Self-Cleaning Cotton Obtained after Grafting Thermoresponsive Poly(N-vinylcaprolactam) through Surface-Initiated Atom Transfer Radical Polymerization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

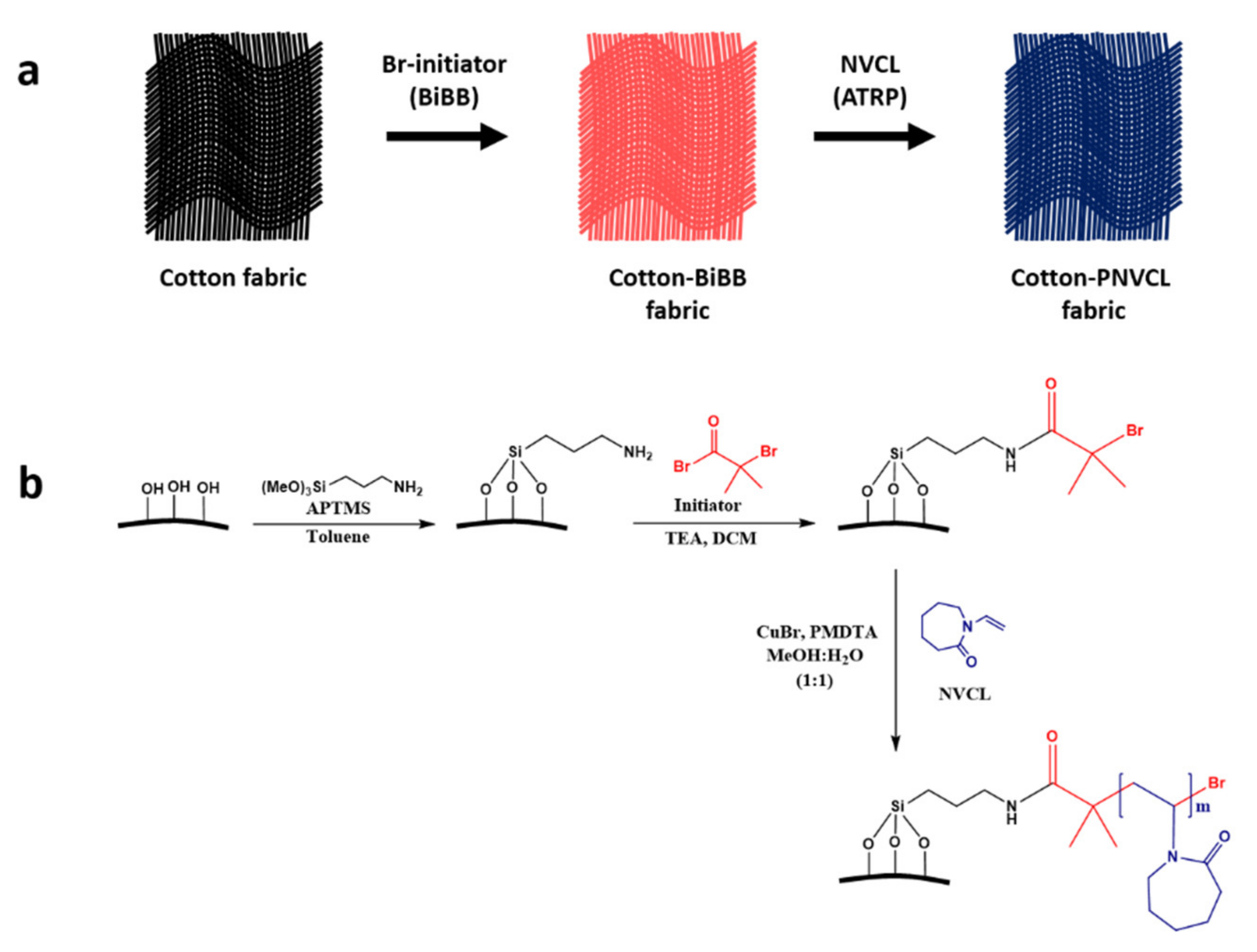

2.2. SI-ATRP Initiator Immobilization on Cotton Fabric

2.3. Fabrication of PNVCL-Grafted Cotton Fabric through SI-ATRP

2.4. Surface Characterization

2.5. Thermoresponsive Behavior of Polymer-Grafted Cotton Fabrics

2.6. Self-Cleaning PNVCL-Grafted Cotton Fabric

3. Results and Discussion

3.1. Grafting the Thermoresponsive Polymer onto Cotton Fabric through SI-ATRP

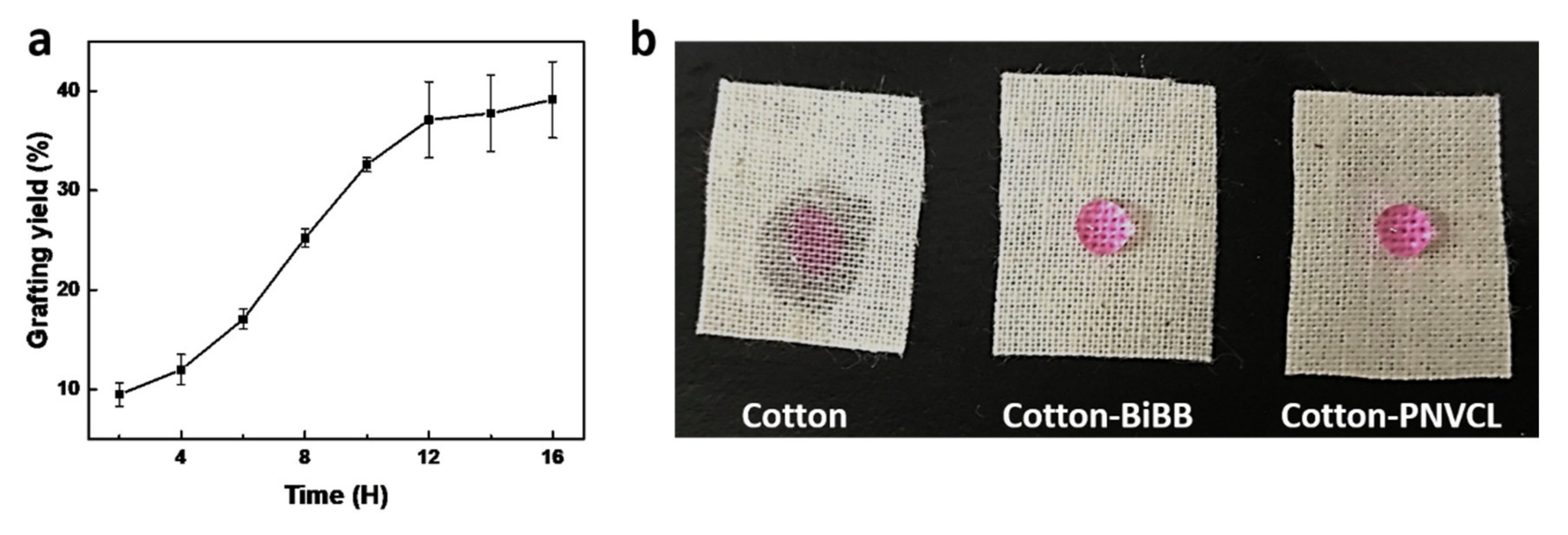

3.2. Polymerization Kinetics

3.3. Surface Characterization of Thermoresponsive Polymer-Grafted Fabric

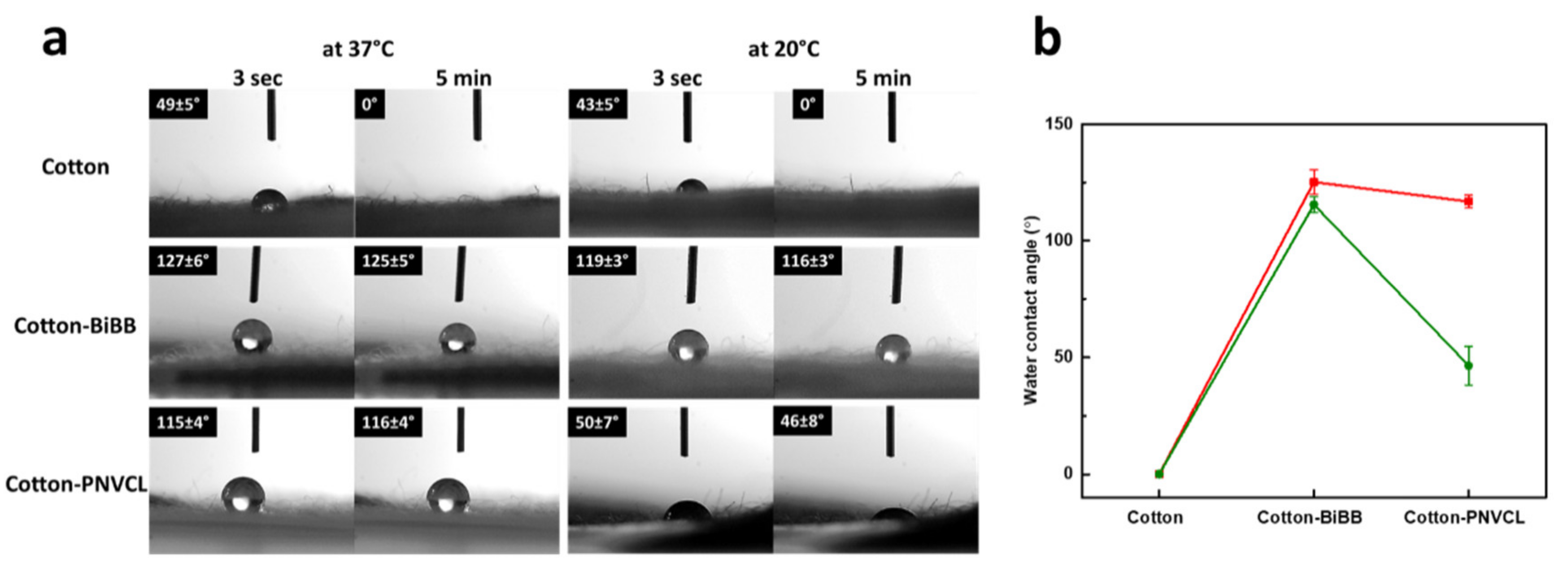

3.4. Surface Wettability of Initiator- and Polymer-Grafted Fabrics

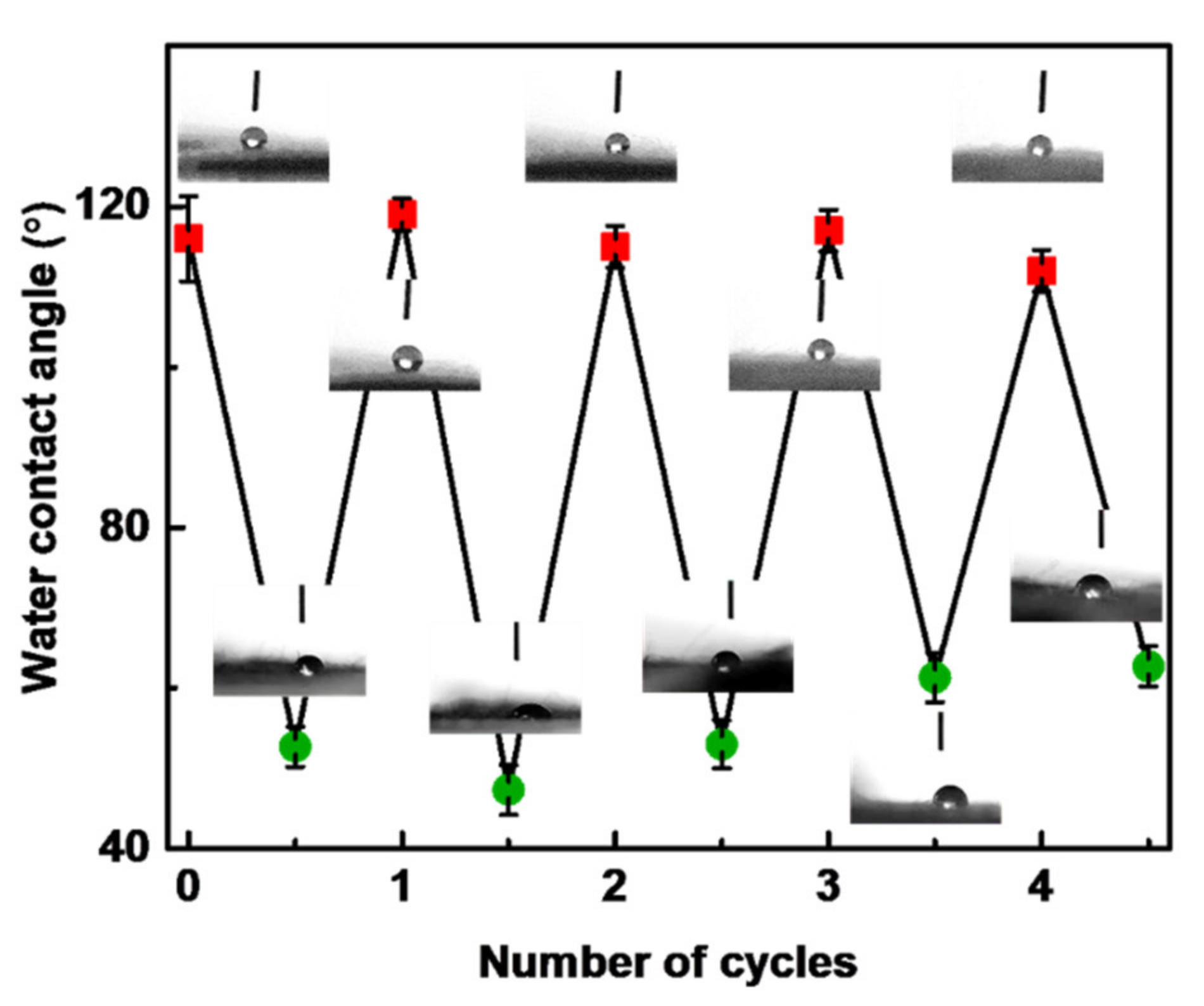

3.5. Reversibility of the Wettability Transition of the Thermoresponsive Polymer-Grafted Fabric

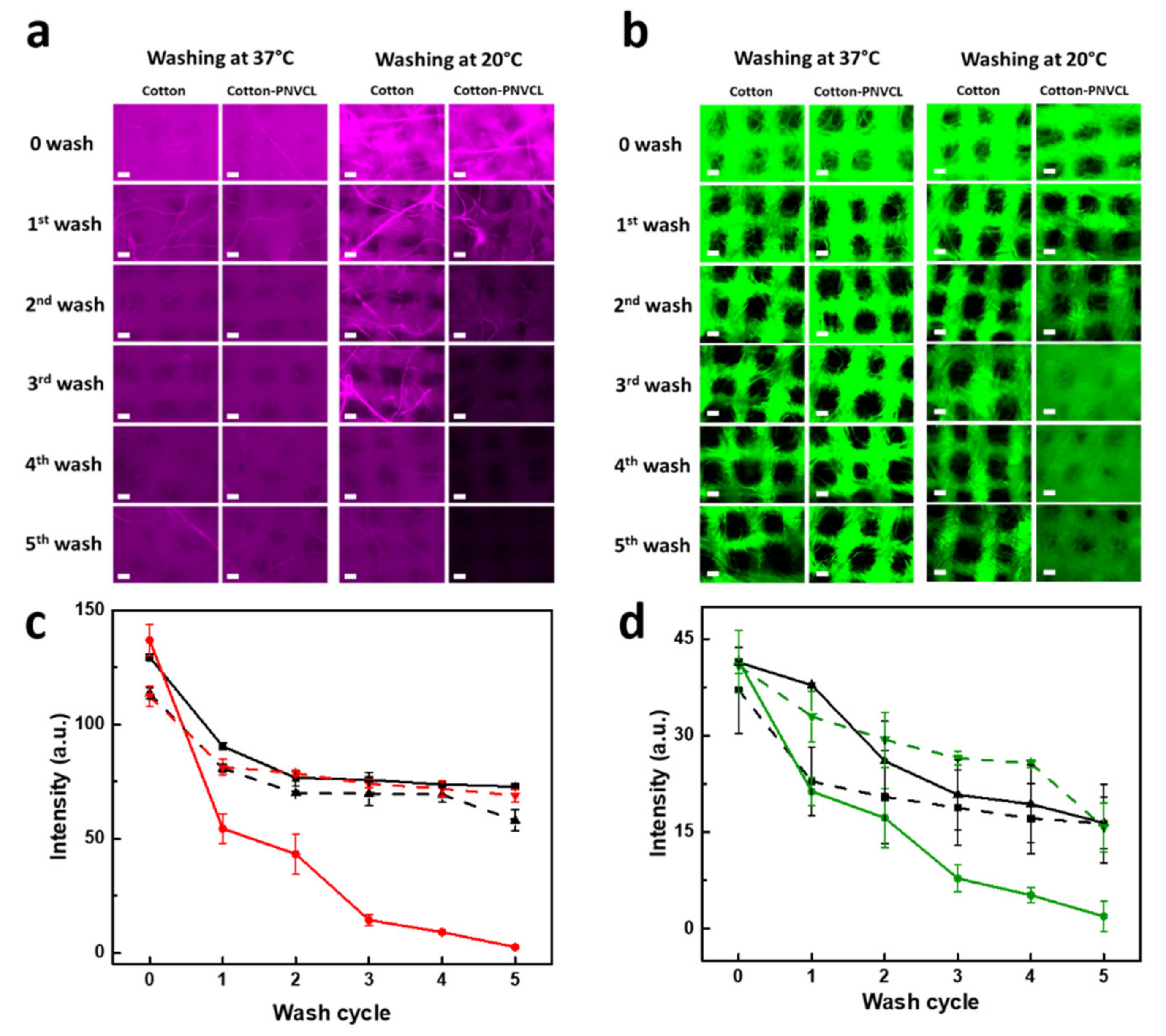

3.6. Self-Cleaning of the PNVCL-Grafted Cotton Fabric

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nishimoto, S.; Bhushan, B. Bioinspired self-cleaning surfaces with superhydrophobicity, superoleophobicity, and superhydrophilicity. RSC Adv. 2013, 3, 671–690. [Google Scholar] [CrossRef]

- Huang, J.Y.; Li, S.H.; Ge, M.Z.; Wang, L.N.; Xing, T.L.; Chen, G.Q.; Liu, X.F.; Al-Deyab, S.S.; Zhang, K.Q.; Chen, T.; et al. Robust superhydrophobic TiO2@fabrics for UV shielding, self-cleaning and oil-water separation. J. Mater. Chem. B 2015, 6, 2825–2832. [Google Scholar] [CrossRef]

- Li, Z.Q.; Dong, Y.; Li, B.; Wang, P.; Chen, Z.; Bian, L. Creation of self-cleaning polyester fabric with TiO2 nanoparticles via a simple exhaustion process: Conditions optimization and stain decomposition pathway. Mater. Des. 2018, 140, 366–375. [Google Scholar] [CrossRef]

- Zhong, Q.P.; Macharia, D.K.; Zhong, W.; Liu, Z.; Chen, Z. Synthesis of hydrophobic W18O49 nanorods for constructing UV/NIR-shielding and self-cleaning film. Ceram. Int. 2020, 8, 11898–11904. [Google Scholar] [CrossRef]

- Isaifan, R.J.; Samara, A.; Suwaileh, W.; Johnson, D.; Yiming, W.; Abdallah, A.A.; Aïssa, B. Improved self-cleaning properties of an efficient and easy to scale up TiO2 thin films prepared by adsorptive self-assembly. Sci. Rep. 2017, 1, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-icing superhydrophobic coatings. Langmuir 2009, 21, 12444–12448. [Google Scholar] [CrossRef]

- Geyer, F.; D’Acunzi, M.; Sharifi-Aghili, A.; Saal, A.; Gao, N.; Kaltbeitzel, A.; Sloot, T.F.; Berger, R.; Butt, H.J.; Vollmer, D. When and how self-cleaning of superhydrophobic surfaces works. Sci. Adv. 2020, 3, eaaw9727. [Google Scholar] [CrossRef]

- Heckenthaler, T.; Sadhujan, S.; Morgenstern, Y.; Natarajan, P.; Bashouti, M.; Kaufman, Y. Self-cleaning mechanism: Why nanotexture and hydrophobicity matter. Langmuir 2019, 48, 15526–15534. [Google Scholar] [CrossRef]

- Arabatzis, I.; Todorova, N.; Fasaki, I.; Tsesmeli, C.; Peppas, A.; Li, W.X.; Zhao, Z. Photocatalytic, self-cleaning, antireflective coating for photovoltaic panels: Characterization and monitoring in real conditions. Sol. Energy 2018, 159, 251–259. [Google Scholar] [CrossRef]

- Tung, W.S.; Daoud, W.A. Self-cleaning fibers via nanotechnology: A virtual reality. J. Mater. Chem. 2011, 22, 7858–7869. [Google Scholar] [CrossRef]

- Shirgholami, M.A.; Nazari, A.; Mirjalili, M. Statistical optimization of self-cleaning technology and color reduction in wool fabric by nano zinc oxide and eco-friendly cross-linker. Clean Technol. Environ. Policy 2015, 4, 905–919. [Google Scholar] [CrossRef]

- Saad, S.R.; Mahmed, N.; Abdullah, M.M.; Sandu, A.V. Self-cleaning technology in fabric: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Lasi, Romania, 2016. [Google Scholar]

- Wu, J.D.; Zhang, C. Self-cleaning pH/thermo-responsive cotton fabric with smart-control and reusable functions for oil/water separation. RSC Adv. 2016, 6, 24076–24082. [Google Scholar] [CrossRef]

- Mokhtari, F.; Foroughi, J.; Zhong, T.; Cheng, Z.; Spinks, G.M. Triaxial braided piezo fiber energy harvester for self-powered wearable technologies. J. Mater. Chem. A 2019, 7, 8245–8257. [Google Scholar] [CrossRef]

- Rao, K.M.; Rao, K.S. Stimuli responsive poly(vinyl caprolactam) gels for biomedical applications. Gels 2016, 2, 6. [Google Scholar] [CrossRef] [PubMed]

- Rusen, L.; Dinca, V.; Mustaciosu, C.; Icriverzi, M.; Sima, L.E.; Bonciu, A.; Brajnicov, S.; Mihailescu, N.; Dumitrescu, N.; Popovici, A.I.; et al. Smart thermoresponsive surfaces based on pNIPAm coatings and laser method for biological applications. In Modern Technologies for Creating the Thin-film Systems and Coatings; BoD—Books on Demand: Norderstedt, Germany, 2017; Chapter 10. [Google Scholar]

- Winninger, J.; Lurea, D.M.; Atanase, L.I.; Salhi, S.; Delaite, C.; Riess, G. Micellization of novel biocompatible thermo-sensitive graft copolymers based on poly(ε-caprolactone), poly(N-vinylcaprolactam) and poly (N-vinylpyrrolidone). Eur. Polym. J. 2019, 119, 74–82. [Google Scholar] [CrossRef]

- Cortez-Lemus, N.A.; Licea-Claverie, A. Poly(N-vinylcaprolactam), a comprehensive review on a thermoresponsive polymer becoming popular. Prog. Poly. Sci. 2016, 53, 1–51. [Google Scholar] [CrossRef]

- Ramos, J.; Imaz, A.; Forcada, J.J.P.C. Temperature-sensitive nanogels: Poly(N-vinylcaprolactam) versus poly(N-isopropylacrylamide). Polym. Chem. 2012, 4, 852–856. [Google Scholar] [CrossRef]

- Yang, Y.S.; Zhou, Y. Temperature-responsive hydroxypropylcellulose based thermochromic material and its smart window application. RSC Adv. 2016, 66, 61449–61453. [Google Scholar] [CrossRef]

- Kim, D.; Lee, E.; Lee, H.S.; Yoon, J. Energy efficient glazing for adaptive solar control fabricated with photothermotropic hydrogels containing graphene oxide. Sci. Rep. 2015, 5, 7646. [Google Scholar] [CrossRef]

- Sala, R.L.; Goncalves, R.H.; Camargo, E.R.; Leite, E.R. Thermosensitive poly(N-vinylcaprolactam) as a transmission light regulator in smart windows. Sol. Energy Mater. Sol. Cells 2018, 186, 266–272. [Google Scholar] [CrossRef]

- Yamada, N.; Okano, T.; Sakai, H.; Karikusa, F.; Sawasaki, Y.; Sakurai, Y. Thermo-responsive polymeric surfaces: Control of attachment and detachment of cultured cells. Makrolmol. Chem. Rapid Commun. 1990, 11, 571–576. [Google Scholar] [CrossRef]

- Kobayashi, J.; Okano, T. Fabrication of a thermoresponsive cell culture dish: A key technology for cell sheet tissue engineering. Sci. Technol. Adv. Mater. 2010, 11, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Sáfrány, Á.; Wojnárovits, L.J.R.P. Chemistry, Electron-beam initiated crosslinking in poly(N-isopropylacrylamide) aqueous solution. Radiat. Phys. Chem. 2004, 4, 289–293. [Google Scholar] [CrossRef]

- Lucero, A.E.; Reed, J.A.; Wu, X.; Canavan, H.E. Fabrication and characterization of thermoresponsive films deposited by an rf plasma reactor. Plasma Processes Polym. 2010, 12, 992–1000. [Google Scholar] [CrossRef]

- Saito, N.; Kagari, Y.; Okubo, M.J.L. Effect of colloidal stabilizer on the shape of polystyrene/poly(methyl methacrylate) composite particles prepared in aqueous medium by the solvent evaporation method. Langmuir 2006, 22, 9397–9402. [Google Scholar] [CrossRef]

- Sakulaue, P.; Swe, A.Y.; Benchaprathanphorn, K.; Lertvanithphol, T.; Viravaidya-Pasuwat, K.; Siriwatwechakul, W. Improving cell detachment from temperature-responsive poly(N-isopropylacrylamide-co-acrylamide)-grafted culture surfaces by spin coating. ACS Omega 2018, 12, 18181–18188. [Google Scholar] [CrossRef]

- Ou, K.; Wu, X.; Wang, B.; Meng, C.; Dong, X.; He, J. Controlled in situ graft polymerization of DMAEMA onto cotton surface via SI-ARGET ATRP for low-adherent wound dressings. Cellulose 2017, 11, 5211–5224. [Google Scholar] [CrossRef]

- Dong, X.; Bao, H.; Ou, K.; Yao, J.; Zhang, W.; He, J. Polymer-grafted modification of cotton fabrics by SI-ARGET ATRP. Fibers Polym. 2015, 7, 1478–1486. [Google Scholar] [CrossRef]

- Karesoja, M.; McKee, J. Mesoporous silica particles grafted with poly(ethyleneoxide-block-N-vinylcaprolactam). Polym. Chem. 2013, 51, 5012–5020. [Google Scholar] [CrossRef]

- Kavitha, T.; Kang, I.K. Poly(N-vinyl caprolactam) grown on nanographene oxide as an effective nanocargo for drug delivery. Colloids Surf. B Biointerfaces 2014, 115, 37–45. [Google Scholar] [CrossRef]

- Çakmak, S.; Çakmak, A.S.; Gümüşderelioğlu, M. PNIPAAm-grafted thermoresponsive microcarriers: Surface-initiated ATRP synthesis and characterization. Mater. Sci. Eng. C 2013, 5, 3033–3040. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Pan, X.; Schmitt, M.; Wang, Z.; Bockstaller, M.R.; Matyjaszewski, K. Enhancing initiation efficiency in metal-free surface-initiated atom transfer radical polymerization (SI-ATRP). ACS Macro Lett. 2016, 6, 661–665. [Google Scholar] [CrossRef]

- Gruszkiewicz, A.; Słowikowska, M.; Grześ, G.; Wójcik, A.; Rokita, J.; Fiocco, A.; Wytrwal-Sarna, M.; Marzec, M.; Trzebicka, B.; Kopeć, M.; et al. Enhancement of the growth of polymer brushes via ATRP initiated from ions-releasing indium tin oxide substrates. Eur. Polym. J. 2019, 112, 817–821. [Google Scholar] [CrossRef]

- Flejszar, M.; Chmielarz, P.J.M. Surface-initiated atom transfer radical polymerization for the preparation of well-defined organic–inorganic hybrid nanomaterials. Materials 2019, 18, 3030. [Google Scholar] [CrossRef] [PubMed]

- Crespy, D.; Golosova, A.; Makhaeva, E.; Khokhlov, A.R.; Fortunato, G.; Rossi, R. Synthesis and characterization of temperature-responsive copolymers based on N-vinylcaprolactam and their grafting on fibres. Polym Int. 2009, 11, 1326–1334. [Google Scholar] [CrossRef]

- Dong, X.; Gao, S.; Huang, J.; Li, S.; Zhu, T.; Cheng, Y.; Zhao, Y.; Chen, Z.; Lai, Y. A self-roughened and biodegradable superhydrophobic coating with UV shielding, solar-induced self-healing and versatile oil–water separation ability. J. Mater. Chem. A 2019, 5, 2122–2128. [Google Scholar] [CrossRef]

- Zou, H.; Lin, S.; Tu, Y.; Li, F.; Hu, J.; Liu, G.; Hu, S.; Yang, G.; Yu, Z. An aqueous process for durable superamphiphobic diblock copolymer coatings on fabrics. Adv. Mater. Interfaces 2016, 8, 1500693. [Google Scholar] [CrossRef]

- Fábio, T.; Sydenstricker, T.H.; Satyanarayana, K.G. Studies on lignocellulosic fibers of Brazil. Part II: Morphology and properties of Brazilian coconut fibers. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1710–1721. [Google Scholar]

- Satyanarayana, K.G.; Guimarães, J.L.; Wypych, F.E. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1694–1721. [Google Scholar]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Xu, L.-L.; Guo, M.X.; Liu, S.; Bian, S.W. Graphene/cotton composite fabrics as flexible electrode materials for electrochemical capacitors. RSC Adv. 2015, 5, 25244–25249. [Google Scholar] [CrossRef]

- Xu, Q.; Xie, L.; Diao, H.; Li, F.; Zhang, Y.; Fu, F.; Liu, X. Antibacterial cotton fabric with enhanced durability prepared using silver nanoparticles and carboxymethyl chitosan. Carbohydr. Polym. 2017, 177, 187–193. [Google Scholar] [CrossRef] [PubMed]

- Smith, B.C. Fundamentals of Fourier Transform Infrared Spectroscopy; CRC Press: New York, NY, USA, 2011. [Google Scholar]

- Bora, L.; Jiao, A.; Yu, S.; You, J.B.; Kim, D.H.; Im, S.G. Initiated chemical vapor deposition of thermoresponsive poly(N-vinylcaprolactam) thin film for cell sheet engineering. Acta Biomater. 2013, 9, 7691–7698. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gautam, B.; Yu, H.-h. Self-Cleaning Cotton Obtained after Grafting Thermoresponsive Poly(N-vinylcaprolactam) through Surface-Initiated Atom Transfer Radical Polymerization. Polymers 2020, 12, 2920. https://doi.org/10.3390/polym12122920

Gautam B, Yu H-h. Self-Cleaning Cotton Obtained after Grafting Thermoresponsive Poly(N-vinylcaprolactam) through Surface-Initiated Atom Transfer Radical Polymerization. Polymers. 2020; 12(12):2920. https://doi.org/10.3390/polym12122920

Chicago/Turabian StyleGautam, Bhaskarchand, and Hsiao-hua Yu. 2020. "Self-Cleaning Cotton Obtained after Grafting Thermoresponsive Poly(N-vinylcaprolactam) through Surface-Initiated Atom Transfer Radical Polymerization" Polymers 12, no. 12: 2920. https://doi.org/10.3390/polym12122920

APA StyleGautam, B., & Yu, H.-h. (2020). Self-Cleaning Cotton Obtained after Grafting Thermoresponsive Poly(N-vinylcaprolactam) through Surface-Initiated Atom Transfer Radical Polymerization. Polymers, 12(12), 2920. https://doi.org/10.3390/polym12122920