Chemical Modification of Pullulan Exopolysaccharide by Grafting Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) via Click Chemistry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Propargyl-Terminated Poly(hydroxybutyrate-co-hydroxyvalerate)

2.3. Synthesis of Pull-g-PHBHV Grafted Copolymer

2.4. Characterizations

2.4.1. Proton Nuclear Magnetic Resonance (1H NMR)

2.4.2. Carbon-13 Nuclear Magnetic Resonance (13C NMR)

2.4.3. Gel Permeation Chromatography (GPC)

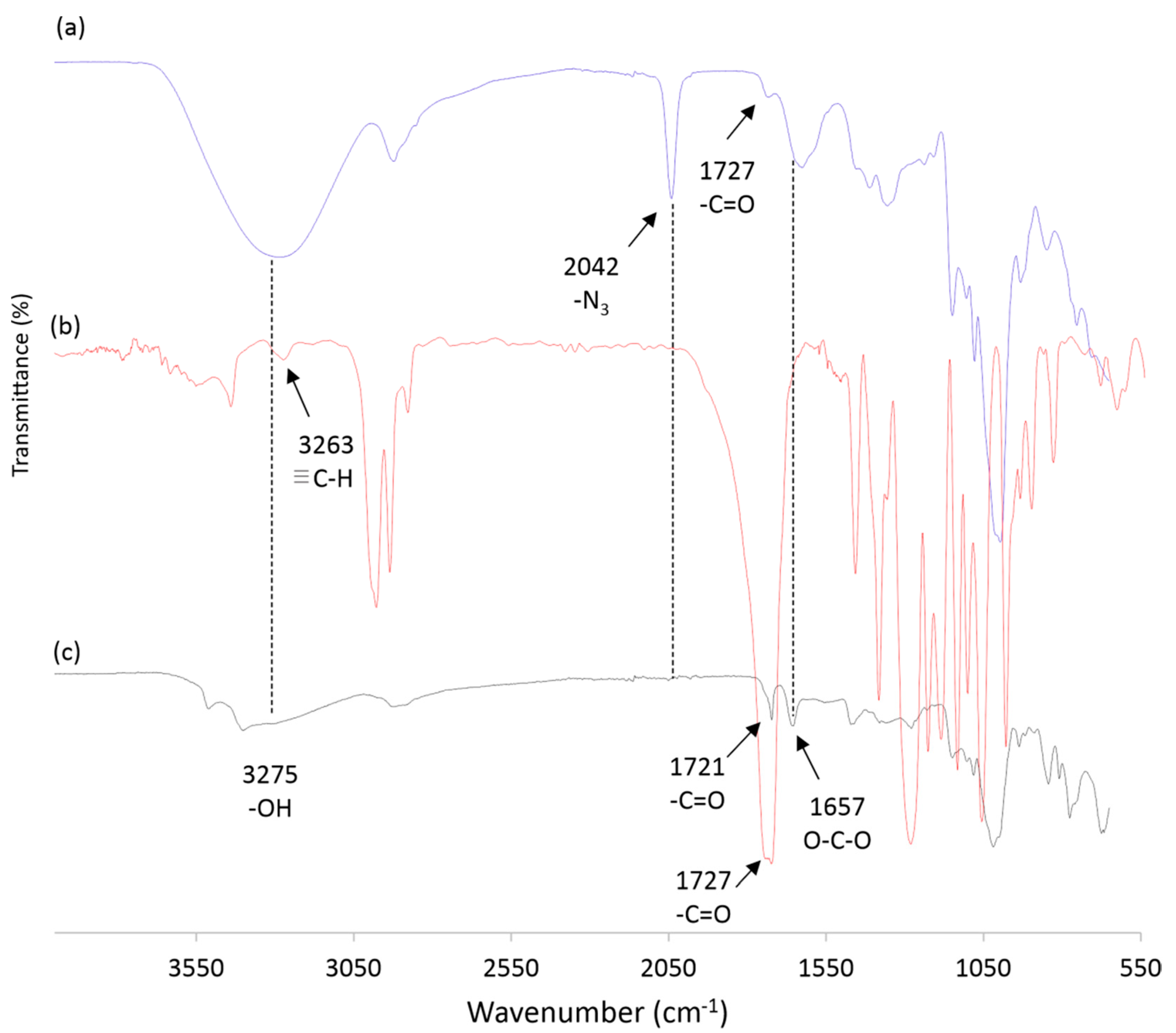

2.4.4. FTIR

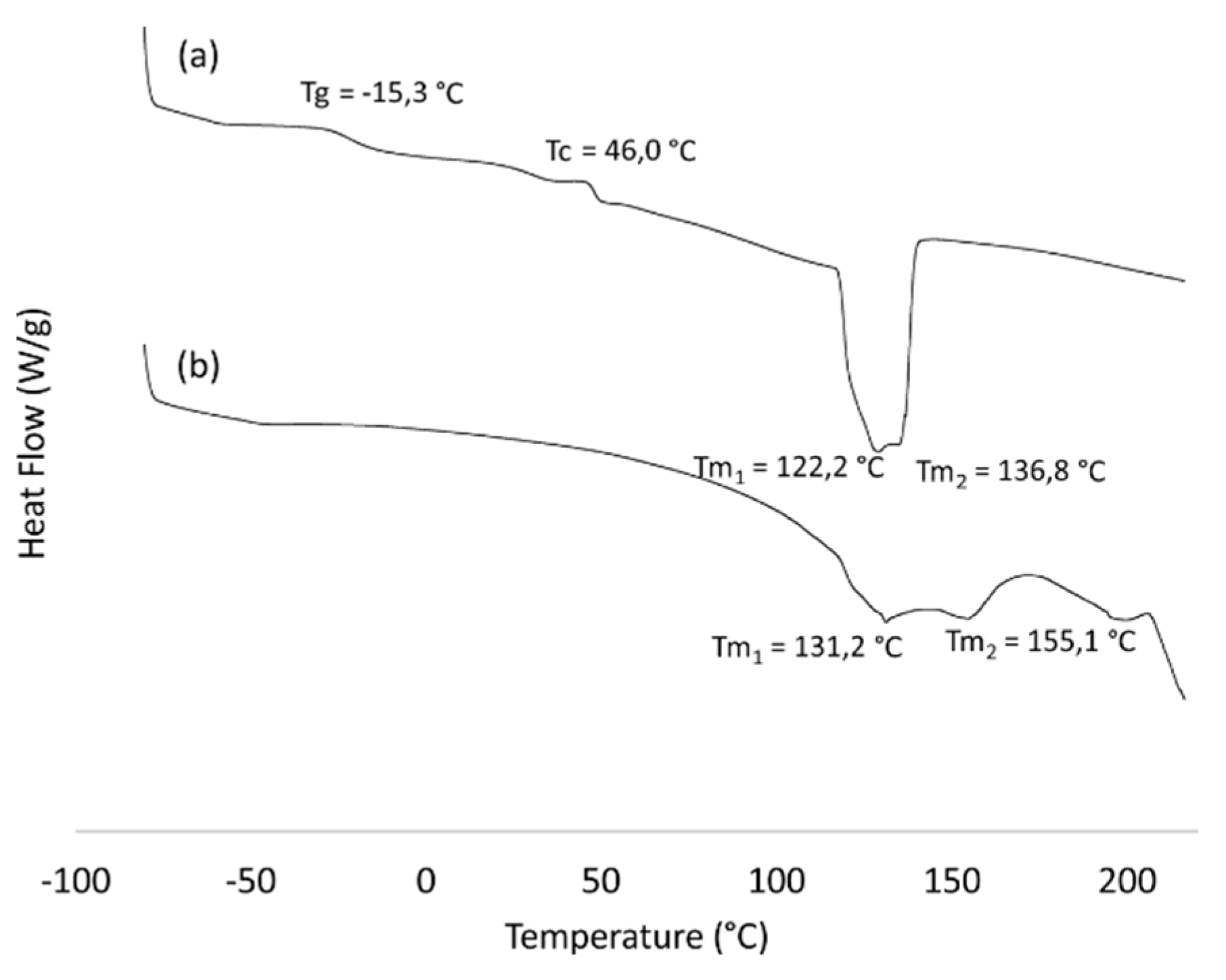

2.4.5. Thermal Analysis

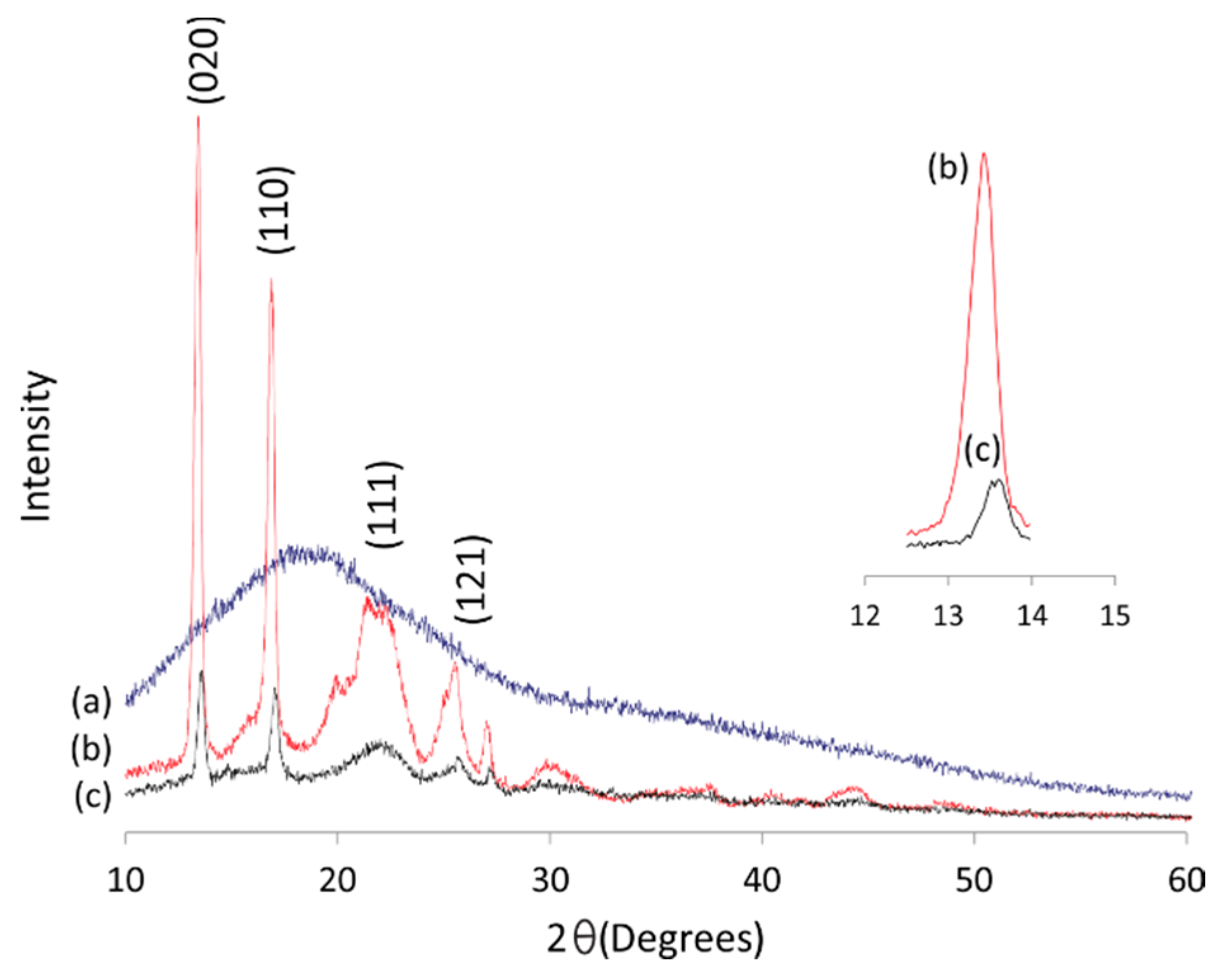

2.4.6. X-ray Diffraction

3. Results and Discussion

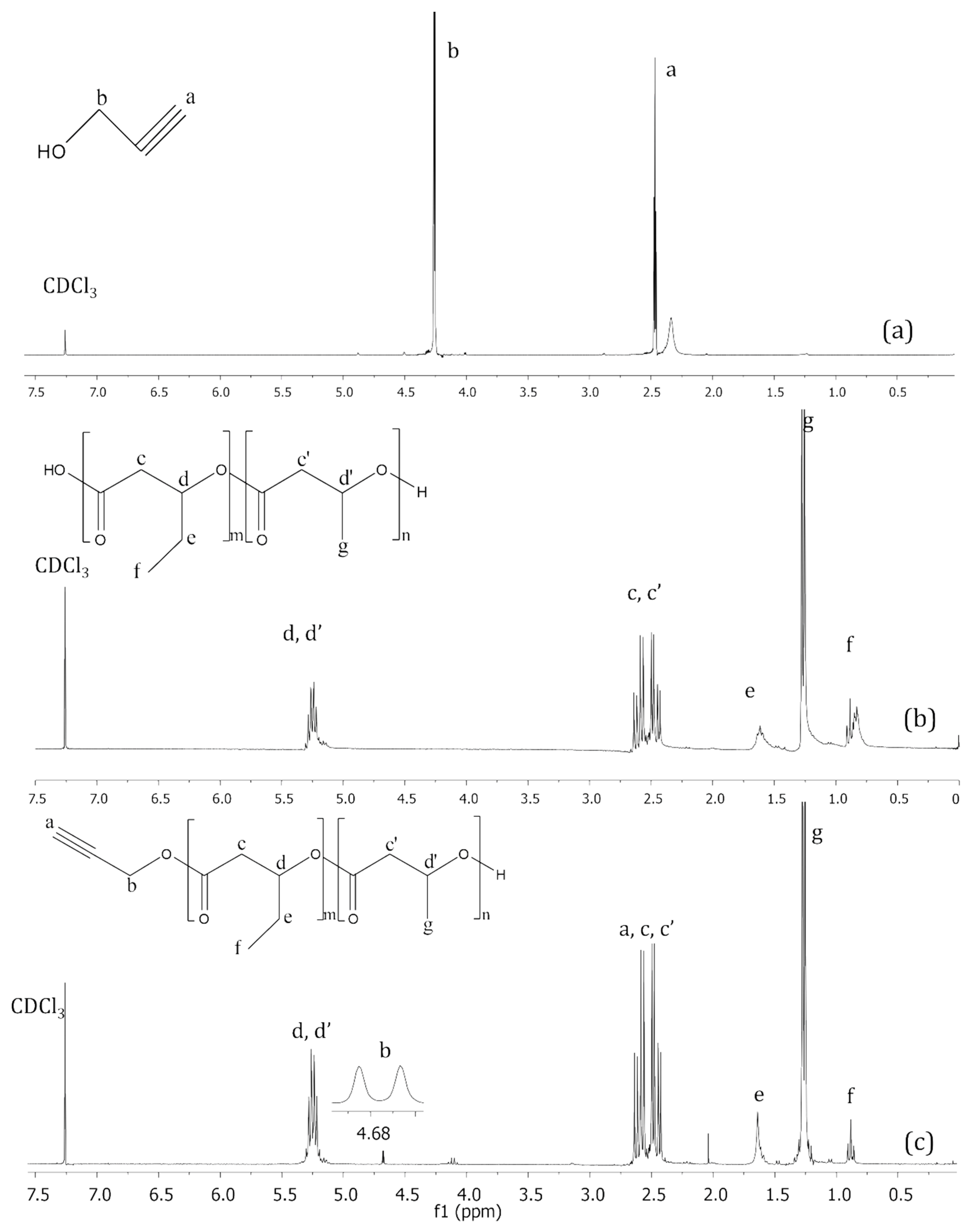

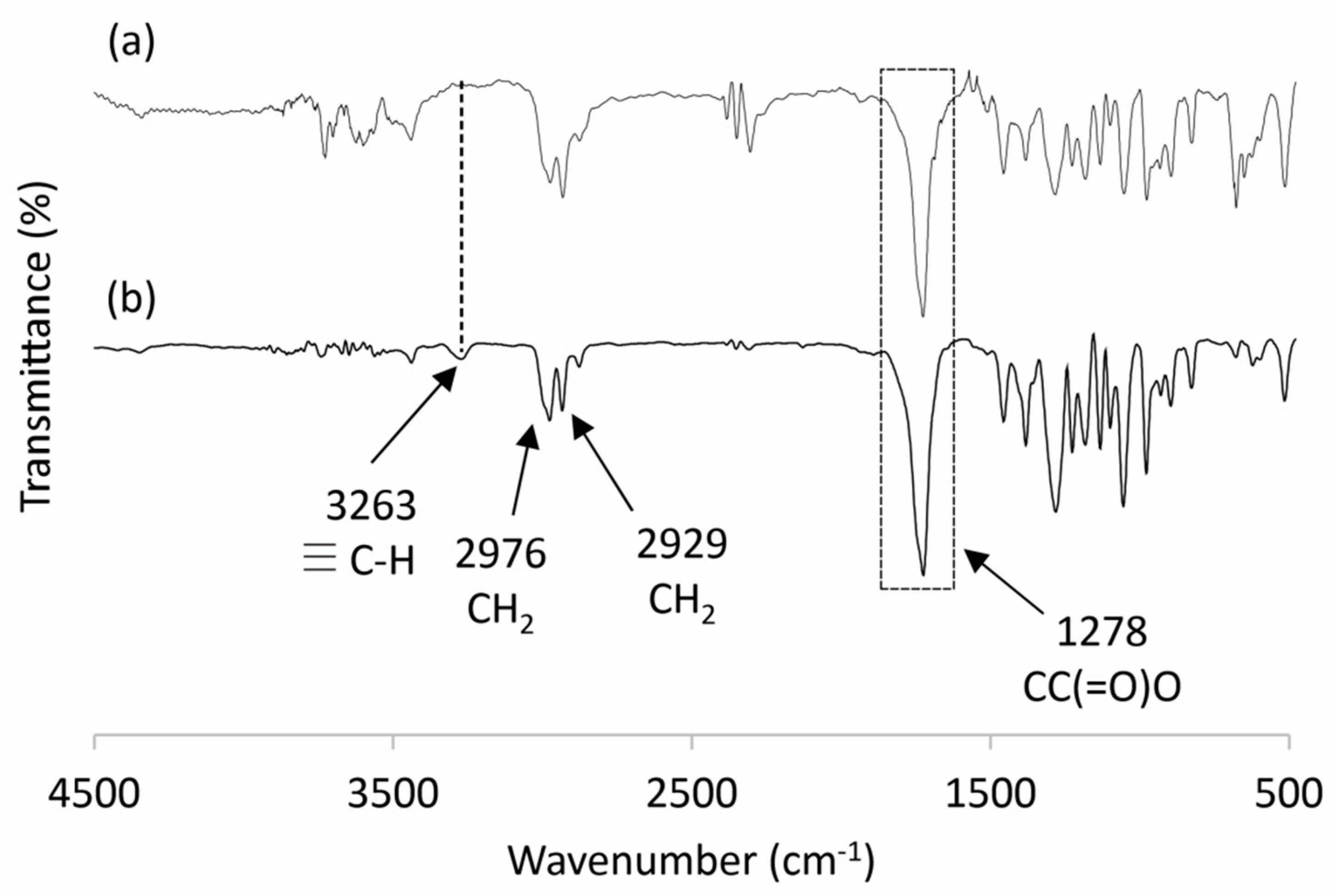

3.1. Propargyl-Terminated Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)

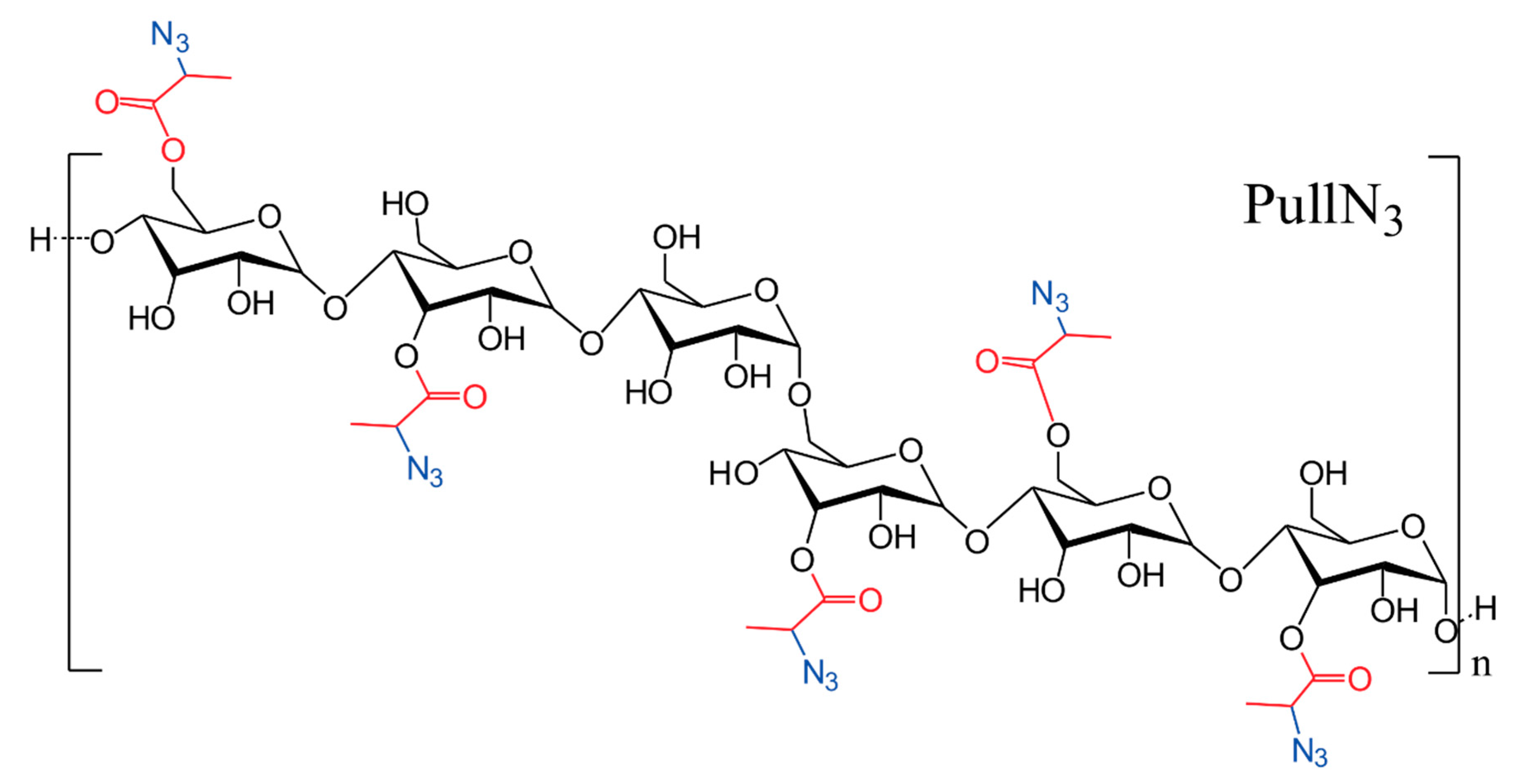

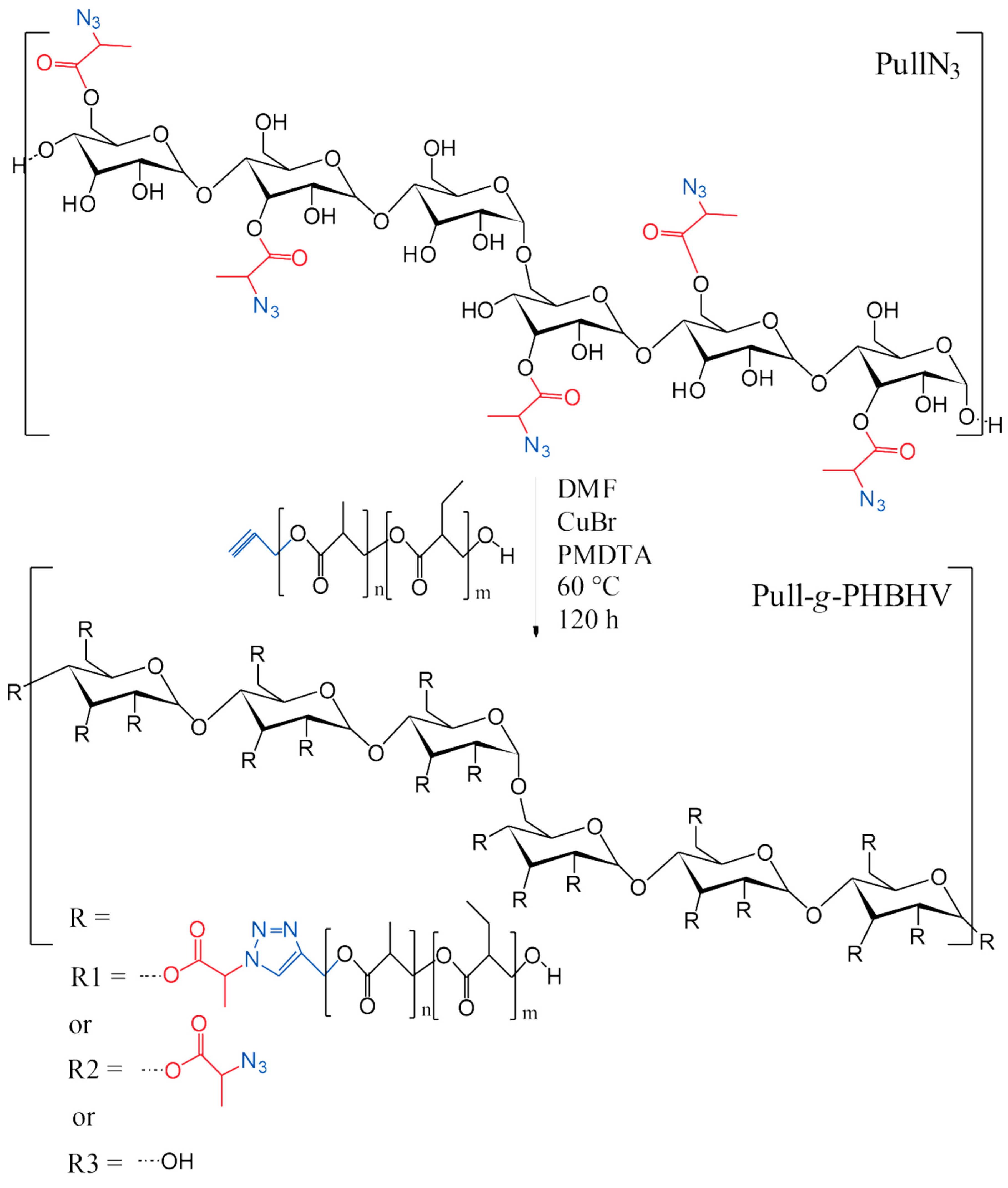

3.2. Grafting of PHBHV-Alkyne onto PullN3 Chains via Click Chemistry

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luef, K.P.; Stelzer, F.; Wiesbrock, F. Poly(hydroxy alkanoate)s in medical applications. Chem. Biochem. Eng. Q. 2015, 29, 287–297. [Google Scholar]

- Li, Z.; Pan, T.; Wu, Y.; Kang, W.; Liu, Y. Preparation and characterization of long-term stable pullulan nanofibers via in situ cross-linking electrospinning. Adsorpt. Sci. Technol. 2018, 37, 401–411. [Google Scholar] [CrossRef] [Green Version]

- Ulery, B.D.; Nair, L.S.; Laurencin, C.T. Biomedical Applications of Biodegradable Polymers. J. Polym. Sci. B Polym. Phys. 2011, 49, 832–864. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farris, S.; Introzzi, L.; Fuentes-Alventosa, J.M.; Santo, N.; Rocca, R.; Piergiovanni, L. Self-Assembled Pullulan–Silica Oxygen Barrier Hybrid Coatings for Food Packaging Applications. Agric. Food Chem. 2012, 60, 782–790. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meng, L.; Xie, F.; Zhang, B.; Wang, D.K.; Yu, L. Natural Biopolymer Alloys with Superior Mechanical Properties. ACS Sustain. Chem. Eng. 2018, 7, 2792–2802. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.; Edgar, K.J. “Click” reactions in polysaccharide modification. Prog. Polym. Sci. 2016, 53, 52–85. [Google Scholar] [CrossRef] [Green Version]

- Pilon, L.; Kelly, C. Modification of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) properties by reactive blending with a monoterpene derivative. J. Appl. Polym. Sci. 2015, 133, 42588. [Google Scholar] [CrossRef]

- Singh, R.S.; Kaur, N.; Rana, V.; Kennedy, J.F. Pullulan: A novel molecule for biomedical applications. Carbohyd. Polym. 2017, 171, 102–121. [Google Scholar] [CrossRef]

- Hasuda, H.; Kwon, O.H.; Kang, I.-K.; Ito, Y. Synthesis of photoreactive pullulan for surface modification. Biomaterials 2005, 26, 2401–2406. [Google Scholar] [CrossRef]

- Farris, S.; Unalan, I.U.; Introzzi, L.; Fuentes-Alventosa, J.M.; Cozzolino, C.A. Pullulan-based films and coatings for food packaging: Present applications, emerging opportunities, and future challenges. J. Appl. Polym. Sci. 2014, 131, 40539. [Google Scholar] [CrossRef] [Green Version]

- Kachhawa, D.K.; Bhattacharjee, P.; Singhal, R.S. Studies on downstream processing of pullulan. Carbohyd. Polym. 2013, 52, 25–28. [Google Scholar] [CrossRef]

- Ganeshkumar, M.; Ponrasu, T.; Subamekala, M.K.; Janani, M.; Suguna, L. Curcumin loaded on pullulan acetate nanoparticles protects the liver from damage induced by DEN. R. Soc. Chem. 2016, 6, 5599–5610. [Google Scholar] [CrossRef]

- Singh, R.S.; Kaur, N.; Kennedy, J.F. Pullulan and pullulan derivatives as promising biomolecules for drug and gene targeting. Carbohyd. Polym. 2015, 123, 190–207. [Google Scholar] [CrossRef]

- Tabasum, S.; Noreen, A.; Maqsood, M.F.; Umar, H.; Akram, N.; Nazli, Z.; Chatha, S.A.S.; Zia, K.M. A review on versatile applications of blends and composites of pullulan with natural and synthetic polymers. Int. J. Biol. Macromol. 2018, 120, 603–632. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Liu, Y.; Wang, Y.; Wu, J.; Yang, X.; Li, R.; Wang, Y.; Zhang, N. pH-sensitive pullulan-based nanoparticle carrier for adriamycin to overcome drug-resistance of cancer cells. Carbohyd. Polym. 2014, 111, 908–917. [Google Scholar] [CrossRef]

- Bontempo, D.; Masci, G.; De Leonardis, P.; Mannina, L.; Capitani, D.; Crescenzi, V. Versatile Grafting of Polysaccharides in Homogeneous Mild Conditions by Using Atom Transfer Radical Polymerization. Biomacromolecules 2006, 7, 2154–2161. [Google Scholar] [CrossRef]

- Spatareanu, A.; Bercea, M.; Budtova, T.; Harabagiu, V.; Sacarescu, L.; Coseri, S. Synthesis, characterization and solution behaviour of oxidized pullulan. Carbohyd. Polym. 2014, 111, 63–71. [Google Scholar] [CrossRef]

- Constantin, M.; Mihalcea, I.; Oanea, I.; Harabagiu, V.; Fundueanu, G. Studies on graft copolymerization of 3-acrylamidopropyl trimethylammonium chloride on pullulan. Carbohyd. Polym. 2011, 84, 926–932. [Google Scholar] [CrossRef]

- Wang, L.; Shen, J.; Men, Y.; Wu, Y.; Peng, Q.; Wang, X.; Yang, R.; Mahmood, K.; Liu, Z. Corn starch-based graft copolymers prepared via ATRP at the molecular level. Polym. Chem. 2015, 6, 3480–3488. [Google Scholar] [CrossRef]

- Hezarkhani, M.; Yilmaz, E. Pullulan modification via poly(N-vinylimidazole) grafting. Int. J. Biol. Macromol. 2019, 15, 149–156. [Google Scholar] [CrossRef]

- Yang, X.; Shia, X.; D’arcy, R.; Tirelli, N.; Zhaia, G. Amphiphilic polysaccharides as building blocks for self-assembled nanosystems: Molecular design and application in cancer and inflammatory diseases. J. Control. Release 2018, 272, 114–144. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, A.K.; Shukla, S.K.; Bhanu, S.; Kankane, S. Responsive Polymers in Controlled Drug Delivery. Prog. Polym. Sci. 2008, 33, 1088–1118. [Google Scholar] [CrossRef]

- Vardhan, H.; Mittal, P.; Adena, S.K.R.; Upadhyay, M.; Mishra, B. Long-circulating polyhydroxybutyrate-co-hydroxyvalerate nanoparticles for tumor targeted docetaxel delivery: Formulation, optimization and in vitro characterization. Eur. J. Pharm. Sci. 2017, 99, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Radu, I.-C.; Hudita, A.; Zaharia, C.; Stanescu, P.O.; Vasile, E.; Iovu, H.; Stan, M.; Ginghina, O.; Galateanu, B.; Costache, M.; et al. Poly(HydroxyButyrate-co-HydroxyValerate) (PHBHV) Nanocarriers for Silymarin Release as Adjuvant Therapy in Colo-rectal Cancer. Front. Pharmacol. 2017, 8, 508. [Google Scholar] [CrossRef] [Green Version]

- Gracida, J.; Alba, J.; Cardoso, J.; Perez-Guevara, P. Studies of biodegradation of binary blends of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) with poly(2-hydroxyethylmetacrilate) (PHEMA). Polym. Degrad. Stabil. 2004, 83, 247–253. [Google Scholar] [CrossRef]

- Montoro, S.R.; Tebaldi, M.L.; Alves, G.M.; Barboza, J.C.D.S. Redução da Massa Molecular e Funcionalização do Poli(3-Hidroxibutirato-co-3-Hidroxivalerato) (PHBHV) Via Hidrólise Ácida e Transesterificação com Glicóis. Polímeros 2011, 21, 182–187. [Google Scholar] [CrossRef]

- Sadik, T.; Massardier, V.; Becquart, F.; Taha, M. Synthesis and characterizations of poly(ethylene-co-vinylalcohol)-grafted-poly(3-hydroxybutyrate-co-hydroxyvalerate) copolymers. Polymers 2012, 53, 4585–4594. [Google Scholar] [CrossRef]

- Radu, I.-C.; Hudita, A.; Zaharia, C.; Galateanu, B.; Iovu, H.; Tanasa, E.; Nitu, S.G.; Ginghina, O.; Negrei, C.; Tsatsakis, A.; et al. Poly(3-hydroxybutyrate-CO-3-hydroxyvalerate) PHBHV biocompatible nanocarriers for 5-FU delivery targeting colorectal câncer. Drug Deliv. 2019, 26, 318–327. [Google Scholar] [CrossRef]

- Carvalho, L.T.; Moraes, R.M.; Alves, G.M.; Lacerda, T.M.; Santos, J.C.; Santos, A.M.; Medeiros, S.F. Synthesis of Amphiphilic Pullulan-Graft-Poly(ε-Caprolactone) via Click Chemistry. Int. J. Biol. Macromol. 2020, 145, 701–711. [Google Scholar] [CrossRef]

- Lemechko, P.; Renard, E.; Voleta, G.; Colin, C.S.; Guezenne, J.; Langlois, V. Functionalized oligoesters from poly(3-hydroxyalkanoate)s containing reactive end group for click chemistry: Application to novel copolymer synthesis with poly(2-methyl-2-oxazoline). React. Funct. Polym. 2012, 72, 160–167. [Google Scholar] [CrossRef]

- Lu, C.; Zhong, W. Synthesis of Propargyl-Terminated Heterobifunctional Poly(ethylene glycol). Polymers 2010, 2, 407–417. [Google Scholar] [CrossRef]

- Ali, M.W.; Gao, Y.; Siddiq, M.; Ye, X. A Novel Initiator Containing Alkyne Group for the Polymerization of 2-Ethyl-2-oxazoline. Chin. J. Chem. Phys. 2018, 31, 77–84. [Google Scholar] [CrossRef]

- Lemechko, P.; Renard, E.; Guezennec, J.; Simon-Colin, C.; Langlois, V. Synthesis of dextran-graft-PHBHV amphiphilic copolymer using click chemistry approach. React. Funct. Polym. 2012, 72, 487–494. [Google Scholar] [CrossRef]

- Teramoto, N.; Shibata, M. Synthesis and properties of pullulan acetate. Thermal properties, biodegradability, and a semi-clear gel formation in organic solvents. Carbohydr. Polym. 2006, 63, 476–481. [Google Scholar] [CrossRef]

- Montanheiro TL do, A.; Passadora, F.R.; Oliveira MP, d.e.; Durán, N.; Lemes, A.P. Preparation and Characterization of Maleic Anhydride Grafted Poly (Hydroxybutirate-CO-Hydroxyvalerate)—PHBV-g-MA. Mater. Res. 2016, 19, 229–235. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.-S.; Zhu, M.-F.; Wu, W.-H.; Qin, Z.-Y. Reducing the formation of six-membered ring ester during thermal degradation of biodegradable PHBV to enhance its thermal stability. Polym. Degrad. Stabil. 2009, 94, 18–24. [Google Scholar] [CrossRef]

- Islam, M.S.; Yeum, J.H.; Das, A.K. Synthesis of poly(vinyl acetate–methyl methacrylate) copolymer microspheres using suspension polymerization. J. Colloid Interface Sci. 2012, 368, 400–405. [Google Scholar] [CrossRef]

- Thiré, R.M.D.S.; Arruda, L.C.; Barreto, L.S. Morphology and Thermal Properties of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/Attapulgite Nanocomposites. Mater. Res. 2011, 14, 340–344. [Google Scholar]

- Barcelosa, M.V.; Neto, G.R.D.A.; Almeida, F.M.; Rodríguez, R.J.S.; Gomez, J.G.C. Mechanical Properties of P(HB-HV) Nanocomposites Reinforced by Nanodiamonds. Mater. Res. Ibero Am. J. 2017, 20, 1–7. [Google Scholar] [CrossRef] [Green Version]

| Sample | Mn(Da) a | Mn(Da) b | Đ |

|---|---|---|---|

| Unmodified PHBHV | - | 114,873 | 2.86 |

| PHBHV-alkyne | 2843 | 4049 | 1.54 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

T. de Carvalho, L.; da S. Paula, M.L.; M. de Moraes, R.; Alves, G.M.; M. Lacerda, T.; Santos, J.C.d.; M. dos Santos, A.; Medeiros, S.d.F. Chemical Modification of Pullulan Exopolysaccharide by Grafting Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) via Click Chemistry. Polymers 2020, 12, 2527. https://doi.org/10.3390/polym12112527

T. de Carvalho L, da S. Paula ML, M. de Moraes R, Alves GM, M. Lacerda T, Santos JCd, M. dos Santos A, Medeiros SdF. Chemical Modification of Pullulan Exopolysaccharide by Grafting Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) via Click Chemistry. Polymers. 2020; 12(11):2527. https://doi.org/10.3390/polym12112527

Chicago/Turabian StyleT. de Carvalho, Layde, Maria Luiza da S. Paula, Rodolfo M. de Moraes, Gizelda M. Alves, Talita M. Lacerda, Julio C. dos Santos, Amilton M. dos Santos, and Simone de F. Medeiros. 2020. "Chemical Modification of Pullulan Exopolysaccharide by Grafting Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) via Click Chemistry" Polymers 12, no. 11: 2527. https://doi.org/10.3390/polym12112527

APA StyleT. de Carvalho, L., da S. Paula, M. L., M. de Moraes, R., Alves, G. M., M. Lacerda, T., Santos, J. C. d., M. dos Santos, A., & Medeiros, S. d. F. (2020). Chemical Modification of Pullulan Exopolysaccharide by Grafting Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) via Click Chemistry. Polymers, 12(11), 2527. https://doi.org/10.3390/polym12112527