Engineering and Characterization of Antibacterial Coaxial Nanofiber Membranes for Oil/Water Separation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Characterizations

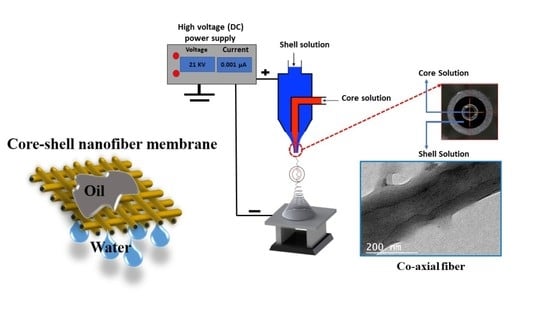

2.1.1. Surface Morphology and Material Hydrophilicity

2.1.2. Mechanical Properties and FTIR Analysis

2.1.3. Antibacterial Activity and Oil/Water Separation

3. Results and Discussion

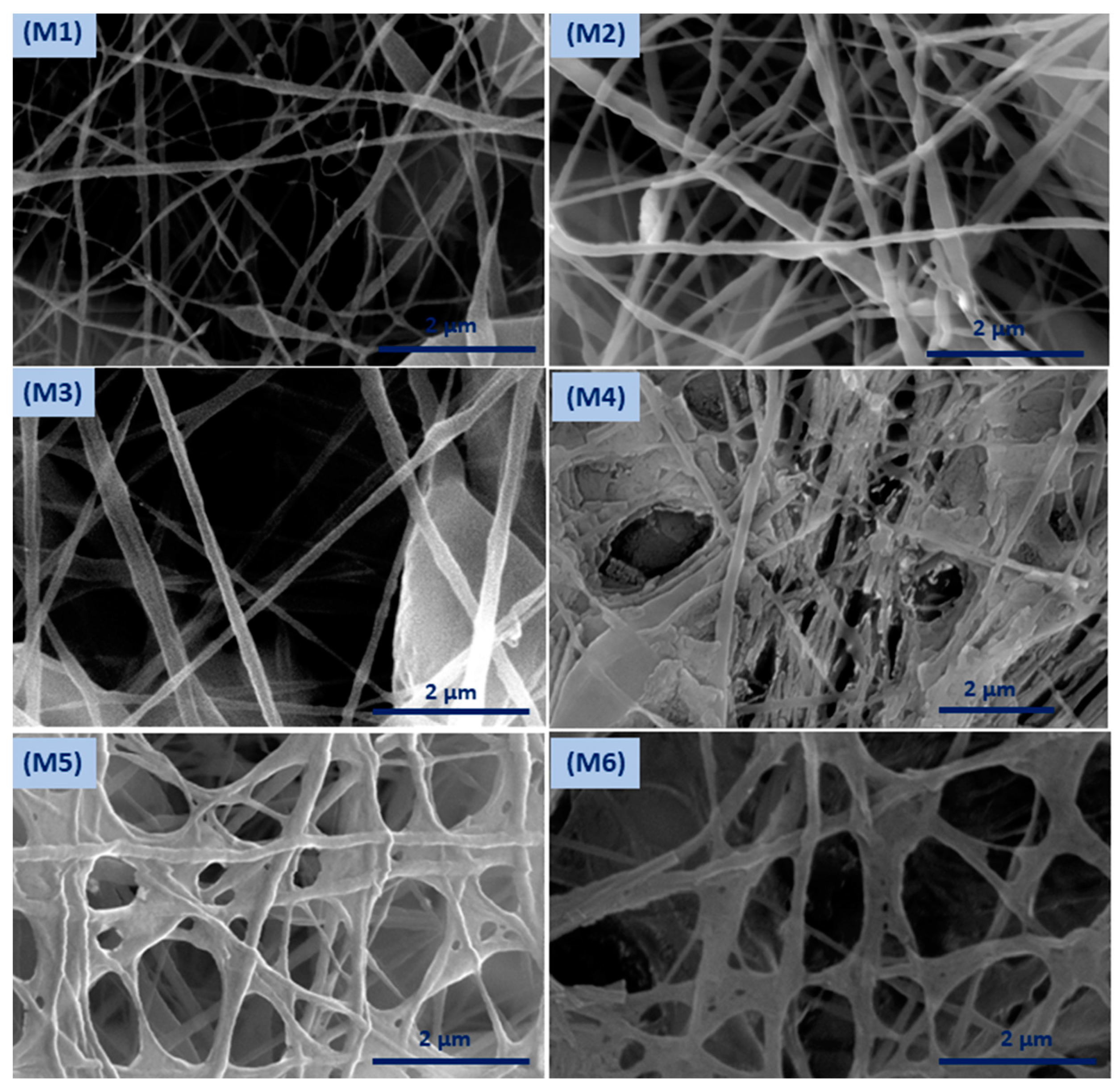

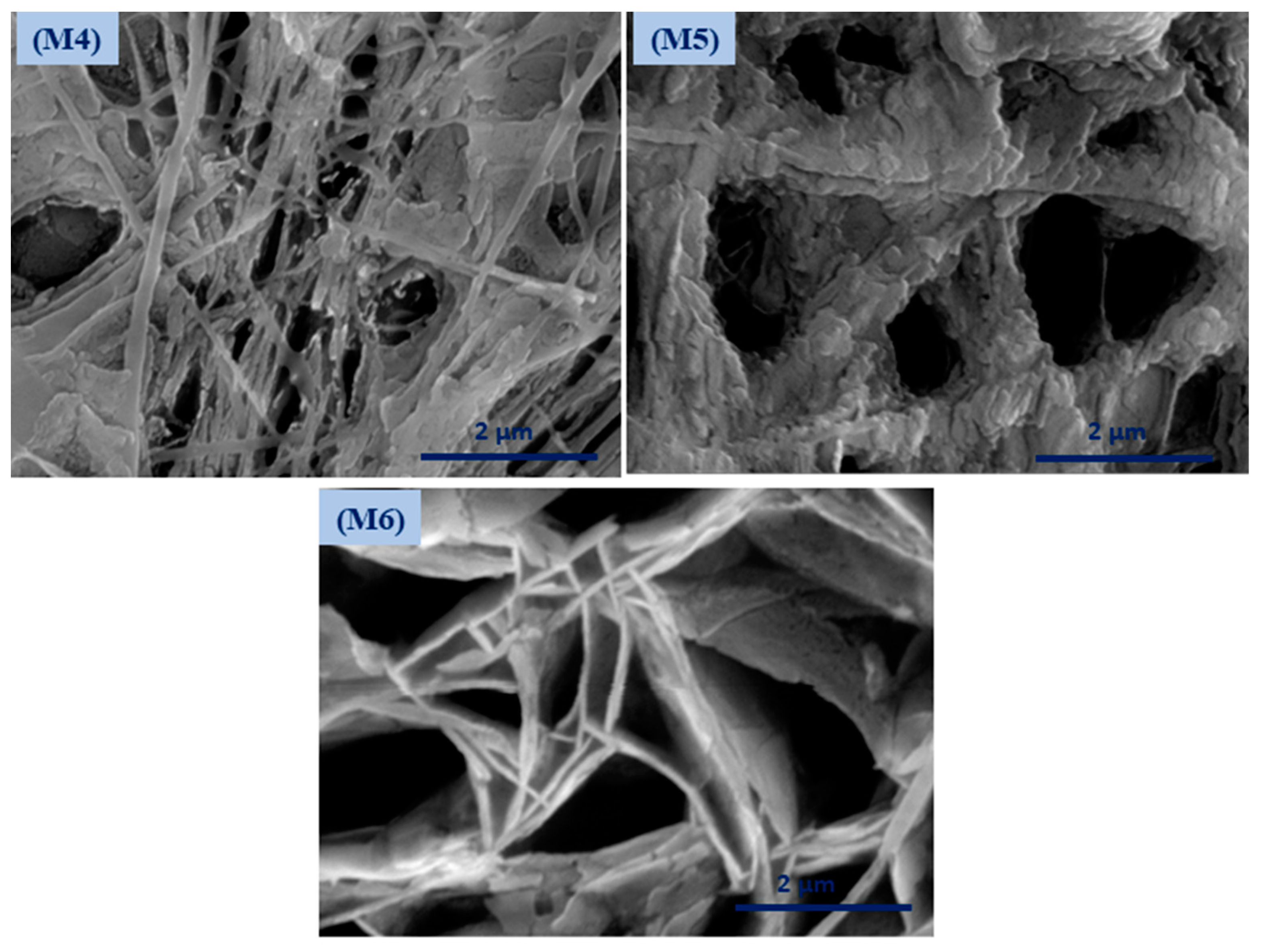

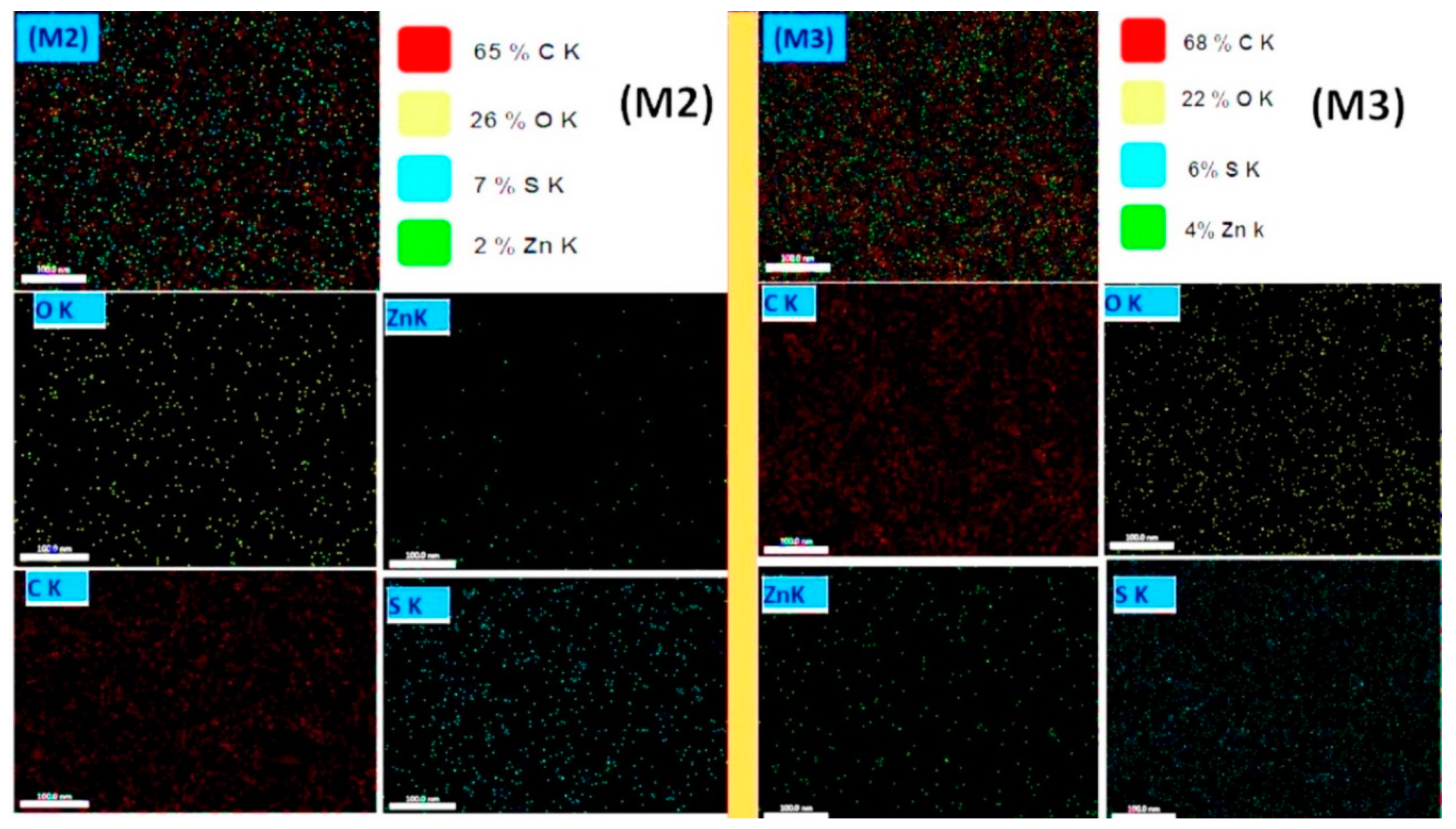

3.1. Membrane Morphology

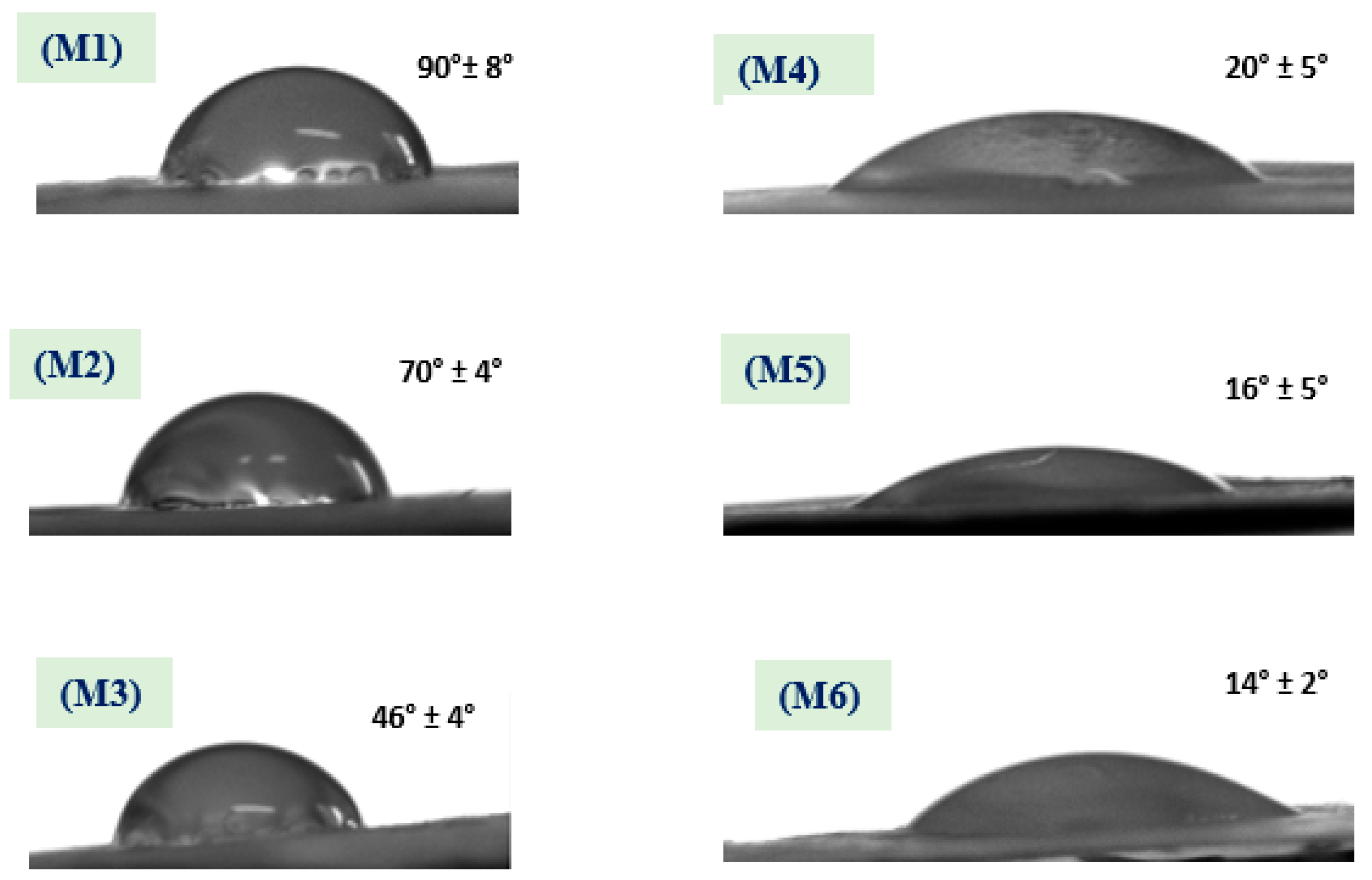

3.2. Membrane Wettability

3.3. Membrane Chemical Bonding

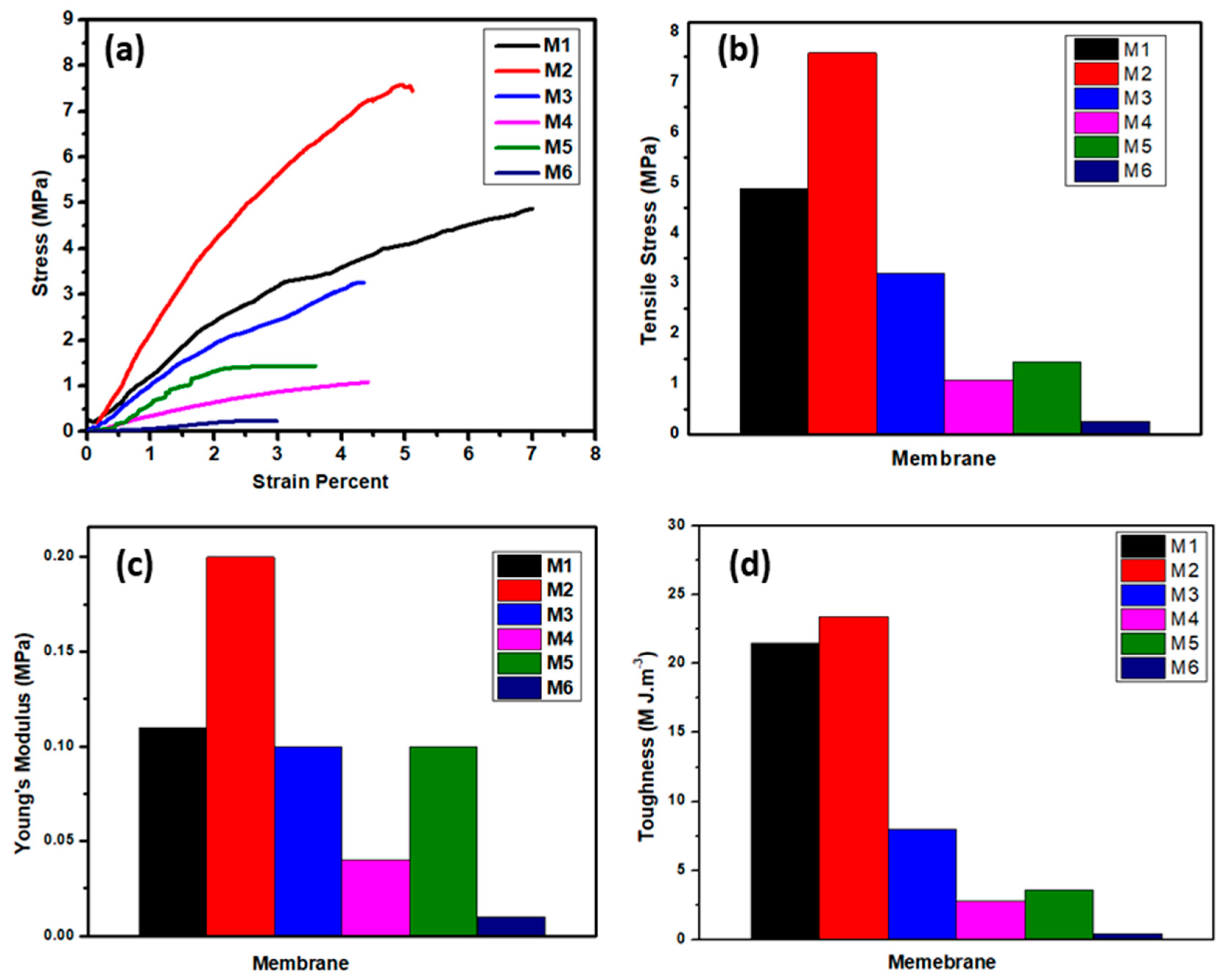

3.4. Membrane Mechanical Properties

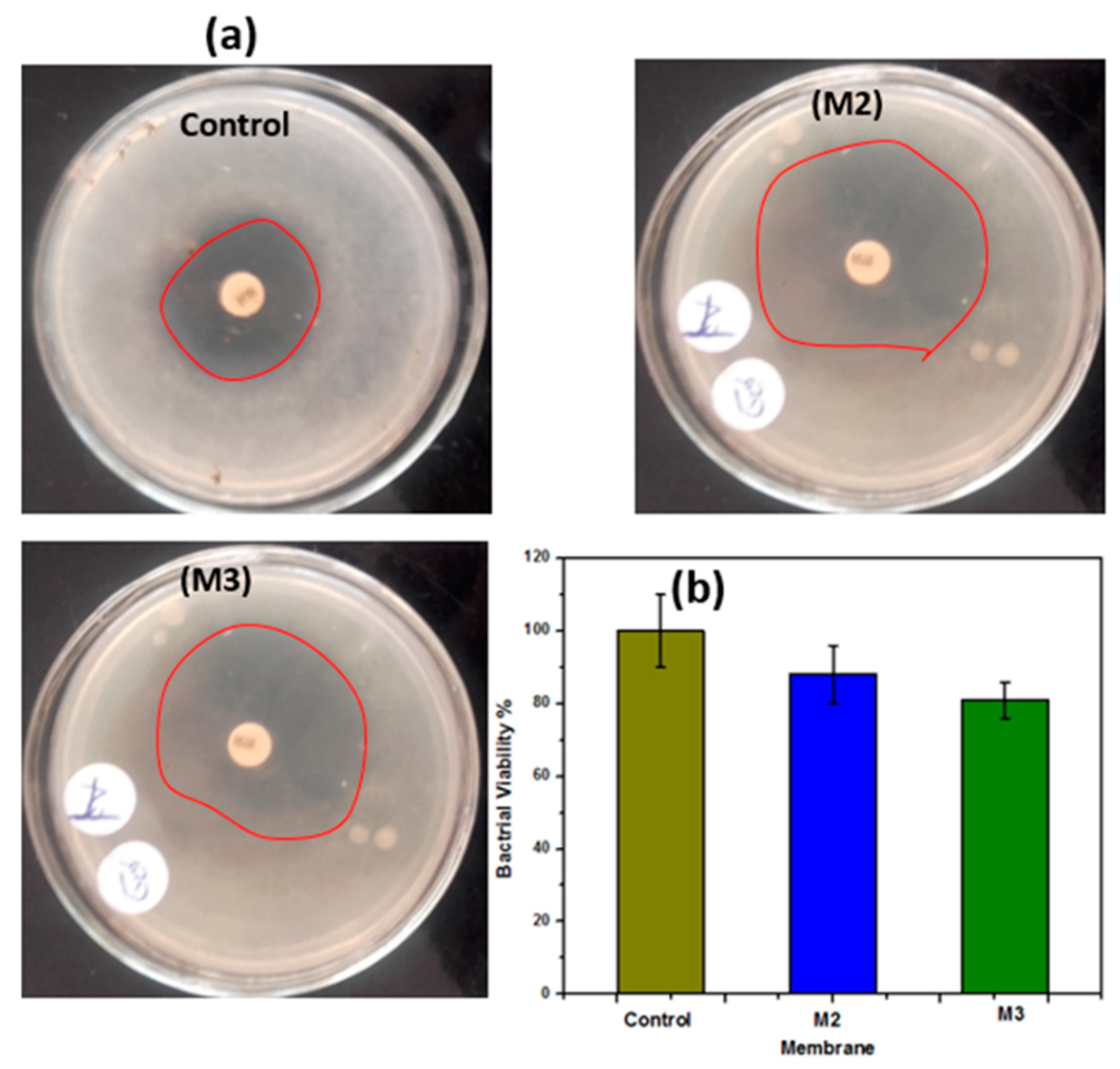

3.5. Antibacterial Activity and Oil Separation

4. Conclusions and Future Perspectives

- The results demonstrated smooth and bead-free nanofibers with a unique CA (core) and PSf (shell-ZnO) (shell); the outer diameter was 323.1 nm for PSf (shell-ZnO) and 102.4 nm is the diameter of CA (core).

- Treatment with NaOH layer changed membranes’ WCA from hydrophobic (90 ± 8°) to super hydrophilic (14 ± 2°), and subsequently, membrane water flux increased.

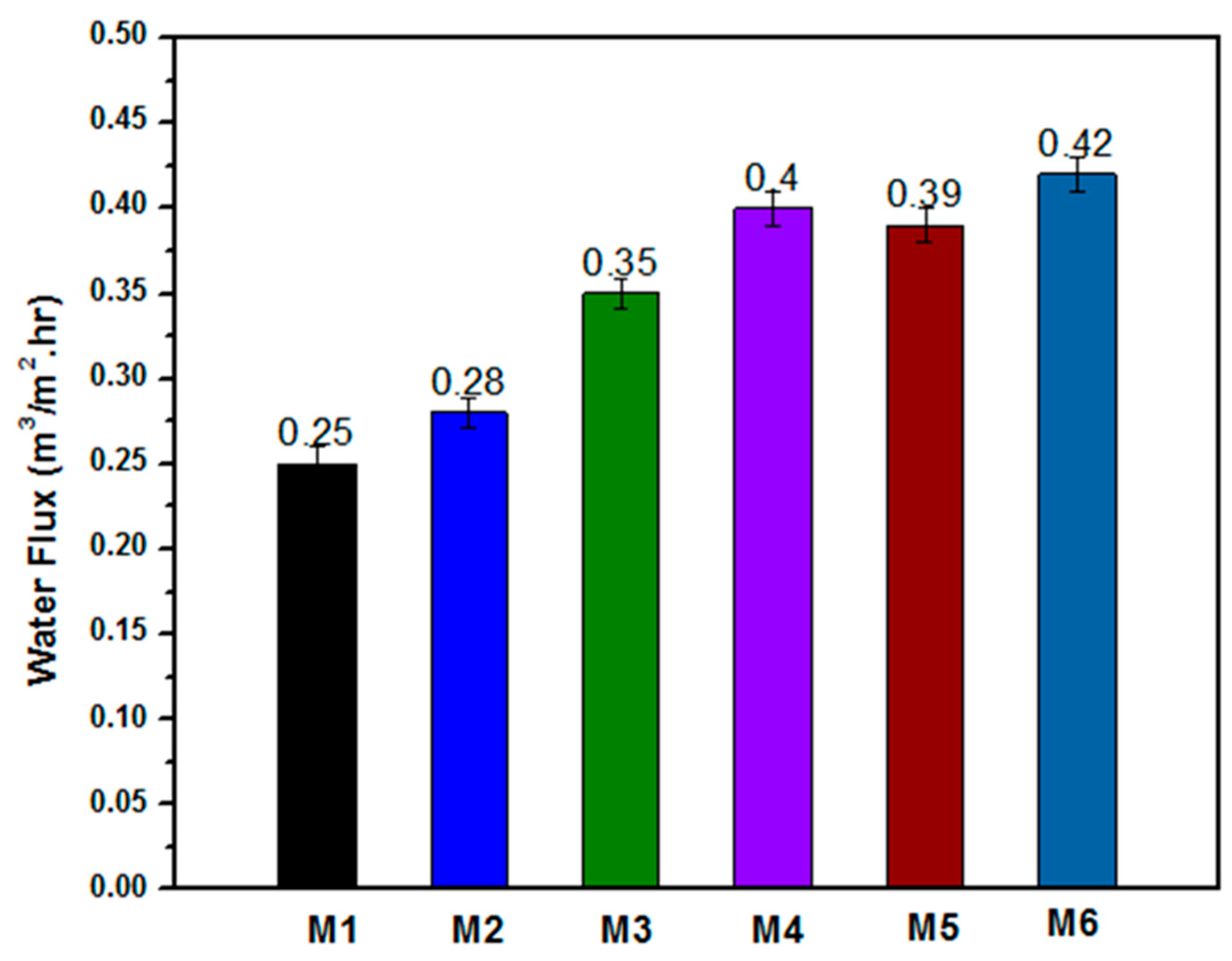

- The permeate flux for coaxial membranes is higher than for solid fiber; moreover, the modified membrane flux was 0.4 m3.m−2.hr−1 while for the unmodified membrane it was 0.25 m3.m−2.hr−1 which is accounted for by NaOH treatment.

- Membrane mechanical properties, in terms of Young’s modulus, tensile strength, and toughness, of the polymeric membranes are higher than those of the NaOH-treated membranes. Furthermore, the membranes have high antibacterial activity and successfully separated water from oil–water wastewater.

- A future prospective study should include an oil/water mixture with the actual content, as the oil/water used in this study was prepared in the laboratory. Future studies should use a real oil/water mixture that includes heavy metals, microorganisms, and dyes to assess the developed membranes. In addition, a pressure-driven cell should be used instead of the gravity-driven cell that was used in the present study as a future filtration device. Besides that, membrane development should include more nanofiber properties, such as flexibility and durability, to consider inspiration at the industrial scale with low cost.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xue, Z.; Cao, Y.; Liu, N.; Feng, L.; Jiang, L. Special wettable materials for oil/water separation. J. Mater. Chem. A 2014, 2, 2445–2460. [Google Scholar] [CrossRef]

- Lim, G.; Bae, S.; Jeon, H.; Kim, M.; Cho, S.J.; Lim, G. An underwater superoleophobic nanofibrous cellulosic membrane for oil/water separation with high separation flux and high chemical stability. Nanoscale 2018, 10, 3037–3045. [Google Scholar]

- Ma, W.; Guo, Z.; Zhao, J.; Yu, Q.; Wang, F.; Han, J.; Pan, H.; Yao, J.; Zhang, Q.; Samal, S.K.; et al. Polyimide/cellulose acetate core/shell electrospun fibrous membranes for oil-water separation. Sep. Purif. Technol. 2017, 177, 71–85. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Su, Y.; Cao, J.; Guan, J.; Zhang, R.; He, M.; Fan, L.; Zhang, Q.; Jiang, Z. Antifouling, high-flux oil/water separation carbon nanotube membranes by polymer-mediated surface charging and hydrophilization. J. Membr. Sci. 2017, 542, 254–263. [Google Scholar] [CrossRef]

- Cui, J.; Zhou, Z.; Xie, A.; Wang, Q.; Liu, S.; Lang, J.; Li, C.; Yan, Y.; Dai, J. Facile preparation of grass-like structured NiCo-LDH/PVDF composite membrane for efficient oil–water emulsion separation. J. Membr. Sci. 2019, 573, 226–233. [Google Scholar] [CrossRef]

- Sharma, P.R.; Sharma, S.K.; Lindström, T.; Hsiao, B.S. Nanocellulose-Enabled Membranes for Water Purification: Perspectives. Adv. Sustain. Syst. 2020, 4, 1900114. [Google Scholar] [CrossRef]

- Sharma, P.R.; Chattopadhyay, A.; Sharma, S.K.; Geng, L.-H.; Amiralian, N.; Martin, D.J.; Hsiao, B.S. Nanocellulose from Spinifex as an Effective Adsorbent to Remove Cadmium(II) from Water. ACS Sustain. Chem. Eng. 2018, 6, 3279–3290. [Google Scholar] [CrossRef]

- Huang, S.; Ras, R.H.; Tian, X. Antifouling membranes for oily wastewater treatment: Interplay between wetting and membrane fouling. Curr. Opin. Colloid Interface Sci. 2018, 36, 90–109. [Google Scholar] [CrossRef]

- Kang, Y.; Obaid, M.; Jang, J.; Ham, M.-H.; Kim, I.S. Novel sulfonated graphene oxide incorporated polysulfone nanocomposite membranes for enhanced-performance in ultrafiltration process. Chemosphere 2018, 207, 581–589. [Google Scholar] [CrossRef]

- Ahmad, A.; Majid, M.; Ooi, B. Functionalized PSf/SiO2 nanocomposite membrane for oil-in-water emulsion separation. Desalination 2011, 268, 266–269. [Google Scholar] [CrossRef]

- Yu, H.; Liu, H.; Yuan, X.; Ding, W.; Li, Y.; Wang, J. Separation of oil-water emulsion and adsorption of Cu(II) on a chitosan-cellulose acetate-TiO2 based membrane. Chemosphere 2019, 235, 239–247. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, Q.; Samal, S.K.; Wang, F.; Gao, B.; Pan, H.; Xu, H.; Yao, J.; Zhan, X.; De Smedt, S.C.; et al. Core–sheath structured electrospun nanofibrous membranes for oil–water separation. RSC Adv. 2016, 6, 41861–41870. [Google Scholar] [CrossRef]

- Thakur, N.; Ranganath, A.S.; Sopiha, K.V.; Baji, A. Thermoresponsive Cellulose Acetate–Poly(N-isopropylacrylamide) Core–Shell Fibers for Controlled Capture and Release of Moisture. ACS Appl. Mater. Interfaces 2017, 9, 29224–29233. [Google Scholar] [CrossRef] [PubMed]

- Jang, W.; Yun, J.; Park, Y.; Park, I.K.; Byun, H.; Lee, C.H. Polyacrylonitrile Nanofiber Membrane Modified with Ag/GO Composite for Water Purification System. Polymers 2020, 12, 2441. [Google Scholar] [CrossRef]

- Alammar, A.; Park, S.-H.; Williams, C.J.; Derby, B.; Szekely, G. Oil-in-water separation with graphene-based nanocomposite membranes for produced water treatment. J. Membr. Sci. 2020, 603, 118007. [Google Scholar] [CrossRef]

- Zhang, D.; Dai, F.; Zhang, P.; An, Z.; Zhao, Y.; Chen, L. The photodegradation of methylene blue in water with PVDF/GO/ZnO composite membrane. Mater. Sci. Eng. C 2019, 96, 684–692. [Google Scholar] [CrossRef] [PubMed]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [Google Scholar] [CrossRef]

- Pang, W.Y.; Ahmad, A.L.; Zaulkiflee, N.D. Antifouling and antibacterial evaluation of ZnO/MWCNT dual nanofiller polyethersulfone mixed matrix membrane. J. Environ. Manag. 2019, 249, 109358. [Google Scholar] [CrossRef]

- Urošević, T.; Trivunac, K. Chapter 3—Achievements in low-pressure membrane processes microfiltration (MF) and ultrafiltration (UF) for wastewater and water treatment. In Current Trends and Future Developments on (Bio-) Membranes; Basile, A., Ghasemzadeh, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–107. [Google Scholar]

- Li, Q.; Mahendra, S.; Lyon, D.Y.; Brunet, L.; Liga, M.V.; Li, D.; Alvarez, P.J.J. Antimicrobial nanomaterials for water disinfection and microbial control: Potential applications and implications. Water Res. 2008, 42, 4591–4602. [Google Scholar] [CrossRef]

- Mousa, H.M.; Hussein, K.H.; Sayed, M.M.; El-Aassar, M.; Mohamed, I.M.; Kwak, H.-H.; Woo, H.-M.; Abdal-Hay, A. Development of biocompatible tri-layered nanofibers patches with endothelial cells for cardiac tissue engineering. Eur. Polym. J. 2020, 129, 109630. [Google Scholar] [CrossRef]

- Shrestha, B.K.; Mousa, H.M.; Tiwari, A.P.; Ko, S.W.; Park, C.H.; Kim, C.S. Development of polyamide-6,6/chitosan electrospun hybrid nanofibrous scaffolds for tissue engineering application. Carbohydr. Polym. 2016, 148, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Sagitha, P.; Reshmi, C.; Sundaran, S.P.; Sujith, A. Recent advances in post-modification strategies of polymeric electrospun membranes. Eur. Polym. J. 2018, 105, 227–249. [Google Scholar] [CrossRef]

- Neibolts, N.; Platnieks, O.; Gaidukovs, S.; Barkane, A.; Thakur, V.K.; Filipova, I.; Mihai, G.; Zelca, Z.; Yamaguchi, K.; Enachescu, M. Needle-free electrospinning of nanofibrillated cellulose and graphene nanoplatelets based sustainable poly (butylene succinate) nanofibers. Mater. Today Chem. 2020, 17, 100301. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Sun, G.; Ding, B. Electrospun nanofibrous materials: A versatile medium for effective oil/water separation. Mater. Today 2016, 19, 403–414. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, D.; Zhao, J.; Feng, Q.; Li, Z.; Bai, H.; Sun, D.D. Efficient Oil/Water Separation Membrane Derived from Super-Flexible and Superhydrophilic Core-Shell Organic/Inorganic Nanofibrous Architectures. Polymers 2019, 11, 974. [Google Scholar] [CrossRef] [PubMed]

- Chu, B.; Hsiao, B.S.; Ma, H. High Flux Fluid Separation Membranes Comprising a Cellulose or Cellulose Derivative Layer. U.S. Patent No. 9,010,547, 21 April 2015. [Google Scholar]

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Michalska-Pożoga, I.; Thakur, V.K. Biopolymers for biomedical and pharmaceutical applications: Recent advances and overview of alginate electrospinning. Nanomaterials 2019, 9, 404. [Google Scholar] [CrossRef] [Green Version]

- Saporito, F.; Sandri, G.; Bonferoni, M.C.; Rossi, S.; Malavasi, L.; Fante, C.D.; Vigani, B.; Black, L.; Ferrari, F. Electrospun gelatin–chondroitin sulfate scaffolds loaded with platelet lysate promote immature cardiomyocyte proliferation. Polymers 2018, 10, 208. [Google Scholar] [CrossRef] [Green Version]

- Zangeneh, H.; Zinatizadeh, A.A.; Zinadini, S.; Feyzi, M.; Bahnemann, D.W. Preparation and characterization of a novel photocatalytic self-cleaning PES nanofiltration membrane by embedding a visible-driven photocatalyst boron doped-TiO2SiO2/CoFe2O4 nanoparticles. Sep. Purif. Technol. 2019, 209, 764–775. [Google Scholar] [CrossRef]

- Mousa, H.M.; Tiwari, A.P.; Kim, J.; Adhikari, S.P.; Park, C.H.; Kim, C.S. A novel in situ deposition of hydroxyapatite nanoplates using anodization/hydrothermal process onto magnesium alloy surface towards third generation biomaterials. Mater. Lett. 2016, 164, 144–147. [Google Scholar] [CrossRef]

- Han, D.; Steckl, A.J. Coaxial Electrospinning Formation of Complex Polymer Fibers and their Applications. ChemPlusChem 2019, 84, 1453–1497. [Google Scholar] [CrossRef]

- Mikaeili, F.; Gouma, P.I. Super Water-Repellent Cellulose Acetate Mats. Sci. Rep. 2018, 8, 12472. [Google Scholar] [CrossRef]

- Ji, M.; Luo, J.; Wei, J.; Woodley, J.M.; Daugaard, A.E.; Pinelo, M. Commercial polysulfone membranes pretreated with ethanol and NaOH: Effects on permeability, selectivity and antifouling properties. Sep. Purif. Technol. 2019, 219, 82–89. [Google Scholar] [CrossRef]

- Harish, S.; Archana, J.; Sabarinathan, M.; Navaneethan, M.; Nisha, K.; Ponnusamy, S.; Muthamizhchelvan, C.; Ikeda, H.; Aswal, D.K.; Hayakawa, Y. Controlled structural and compositional characteristic of visible light active ZnO/CuO photocatalyst for the degradation of organic pollutant. Appl. Surf. Sci. 2017, 418, 103–112. [Google Scholar] [CrossRef]

- Rajabi, S.; Sohrabnezhad, S. Fabrication and characteristic of Fe3O4@MOR@CuO core-shell for investigation antibacterial properties. J. Fluor. Chem. 2018, 206, 36–42. [Google Scholar] [CrossRef]

- Huang, F.; Rad, A.T.; Zheng, W.; Nieh, M.-P.; Cornelius, C. Hybrid organic-inorganic 6FDA-6pFDA and multi-block 6FDA-DABA polyimide SiO2–TiO2 nanocomposites: Synthesis, FFV, FTIR, swelling, stability, and X-ray scattering. Polymer 2017, 108, 105–120. [Google Scholar] [CrossRef]

- Li, F.; Gao, R.; Wu, T.; Li, Y. Role of layered materials in emulsified oil/water separation and anti-fouling performance of modified cellulose acetate membranes with hierarchical structure. J. Membr. Sci. 2017, 543, 163–171. [Google Scholar] [CrossRef]

- Mahmoudi, E.; Ng, L.Y.; Mohammad, A.W.; Ba-Abbad, M.M.; Razzaz, Z. Enhancement of polysulfone membrane with integrated ZnO nanoparticles for the clarification of sweetwater. Int. J. Environ. Sci. Technol. 2018, 15, 561–570. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Awasthi, G.P.; Adhikari, S.P.; Ko, S.; Kim, H.J.; Park, C.H.; Kim, C. Facile synthesis of ZnO flowers modified graphene like MoS2 sheets for enhanced visible-light-driven photocatalytic activity and antibacterial properties. J. Alloys Compd. 2016, 682, 208–215. [Google Scholar] [CrossRef]

- Kim, J.; Mousa, H.M.; Park, C.H.; Kim, C.S. Enhanced corrosion resistance and biocompatibility of AZ31 Mg alloy using PCL/ZnO NPs via electrospinning. Appl. Surf. Sci. 2017, 396, 249–258. [Google Scholar] [CrossRef]

- Sirelkhatim, A.; Mahmud, S.; Seeni, A.; Kaus, N.H.M.; Ann, L.C.; Bakhori, S.K.M.; Hasan, H.; Mohamad, D. Review on Zinc Oxide Nanoparticles: Antibacterial Activity and Toxicity Mechanism. Nano-Micro Lett. 2015, 7, 219–242. [Google Scholar] [CrossRef] [Green Version]

- Mousa, H.M.; Abdal-Hay, A.; Bartnikowski, M.; Mohamed, I.M.A.; Yasin, A.S.; Ivanovski, S.; Park, C.H.; Kim, C.S. A Multifunctional Zinc Oxide/Poly(Lactic Acid) Nanocomposite Layer Coated on Magnesium Alloys for Controlled Degradation and Antibacterial Function. ACS Biomater. Sci. Eng. 2018, 4, 2169–2180. [Google Scholar] [CrossRef]

- Applerot, G.; Lipovsky, A.; Dror, R.; Perkas, N.; Nitzan, Y.; Lubart, R.; Gedanken, A. Enhanced Antibacterial Activity of Nanocrystalline ZnO Due to Increased ROS-Mediated Cell Injury. Adv. Funct. Mater. 2009, 19, 842–852. [Google Scholar] [CrossRef]

- Jebel, F.S.; Almasi, H. Morphological, physical, antimicrobial and release properties of ZnO nanoparticles-loaded bacterial cellulose films. Carbohydr. Polym. 2016, 149, 8–19. [Google Scholar] [CrossRef]

- Li, L.-Q.; Zhan, Z.-M.; Huang, B.-Q.; Xue, S.-M.; Ji, C.-H.; Wang, R.-Z.; Tang, Y.-J.; Xu, Z.-L. RO membrane fabricated via a facile modified heat-treating strategy for high-flux desalination. J. Membr. Sci. 2020, 614, 118498. [Google Scholar] [CrossRef]

- Obaid, M.; Barakat, N.A.; Fadali, O.A.; Al-Meer, S.; Elsaid, K.; Khalil, K.A. Stable and effective super-hydrophilic polysulfone nanofiber mats for oil/water separation. Polymer 2015, 72, 125–133. [Google Scholar] [CrossRef]

- Obaid, M.; Fadali, O.; Lim, B.-H.; Fouad, H.; Barakat, N.A.M. Super-hydrophilic and highly stable in oils polyamide-polysulfone composite membrane by electrospinning. Mater. Lett. 2015, 138, 196–199. [Google Scholar] [CrossRef]

- Mousa, H.M.; Alfadhel, H.; Ateia, M.; Gomaa, A.A.; Abdel-Jaber, G.T. Polysulfone-iron acetate/polyamide nanocomposite membrane for oil-water separation. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100314. [Google Scholar] [CrossRef]

| Membrane | Core | Shell | Remarks |

|---|---|---|---|

| M1 | PSf | CA |

|

| M2 | PSf/ZnO NPs * | CA | |

| M3 | PSf | CA/ZnO NPs * | |

| M4 | ¥ Modified M1 |

| |

| M5 | ¥ Modified M2 | ||

| M6 | ¥ Modified M3 | ||

| Materials | Water Flux (m3. m-2.hr−1) | Technique | WCA | Tensile Stress (MPa) | Young Modulus (MPa) | Toughness (MJ/m3) | Antibacterial Properties | Oil Type | Membrane Properties | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| PSf/NaOH | 0.33 | Electrospinning nanofiber | 12° | 1.10 | × | × | × | Soybean oil | High flux, super hydrophilic. | [48] |

| (PSf/NaOH) PA layer | 0.33 | 3° | × | × | × | × | Soybean oil | Super hydrophilic, high flux. | [49] | |

| PSf | 0.14 | 100° | 0.9 | 3.7 | × | × | Sunflower oil | Hydrophobic, degradation by oil, heat resistance. | [50] | |

| PSf/Iron acetate/PA film | 0.38 | 37° | 0.25 | 7.0 | × | × | High flux, cheap materials, no particles agglomeration. | |||

| M1 | 0.25 | Coaxial electrospinning nanofiber | 90 ± 8° | 4.89 | 0.11 | 21.5 | × | Hydrophobic. | This study | |

| M2 | 0.28 | 70 ± 4° | 7.58 | 0.2 | 23.4 | √ | Moderate hydrophilic. | |||

| M3 | 0.35 | 46 ± 4° | 3.2 | 0.1 | 8 | √ | Hydrophilic. | |||

| M4 | 0.40 | 20 ± 5° | 1.08 | 0.04 | 2.8 | × | High flux, super hydrophilic. | |||

| M5 | 0.39 | 16 ± 5° | 1.44 | 0.1 | 3.6 | √ | High flux, super hydrophilic. | |||

| M6 | 0.42 | 14 ± 2° | 0.25 | 0.01 | 0.4 | √ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mousa, H.M.; Alfadhel, H.; Abouel Nasr, E. Engineering and Characterization of Antibacterial Coaxial Nanofiber Membranes for Oil/Water Separation. Polymers 2020, 12, 2597. https://doi.org/10.3390/polym12112597

Mousa HM, Alfadhel H, Abouel Nasr E. Engineering and Characterization of Antibacterial Coaxial Nanofiber Membranes for Oil/Water Separation. Polymers. 2020; 12(11):2597. https://doi.org/10.3390/polym12112597

Chicago/Turabian StyleMousa, Hamouda M., Husain Alfadhel, and Emad Abouel Nasr. 2020. "Engineering and Characterization of Antibacterial Coaxial Nanofiber Membranes for Oil/Water Separation" Polymers 12, no. 11: 2597. https://doi.org/10.3390/polym12112597

APA StyleMousa, H. M., Alfadhel, H., & Abouel Nasr, E. (2020). Engineering and Characterization of Antibacterial Coaxial Nanofiber Membranes for Oil/Water Separation. Polymers, 12(11), 2597. https://doi.org/10.3390/polym12112597