Characterization of Microcrystalline Cellulose Isolated from Conocarpus Fiber

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials and Chemicals

2.2. MCC Extraction

2.3. Characterization

2.3.1. Functional Chemistry Analysis

2.3.2. Crystallinity Analysis

2.3.3. Morphology, Particle Size, Elements, and Yield Analyses

2.3.4. Thermal Stability Analysis

3. Results and Discussion

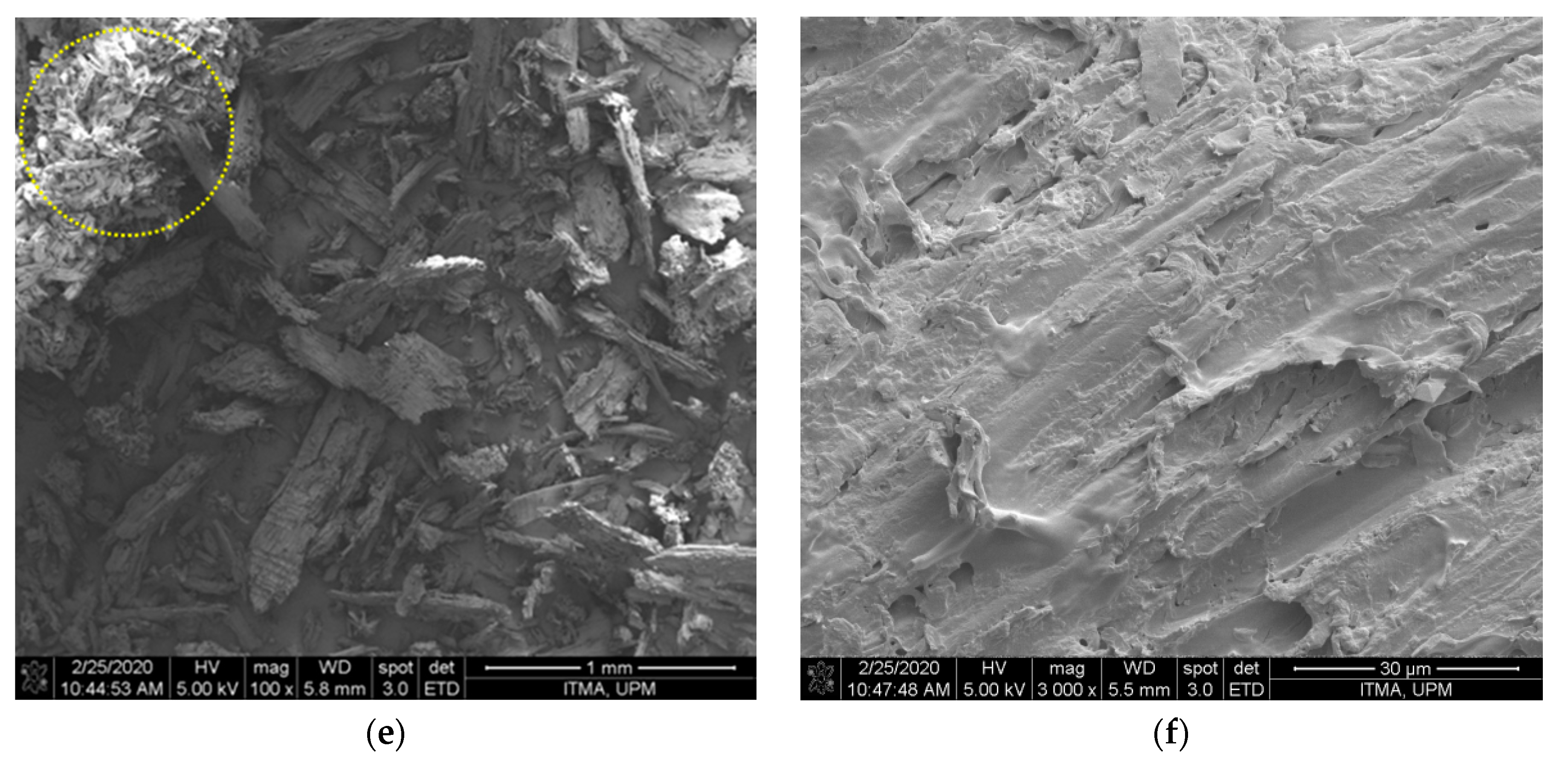

3.1. Morphology and Elements Analysis

3.2. FTIR

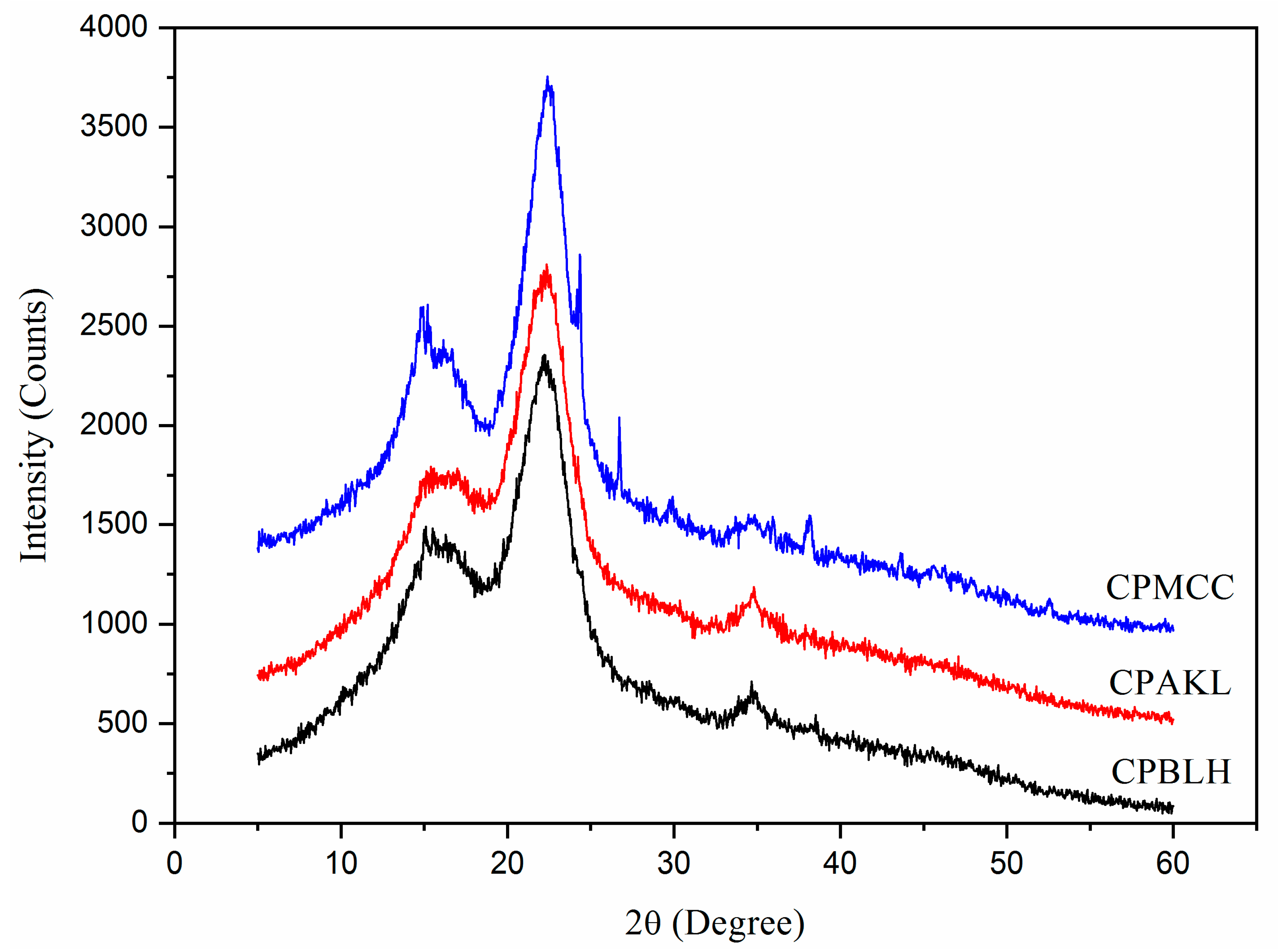

3.3. XRD

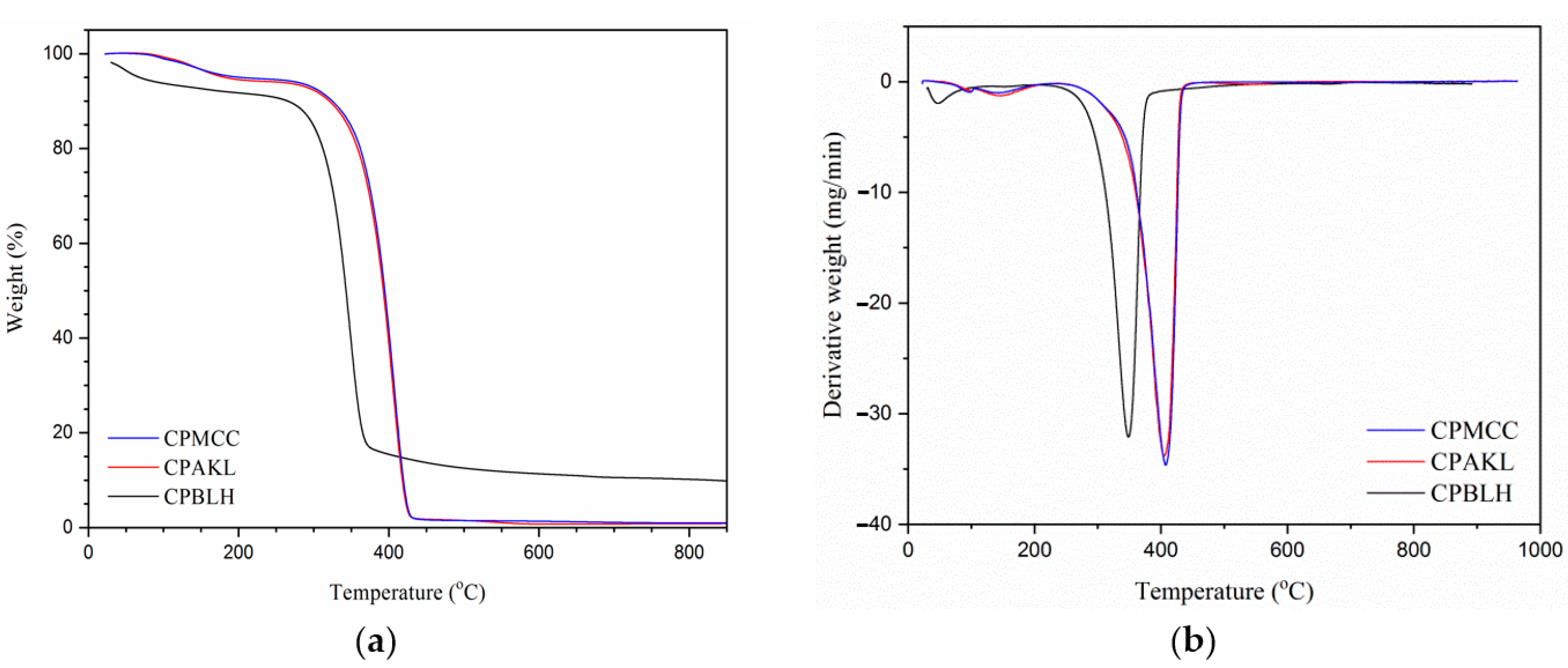

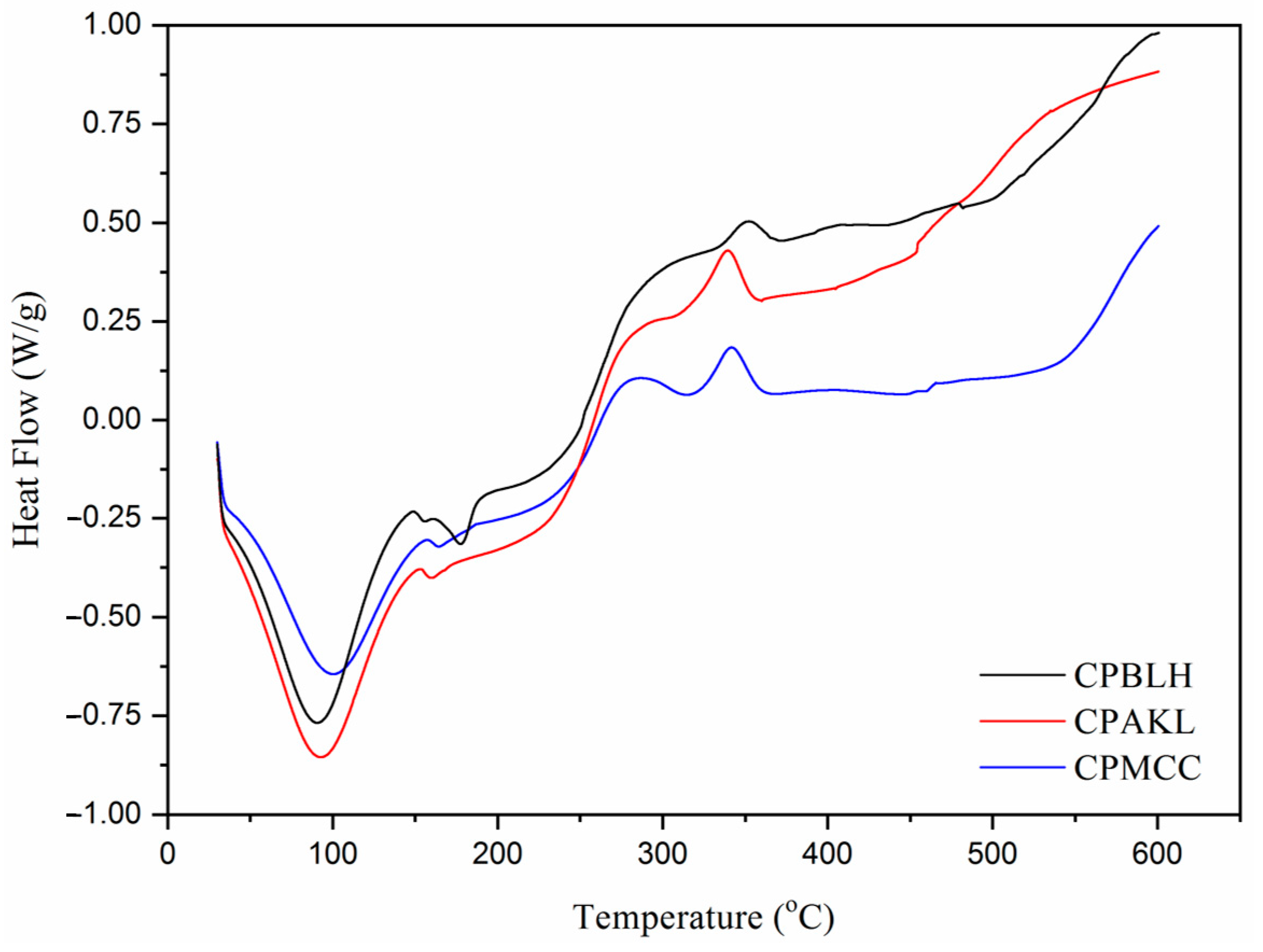

3.4. Thermostability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Katakojwala, R.; Mohan, S.V. Microcrystalline cellulose production from sugarcane bagasse: Sustainable process development and life cycle assessment. J. Clean. Prod. 2020, 249, 119342. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, A.; Ibrahim, S.A.; Yang, H.; Huang, W. Isolation and characterization of microcrystalline cellulose from pomelo peel. Int. J. Biol. Macromol. 2018, 111, 717–721. [Google Scholar] [CrossRef] [PubMed]

- Rehman, S.; Abbas, G.; Shahid, M.; Saqib, M.; Farooq, A.B.U.; Hussain, M.; Farooq, A. Effect of salinity on cadmium tolerance, ionic homeostasis and oxidative stress responses in conocarpus exposed to cadmium stress: Implications for phytoremediation. Ecotox. Environ. Saf. 2019, 171, 146–153. [Google Scholar] [CrossRef] [PubMed]

- Tauqeer, H.M.; Rahman, M.; Hussain, S.; Abbas, F.; Iqbal, M. The potential of an energy crop “Conocarpus erectus” for lead phytoextraction and phytostabilization of chromium, nickel, and cadmium: An excellent option for the management of multi-metal contaminated soils. Ecotox. Environ. Saf. 2019, 173, 273–284. [Google Scholar] [CrossRef]

- Rajabpour, A.; Mashahdi, A.R.A.; Ghorbani, M.R. Chemical compositions of leaf extracts from Conocarpus erectus L. (Combretaceae) and their bioactivities against Tribolium castaneum Herbst (Coleoptera: Tenebrionidae). J. Asia Pac. Entomol. 2019, 22, 333–337. [Google Scholar] [CrossRef]

- Santos, N.D.K.D.; Barros, B.R.S.; Aguiar, L.M.S.; Filho, I.J.C.; Lorena, V.M.B.; Melo, C.M.L.; Napoleão, T.H. Immunostimulatory and antioxidant activities of a lignin isolated from Conocarpus erectus leaves. Int. J. Biol. Macromol. 2020, 150, 169–177. [Google Scholar] [CrossRef]

- Tarchoun, A.F.; Trache, D.; Klapötke, T.M.; Derradji, M.; Bessa, W. Ecofriendly isolation and characterization of microcrystalline cellulose from giant reed using various acidic media. Cellulose 2019, 26, 7635–7651. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Fouad, H. Characterization of microcrystalline cellulose extracted from olive fiber. Int. J. Biol. Macromol. 2020, 156, 347–353. [Google Scholar] [CrossRef]

- Hou, W.; Ling, C.; Shi, S.; Yan, Z. Preparation and characterization of microcrystalline cellulose from waste cotton fabrics by using phosphotungstic acid. Int. J. Biol. Macromol. 2019, 123, 363–368. [Google Scholar] [CrossRef]

- Yavorov, N.; Valchev, I.; Radeva, G.; Todorova, D. Kinetic investigation of dilute acid hydrolysis of hardwood pulp for microcrystalline cellulose production. Carbohydr. Res. 2020, 488, 107910. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, Z.; Lin, X.; Ren, Z.; Li, B.; Zhang, Y. Preparation and characterization of microcrystalline cellulose (MCC) from tea waste. Carbohydr. Polym. 2018, 184, 164–170. [Google Scholar] [CrossRef] [PubMed]

- French, A.D.; Cintron, M.S. Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 2013, 20, 583–588. [Google Scholar] [CrossRef]

- Trache, D.; Khimeche, K.; Mezroua, A.; Benziane, M. Physicochemical properties of microcrystalline nitrocellulose from Alfa grass fibres and its thermal stability. J. Therm. Anal. Calorim. 2016, 124, 1485–1496. [Google Scholar] [CrossRef]

- Xiang, L.Y.; Mohammed, M.A.; Baharuddin, A.S. Characterisation of microcrystalline cellulose from oil palm fibres for food applications. Carbohydr. Polym. 2016, 148, 11–20. [Google Scholar] [CrossRef]

- Merci, A.; Urbano, A.; Grossmann, M.V.E.; Tischer, C.A.; Mali, S. Properties of microcrystalline cellulose extracted from soybean hulls by reactive extrusion. Food Res. Int. 2015, 73, 38–43. [Google Scholar] [CrossRef]

- Ferrer, A.; Salas, C.; Rojas, O.J. Physical, thermal, chemical and rheological characterization of cellulosic microfibrils and microparticles produced from soybean hulls. Ind. Crops Prod. 2016, 84, 337–343. [Google Scholar] [CrossRef]

- Owolabi, A.F.; Haafiz, M.K.M.; Hossain, M.S.; Hussin, M.H.; Fazita, M.R.N. Influence of alkaline hydrogen peroxide pre-hydrolysis on the isolation of microcrystalline cellulose from oil palm fronds. Int. J. Biol. Macromol. 2017, 95, 1228–1234. [Google Scholar] [CrossRef]

- Zeni, M.; Favero, D. Preparation of microcellulose (Mcc) and nanocellulose (Ncc) from eucalyptus kraft ssp pulp. Polym. Sci. 2016, 1, 1–5. [Google Scholar] [CrossRef]

- Nomura, S.; Kugo, Y.; Erata, T. 13C NMR and XRD studies on the enhancement of cellulose II crystallinity with low concentration NaOH post-treatments. Cellulose 2020, 27, 3553–3563. [Google Scholar] [CrossRef]

- Hussin, M.H.; Pohan, N.A.; Garba, Z.N.; Kassim, M.J.; Rahim, A.A.; Brosse, N.; Haafiz, M.K.M. Physicochemical of microcrystalline cellulose from oil palm fronds as potential methylene blue adsorbents. Int. J. Biol. Macromol. 2016, 92, 11–19. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Sonia, A.; Dasan, K.P. Chemical, morphology and thermal evaluation of cellulose microfibers obtained from Hibiscus sabdariffa. Carbohydr. Polym. 2013, 92, 668–674. [Google Scholar] [CrossRef] [PubMed]

| Samples | C (%) a | O (%) b | Sb (%) c | F (%) d | Zr (%) e | Nb (%) f | Yield (%) |

|---|---|---|---|---|---|---|---|

| CPBLH | 64.71 | 34.51 | 0.02 | - | 0.75 | - | 52 |

| CPAKL | 64.76 | 32.48 | - | 0.91 | 1.08 | 0.77 | 41 |

| CPMCC | 66.62 | 32.37 | - | - | 0.62 | 0.40 | 27 |

| Samples | TD (°C) a | TMD (°C) b | WL (%) c | WCR (%) d |

|---|---|---|---|---|

| CPBLH | 309.5 | 349.8 | 89.6 | 7.4 |

| CPAKL | 367.3 | 402.8 | 96.0 | 1.3 |

| CPMCC | 372.9 | 408.5 | 96.4 | 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouad, H.; Kian, L.K.; Jawaid, M.; Alotaibi, M.D.; Alothman, O.Y.; Hashem, M. Characterization of Microcrystalline Cellulose Isolated from Conocarpus Fiber. Polymers 2020, 12, 2926. https://doi.org/10.3390/polym12122926

Fouad H, Kian LK, Jawaid M, Alotaibi MD, Alothman OY, Hashem M. Characterization of Microcrystalline Cellulose Isolated from Conocarpus Fiber. Polymers. 2020; 12(12):2926. https://doi.org/10.3390/polym12122926

Chicago/Turabian StyleFouad, H., Lau Kia Kian, Mohammad Jawaid, Majed D. Alotaibi, Othman Y. Alothman, and Mohamed Hashem. 2020. "Characterization of Microcrystalline Cellulose Isolated from Conocarpus Fiber" Polymers 12, no. 12: 2926. https://doi.org/10.3390/polym12122926

APA StyleFouad, H., Kian, L. K., Jawaid, M., Alotaibi, M. D., Alothman, O. Y., & Hashem, M. (2020). Characterization of Microcrystalline Cellulose Isolated from Conocarpus Fiber. Polymers, 12(12), 2926. https://doi.org/10.3390/polym12122926