Functional Investigation on Automotive Interior Materials Based on Variable Knitted Structural Parameters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

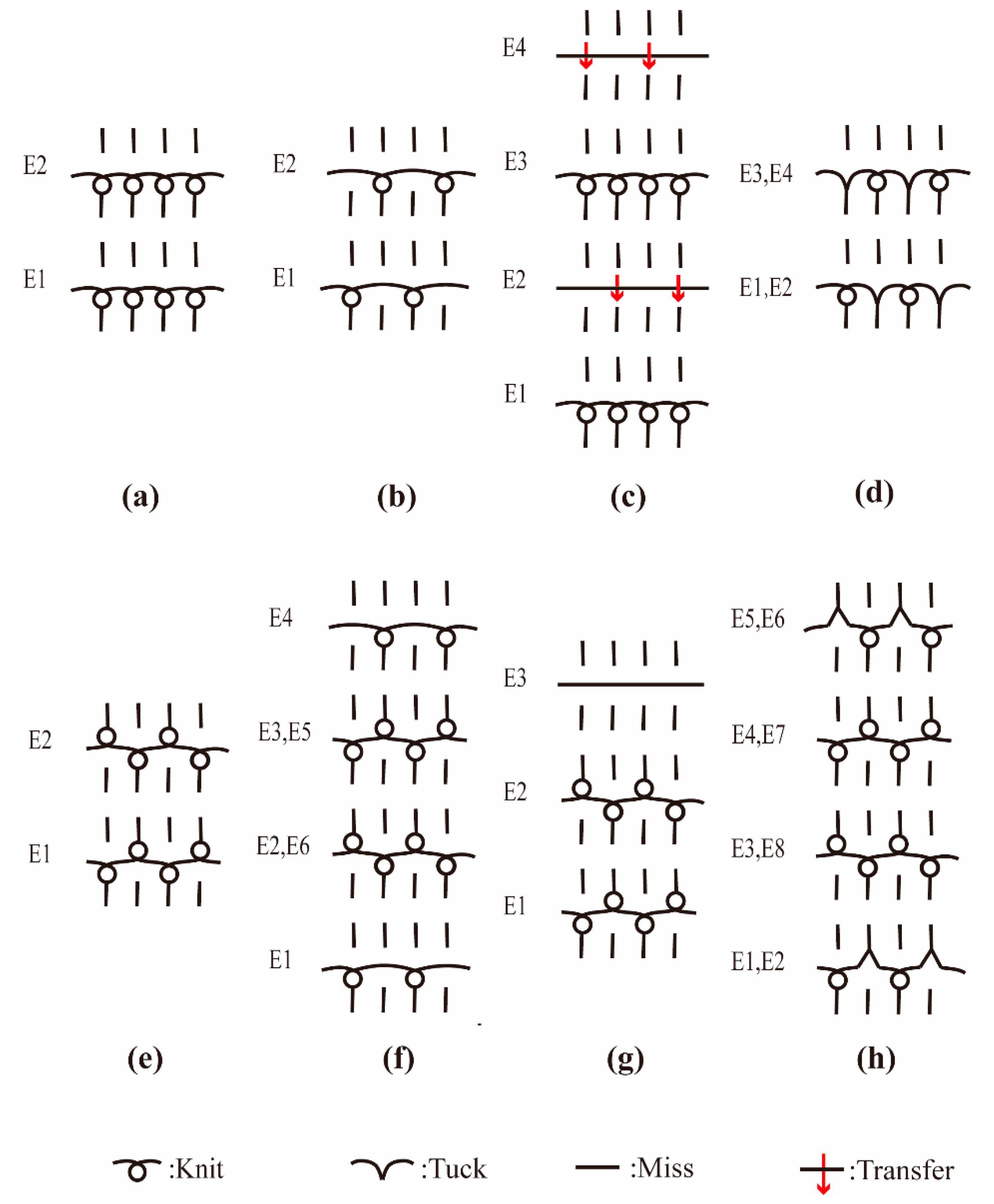

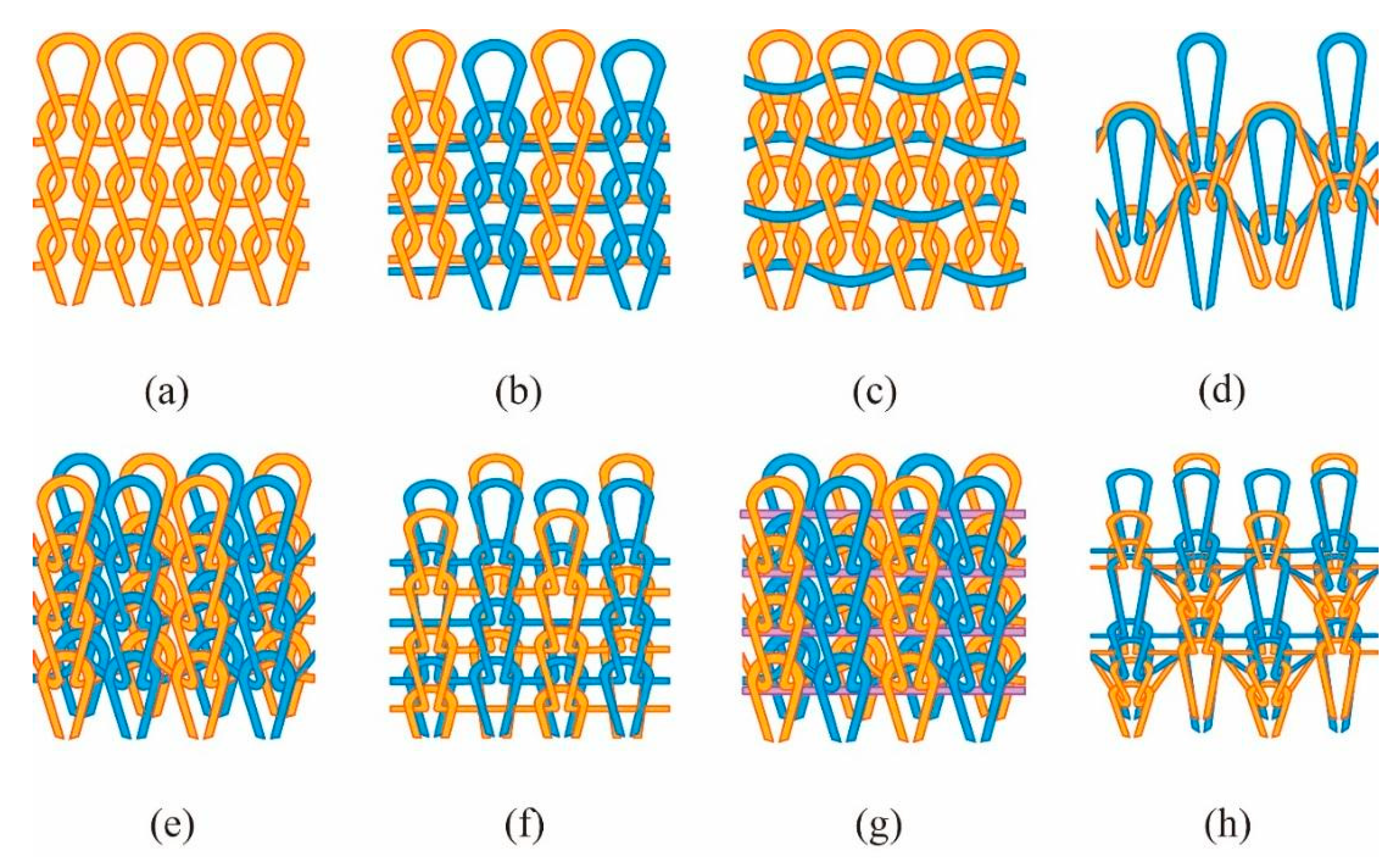

2.2. Samples Preparation

2.3. Testing Methods

2.3.1. Air Permeability Testing

2.3.2. Abrasion Resistance Testing

2.3.3. Strip Testing

2.3.4. Tear Strength Testing

3. Results and Discussion

3.1. Air Permeability

3.2. Abrasion Resistance

3.3. Breaking Strength

3.4. Tearing Strength

3.5. Comprehensive Evaluation of Utility Performance of Knitted Fabric

4. Conclusions

- The air permeability of DTPE fabric is 29.7–90% higher than that of DTPA fabric. Among the eight different structures, the fabric with tuck stitches can increase the air permeability by 50–100%, while those structures with inlaid yarn can reduce the air permeability by 12.1–28.8%;

- Compared with DTPE fabric, DTPA fabric has a better wear resistance. After 20,000 cycles of abrasion testing, there were only a few hairs on the surface of the DTPA samples, and the structure was still intact, while the DTPE samples showed obvious pilling. A comprehensive comparison of the wear and mass loss shows that S3 (plain knit with weft-inlay) has the worst abrasion resistance due to the presence of floating yarns on the surface;

- The good elasticity of DTPA makes the breaking elongation be 1.3–2.2 times higher than for the DTPE samples. The double jersey structures have higher breaking and tearing strengths as the yarns are more tightly connected, especially the S5 (interlock). Meanwhile, the addition of weft-inlaid yarns and tuck stitches can enhance the dimensional stability and strength of the fabric;

- The comprehensive evaluation shows that the comprehensive performance of DTPA fabrics is higher than that of DTPE, and among the eight different structures, S8 (variable half cardigan) is more suitable for automotive interior fabrics;

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Shim, E.; Chang, H.-K.; Lee, N.; Kim, H.R.; Park, J. Sustainable and high-power wearable glucose biofuel cell using long-term and high-speed flow in sportswear fabrics. Biosens. Bioelectron. 2020, 169, 112652. [Google Scholar] [CrossRef]

- Krithika, S.M.U.; Prakash, C.; Sampath, M.B.; Kumar, M.S. Thermal Comfort Properties of Bi-Layer Knitted Fabrics. Fibres Text. East Eur. 2020, 28, 50–55. [Google Scholar]

- Revaiah, R.G.; Kotresh, T.M.; Kandasubramanian, B. Technical Textiles for Military Aptions. J. Text. Inst. 2019, 111, 273–308. [Google Scholar] [CrossRef]

- Janarthanan, M.; Kumar, M.S. The properties of bioactive substances obtained from seaweeds and their applications in textile industries. J. Ind. Text. 2017, 48, 361–401. [Google Scholar] [CrossRef]

- Willenbacher, B.; May, D.; Mitschang, P. Out-of-plane capillary pressure of technical textiles. Compos. Part. A Appl. Sci. Manuf. 2019, 124, 105495. [Google Scholar] [CrossRef]

- Yasin, S.; Sun, D. Propelling textile waste to ascend the ladder of sustainability: EOL study on probing environmental parity in technical textiles. J. Clean. Prod. 2019, 233, 1451–1464. [Google Scholar] [CrossRef]

- Khattab, T.; Abdelrahman, M.S. From Smart Materials to Chromic Textiles. In Advances in Functional Finishing of Textiles; Shahid, M., Adivarekar, R., Eds.; Springer: Singapore, 2020; pp. 257–274. [Google Scholar]

- Dias, T.; Monaragala, R. Development and analysis of novel electroluminescent yarns and fabrics for localized automotive interior illumination. Text. Res. J. 2012, 82, 1164–1176. [Google Scholar] [CrossRef]

- Pamuk, G.; Çeken, F. Research on the Breaking and Tearing Strengths and Elongation of Automobile Seat Cover Fabrics. Text. Res. J. 2009, 79, 47–58. [Google Scholar] [CrossRef]

- Jerkovic, I.; Pallares, J.; Ardanuy, M.; Capdevila, X. Abrasive Elements and Abrasion Resistance Tests for Car Seat Upholstery. J. Eng. Fibers Fabr. 2013, 8, 35–41. [Google Scholar] [CrossRef]

- Pamuk, G.; Ceken, F. Comparative Study of the Abrasion Resistance of Automobile Seat Covers. Fibres Text. East. Eur. 2008, 16, 57–61. [Google Scholar]

- Ulku, S.; Ortlek, H.G.; Omeroglu, S. The Effect of Chenille Yarn Properties on the Abrasion Resistance of Upholstery Ffabrics. Fibres Text. East. Eur. 2003, 11, 38–41. [Google Scholar]

- Schwarz, I.; Kovačević, S.; Kos, I. Physical–mechanical properties of automotive textile materials. J. Ind. Text. 2014, 45, 323–337. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, Z.; Dong, X.; Li, D. Tensile properties with or without heat dispersion of automotive needlepunched carpets made up of two layers of different materials. J. Wuhan Univ. Technol. Sci. Ed. 2008, 23, 625–631. [Google Scholar] [CrossRef]

- Chen, W.L.; Yi, D.H.; He, M.M.; Zhang, J.F. Extension and Thermal-shrinkage Properties of Warp-knitted Automobile Interior Fabric for Injection Molding. J. Text. Res. 2012, 33, 122–126. [Google Scholar]

- Choi, Y.J.; Kim, I.; Kim, S.H. Effect of heat-setting on the physical properties of chemically recycled polyester nonwoven fabrics. Text. Res. J. 2018, 89, 498–509. [Google Scholar] [CrossRef]

- Pakdel, E.; Naebe, M.; Kashi, S.; Cai, Z.; Xie, W.; Yuen, A.C.Y.; Montazer, M.; Sun, L.; Wang, X.-G. Functional cotton fabric using hollow glass microspheres: Focus on thermal insulation, flame retardancy, UV-protection and acoustic performance. Prog. Org. Coat. 2020, 141, 105553. [Google Scholar] [CrossRef]

- Di, J.F.; Xu, J.; Du, W.Q. Preparation and Properties of Knitted Coated Fabric with Flame Retardancy. Adv. Mater. Res. 2010, 156, 1313–1317. [Google Scholar] [CrossRef]

- Glombikova, V.; Komarkova, P.; Havelka, A.; Kolinova, M. Approach to evaluation of car seats fabrics performance. Ind. Text. 2018, 69, 96–103. [Google Scholar] [CrossRef]

- Thilagavathi, G.; Pradeep, E.; Kannaian, T.; Sasikala, L. Development of Natural Fiber Nonwovens for Application as Car Interiors for Noise Control. J. Ind. Text. 2010, 39, 267–278. [Google Scholar] [CrossRef]

- Ma, M.; Bai, Y.; Qian, X.M. Development of Natural Fibre Non-Woven Materials’ Application as Car Interiors for Noise Reduction. Adv. Mater. Res. 2011, 332, 1531–1534. [Google Scholar] [CrossRef]

- Li, H.; Zhang, N.; Fan, X.; Gong, J.; Zhang, J.; Zhao, X. Investigation of effective factors of woven structure fabrics for acoustic absorption. Appl. Acoust. 2020, 161, 107081. [Google Scholar] [CrossRef]

- Dias, T.; Monaragala, R. Sound absorbtion in knitted structures for interior noise reduction in automobiles. Meas. Sci. Technol. 2006, 17, 2499–2505. [Google Scholar] [CrossRef]

- Başyiğit, Z. Ömeroğullari Improvement of multifunctional automotive textile. Tekst Ve Konfeksiyon 2019, 29, 121–130. [Google Scholar] [CrossRef]

- Stegmaier, T.; Mavely, J.; Schweins, M.; Arnim, V.V.; Schmeer, L.G.; Schneider, P.; Finckh, H.; Planck, H. Woven and Knitted Fabrics Used in Automotive Interiors. In Textile Advances in the Automotive Industry; Shishoo, R., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2008; pp. 43–62. [Google Scholar]

- Tian, F.; Jiang, G.; Gao, Z. Preparation and filtration performance of the circular weft-knitted seamless weft-insertion fabric materials. J. Ind. Text. 2019, 1–20. [Google Scholar] [CrossRef]

- Zhang, H.J.; Chen, L.Q.; Xie, M.D.; Shen, J.M.; Qiu, P.F. Study on the Comfort of Weft Plain Stitch Running Clothes in Different Temperature and Humidity Environment. Melliand China 2017, 45, 29–31+34–36+38–39. [Google Scholar]

| Material | Yarn Count | Color | Provider |

|---|---|---|---|

| DTPE | 300D/96F | White | PM Yarns and Textiles |

| DTPA | 300D/96F | White | PM Yarns and Textiles |

| Structure No. | NP Value | Knitting Speed (mm/s) | Yarn Tension (N) | Pulling Value |

|---|---|---|---|---|

| S1 | 11.3 | 0.55 | 2.5 | 4.0 |

| S2 | 11.3 | 0.55 | 2.5 | 4.0 |

| S3 | 11.3 | 0.50 | 2.5 | 4.5 |

| S4 | 11.3 | 0.55 | 2.5 | 4.5 |

| S5 | 10.0 | 0.55 | 2.5 | 5.5 |

| S6 | 10.0 | 0.55 | 2.5 | 5.5 |

| S7 | 10.0 | 0.50 | 2.5 | 5.5 |

| S8 | 10.0 | 0.55 | 2.5 | 5.5 |

| Sample No. | Material | Yarn Count | CPC 1 | WPC 1 | Thickness (mm) | Weight (g/m2) |

|---|---|---|---|---|---|---|

| A1 | DTPE | 300D × 3 | 7.6 | 9.8 | 1.32 | 383.64 |

| A1 | 8.4 | 8.8 | 1.69 | 483.60 | ||

| A3 | 6.4 | 10.0 | 1.77 | 455.56 | ||

| A4 | 5.4 | 8.8 | 2.12 | 484.72 | ||

| A5 | 7.2 | 9.2 | 2.16 | 778.44 | ||

| A6 | 7.4 | 7.2 | 2.35 | 780.80 | ||

| A7 | 6.0 | 10.0 | 2.24 | 784.40 | ||

| A8 | 5.8 | 6.8 | 2.93 | 849.04 | ||

| B1 | DTPA | 300D × 2 | 7.2 | 12.0 | 1.47 | 333.28 |

| B2 | 8.0 | 9.6 | 1.81 | 414.72 | ||

| B3 | 7.2 | 10.4 | 1.67 | 385.12 | ||

| B4 | 6.0 | 9.2 | 2.15 | 416.40 | ||

| B5 | 6.8 | 12.8 | 2.25 | 621.04 | ||

| B6 | 7.2 | 8.4 | 2.24 | 642.56 | ||

| B7 | 6.4 | 10.4 | 2.16 | 671.32 | ||

| B8 | 5.6 | 7.2 | 2.54 | 674.44 |

| Samples No. | Air Permeability (mm/s) | Mass Loss (mg) | Breaking Strength in Course Direction (N) | Breaking Strength in Wale Direction (N) | Tearing Strength in Course Direction (N) | Tearing Strength in Wale Direction (N) |

|---|---|---|---|---|---|---|

| A1 | 1867.53 | 11.53 | 631.02 | 798.48 | 349.94 | 402.84 |

| A2 | 1358.68 | 10.27 | 1085.60 | 810.14 | 448.45 | 504.57 |

| A3 | 1298.69 | 11.37 | 1370.32 | 803.75 | 443.91 | 289.21 |

| A4 | 1957.20 | 9.87 | 1155.68 | 796.20 | 450.71 | 329.88 |

| A5 | 913.47 | 9.23 | 1264.16 | 2309.54 | 485.02 | 996.64 |

| A6 | 919.24 | 8.43 | 1314.97 | 1865.92 | 585.95 | 707.61 |

| A7 | 613.04 | 8.37 | 1546.68 | 1949.c | 670.91 | 731.55 |

| A8 | 951.89 | 7.77 | 1845.08 | 1514.55 | 757.60 | 563.55 |

| B1 | 1007.18 | 0.97 | 660.90 | 705.80 | 233.41 | 331.17 |

| B2 | 715.23 | 0.57 | 1171.48 | 865.60 | 382.97 | 385.70 |

| B3 | 683.54 | 3.57 | 1119.63 | 722.24 | 357.26 | 269.80 |

| B4 | 1437.42 | 0.27 | 1088.23 | 763.58 | 385.55 | 323.75 |

| B5 | 490.61 | 0.13 | 1182.93 | 1680.60 | 550.29 | 704.27 |

| B6 | 495.20 | −1.10 | 1318.13 | 1532.82 | 557.99 | 703.67 |

| B7 | 472.59 | −0.67 | 1407.82 | 1564.63 | 587.76 | 620.92 |

| B8 | 692.45 | −3.03 | 1645.19 | 1263.42 | 645.37 | 523.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siyao, M.; Liu, S.; Peihua, Z.; Hairu, L. Functional Investigation on Automotive Interior Materials Based on Variable Knitted Structural Parameters. Polymers 2020, 12, 2455. https://doi.org/10.3390/polym12112455

Siyao M, Liu S, Peihua Z, Hairu L. Functional Investigation on Automotive Interior Materials Based on Variable Knitted Structural Parameters. Polymers. 2020; 12(11):2455. https://doi.org/10.3390/polym12112455

Chicago/Turabian StyleSiyao, Mao, Su Liu, Zhang Peihua, and Long Hairu. 2020. "Functional Investigation on Automotive Interior Materials Based on Variable Knitted Structural Parameters" Polymers 12, no. 11: 2455. https://doi.org/10.3390/polym12112455

APA StyleSiyao, M., Liu, S., Peihua, Z., & Hairu, L. (2020). Functional Investigation on Automotive Interior Materials Based on Variable Knitted Structural Parameters. Polymers, 12(11), 2455. https://doi.org/10.3390/polym12112455