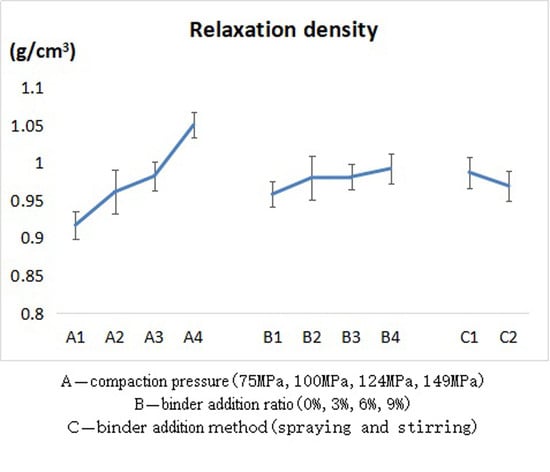

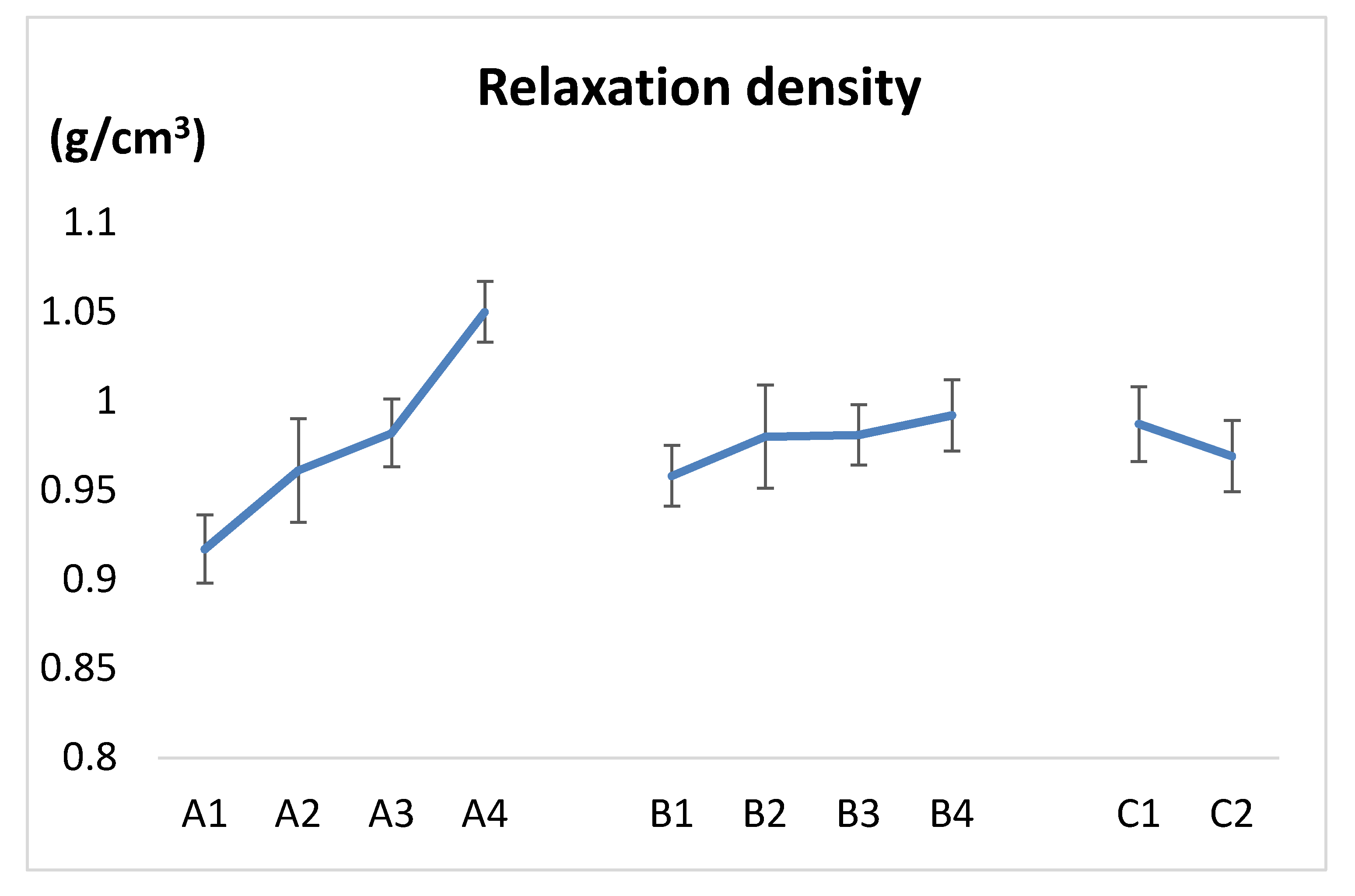

3.2.1. Experimental Results of Relaxation Density

3.2.2. Range Analysis

3.2.3. Multiple Linear Regression Analysis

3.3. Destruction Test

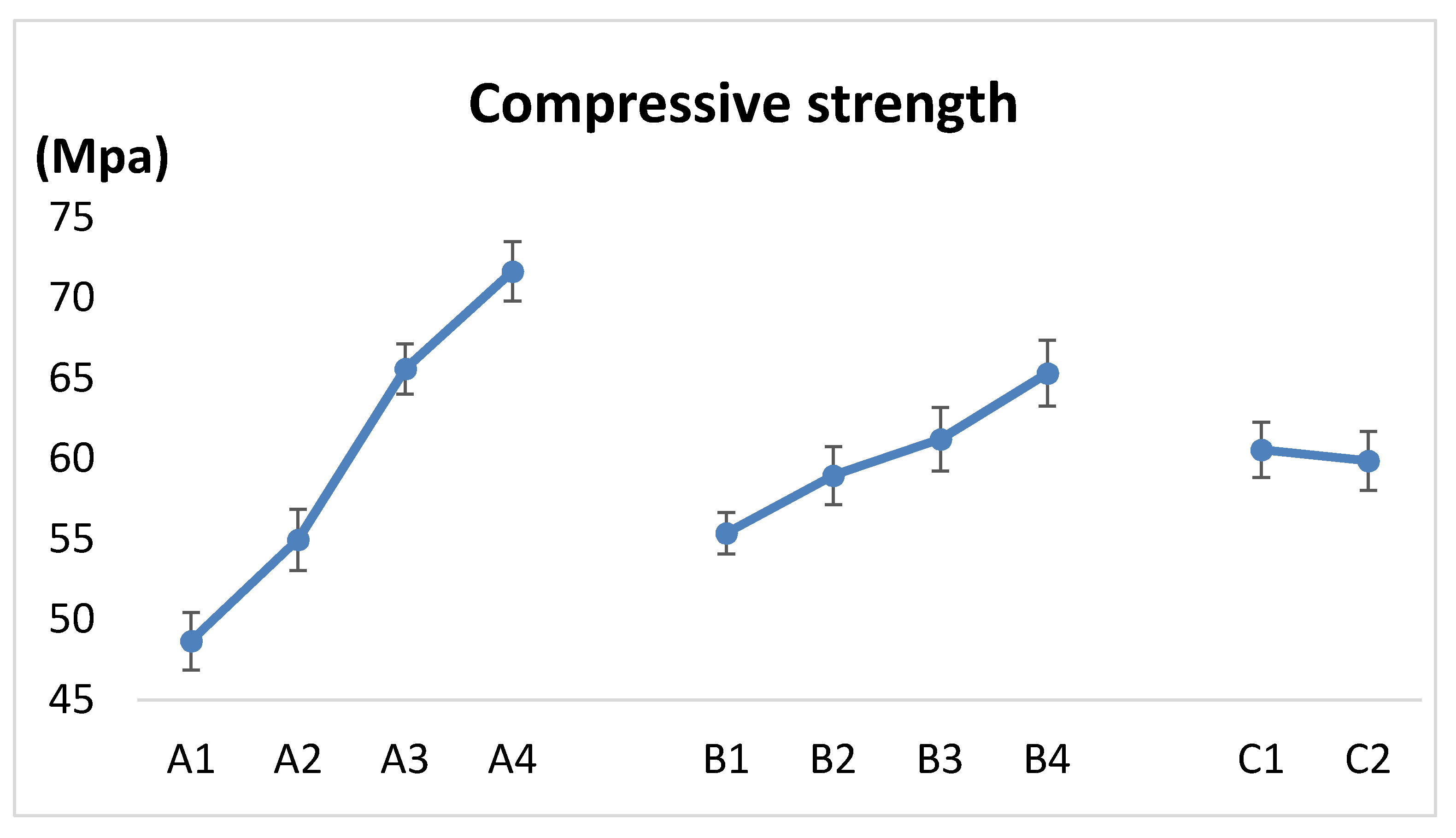

3.3.1. Experimental Results of Compressive Strength

3.3.2. Range Analysis

3.3.3. Multiple Linear Regression Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Junfeng, L.; Runqing, H. Sustainable biomass production for energy in China. Biomass Bioenergy 2003, 25, 483–499. [Google Scholar] [CrossRef]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [Google Scholar] [CrossRef] [PubMed]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P. Wood pellets as a sustainable energy alternative in Portugal. Renew. Energy 2016, 85, 1011–1016. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Sun, C.; Thakur, S.; Gupta, V.K.; Thakur, V.K. Energy production from steam gasification processes and parameters that contemplate in biomass gasifier—A review. Bioresour. Technol. 2020, 297, 122481. [Google Scholar] [CrossRef]

- Hu, J.; Lei, T.; Wang, Z.; Yan, X.; Shi, X.; Li, Z.; He, X.; Zhang, Q. Economic, environmental and social assessment of briquette fuel from agricultural residues in China—A study on flat die briquetting using corn stalk. Energy 2014, 64, 557–566. [Google Scholar] [CrossRef]

- Zhang, Y.; Yao, A.; Song, K. Torrefaction of cultivation residue of Auricularia auricula-judae to obtain biochar with enhanced fuel properties. Bioresour. Technol. 2016, 206, 211–216. [Google Scholar] [CrossRef]

- Panwar, V.; Prasad, B.; Wasewar, K.L. Biomass Residue Briquetting and Characterization. J. Energy Eng. 2011, 137, 108–114. [Google Scholar] [CrossRef]

- Hu, X.L. Experimental study on the use of compression molding technology on biomass fuels of sawdust, leaves and wheat straw. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, June 2017. [Google Scholar]

- Razuan, R.; Finney, K.N.; Chen, Q.; Sharifi, V.; Swithenbank, J. Pelletised fuel production from palm kernel cake. Fuel Process. Technol. 2011, 92, 609–615. [Google Scholar] [CrossRef]

- Li, M.H. The Study on biofuel solidification parameter. Master’s Thesis, Beijing Forestry University, Beijing, China, May 2005. [Google Scholar]

- Xing, L.; Wang, S.Y.; Liu, X.D. Experiment and Analysis of Straw Compression. J. Jiamusi Univ.(Nat. Sci. Ed.) 2005, 23, 574–576. [Google Scholar]

- Yan, S. Study on the Compression Molding Technology and the Combustion Characteristics of Biomass Fuel. Master’s Thesis, Hebei University of Science and Technology, Shijiazhuang, China, May 2013. [Google Scholar]

- Zhang, Y.; Tong, D.; Song, K. Analysis on Solid Biofuels Densification and its Influencing Factors. For. Mach. Woodwork. Equip. 2012, 4, 20–22. [Google Scholar]

- Grover, P.; Mishra, S.; Clancy, J. Development of an appropriate biomass briquetting technology suitable for production and use in developing countries. Energy Sustain. Dev. 1994, 1, 45–48. [Google Scholar] [CrossRef]

- Zhang, X.; Cai, Z.; Chen, L.; Chen, Y.; Zhang, Y. Research on the compressing mechanism and quality evaluation parameters of densified biomass fuel. Renew. Energy Resour. 2014, 32, 1917–1921. [Google Scholar]

- Xianfei, X.; Kai, W.; Yu, S.; Qinghai, J. Research progress of the biomass (straw) densification forming technology. J. Chin. Agric. Mech. 2013, 34, 36–42. [Google Scholar]

- Ji, A.; Zhao, R.; Li, H.; Zhang, Z. Study on the Influencing Factors of Straw Biomass Pressure Forming Process Design of the Divided No—Till Wheat Planter. J. Agric. Mech. Res. 2017, 39, 220–225. [Google Scholar]

- Abedi, A.; Cheng, H.; Dalai, A. Effects of Natural Additives on the Properties of Sawdust Fuel Pellets. Energy Fuels 2018, 32, 1863–1873. [Google Scholar] [CrossRef]

- Lindley, J.A.; Vossoughi, M. Physical Properties of Biomass Briquets. Trans. ASAE. 1989, 32, 361–366. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Lei, W.; Huang, T.; Wang, P.; Jia, C. Recent progress in research and application of DBBF additive in preparation and combustion process. Chem. Ind. Eng. Prog. 2017, 36, 1247–1257. [Google Scholar]

- Tabil, L.G., Jr.; Sokhansanj, S.; Tyler, R.T. Performance of different binders during alfalfa pelleting. Can. Agric. Eng. 1997, 39, 017–023. [Google Scholar]

- Zhang, J. Preparation and Study of Application Performance on Mimosa tannin-Furanic Resins. Ph.D. Thesis, Beijing Forestry University, Beijing, China, May 2016. [Google Scholar]

- Pfost, H.B. The effect of lignin binders, die thickness and temperature on the pelleting process. Feedstuffs 1964, 36, 54–69. [Google Scholar]

- Lam, P.S.; Sokhansanj, S.; Bi, X.T.; Lim, C.; Lam, P.Y. Mechanical and compositional characteristics of steam-treated Douglas fir (Pseudotsuga menziesii L.) during pelletization. Biomass Bioenergy 2013, 56, 116–126. [Google Scholar] [CrossRef]

- Zhai, Y.; Wang, T.; Zhu, Y.; Peng, C.; Wang, B.; Li, X.; Li, C.; Zeng, G. Production of fuel pellets via hydrothermal carbonization of food waste using molasses as a binder. Waste Manag. 2018, 77, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Mania, S.; Ryl, J.; Jinn, J.-R.; Wang, Y.-J.; Michałowska, A.; Tylingo, R. The Production Possibility of the Antimicrobial Filaments by Co-Extrusion of the PLA Pellet with Chitosan Powder for FDM 3D Printing Technology. Polymers 2019, 11, 1893. [Google Scholar] [CrossRef] [PubMed]

- Manyuchi, M.; Mbohwa, C.; Muzenda, E. Value addition of coal fines and sawdust to briquettes using molasses as a binder. South Afr. J. Chem. Eng. 2018, 26, 70–73. [Google Scholar] [CrossRef]

- Singh, A.; Singh, Y. Briquetting of paddy straw. Agric. Mech. Asia Afr. Lat. Am. 1982, 13, 42–49. [Google Scholar]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1109. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, X.L.; Grewal, R.; Tabil, L.G. Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 2017, 193, 134–141. [Google Scholar] [CrossRef]

- Zhang, K.; Song, S.; Chen, Z.; Zhou, J. Effects of Brown Sugar Water Binder Added by Spraying Method as Solid Bridge on the Physical Characteristics of Biomass Pellets. Polymers 2020, 12, 674. [Google Scholar] [CrossRef]

- Kumar, R.A.; Sabapathy, H.K.; Neethimanickam, I.; Information, R. Mechanical, physical and chemical properties of saw dust briquette. World J. Eng. 2015, 12, 347–352. [Google Scholar] [CrossRef]

- Hui, C. The Studies of Biomass Solidifying Technology and Principle with High Pressure on Natural Conditions for Bio-fuel Making. Ph.D. Thesis, Beijing Forestry University, Beijing, China, May 2006. [Google Scholar]

- Bing-bing, S.H.I. Sucrose Solubility in Alcohol—Water Solution. Guangzhou Chem. Ind. 2009, 37, 101–102. [Google Scholar]

- Gilvari, H.; Cutz, L.; Tiringer, U.; Mol, J.M.C.; De Jong, W.; Schott, D.l. The Effect of Environmental Conditions on the Degradation Behavior of Biomass Pellets. Polymers 2020, 12, 970. [Google Scholar] [CrossRef]

- Ma, Y. Study on Rheological Properties and Product Microstructure Analysis in Biomass Densification under Assistive Vibration Force Field. Ph.D. Thesis, Inner Mongolia Agricultural University, Hohhot, China, December 2015. [Google Scholar]

- Si, Y. Study on the Quality Promotion and Bonding Mechanism of Agricultural Residues Pellets. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2018. [Google Scholar]

- Lv, Z. Affect the physical properties of biomass pretreatment technology was studied. Master’s Thesis, Heilongjiang Bayi Agricultural University, Daqing, China, June 2015. [Google Scholar]

| Level | Factor | ||

|---|---|---|---|

| Compaction Pressure (MPa) | Binder Addition Ratio (%) | Binder Addition Method | |

| 1 | 75 | 0 | Spraying |

| 2 | 100 | 3 | Stirring |

| 3 | 124 | 6 | |

| 4 | 149 | 9 | |

| Factor | Relaxation Density (g/cm³) | Surface Quality of Pellets |

|---|---|---|

| a | 0.588 ± 0.004 | Many large cracks on the surface and fracture easily |

| b | 0.624 ± 0.005 | Less large cracks and not easy to fracture |

| c | 0.678 ± 0.002 | Tiny cracks on the surface |

| Test group | A (MPa) | B (%) | C | Y1 (g/cm³) |

|---|---|---|---|---|

| 1 | 75 (1) | 0 (1) | Spraying (1) | 0.897 ± 0.010 |

| 2 | 75 (1) | 3 (2) | Stirring (2) | 0.903 ± 0.005 |

| 3 | 75 (1) | 6 (3) | Spraying (1) | 0.933 ± 0.027 |

| 4 | 75 (1) | 9 (4) | Stirring (2) | 0.936 ± 0.028 |

| 5 | 100 (2) | 0 (1) | Stirring (2) | 0.924 ± 0.029 |

| 6 | 100 (2) | 3 (2) | Spraying (1) | 0.979 ± 0.042 |

| 7 | 100 (2) | 6 (3) | Stirring (2) | 0.948 ± 0.005 |

| 8 | 100 (2) | 9 (4) | Spraying (1) | 0.993 ± 0.038 |

| 9 | 124 (3) | 0 (1) | Spraying (1) | 0.976 ± 0.007 |

| 10 | 124 (3) | 3 (2) | Stirring (2) | 0.982 ± 0.042 |

| 11 | 124 (3) | 6 (3) | Spraying (1) | 0.995 ± 0.016 |

| 12 | 124 (3) | 9 (4) | Stirring (2) | 0.977 ± 0.010 |

| 13 | 149 (4) | 0 (1) | Stirring (2) | 1.035 ± 0.021 |

| 14 | 149 (4) | 3 (2) | Spraying (1) | 1.056 ± 0.025 |

| 15 | 149 (4) | 6 (3) | Stirring (2) | 1.049 ± 0.018 |

| 16 | 149 (4) | 9 (4) | Spraying (1) | 1.062 ± 0.002 |

| A | B | C | ||

|---|---|---|---|---|

| Y1 | K1 | 3.669 ± 0.070 | 3.832 ± 0.067 | 7.892 ± 0.168 |

| K2 | 3.844 ± 0.114 | 3.920 ± 0.114 | 7.752 ± 0.158 | |

| K3 | 3.928 ± 0.075 | 3.924 ± 0.066 | — | |

| K4 | 4.202 ± 0.066 | 3.968 ± 0.078 | — | |

| k1 | 0.917 ± 0.019 | 0.958 ± 0.017 | 0.987 ± 0.021 | |

| k2 | 0.961 ± 0.029 | 0.980 ± 0.029 | 0.969 ± 0.020 | |

| k3 | 0.982 ± 0.019 | 0.981 ± 0.017 | — | |

| k4 | 1.050 ± 0.017 | 0.992 ± 0.020 | — | |

| R | 0.133 ± 0.036 | 0.034 ± 0.036 | 0.018 ± 0.041 | |

| Optimal level | A4 | B4 | C1 |

| Coefficient a | |||||

|---|---|---|---|---|---|

| Model | Unnormalized Coefficient | Normalized Coefficient | t | Significance | |

| Standard Error | Beta | ||||

| 1 | (constant) | 0.021 | 38.424 | 0.000 | |

| A(MPa) | 0.001 | 0.922 | 11.993 | 0.000 | |

| B(%) | 0.001 | 0.226 | 2.940 | 0.012 | |

| C | 0.008 | −0.168 | −2.180 | 0.050 | |

| Test Group | A(MPa) | B(%) | C | Maximum Axial Force (KN) | Y2 (MPa) |

|---|---|---|---|---|---|

| 1 | 75 (1) | 0 (1) | Spraying (1) | 9.10 ± 0.16 | 45.26 ± 0.78 |

| 2 | 75 (1) | 3 (2) | Stirring (2) | 9.37 ± 0.45 | 46.60 ± 2.24 |

| 3 | 75 (1) | 6 (3) | Spraying (1) | 9.64 ± 0.44 | 47.95 ± 2.19 |

| 4 | 75 (1) | 9 (4) | Stirring (2) | 11.03 ± 0.39 | 54.86 ± 1.94 |

| 5 | 100 (2) | 0 (1) | Stirring (2) | 9.65 ± 0.28 | 47.99 ± 1.39 |

| 6 | 100 (2) | 3 (2) | Spraying (1) | 11.36 ± 0.44 | 56.50 ± 2.16 |

| 7 | 100 (2) | 6 (3) | Stirring (2) | 11.38 ± 0.33 | 56.60 ± 1.63 |

| 8 | 100 (2) | 9 (4) | Spraying (1) | 11.82 ± 0.49 | 58.79 ± 2.43 |

| 9 | 124 (3) | 0 (1) | Spraying (1) | 12.43 ± 0.17 | 61.82 ± 0.86 |

| 10 | 124 (3) | 3 (2) | Stirring (2) | 13.02 ± 0.22 | 64.76 ± 1.10 |

| 11 | 124 (3) | 6 (3) | Spraying (1) | 13.51 ± 0.42 | 67.19 ± 2.08 |

| 12 | 124 (3) | 9 (4) | Stirring (2) | 13.80 ± 0.45 | 68.63 ± 2.24 |

| 13 | 149 (4) | 0 (1) | Stirring (2) | 13.35 ± 0.43 | 66.40 ± 2.14 |

| 14 | 149 (4) | 3 (2) | Spraying (1) | 13.68 ± 0.34 | 68.04 ± 1.71 |

| 15 | 149 (4) | 6 (3) | Stirring (2) | 14.71 ± 0.39 | 73.16 ± 1.96 |

| 16 | 149 (4) | 9 (4) | Spraying (1) | 15.89 ± 0.32 | 79.03 ± 1.58 |

| A | B | C | ||

|---|---|---|---|---|

| Y2 | K1 | 194.67 ± 7.15 | 221.47 ± 5.17 | 484.58 ± 13.79 |

| K2 | 219.88 ± 7.61 | 235.90 ± 7.21 | 479.00 ± 14.64 | |

| K3 | 262.40 ± 6.28 | 244.90 ± 7.86 | — | |

| K4 | 286.63 ± 7.39 | 261.31 ± 8.19 | — | |

| k1 | 48.67 ± 1.79 | 55.37 ± 1.29 | 60.57 ± 1.72 | |

| k2 | 54.97 ± 1.90 | 58.97 ± 1.80 | 59.87 ± 1.83 | |

| k3 | 65.60 ± 1.57 | 61.22 ± 1.97 | — | |

| k4 | 71.66 ± 1.85 | 65.33 ± 2.05 | — | |

| R | 22.99 ± 3.64 | 9.96 ± 3.34 | 0.7 ± 3.55 | |

| Optimal level | A4 | B4 | C1 | |

| Coefficient a | |||||

|---|---|---|---|---|---|

| Model | Unnormalized Coefficient | Normalized Coefficient | t | Significance | |

| Standard Error | Beta | ||||

| 1 | (constant) | 2.902 | 6.976 | 0.000 | |

| C | 0.020 | 0.909 | 16.322 | 0.000 | |

| B(%) | 0.162 | 0.367 | 6.594 | 0.002 | |

| A(MPa) | 1.089 | −0.036 | −0.640 | 0.534 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, X.; Zhang, K.; Chen, Z.; Zhou, J. A Method of Adding Binder by High-Pressure Spraying to Improve the Biomass Densification. Polymers 2020, 12, 2374. https://doi.org/10.3390/polym12102374

Ju X, Zhang K, Chen Z, Zhou J. A Method of Adding Binder by High-Pressure Spraying to Improve the Biomass Densification. Polymers. 2020; 12(10):2374. https://doi.org/10.3390/polym12102374

Chicago/Turabian StyleJu, Xiaonan, Kexin Zhang, Zhongjia Chen, and Jianbo Zhou. 2020. "A Method of Adding Binder by High-Pressure Spraying to Improve the Biomass Densification" Polymers 12, no. 10: 2374. https://doi.org/10.3390/polym12102374

APA StyleJu, X., Zhang, K., Chen, Z., & Zhou, J. (2020). A Method of Adding Binder by High-Pressure Spraying to Improve the Biomass Densification. Polymers, 12(10), 2374. https://doi.org/10.3390/polym12102374