In-Situ Observations of Microscale Ductility in a Quasi-Brittle Bulk Scale Epoxy

Abstract

1. Introduction

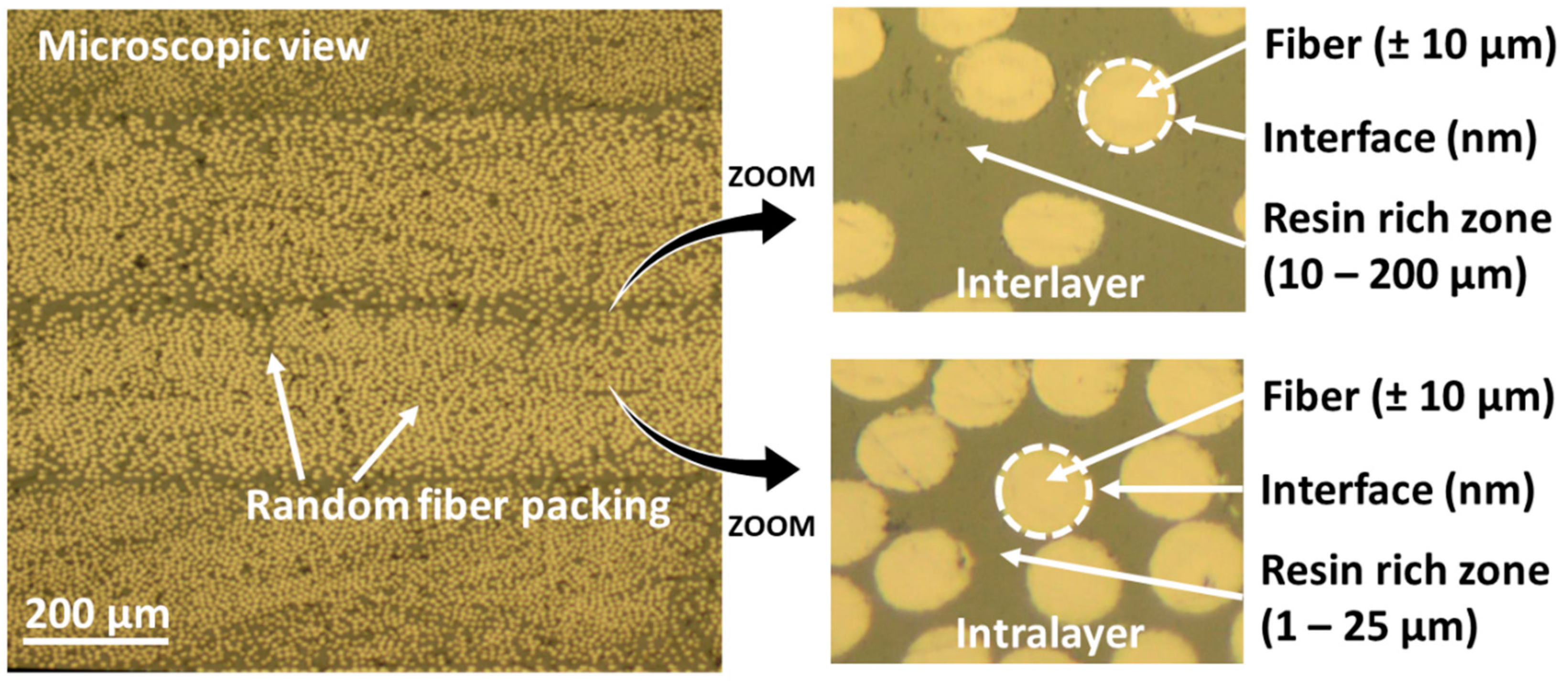

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Production

2.2.2. Mechanical Tests

2.2.3. Microscopical Observations

3. Results and Discussion

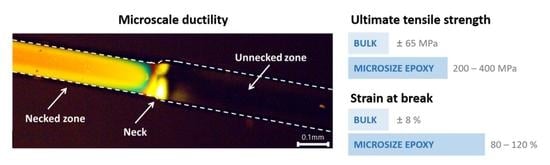

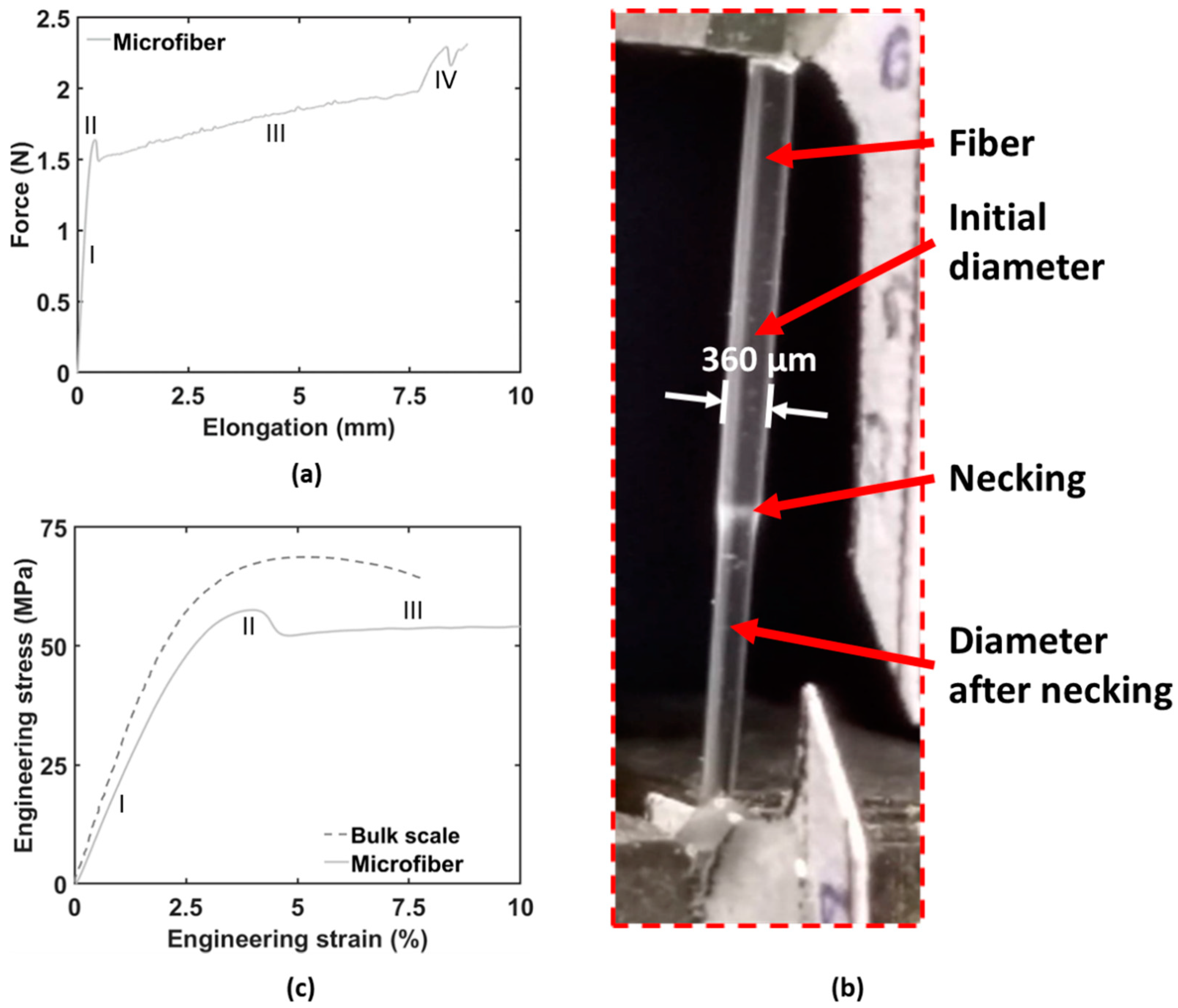

3.1. Mechanical Comparison between Bulk and Microscale Epoxy

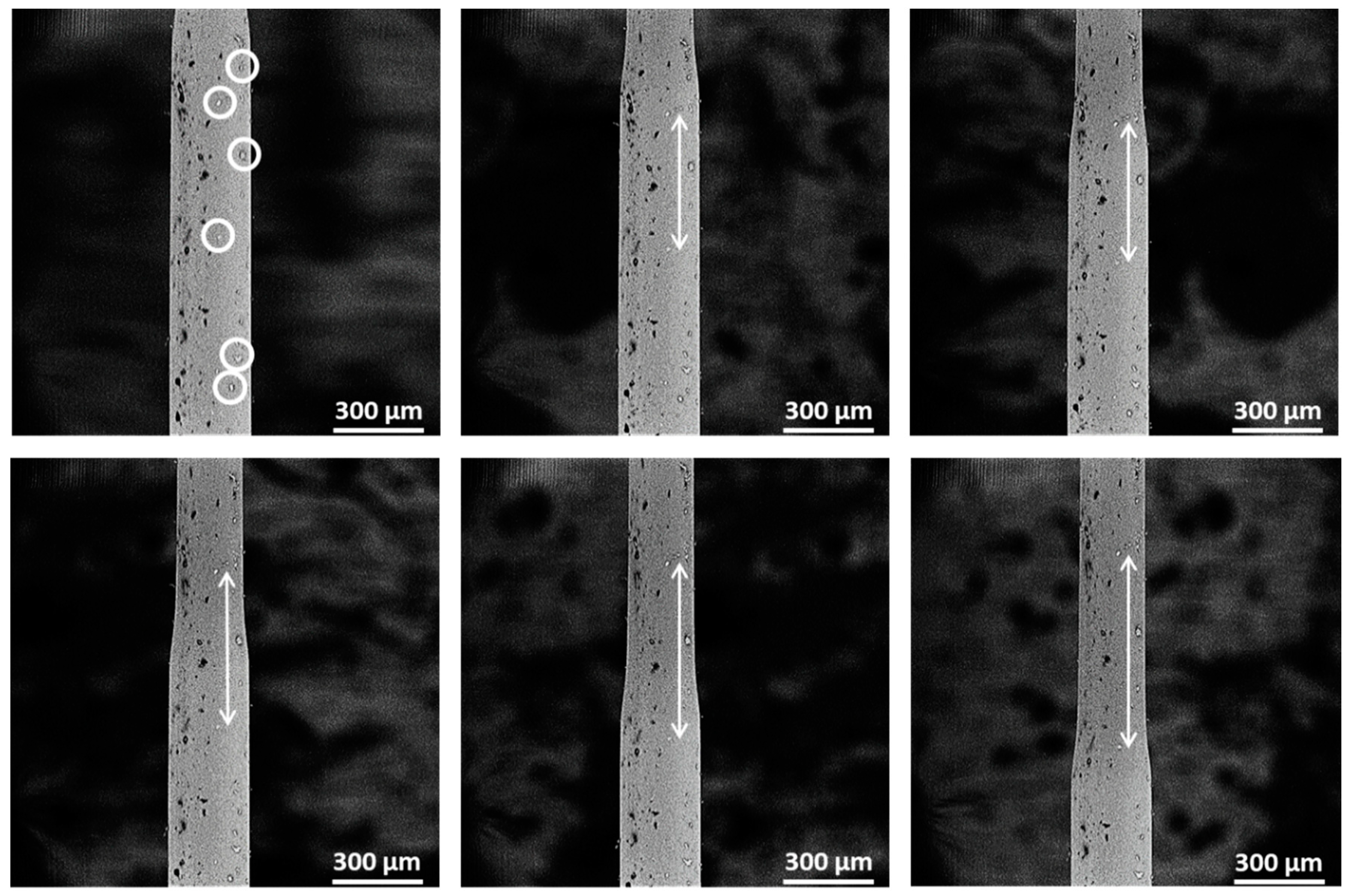

3.2. In-Situ Scanning Electron Microscopy Inspection of the Tensile Deformation of Epoxy Microfibers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Beardmore, P.; Johnson, C.F. The potential for composites in structural automotive applications. Compos. Sci. Technol. 1986, 26, 251–281. [Google Scholar] [CrossRef]

- Brøndsted, P.; Lilholt, H.; Lystrup, A. Composite materials for wind power turbine blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Hobbiebrunken, T.; Hojo, M.; Adachi, T.; De Jong, C.; Fiedler, B. Evaluation of interfacial strength in CF/epoxies using FEM and in-situ experiments. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2248–2256. [Google Scholar] [CrossRef]

- Hobbiebrunken, T.; Fiedler, B.; Hojo, M.; Tanaka, M. Experimental determination of the true epoxy resin strength using micro-scaled specimens. Compos. Part A Appl. Sci. Manuf. 2007, 38, 814–818. [Google Scholar] [CrossRef]

- Odom, E.M.; Adams, D.F. Specimen size effect during tensile testing of an unreinforced polymer. J. Mater. Sci. 1992, 27, 1767–1771. [Google Scholar] [CrossRef]

- Misumi, J.; Ganesh, R.; Sockalingam, S.; Gillespie, J.W. Experimental characterization of tensile properties of epoxy resin by using micro-fiber specimens. J. Reinf. Plast. Compos. 2016, 35, 1792–1801. [Google Scholar] [CrossRef]

- Sui, X.M.; Tiwari, M.; Greenfeld, I.; Khalfin, R.L.; Meeuw, H.; Fiedler, B.; Wagner, H.D. Extreme scale-dependent tensile properties of epoxy fibers. eXPRESS Polym. Lett. 2019, 13, 993–1003. [Google Scholar] [CrossRef]

- Gilabert, F.A.; Garoz, D.; Sevenois, R.D.B.; Spronk, S.W.F.; Rezaei, A.; Van Paepegem, W. Composite micro-scale model accounting for debonding, strain rate-dependence and damage under impact using an explicit finite element solver. In Proceedings of the ECCM 2016-Proceeding 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016; pp. 26–30. [Google Scholar]

- Vaughan, T.J.; McCarthy, C.T. Micromechanical modelling of the transverse damage behaviour in fibre reinforced composites. Compos. Sci. Technol. 2011, 71, 388–396. [Google Scholar] [CrossRef]

- Tan, W.; Naya, F.; Yang, L.; Chang, T.; Falzon, B.G.; Zhan, L.; Molina-Aldareguía, J.M.; González, C.; Llorca, J. The role of interfacial properties on the intralaminar and interlaminar damage behaviour of unidirectional composite laminates: Experimental characterization and multiscale modelling. Compos. Part B Eng. 2018, 138, 206–221. [Google Scholar] [CrossRef]

- Ren, M.F.; Zhang, X.W.; Huang, C.; Wang, B.; Li, T. An integrated macro/micro-scale approach for in situ evaluation of matrix cracking in the polymer matrix of cryogenic composite tanks. Compos. Struct. 2019, 216, 201–212. [Google Scholar] [CrossRef]

- González, C.; Lorca, J.L. Multiscale modeling of fracture in fiber-reinforced composites. Acta Mater. 2006, 54, 4171–4181. [Google Scholar] [CrossRef]

- Llorca, J.; González, C.; Molina-Aldareguía, J.M.; Segurado, J.; Seltzer, R.; Sket, F.; Rodríguez, M.; Sádaba, S.; Muñoz, R.; Canal, L.P. Multiscale modeling of composite materials: A roadmap towards virtual testing. Adv. Mater. 2011, 23, 5130–5147. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Composite materials for wind energy applications: Micromechanical modeling and future directions. Comput. Mech. 2012, 50, 195–207. [Google Scholar] [CrossRef]

- Totry, E.; Molina-Aldareguía, J.M.; González, C.; Lorca, J.L. Effect of fiber, matrix and interface properties on the in-plane shear deformation of carbon-fiber reinforced composites. Compos. Sci. Technol. 2010, 70, 970–980. [Google Scholar] [CrossRef]

- ASTM. ASTM D638-14 Standard Test Method for Tensile Properties of Plastics; ASTM Standard: West Conshohocken, PA, USA, 2014; pp. 1–17. [Google Scholar]

- ISO. ISO 527-1:2019 Plastics-Determination of Tensile Properties-Part 1: General Principles; ISO Standard: Geneva, Switzerland, 2019; pp. 1–26. [Google Scholar]

- Leopold, C.; Liebig, V.W.; Wittich, H.; Fiedler, B. Size effect of graphene nanoparticle modified epoxy matrix. Compos. Sci. Technol. 2016, 134, 217–225. [Google Scholar] [CrossRef]

- Zike, S.; Sørensen, B.F.; Mikkelsen, L.P. Experimental determination of the micro-scale strength and stress-strain relation of an epoxy resin. Mater. Des. 2016, 98, 47–60. [Google Scholar] [CrossRef]

- Harter, H.L. A Survey of the Literature on the Size Effect on Material Strength; Wright-Patterson Air Force Base: Montgomery, OH, USA, 1977. [Google Scholar]

- Griffits, A.A. The phenomena of rupture and flow in solids. Masinovedenie 1995, 1, 9–14. [Google Scholar] [CrossRef]

- Bažant, Z.P. Size effect on structural strength: A review. Arch. Appl. Mech. 1999, 69, 703–725. [Google Scholar] [CrossRef]

- Thorne, D.J. Carbon fibres with large breaking strain. Nature 1974, 248, 754–756. [Google Scholar] [CrossRef]

- Carpinteri, A. Scaling laws and renormalization groups for strength and toughness of disordered materials. Int. J. Solids Struct. 1994, 31, 291–302. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; De Magalhães, F.A.C.R.G.; Chaves, F.J.P.; De Moura, M.F.S.F. Mode II fracture toughness of a brittle and a ductile adhesive as a function of the adhesive thickness. J. Adhes. 2010, 86, 889–903. [Google Scholar] [CrossRef]

- ISO 11566 Carbon Fibre-Determination of Teh Tensile Properties of Single-Filament Specimens; ISO Standardization International: Geneva, Switzerland, 1996.

- Leopold, C.; Augustin, T.; Schwebler, T.; Lehmann, J.; Liebig, V.W.; Fiedler, B. Influence of carbon nanoparticle modification on the mechanical and electrical properties of epoxy in small volumes. J. Colloid Interface Sci. 2017, 506, 620–632. [Google Scholar] [CrossRef]

- Hardis, R.; Jessop, J.L.P.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef]

- Allaer, K.; De Baere, I.; Van Paepegem, W.; Degrieck, J. Direct fracture toughness determination of a ductile epoxy polymer from digital image correlation measurements on a single edge notched bending sample. Polym. Test. 2015, 42, 199–207. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Detwiler, A.T.; Lesser, A.J. Aspects of Network Formation in Glassy Thermosets. J. Appl. Polym. Sci. 2010, 117, 1021–1034. [Google Scholar] [CrossRef]

- Harada, M.; Morimoto, M.; Ochi, M. Influence of network chain orientation on the mechanical property of epoxy resin filled with silica particles. J. Appl. Polym. Sci. 2002, 87, 787–794. [Google Scholar] [CrossRef]

- Leonov, A.I. A theory of necking in semi-crystalline polymers. Int. J. Solids Struct. 2002, 39, 5913–5926. [Google Scholar] [CrossRef]

- Davis, T.; Healy, D.; Bubeck, A.; Walker, R. Stress concentrations around voids in three dimensions: The roots of failure. J. Struct. Geol. 2017, 102, 193–207. [Google Scholar] [CrossRef]

| Diameter Prior to Necking (µm) | Diameter Just after Necking (µm) | Diameter Contraction (%) | Strain (%) | |

|---|---|---|---|---|

| Microfiber 1 | 21.3 | 17.2 | 19.3 | 53.5 |

| Microfiber 2 | 113.0 | 90.1 | 20.3 | 57.3 |

| Microfiber 3 | 141.4 | 117.6 | 16.8 | 44.5 |

| Microfiber 4 | 154.2 | 126.0 | 18.3 | 49.8 |

| Microfiber 5 | 168.1 | 136.8 | 18.6 | 51.0 |

| Microfiber 6 | 275.7 | 225.0 | 18.4 | 50.1 |

| Microfiber 7 | 275.8 | 223.6 | 18.9 | 52.1 |

| Microfiber 8 | 424.7 | 347.7 | 18.1 | 49.2 |

| Microfiber 9 | 610.0 | 412.0 | 16.0 | 41.8 |

| Calculated Strain via Diameter (%) | Strain (%) | |

|---|---|---|

| Microfiber 6 | 50.1 | 52.5 |

| Microfiber 7 | 52.1 | 53.7 |

| Microfiber 9 | 41.8 | 41.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verschatse, O.; Daelemans, L.; Van Paepegem, W.; De Clerck, K. In-Situ Observations of Microscale Ductility in a Quasi-Brittle Bulk Scale Epoxy. Polymers 2020, 12, 2581. https://doi.org/10.3390/polym12112581

Verschatse O, Daelemans L, Van Paepegem W, De Clerck K. In-Situ Observations of Microscale Ductility in a Quasi-Brittle Bulk Scale Epoxy. Polymers. 2020; 12(11):2581. https://doi.org/10.3390/polym12112581

Chicago/Turabian StyleVerschatse, Olivier, Lode Daelemans, Wim Van Paepegem, and Karen De Clerck. 2020. "In-Situ Observations of Microscale Ductility in a Quasi-Brittle Bulk Scale Epoxy" Polymers 12, no. 11: 2581. https://doi.org/10.3390/polym12112581

APA StyleVerschatse, O., Daelemans, L., Van Paepegem, W., & De Clerck, K. (2020). In-Situ Observations of Microscale Ductility in a Quasi-Brittle Bulk Scale Epoxy. Polymers, 12(11), 2581. https://doi.org/10.3390/polym12112581