Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

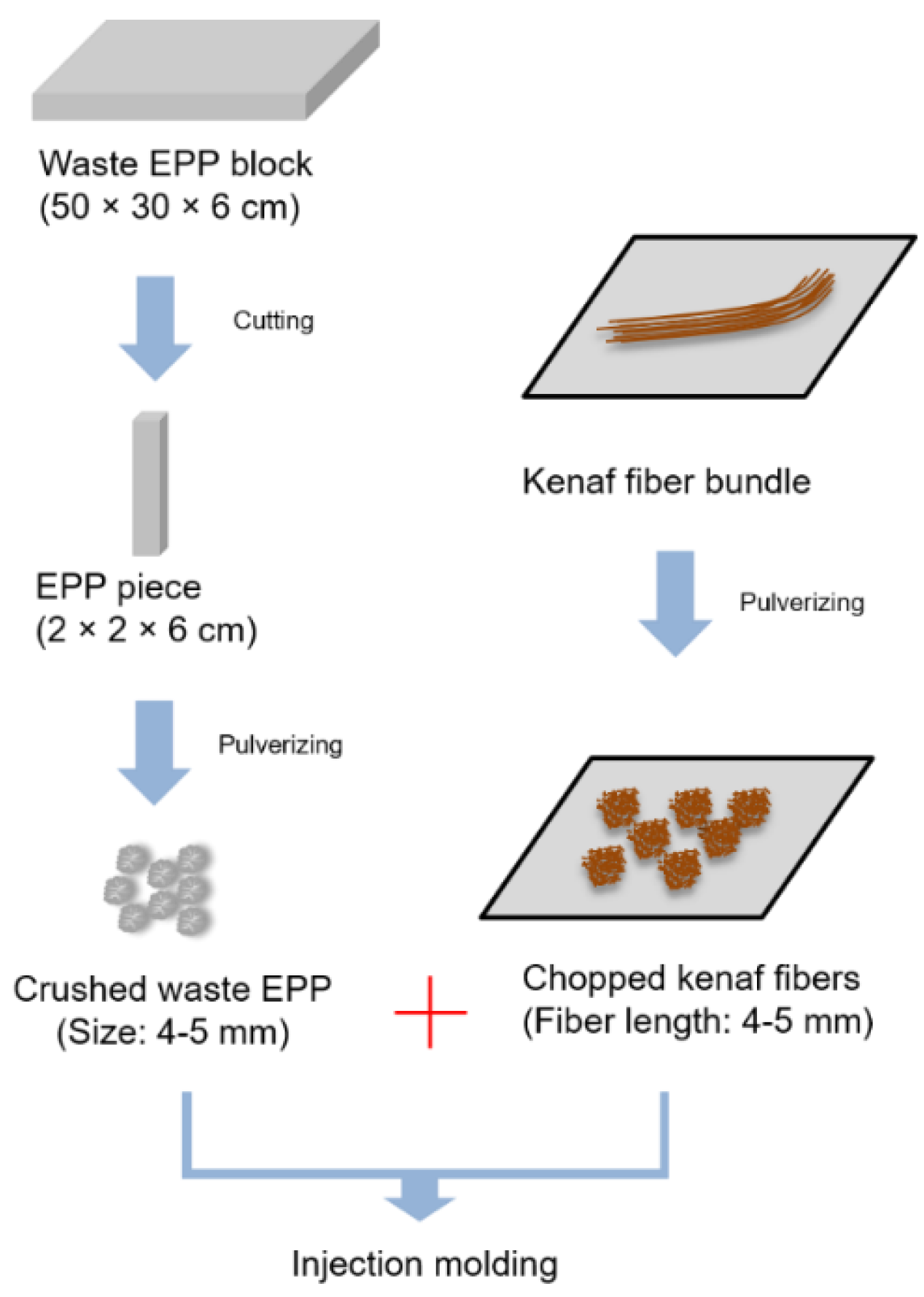

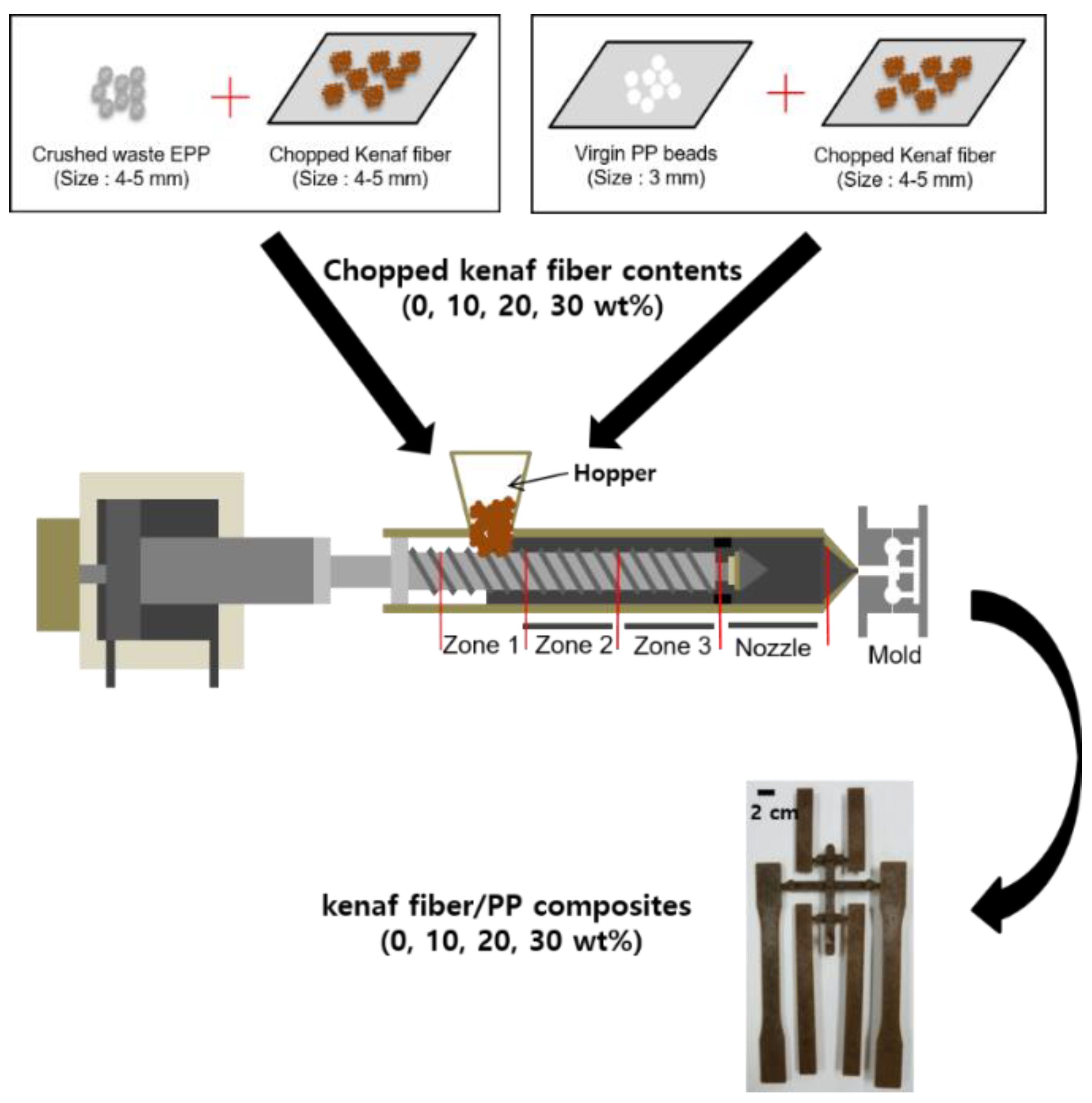

2.2. Processing of Kenaf Fiber/PP Composites through Recycling of Waste EPP

2.3. Characterization of the Composites

2.3.1. Microscopic Observation

2.3.2. Flexural Test

2.3.3. Impact Test

2.3.4. Heat Deflection Temperature Measurement

3. Results and Discussion

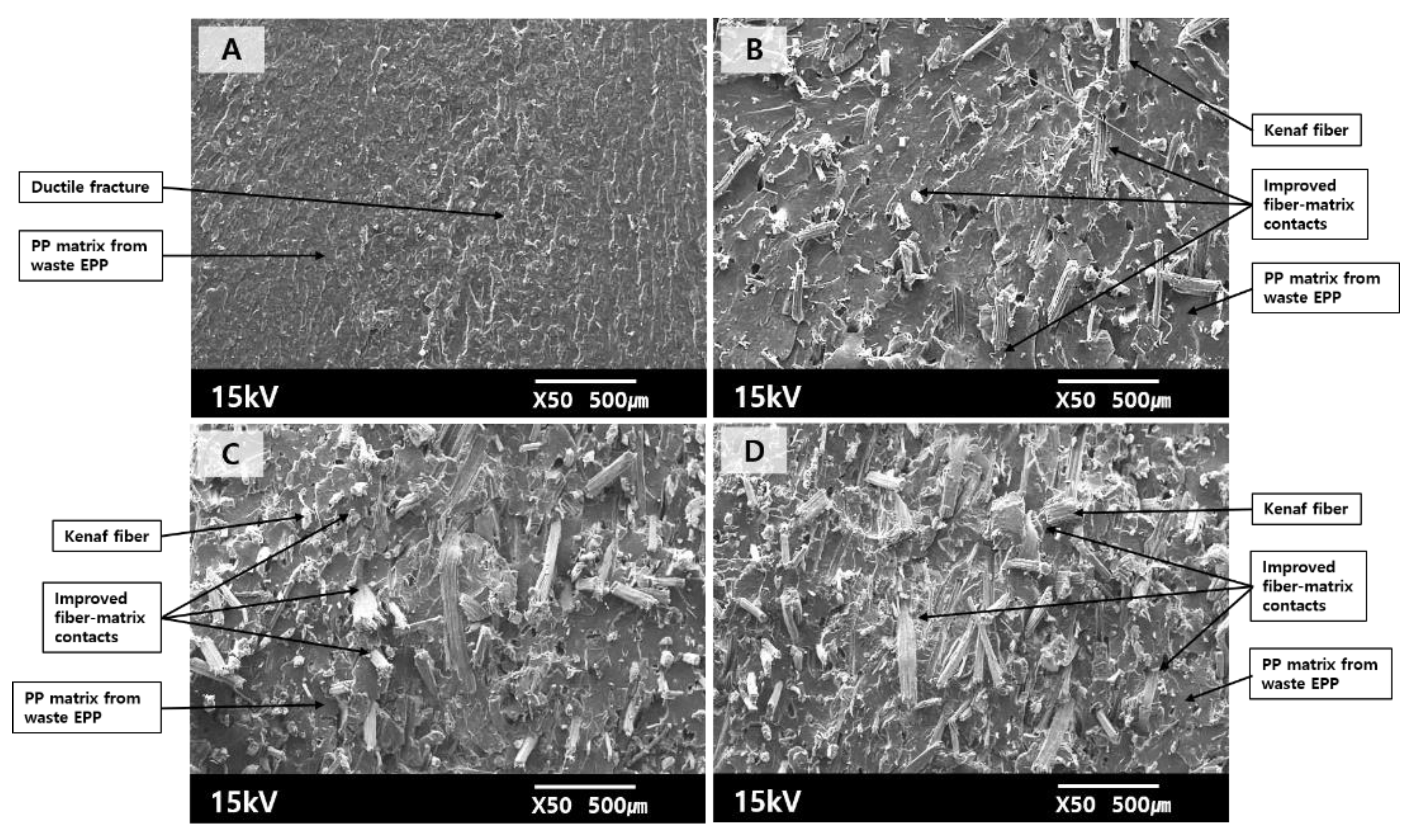

3.1. Fracture Surfaces of Kenaf Fiber/PP Composites Made with Virgin PP and Waste EPP

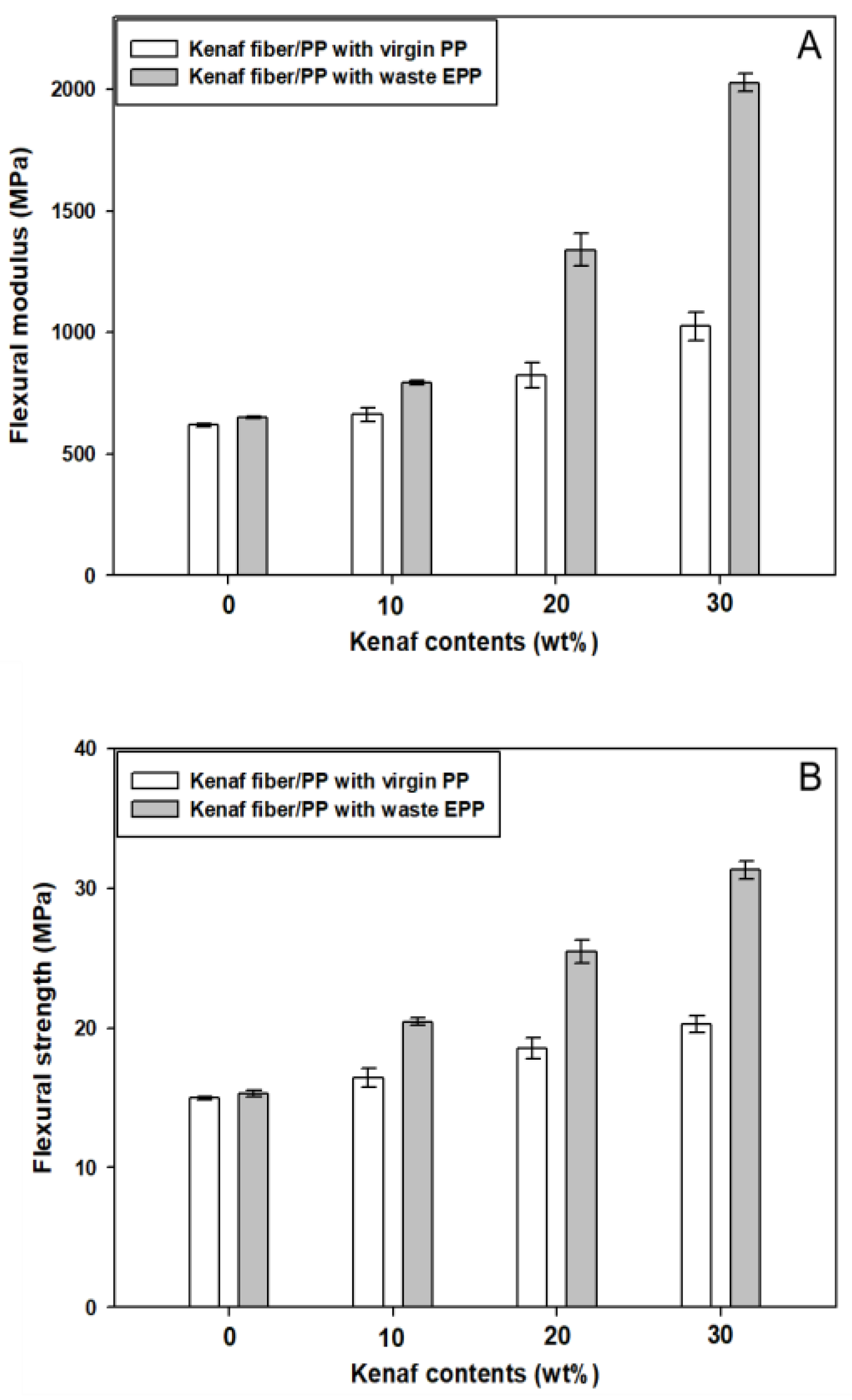

3.2. Effect of Waste EPP on the Flexural Properties

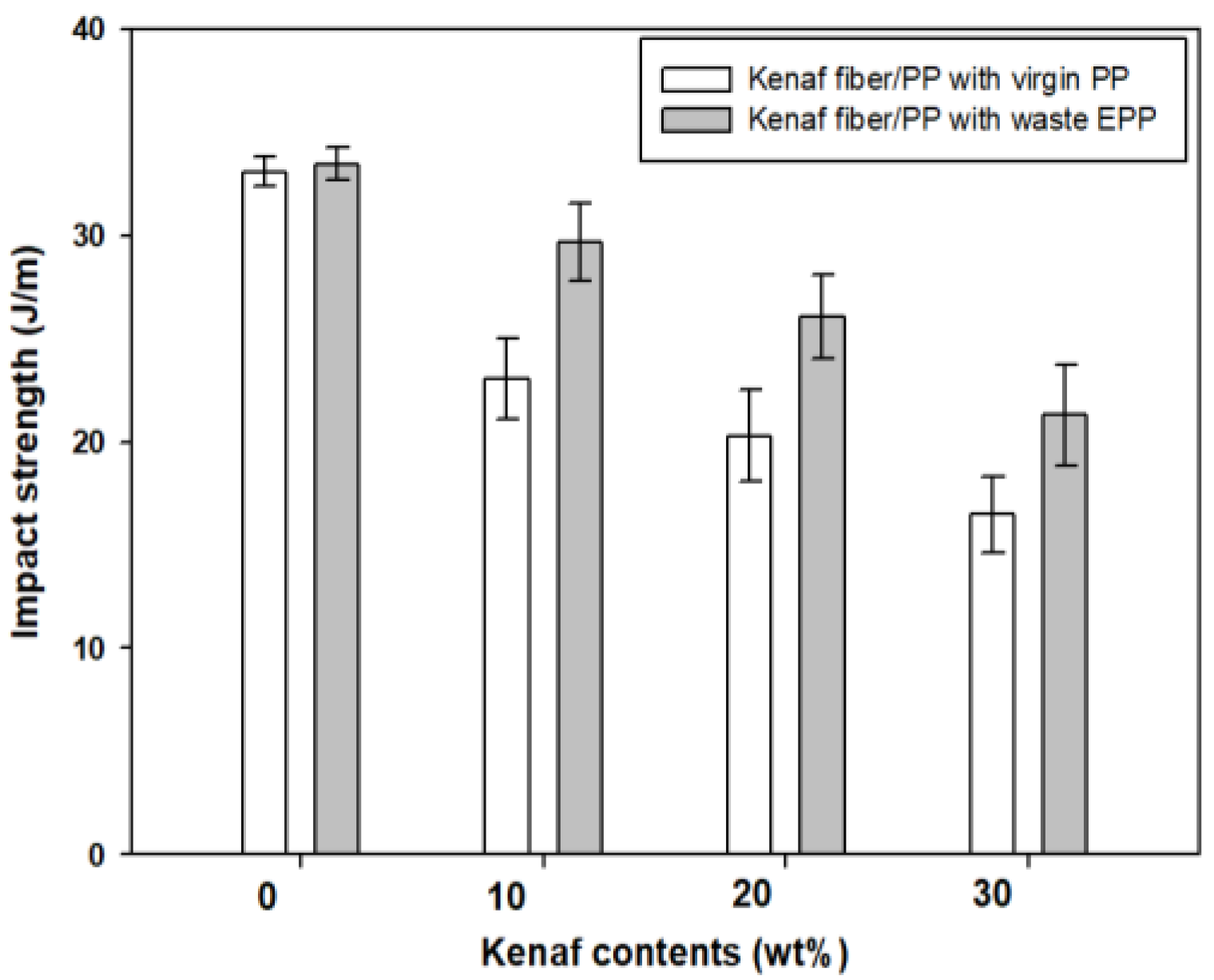

3.3. Effect of Waste EPP on the Impact Strength

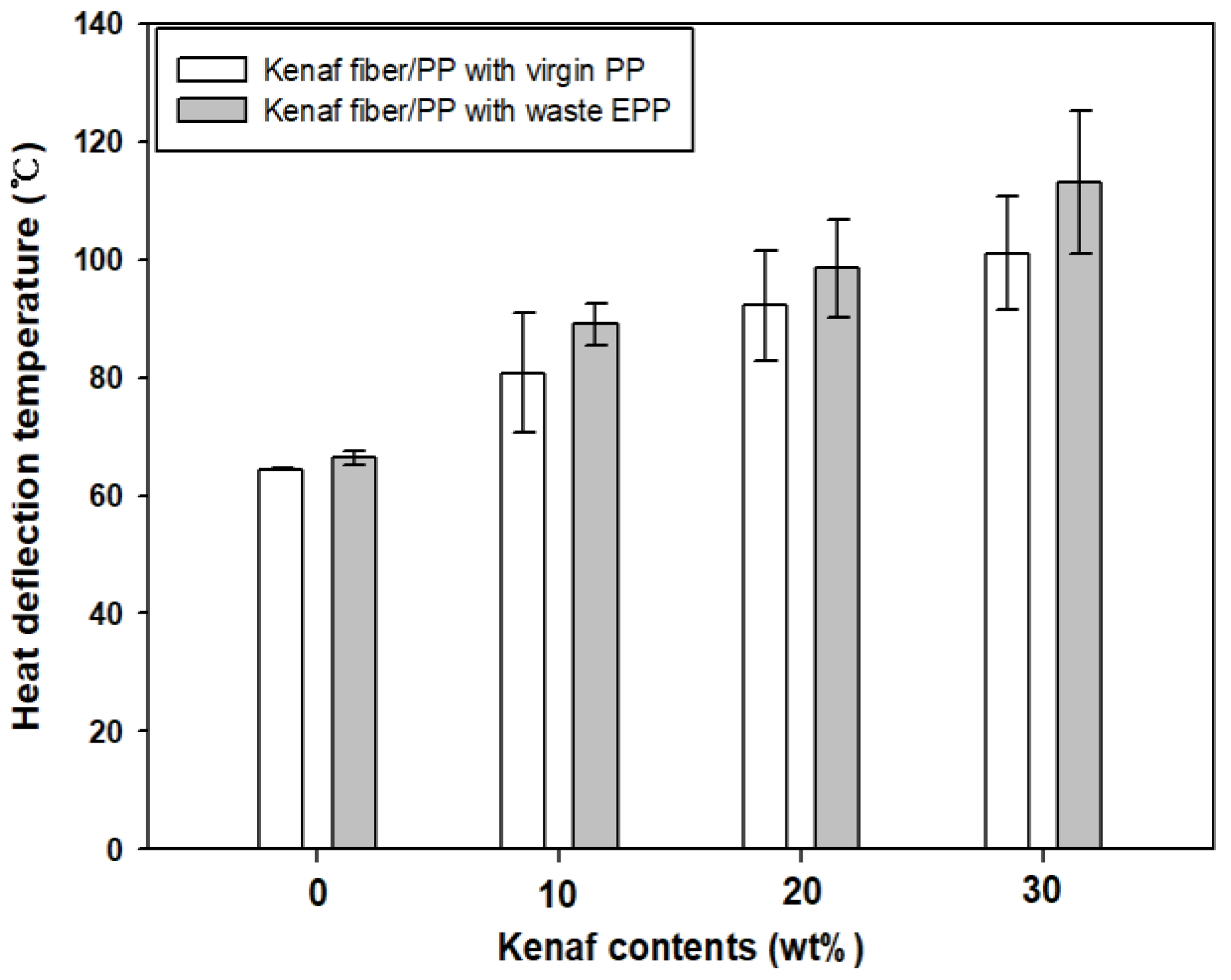

3.4. Effect of Waste EPP on the Heat Deflection Temperature

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Poletto, M.; Dettenborn, J.; Zeni, M.; Zattera, A.J. Characterization of Composites Based on Expanded Polystyrene Wastes and Wood Flour. Waste Manag. 2011, 31, 779–784. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Oza, S. A Comparative Study of the Mechanical Properties of Hemp Fiber with Virgin and Recycled High Density Polyethylene Matrix. Compos. Part B 2013, 45, 1651–1656. [Google Scholar] [CrossRef]

- Guo, Z.; Lan, X.; Xue, P. High-Precision Monitoring of Average Molecular Weight of Polyethylene Wax from Waste High-Density Polyethylene. Polymers 2020, 12, 188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cho, D.; Seo, J.M.; Park, W.H.; Han, S.O.; Hwang, T.W.; Choi, C.H.; Jung, S.J. Fiber Surface Treatments for Improvement of the Interfacial Adhesion and Flexural and Thermal Properties of Jute/Poly(lactic acid) Biocomposites. J. Biobased Mater. Bioenergy 2007, 1, 331–340. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Dimensional Stability and Mechanical Behaviour of Wood-Plastic Composites Based on Recycled and Virgin High-Density Polyethylene (HDPE). Compos. Part B 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Lee, H.S.; Cho, D.; Han, S.O. Effect of Natural Fiber Surface Treatments on the Interfacial and Mechanical Properties of Henequen/Polypropylene Biocomposites. Macromol. Res. 2008, 16, 411–417. [Google Scholar] [CrossRef] [Green Version]

- Cho, D.; Lee, H.S.; Han, S.O. Effect of Fiber Surface Modification on the Interfacial and Mechanical Properties of Kenaf Fiber-Reinforced Thermoplastic and Thermosetting Polymer Composites. Compos. Interfaces 2009, 16, 711–729. [Google Scholar] [CrossRef]

- Bourmaud, A.; Le Duigou, A.; Baley, C. What is the Technical and Environmental Interest in Reusing a Recycled Polypropylene-Hemp Fibre Composite? Polym. Degrad. Stab. 2011, 96, 1732–1739. [Google Scholar] [CrossRef]

- Woo, Y.; Cho, D. Effect of Aluminum Trihydroxide on Flame Retardancy and Dynamic Mechanical and Tensile Properties of Kenaf/Poly(lactic acid) Green Composites. Adv. Compos. Mater. 2013, 22, 451–464. [Google Scholar] [CrossRef]

- Han, Y.H.; Han, S.O.; Cho, D.; Kim, H.I. Kenaf/Polypropylene Biocomposites: Effects of Electron Beam Irradiation and Alkali Treatment on Kenaf Natural Fibers. Compos. Interfaces 2007, 14, 559–578. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.H.; Ariffin, A.H.; Shah, A.U.M. Effects of Fibre Treatment on Mechanical Properties of Kenaf Fibre Reinforced Composites: A Review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Tholibon, D.; Sulong, A.B.; Muhamad, N.; Haron, C.H.C. New Processing Technique for Biodegradable Kenaf Composites: A Simple Alternative to Commercial Automotive Parts. Compos. Part B 2020, 184, 107644. [Google Scholar] [CrossRef]

- Zampaloni, M.; Pourboghrat, F.; Yankovich, S.A.; Rodgers, B.N.; Moore, J.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Kenaf Natural Fiber Reinforced Polypropylene Composites: A Discussion on Manufacturing Problems and Solutions. Compos. Part A 2007, 38, 1569–1580. [Google Scholar] [CrossRef]

- Cho, D.; Lee, H.S.; Han, S.O.; Drzal, L.T. Effects of E-Beam Treatment on the Interfacial and Mechanical Properties of Henequen/Polypropylene Biocomposites. Adv. Compos. Mater. 2007, 16, 315–334. [Google Scholar] [CrossRef]

- Gourier, C.; Bourmaud, A.; Le Duigou, A.; Baley, C. Influence of PA11 and PP Thermoplastic Polymers on Recycling Stability of Unidirectional Flax Fibre Reinforced Biocomposites. Polym. Degrad. Stab. 2017, 136, 1–9. [Google Scholar] [CrossRef]

- Nematollahi, M.; Karevan, M.; Fallah, M.; Farzin, M. Experimental and Numerical Study of the Critical Length of Short Kenaf Fiber Reinforced Polypropylene Composites. Fiber Polym. 2020, 21, 821–828. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Ismail, N.F.; Radzi, M.K.F.M.; Razak, Z.B.; Tharizi, I.B.; Sulong, A.B.; Haron, C.H.C.; Muhamad, N. Kenaf Composites for Automotive Components: Enhancement in Machinability and Moldability. Polymers 2019, 11, 1707. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nematollahi, M.; Karevan, M.; Mosaddegh, P.; Farzin, M. Morphology, Thermal and Mechanical Properties of Extruded Injection Molded Kenaf Fiber Reinforced Polypropylene Composites. Mater. Res. Express 2019, 6, 095409. [Google Scholar] [CrossRef]

- Islam, M.R.; Beg, M.D.H.; Gupta, A. Characterization of Alkali-Treated Kenaf Fibre-Reinforced Recycled Polypropylene Composites. J. Thermoplast. Compos. Mater. 2012, 27, 909–932. [Google Scholar] [CrossRef]

- Bouix, R.; Viot, P.; Lataillade, J.L. Polypropylene Foam Behaviour under Dynamic Loadings: Strain Rate, Density and Microstructure Effects. Int. J. Impact Eng. 2009, 36, 329–342. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Qiu, J.; Xing, H.; Fan, D.; Wang, S.; Li, S.; Jiang, Z.; Tang, T. In-situ Cooling of Adsorbed Water to Control Cellular Structure of Polypropylene Composite Foam During CO2 Batch Foaming Process. Polymer 2018, 155, 116–128. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; He, Z.; Zong, Z.; Fang, J. Dynamic Impact Response of Aluminum Honeycombs Filled with Expanded Polypropylene Foam. Compos. Part B 2019, 156, 17–27. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altstädt, V. Past and Present Developments in Polymer Bead Foams and Bead Foaming Technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Yoshihara, H.; Maruta, M. Measurement of the Shear Properties of Extruded Polystyrene Foam by In-Plane Shear and Asymmetric Four-Point Bending Tests. Polymers 2020, 12, 47. [Google Scholar] [CrossRef] [Green Version]

- Uttaravalli, A.N.; Dinda, S.; Gidla, B.R. Scientific and Engineering Aspects of Potential Applications of Post-Consumer (Waste) Expanded Polystyrene: A Review. Proc. Saf. Environ. Protect. 2020, 137, 140–148. [Google Scholar] [CrossRef]

- Shin, C. Filtration Application from Recycled Expanded Polystyrene. J. Colloid Interfaces Sci. 2006, 302, 267–271. [Google Scholar] [CrossRef]

- Spinacé, M.A.S.; Fermoseli, K.K.G.; Paoli, M.A.D. Recycled Polypropylene Reinforced with Curaua Fibers by Extrusion. J. Appl. Polym. Sci. 2009, 112, 3686–3694. [Google Scholar] [CrossRef]

- Wu, M.; Zhao, M.; Chang, G.; Hu, X.; Guo, Q. A Composite Obtained from Waste Automotive Plastics and Sugarcane Skin Flour: Mechanical Properties and Thermo-Chemical Analysis. Powder Technol. 2019, 347, 27–34. [Google Scholar] [CrossRef]

- Borsoi, C.; Scienza, L.C.; Zattera, A.J. Characterization of Composites Based on Recycled Expanded Polystyrene Reinforced with Curaua Fibers. J. Appl. Polym. Sci. 2013, 128, 653–659. [Google Scholar] [CrossRef]

- Hwang, D.; Cho, D. Fiber Aspect Ratio Effect on Mechanical and Thermal Properties of Carbon Fiber/ABS Composites via Extrusion and Long Fiber Thermoplastic Processes. J. Ind. Eng. Chem. 2019, 80, 335–344. [Google Scholar] [CrossRef]

- Kim, Y.; Kwon, O.H.; Park, W.H.; Cho, D. Thermo-Mechanical and Flexural Properties of Chopped Silk Fiber-Reinforced Poly(butylene succinate) Green Composites: Effect of Electron Beam Treatment of Worm Silk. Adv. Compos. Mater. 2013, 22, 437–449. [Google Scholar] [CrossRef]

- Kwon, H.J.; Sunthornvarabhas, J.; Park, J.W.; Lee, J.H.; Kim, H.J.; Piyachomkwan, K.; Sriroth, K.; Cho, D. Tensile Properties of Kenaf Fiber and Corn Husk Flour Reinforced Poly(lactic acid) Hybrid Bio-Composites: Role of Aspect Ratio of Natural Fibers. Compos. Part B 2014, 56, 232–237. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M.K. Review on Mechanical Properties of Natural Fiber Composites. Mater. Today Proc. 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Cho, D.; Kim, H.J.; Drzal, L.T. Surface Treatment and Characterization of Natural Fiber: Effects on the Properties of Biocomposites. In Polymer Composites Volume 3: Biocomposites; Thomas, S., Joseph, K., Malhotra, S.K., Goda, K., Sreekala, M.S., Eds.; Wiley-VCH: Weinhein, Germany, 2013; pp. 133–177. [Google Scholar]

- Lee, K.Y.; Cho, D. Mechanical and Impact Properties and Heat Deflection Temperature of Wood Flour-Reinforced Recycled Polyethylene Green Composites. Elastom. Compos. 2011, 46, 223–230. [Google Scholar]

- Kim, Y.; Cho, D.; Park, W.H.; Kwon, O.H. Novel Silk Fibroin Fiber-Reinforced Poly(butylene succinate) Biocomposites: Electron Beam Treatment Effect of Silk on the Interfacial, Thermal, Mechanical and Impact Properties. J. Biobased Mater. Bioenergy 2014, 8, 261–272. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, B.H.; Choi, S.W.; Kim, S.; Kim, H.J. The Effect of Types of Maleic Anhydride-Grafted Polypropylene (MAPP) on the Interfacial Adhesion Properties of Bio-Flour-Filled Polypropylene Composites. Compos. Part A 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Lee, J.; Le Boulicaut, N.; Kwon, O.H.; Park, W.H.; Cho, D. Electron Beam Irradiation Effect on the Mechanical and Thermal Properties of 2-D Silk Fibroin Fabric/Poly(lactic acid) Biocomposites. J. Ind. Eng. Chem. 2019, 71, 150–159. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Patiño, W.; Cárdenas, J. Physical-Mechanical Properties of Bamboo Fibers-Reinforced Biocomposites: Influence of Surface Treatment of Fibers. J. Build. Eng. 2020, 28, 101058. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Feldmann, M. Polyoxymethylene Composites with Natural and Cellulose Fibres: Toughness and Heat Deflection Temperature. Compos. Sci. Technol. 2012, 72, 1870–1874. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Cho, D. Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites. Polymers 2020, 12, 2578. https://doi.org/10.3390/polym12112578

Kim J, Cho D. Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites. Polymers. 2020; 12(11):2578. https://doi.org/10.3390/polym12112578

Chicago/Turabian StyleKim, Junghoon, and Donghwan Cho. 2020. "Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites" Polymers 12, no. 11: 2578. https://doi.org/10.3390/polym12112578

APA StyleKim, J., & Cho, D. (2020). Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites. Polymers, 12(11), 2578. https://doi.org/10.3390/polym12112578