Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

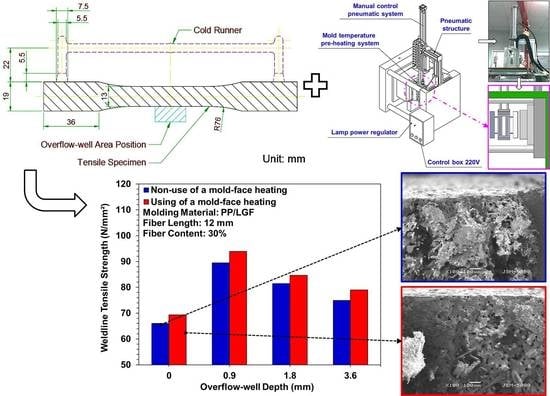

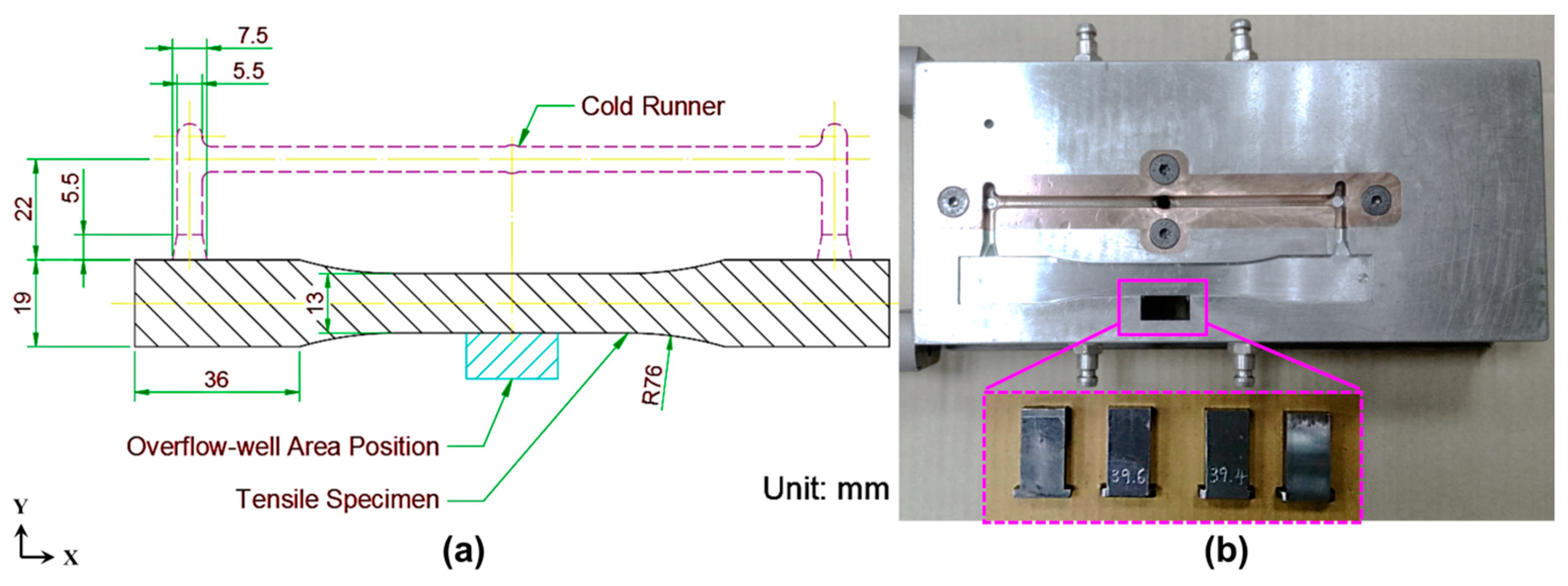

2.2. Mold and Test Samples

2.3. Infrared Heater for Heating Mold-Face

2.4. Test Methodology

3. Results and Discussion

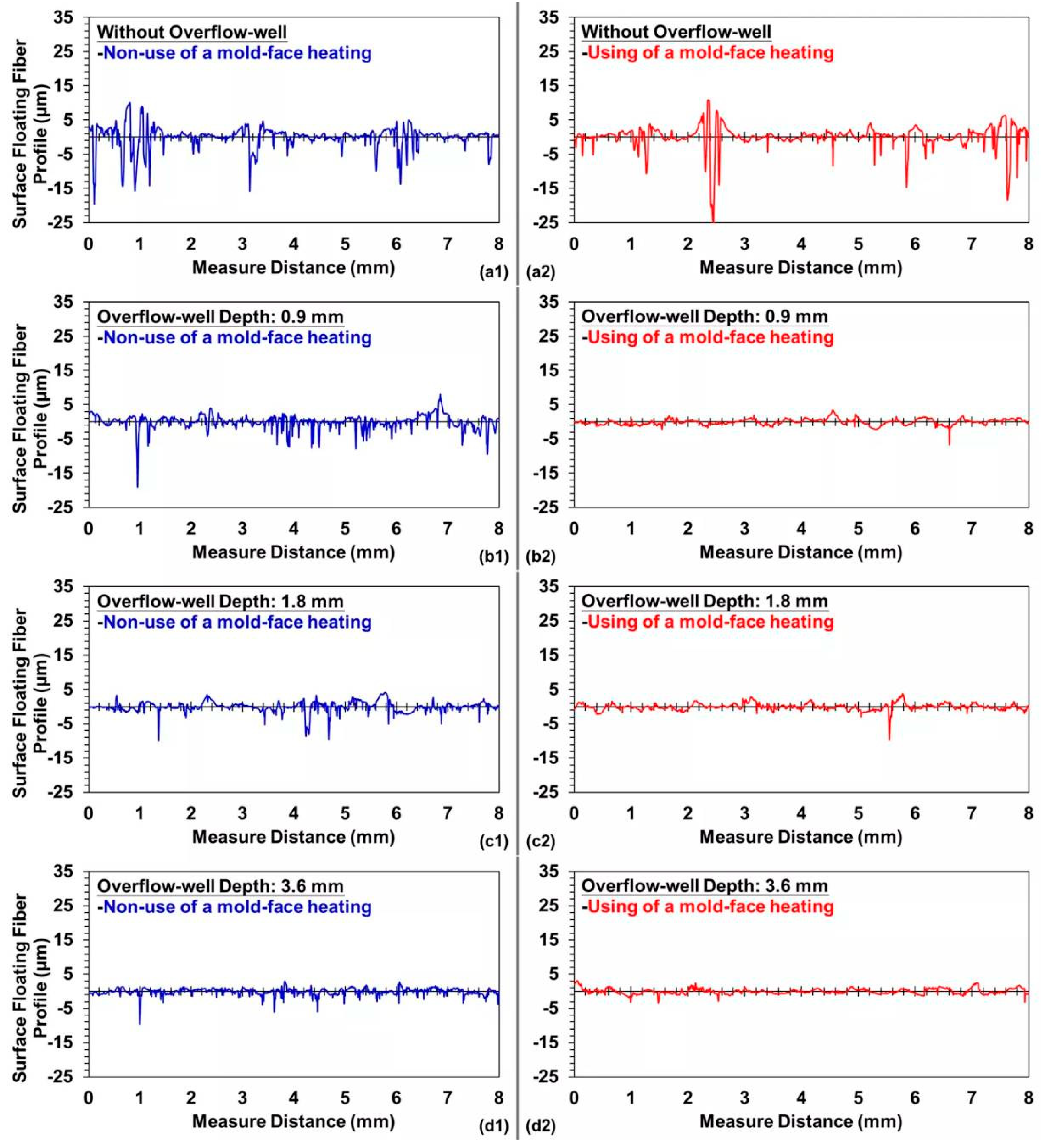

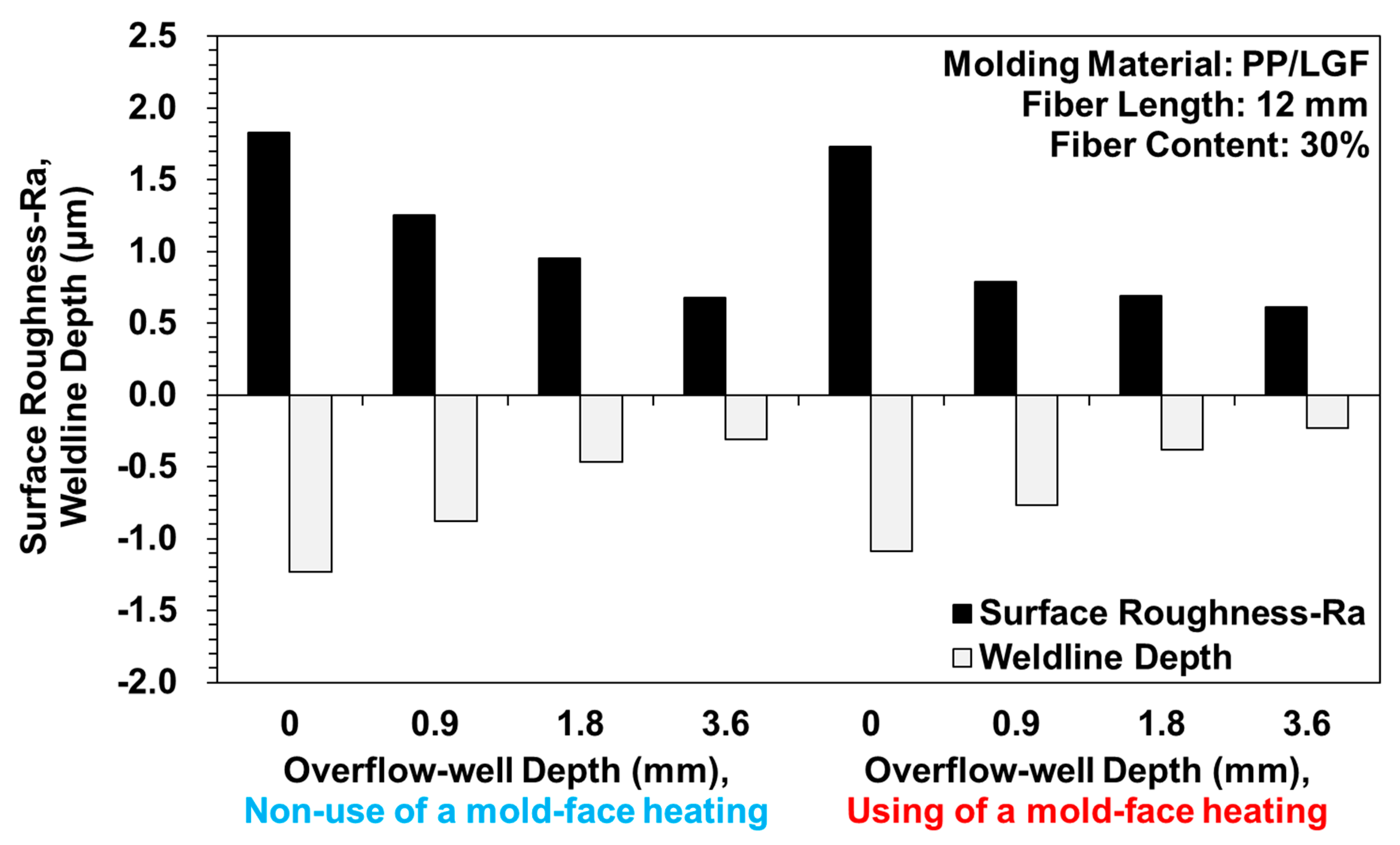

3.1. Surface-Floating Fibers and Roughness of the Samples

3.2. Strength Variation and Fiber Compatibility Assessment

4. Conclusions

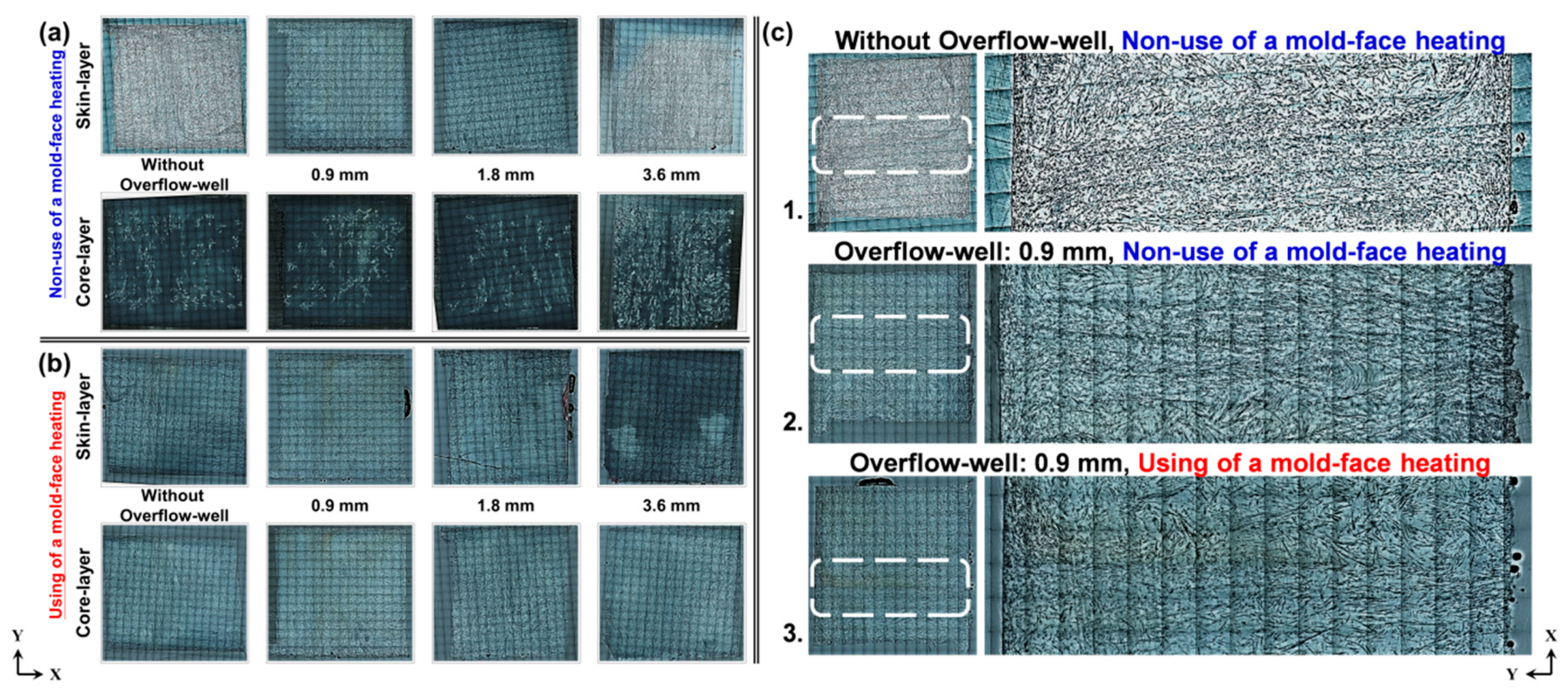

- The surface-floating fibers of the PP/LGF samples fabricated using a double-gate molding design varied with the overflow-well depth. the molding process conducted without using an overflow-well, poor compatibility was observed between the fibers and melts, and, after the use of mold-face heating, the melt flow resistance decreased with an increase in the mold-face temperature. The surface-floating fiber phenomenon weakened when the compatibility between melts increased.

- Samples with weldlines were molded using different overflow-well depths and types of mold-face heating. The cavity volume increased with overflow-well depth. The melt flow length increased with mold-cavity volume, which in turn increased with the compatibility between melts. The surface roughness obtained when using an overflow-well with a depth of 0.9 mm was 31.93% lower than that obtained when not using the overflow-well.

- When using an overflow-well during the high-temperature heating of the mold-face, the melt was not hindered in the filling process, the fibers flowed relatively easily, the phenomenon of fiber turbulence was weakened, and the dispersion of fibers and their compatibility with the melt improved. For the weldline tensile samples obtained through mold-face heating, the flow resistance was small when the melt was filled due to the uniform surface temperature of the mold.

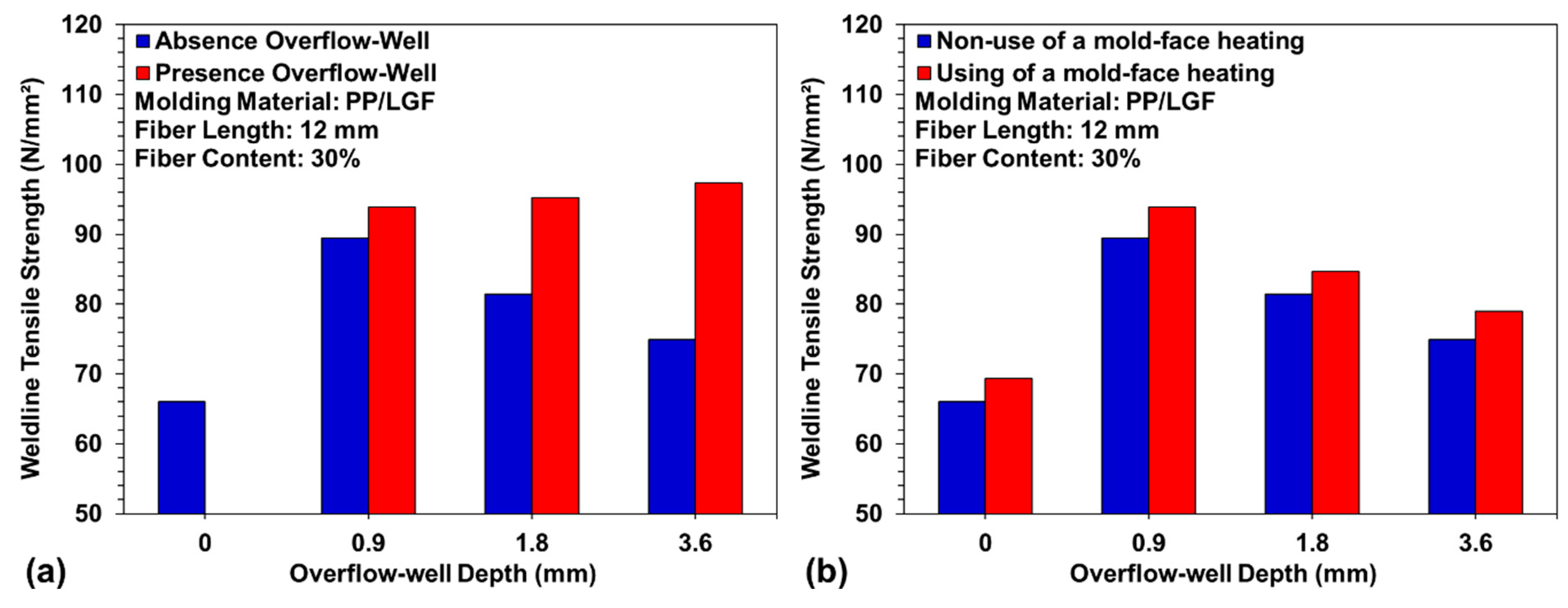

- The data for the tensile strength of the weldline with the use and nonuse of the overflow-well area were measured. The weldline tensile strength increased with the increase of overflow-well depth. When the overflow-well area was removed, the weldline tensile strength decreased and the weldline tensile strength obtained with the 0.9 mm deep overflow-well was 43.54% higher than that obtained without the overflow-well. Moreover, the weldline tensile strength obtained with the 0.9 mm deep overflow-well increased by 4.76% when the mold-face was subjected to high-temperature heating.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Duan, S.; Zhang, Z.; Wei, K.; Wang, F.; Han, X. Theoretical study and physical tests of circular hole-edge stress concentration in long glass fiber reinforced polypropylene composite. J. Compos. Struct. 2020, 236. [Google Scholar] [CrossRef]

- Hou, X.Q.; Chen, X.Y.; Liu, B.C.; Chen, S.C.; Li, H.M.; Cao, W. Fracture and orientation of long-glass-fiber-reinforced polypropylene during injection molding. J. Polym. Eng. Sci. 2019, 60, 13–21. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Wu, L. Impact and energy absorption of long fiber-reinforced thermoplastic based on two-phase modeling and experiments. Int. J. Impact Eng. 2018, 122, 374–383. [Google Scholar] [CrossRef]

- Giusti, R.; Zanini, F.; Lucchetta, G. Automatic glass fiber length measurement for discontinuous fiber-reinforced composites. J. Compos. Part A Appl. Sci. Manuf. 2018, 112, 263–270. [Google Scholar] [CrossRef]

- Azenha, J.; Gomes, M.; Silva, P.; Pontes, A.J. High strength injection molded thermoplastic composites. J. Polym. Eng. Sci. 2018, 58, 560–567. [Google Scholar] [CrossRef]

- Duan, S.; Mo, F.; Yang, X.; Tao, Y.; Wu, D.; Peng, Y. Experimental and numerical investigations of strain rate effects on mechanical properties of LGFRP composite. J. Compos. B Eng. 2016, 88, 101–107. [Google Scholar] [CrossRef]

- Duan, S.; Tao, Y.; Han, X.; Yang, X.; Hou, S.; Hu, Z. Investigation on structure optimization of crashworthiness of fiber reinforced polymers materials. J. Compos. B Eng. 2014, 60, 471–478. [Google Scholar] [CrossRef]

- Kallel, T.K.; Taktak, R.; Guermazi, N.; Mnif, N. Mechanical and structural properties of glass fiber-reinforced polypropylene (PPGF) composites. J. Polym. Compos. 2018, 39, 3497–3508. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length, diameter and concentration on the modulus of glass fibre reinforced polyamide 6,6. J. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1732–1738. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.W.; Lee, S.; Park, S.M.; Lee, D. Mechanical, thermomechanical, and local anisotropy analyses of long basalt fiber reinforced polyamide 6 composites. J. Compos. Struct. 2019, 222. [Google Scholar] [CrossRef]

- Seong, D.G.; Kang, C.; Pak, S.Y.; Kim, C.H.; Song, Y.S. Influence of fiber length and its distribution in three phase poly(propylene) composites. J. Compos. B Eng. 2019, 168, 218–225. [Google Scholar] [CrossRef]

- Lienhard, J.; Schulenberg, L. Strain rate dependent multiaxial characterization of long fiber reinforced plastic. J. Compos. B Eng. 2018, 141, 164–173. [Google Scholar] [CrossRef]

- Bartus, S.D.; Vaidya, U.K.; Ulven, C.A. Design and development of a long fiber thermoplastic bus seat. J. Thermoplast. Compos. Mater. 2006, 19, 131–154. [Google Scholar] [CrossRef]

- Bijsterbosch, H.; Gaymans, R.J. Polyamide 6—Long glass fiber injection moldings. J. Polym. Compos. 1995, 16, 363–369. [Google Scholar] [CrossRef] [Green Version]

- Guan, W.S.; Huang, H.X. Back melt flow in injection–compression molding: Effect on part thickness distribution. J. Int. Commun. Heat Mass Transf. 2012, 39, 792–797. [Google Scholar] [CrossRef]

- Oh, H.J.; Lee, D.J.; Lee, C.G.; Jo, K.Y.; Lee, D.H.; Song, Y.S.; Young, J.R. Warpage analysis of a micro-molded parts prepared with liquid crystalline polymer based composites. J. Compos. Part A Appl. Sci. Manuf. 2013, 53, 34–45. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Tao, Y.; Shao, J.; Deng, Y.; Kou, H.; Zhang, X.; Chen, L. Theoretical model for the temperature dependent longitudinal tensile strength of unidirectional fiber reinforced polymer composites. J. Compos. B Eng. 2019, 161, 121–127. [Google Scholar] [CrossRef]

- Zhang, D.; He, M.; Luo, H.; Qin, S.; Yu, J.; Guo, J. Performance of long glass fiber-reinforced polypropylene composites at different injection temperature. J. Vinyl Addit. Technol. 2016, 24, 233–238. [Google Scholar] [CrossRef]

- Desplentere, F.; Six, W.; Bonte, H.; Debrabandere, E. Influence of the power law index on the fiber breakage during injection molding by numerical simulations. In Proceedings of the International Conference ‘Novel Trends in Rheology V’, Zlin, Czech Republic, 30–31 July 2013. [Google Scholar] [CrossRef]

- Rohde, M.; Ebel., A.; Wolff-Fabris, F.; Altstädt, V. Influence of processing parameters on the fiber length and impact properties of injection molded long glass fiber reinforced polypropylene. Int. Polym. Process 2011, 26, 292–303. [Google Scholar] [CrossRef]

- Spahr, D.E.; Friedrich, K.; Schultz, J.M.; Bailey, R.S. Microstructure and fracture behaviour of short and long fibre-reinforced polypropylene composites. J. Mater. Sci. 1990, 25, 4427–4439. [Google Scholar] [CrossRef]

- Kumar, K.S.; Bhatnagar, N.; Ghosh, A.K. Mechanical properties of injection molded long fiber polypropylene composites, Part 2: Impact and fracture toughness. J. Polym. Compos. 2008, 29, 525–533. [Google Scholar] [CrossRef]

- Hohe, J.; Beckmann, C.; Paul, H. Modeling of uncertainties in long fiber reinforced thermoplastics. J. Mater. Des. 2015, 66, 390–399. [Google Scholar] [CrossRef]

- Lafranche, E.; Krawczak, P.; Ciolczyk, J.P.; Maugey, J. Injection moulding of long glass fiber reinforced polyamide 66: Processing conditions/microstructure/flexural properties relationship. J. Adv. Polym. Technol. 2005, 24, 114–131. [Google Scholar] [CrossRef]

- Wieme, T.; Tang, D.; Delva, L.; D’hooge, D.R.; Cardon, L. The relevance of material and processing parameters on the thermal conductivity of thermoplastic composites. J. Polym. Eng. Sci. 2018, 58, 466. [Google Scholar] [CrossRef] [Green Version]

- Schweizer, R.A. Glass fiber length degradation in thermoplastics processing. J. Polym. Plast. Technol. Eng. 2006, 18, 81–91. [Google Scholar] [CrossRef]

- Arroyo, M.; Avalos, F. Polypropylene/low density polyethylene blend matrices and short glass fibers based composites I. Mechanical degradation of fibers as a function of processing method. J. Polym. Compos. 1989, 10, 117–121. [Google Scholar] [CrossRef]

- Franzén, B.; Klason, C.; Kubát, J.; Kitano, T. Fibre degradation during processing of short fibre reinforced thermoplastics. J. Compos. 1989, 20, 65–76. [Google Scholar] [CrossRef]

- Phelps, J.H.; Abd El-Rahman, A.I.; Kunc, V.; TuckerIII, C.L. A model for fiber length attrition in injection-molded long-fiber composites. J. Compos. Part A Appl. Sci. Manuf. 2013, 51, 11–21. [Google Scholar] [CrossRef]

- Bailey, R.; Rzepka, B. Fibre orientation mechanisms for injection molding of long fibre composites. Int. Polym. Process 1991, 6, 35–41. [Google Scholar] [CrossRef]

- Oppelt, T.; Schulze, J.; Stein, H.; Platzer, B. Comparison of methods for mould surface heating—Part 1: Review. Int. Polym. Sci. Technol. 2012, 39, 1–8. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhao, G.Q.; Guan, Y.J. Thermal response of an electric heating rapid heat cycle molding mold and its effect on surface appearance and tensile strength of the molded part. J. Appl. Polym. Sci. 2013, 3, 1339–1352. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhao, G.Q.; Wang, X.X. Effects of cavity surface temperature on mechanical properties of specimens with and without a weld line in rapid heat cycle molding. J. Mater. Des. Sci. 2013, 46, 457–472. [Google Scholar] [CrossRef]

| Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Controllable Factors | Factors Maintained Constant | ||||||

| Use versus nonuse of mold-face heating | Nonuse | Use | Injection pressure (bar) | 70 | |||

| Packing pressure (bar) | 20 | ||||||

| Cooling time (s) | 20 | ||||||

| Overflow-well depth (mm) | 0 | 0.9 | 1.8 | 3.6 | Mold heating, water temperature (°C) | 80 | |

| Random Order of the Treatments for Molding the Samples | |||||||

| Method | Overflow-Well Depth | Mold-Face Temperature | |||||

| 1 | 0 | Nonuse | |||||

| 2 | 0.9 | Nonuse | |||||

| 3 | 1.8 | Nonuse | |||||

| 4 | 3.6 | Nonuse | |||||

| 5 | 0 | Use | |||||

| 6 | 0.9 | Use | |||||

| 7 | 1.8 | Use | |||||

| 8 | 3.6 | Use | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, P.-W.; Peng, H.-S.; Choong, W.-H. Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding. Polymers 2020, 12, 2474. https://doi.org/10.3390/polym12112474

Huang P-W, Peng H-S, Choong W-H. Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding. Polymers. 2020; 12(11):2474. https://doi.org/10.3390/polym12112474

Chicago/Turabian StyleHuang, Po-Wei, Hsin-Shu Peng, and Wei-Huang Choong. 2020. "Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding" Polymers 12, no. 11: 2474. https://doi.org/10.3390/polym12112474

APA StyleHuang, P.-W., Peng, H.-S., & Choong, W.-H. (2020). Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding. Polymers, 12(11), 2474. https://doi.org/10.3390/polym12112474