Detailed Thermal Characterization of Acrylonitrile Butadiene Styrene and Polylactic Acid Based Carbon Composites Used in Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composite Materials Used

ESD-PLA Samples

2.2. ESD-ABS Samples

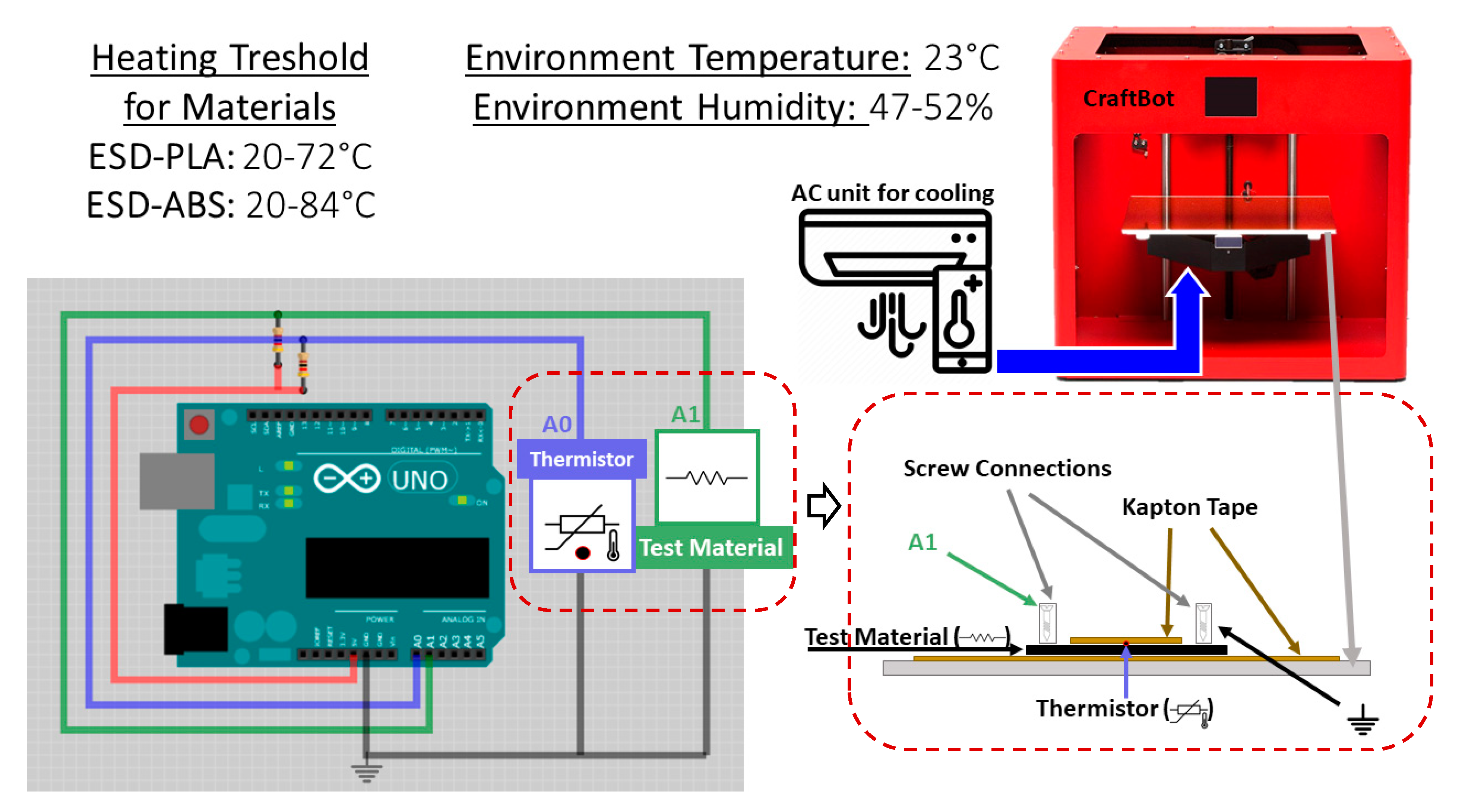

2.3. Resistance Measurements

2.4. DSC-TGA Measurements

2.5. Carbon Content of ESD Samples

2.6. Data Analysis and Figures

3. Results

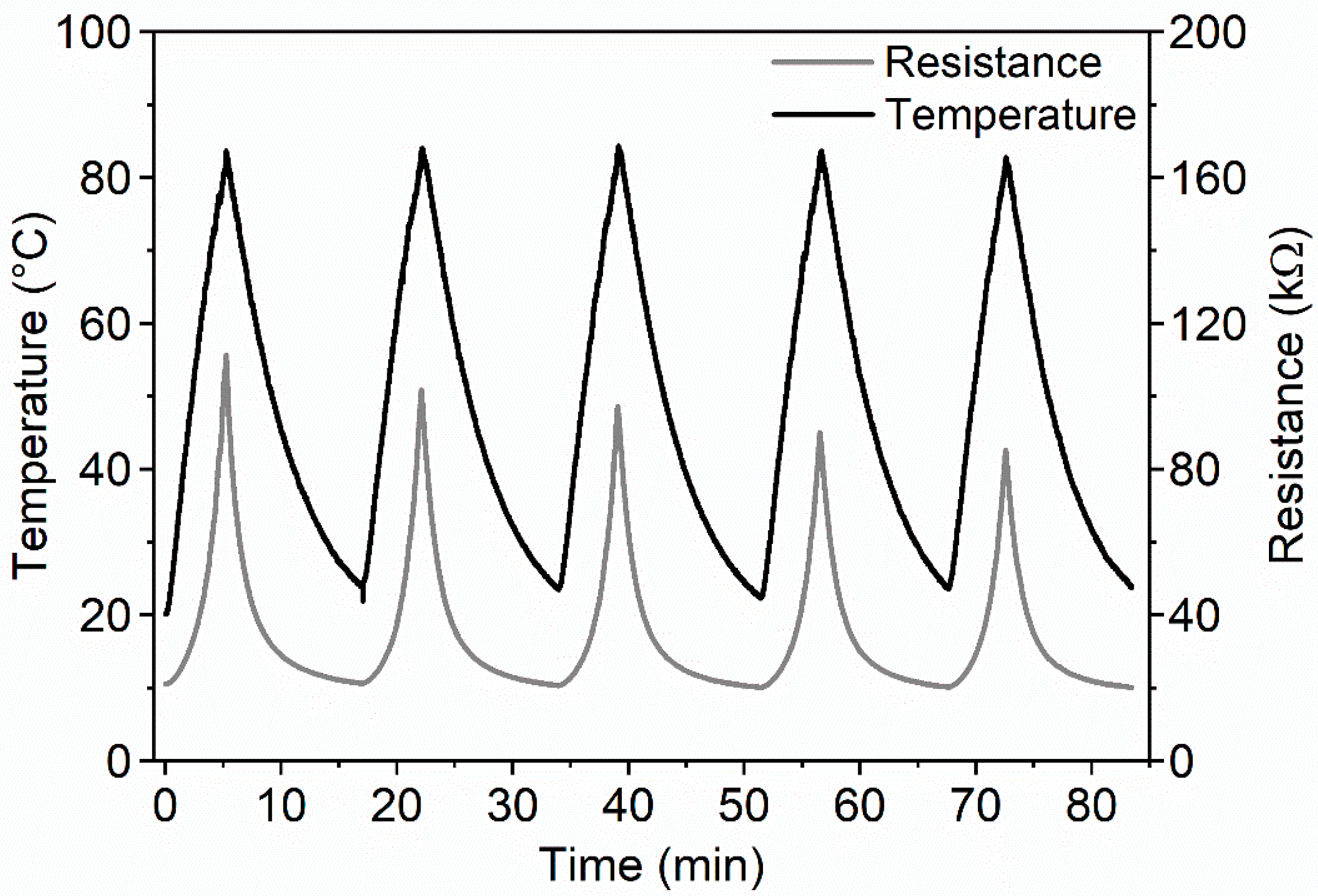

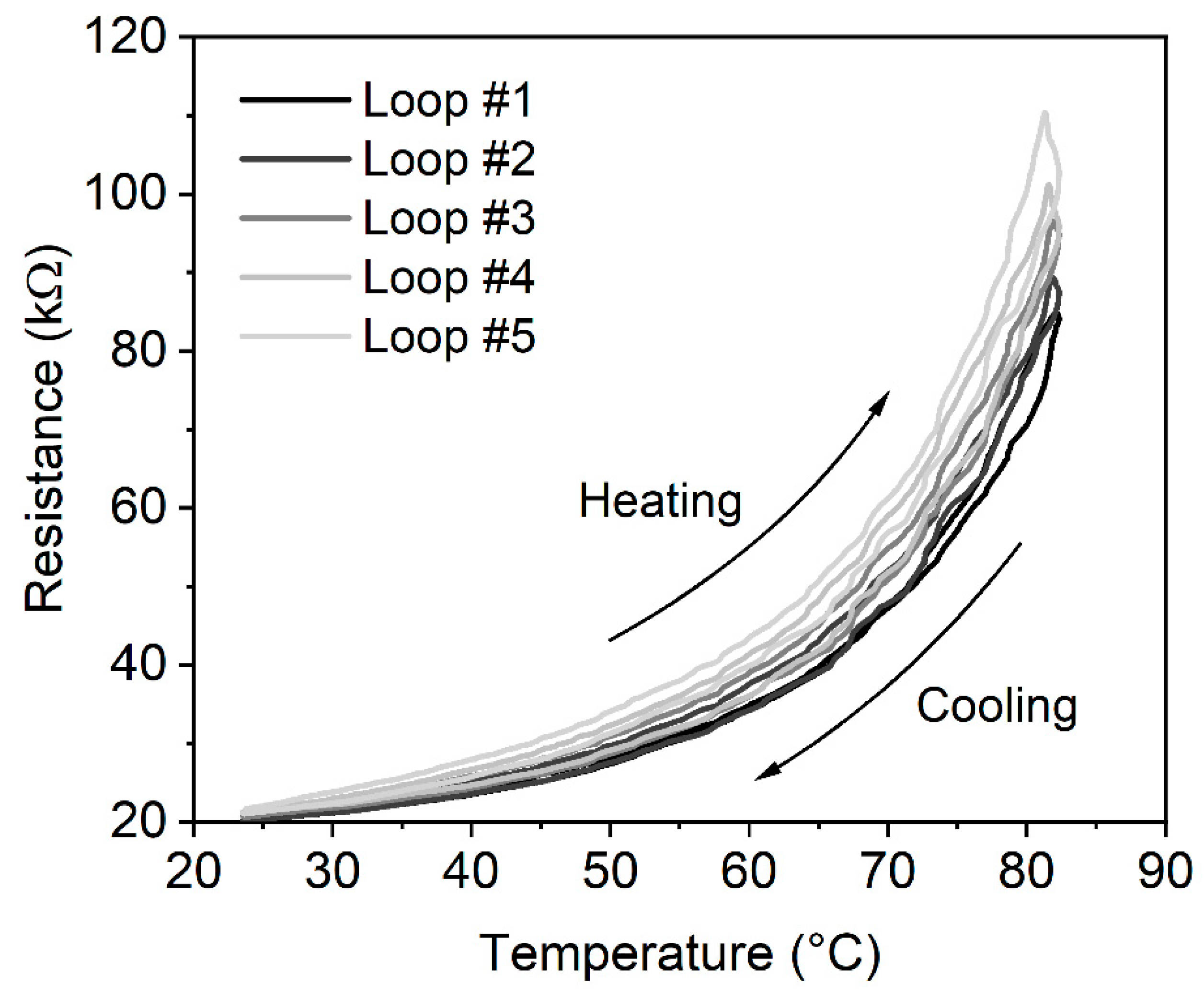

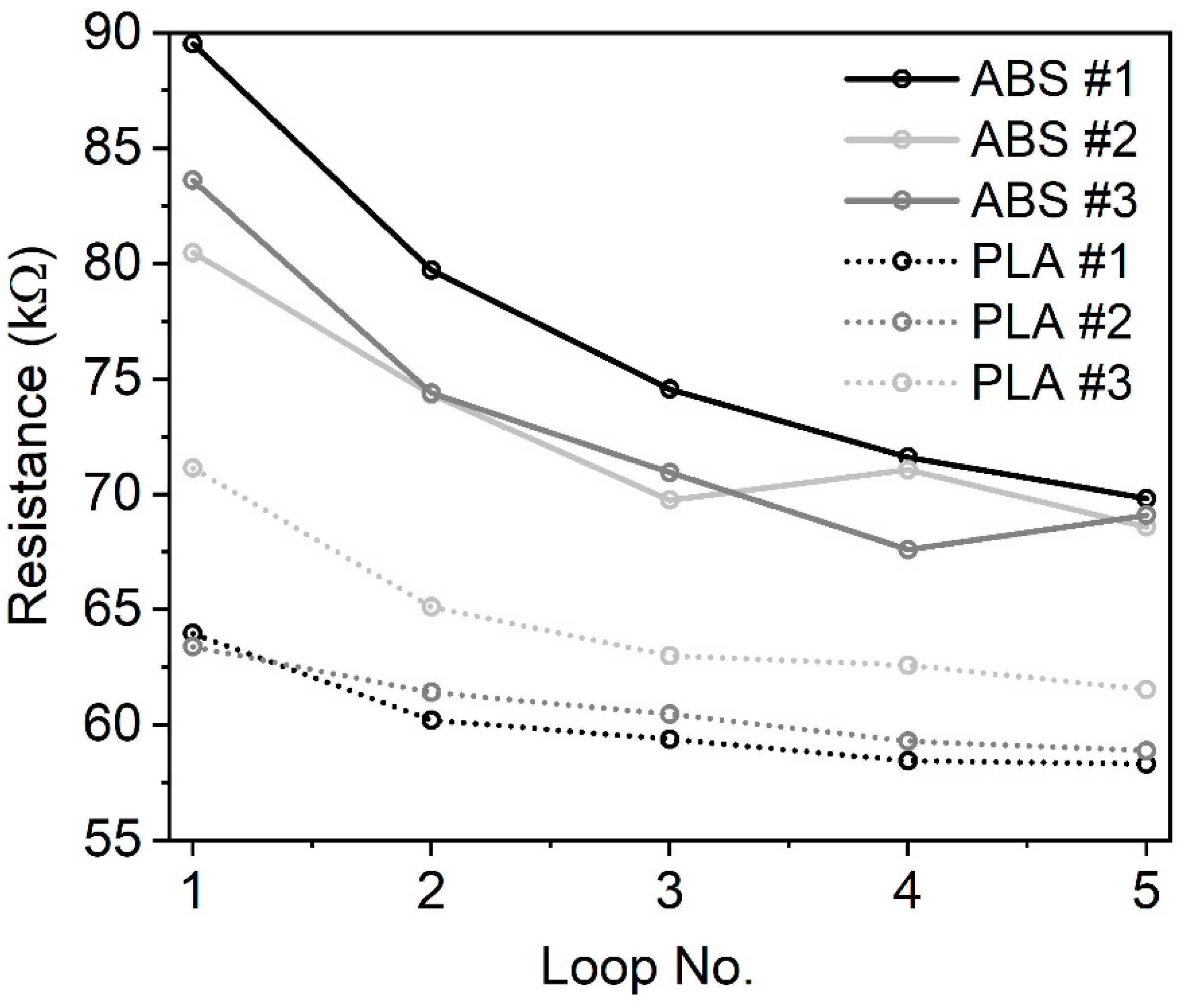

3.1. Resistance of Composites

3.2. Amount of Carbon in ESD Samples

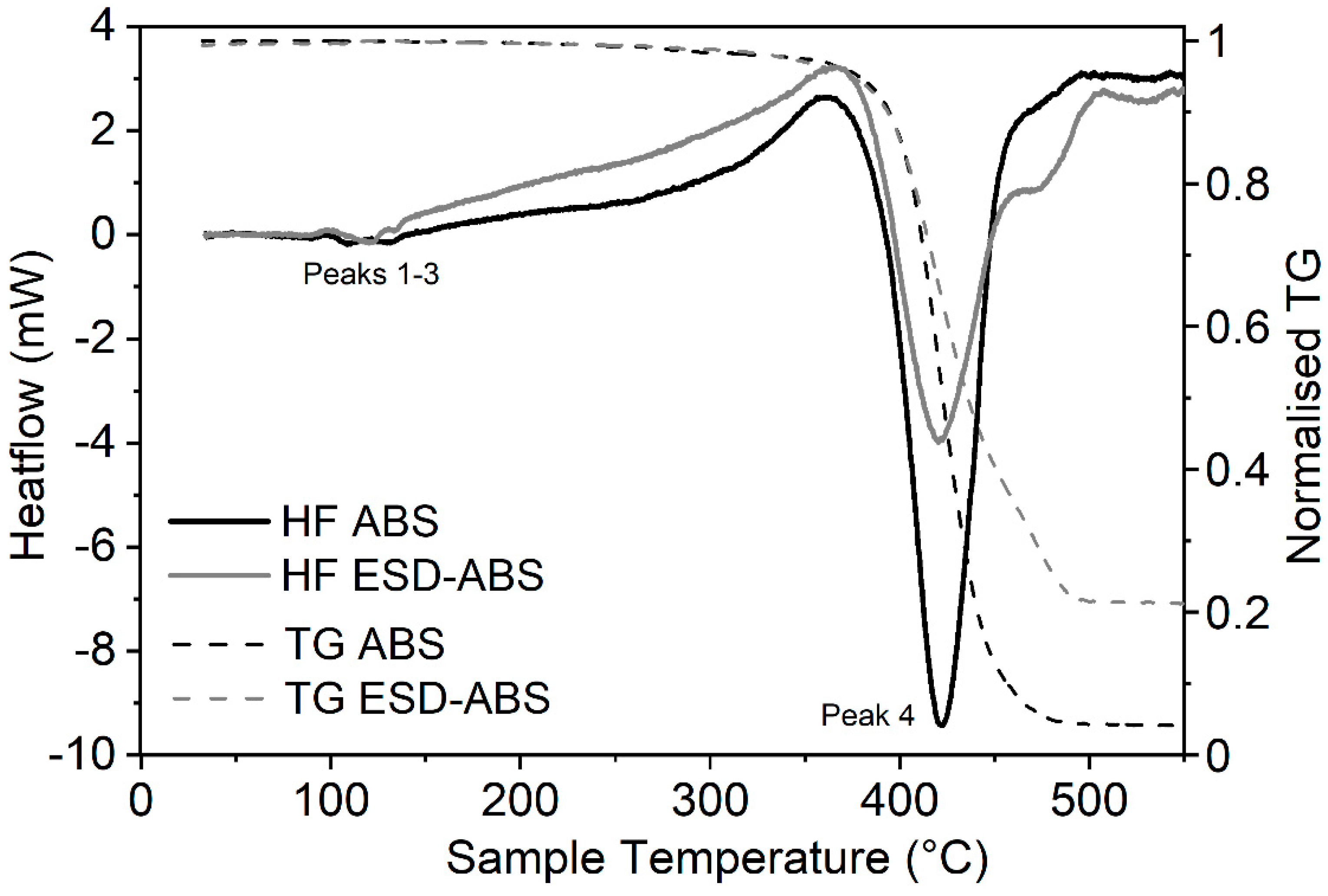

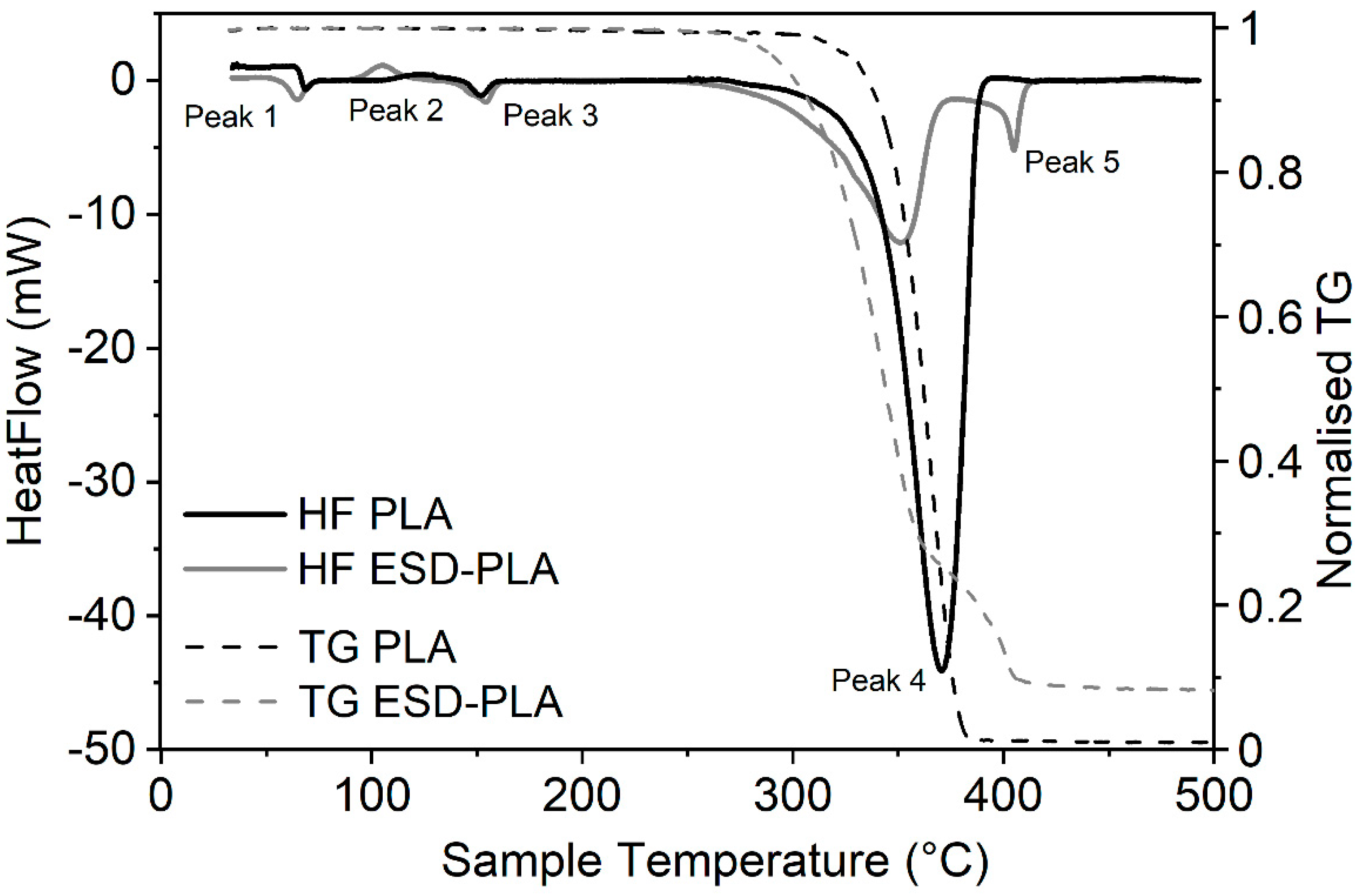

3.3. Thermal Characterisation of Composites

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

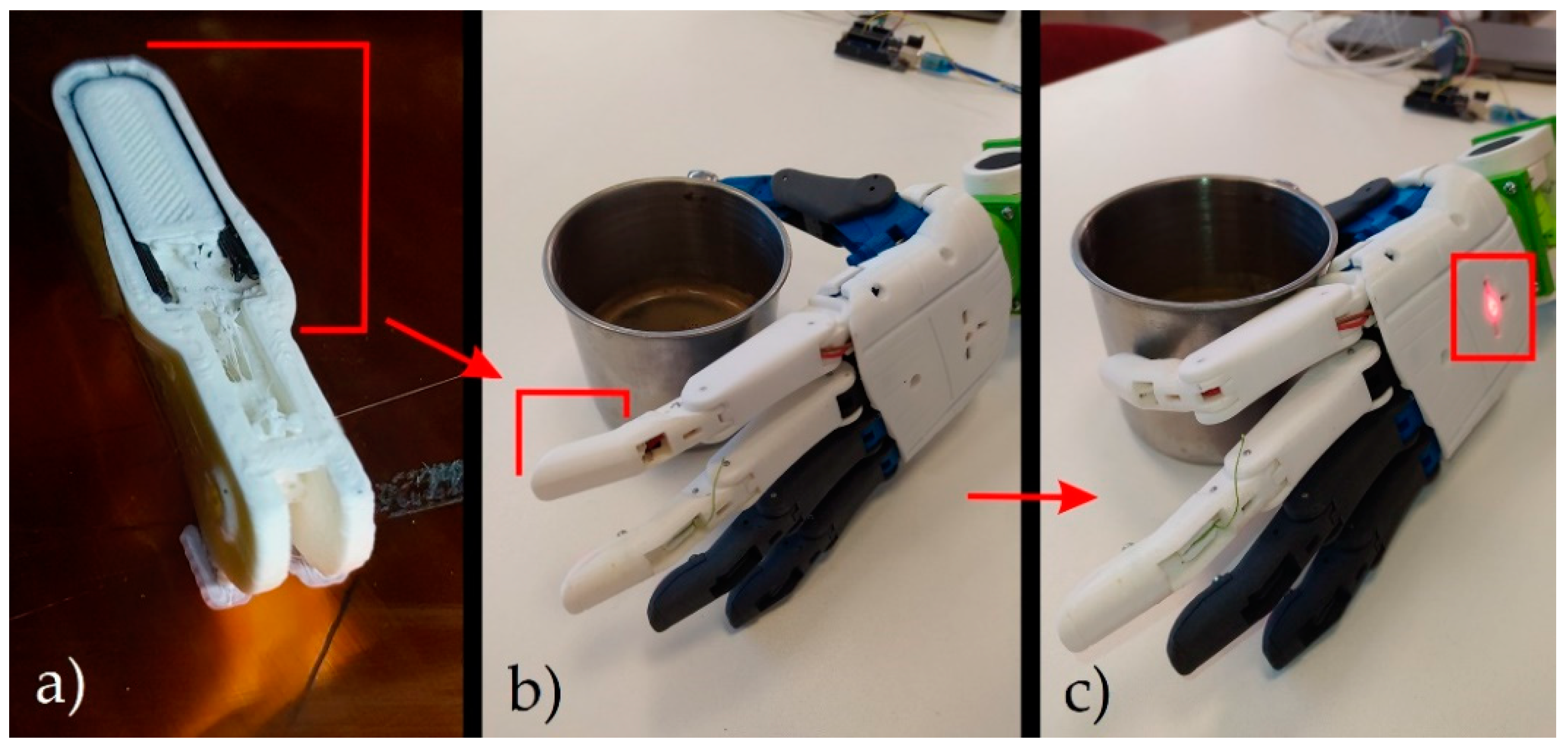

- Maroti, P.; Varga, P.; Abraham, H.; Falk, G.; Zsebe, T.; Meiszterics, Z.; Mano, S.; Csernatony, Z.; Rendeki, S.; Nyitrai, M. Printing orientation defines anisotropic mechanical properties in additive manufacturing of upper limb prosthetics. Mater. Res. Express 2018, 6, 035403. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Additive manufacturing applications in medical cases: A literature based review. Alex. J. Med. 2018, 54, 411–422. [Google Scholar] [CrossRef] [Green Version]

- Jaksic, N.I.; Desai, P.D. Characterization of resistors created by fused filament fabrication using electrically-conductive filament. Procedia Manuf. 2018, 17, 37–44. [Google Scholar] [CrossRef]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B-Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Oztan, C.; Ballikaya, S.; Ozgun, U.; Karkkainen, R.; Celik, E. Additive manufacturing of thermoelectric materials via fused filament fabrication. Appl. Mater. Today 2019, 15, 77–82. [Google Scholar] [CrossRef]

- Palmic, T.; Slavic, J.; Boltezar, M. Process Parameters for FFF 3D-Printed Conductors for Applications in Sensors. Sensors 2020, 20, 4542. [Google Scholar] [CrossRef]

- Drumea, A.; Dobre, R.; Marghescu, C. Thermal and Electrical Investigation of Graphene-Enhanced Conductive Polylactic Acid Based Filaments for 3D-Printing. In Proceedings of the 11th International Conference on Electronics, Computers and Artificial Intelligence (Ecai-2019), Pitesti, Romania, 27–29 June 2019. [Google Scholar] [CrossRef]

- Antoniac, I.; Popescu, D.; Zapciu, A.; Antoniac, A.; Miculescu, F.; Moldovan, H. Magnesium Filled Polylactic Acid (PLA) Material for Filament Based 3D Printing. Materials 2019, 12, 719. [Google Scholar] [CrossRef] [Green Version]

- Singh, R.; Singh, H.; Farina, I.; Colangelo, F.; Fraternali, F. On the additive manufacturing of an energy storage device from recycled material. Compos. Part B-Eng. 2019, 156, 259–265. [Google Scholar] [CrossRef]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater. Des. 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Sanatgar, R.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the Surface Texture and Mechanical Properties of FDM Printed Samples after Thermal and Chemical Treatment. Stroj. Vestn. J. Mech. Eng. 2020, 66, 105–113. [Google Scholar] [CrossRef] [Green Version]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S. Development and Application of Wood Flour-Filled Polylactic Acid Composite Filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Caminero, M.; Chacon, J.; Garcia-Plaza, E.; Nunez, P.; Reverte, J.; Becar, J. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [Green Version]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork–PLA composite filaments for fused deposition modelling. Compos. Sci. Technol. 2018, 168, 230–237. [Google Scholar] [CrossRef]

- Ryder, M.; Lados, D.; Iannacchione, G.; Peterson, A. Fabrication and properties of novel polymer-metal composites using fused deposition modeling. Compos. Sci. Technol. 2018, 158, 43–50. [Google Scholar] [CrossRef]

- Zhong, W.; Li, F.; Zhang, Z.; Song, L.; Li, Z. Short fiber reinforced composites for fused deposition modeling. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D Printing of Soft Electronics. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Pekgor, M.; Nikzad, M.; Arablouei, R.; Masood, S. Sensor-based filament fabrication with embedded RFID microchips for 3D printing. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Macdonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R. 3D Printing for the Rapid Prototyping of Structural Electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- Leigh, S.; Bradley, R.; Purssell, C.; Billson, D.; Hutchins, D. A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors. PLoS ONE 2012, 7. [Google Scholar] [CrossRef] [PubMed]

- Maróti, P.; Varga, P.; Ferencz, A.; Ujfalusi, Z.; Nyitrai, M.; Lőrinczy, D. Testing of innovative materials for medical additive manufacturing by DTA. J. Therm. Anal. Calorim. 2019, 136, 2041–2048. [Google Scholar] [CrossRef]

- Siddiqui, N.; Asawa, S.; Birru, B.; Baadhe, R.; Rao, S. PCL-Based Composite Scaffold Matrices for Tissue Engineering Applications. Mol. Biotechnol. 2018, 60, 506–532. [Google Scholar] [CrossRef] [PubMed]

- Toth, L.; Schiffer, A.; Nyitrai, M.; Pentek, A.; Told, R.; Maroti, P. Developing an anti-spastic orthosis for daily home-use of stroke patients using smart memory alloys and 3D printing technologies. Mater. Des. 2020, 195. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 3rd ed.; Academic Press Ltd-Elsevier Science Ltd.: London, UK, 2018; pp. 1–564. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Sreekumar, T.; Liu, T.; Kumar, S.; Ericson, L.; Hauge, R.; Smalley, R. Crystallization and orientation studies in polypropylene/single wall carbon nanotube composite. Polymer 2003, 44, 2373–2377. [Google Scholar] [CrossRef]

- Olivera, S.; Muralidhara, H.; Venkatesh, K.; Gopalakrishna, K.; Vivek, C. Plating on acrylonitrile-butadiene-styrene (ABS) plastic: A review. J. Mater. Sci. 2016, 51, 3657–3674. [Google Scholar] [CrossRef]

- Bledzki, A.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A-Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Kozior, T.; Dopke, C.; Grimmelsmann, N.; Junger, I.; Ehrmann, A. Influence of fabric pretreatment on adhesion of three-dimensional printed material on textile substrates. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Kozior, T.; Blachowicz, T.; Ehrmann, A. Adhesion of three-dimensional printing on textile fabrics: Inspiration from and for other research areas. J. Eng. Fibers Fabr. 2020, 15. [Google Scholar] [CrossRef] [Green Version]

- Cai, M.; Takagi, H.; Nakagaito, A.; Li, Y.; Waterhouse, G. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A-Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Pentek, A.; Nyitrai, M.; Schiffer, A.; Abraham, H.; Bene, M.; Molnar, E.; Told, R.; Maroti, P. The Effect of Printing Parameters on Electrical Conductivity and Mechanical Properties of PLA and ABS Based Carbon Composites in Additive Manufacturing of Upper Limb Prosthetics. Crystals 2020, 10, 398. [Google Scholar] [CrossRef]

- Aoki, Y.; Watanabe, M. Morphological, thermal, and rheological properties of nylon/acrylonitrile-butadiene-styrene alloys. Polym. Eng. Sci. 1992, 32, 878–885. [Google Scholar] [CrossRef]

- Acquah, S.F.A.; Leonhardt, B.E.; Nowotarski, M.S.; Magi, J.M.; Chambliss, K.A.; Venzel, T.E.S.; Delekar, S.D.; Al-Hariri, L.A. Carbon Nanotubes and Graphene as Additives in 3D Printing. In Carbon Nanotubes-Current Progress of Their Polymer Composites; IntechOpen Ltd.: London, UK, 2016; Chapter 8. [Google Scholar] [CrossRef] [Green Version]

- Barrau, S.; Vanmansart, C.; Moreau, M.; Addad, A.; Stoclet, G.; Lefebvre, J.; Seguela, R. Crystallization Behavior of Carbon Nanotube-Polylactide Nanocomposites. Macromolecules 2011, 44, 6496–6502. [Google Scholar] [CrossRef]

- Grady, B.; Pompeo, F.; Shambaugh, R.; Resasco, D. Nucleation of polypropylene crystallization by single-walled carbon nanotubes. J. Phys. Chem. B 2002, 106, 5852–5858. [Google Scholar] [CrossRef]

- Wu, T.-M.; Chen, E.-C. Crystallization behavior of poly(ε-caprolactone)/multiwalled carbon nanotube composites. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 598–606. [Google Scholar] [CrossRef]

- Bose, S.; Bhattacharyya, A.; Kodgire, P.; Misra, A. Fractionated crystallization in PA6/ABS blends: Influence of a reactive compatibilizer and multiwall carbon nanotubes. Polymer 2007, 48, 356–362. [Google Scholar] [CrossRef]

- Park, S.; Lee, S.; Kim, S. Isothermal crystallization behavior and mechanical properties of polylactide/carbon nanotube nanocomposites. Compos. Part A-Appl. Sci. Manuf. 2013, 46, 11–18. [Google Scholar] [CrossRef]

- Triantou, M.I.; Tarantili, P.A. Thermal Stability and Crystallization Behaviour of Modified ABS/PP Nanocomposites. Int. J. Chem. Mol. Eng. 2014, 8, 973–978. [Google Scholar] [CrossRef]

- Araujo, E.; Hage, E.; Carvalho, A. Thermal properties of nylon6/ABS polymer blends: Compatibilizer effect. J. Mater. Sci. 2004, 39, 1173–1178. [Google Scholar] [CrossRef]

- Hage, E.; Ferreira, L.; Manrich, S.; Pessan, L. Crystallization behavior of PBT/ABS polymer blends. J. Appl. Polym. Sci. 1999, 71, 423–430. [Google Scholar] [CrossRef]

- Ryan, K.; Cadek, M.; Drury, A.; Ruether, M.; Blau, W.; Coleman, J. Carbon nanotube nucleated polymer crystallization. Fuller. Nanotub. Carbon Nanostructures 2005, 13, 431–434. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, J.; Realff, M.; Kumar, S.; Schiraldi, D. Processing, structure, and properties of fibers from polyester/carbon nanofiber composites. Compos. Sci. Technol. 2003, 63, 1617–1628. [Google Scholar] [CrossRef]

- Valentini, L.; Biagiotti, J.; Kenny, J.M.; Santucci, S. Effects of single-walled carbon nanotubes on the crystallization behavior of polypropylene. J. Appl. Polym. Sci. 2003, 87, 708–713. [Google Scholar] [CrossRef]

| Heating (30–600 °C) | |||||||

|---|---|---|---|---|---|---|---|

| Peak 1 | Peak 2 | Peak 3 | Peak 4 | Peak 5 | |||

| Glass Transition | Crystallization | Melting | Decomposition | Extra Peak | |||

| Ton (°C) | Tg (°C) | Tend (°C) | Tc (°C) | Tm (°C) | Td (°C) | Tendo (°C) | |

| PLA | 61.85 ± 0.85 | 65.62 ± 0.17 | 68.51 ± 0.19 | 126.05 ± 0.88 | 151.60 ± 0.31 | 369.27 ± 0.62 | - |

| ESD-PLA | 49.80 ± 0.20 | 60.46 ± 0.04 | 64.32 ± 0.07 | 104.61 ± 0.60 | 153.90 ± 0.11 | 350.34 ± 0.44 | 402.76 ± 0.35 |

| ABS | 97.36 ± 0.09 | 103.89 ± 0.04 | 108.84 ± 0.22 | 119.40 ± 0.98 | 130.70 ± 0.42 | 423.03 ± 0.45 | - |

| ESD-ABS | 97.49 ± 0.09 | 108.11 ± 0.42 | 121.28 ± 0.42 | 130.03 ± 0.23 | 133.76 ± 0.28 | 420.14 ± 0.03 | - |

| ΔH Peak Enthalpies (J/g)—Heating (30–600 °C) | |||||

|---|---|---|---|---|---|

| Peak 1 | Peak 2 | Peak 3 | Peak 4 | Peak 5 | |

| Endotherm | Exotherm | Endotherm | Endotherm | Endotherm | |

| PLA | 12.72 ± 0.59 | −3.25 ± 0.12 | 14.55 ± 0.71 | 1016.18 ± 26.49 | - |

| ESD-PLA | 18.58 ± 2.55 | −18.49 ± 1.36 | 22.60 ± 0.96 | 425.85 ± 18.46 | 42.36 ± 0.76 |

| ABS | 2.55 ± 0.50 | −6.22 ± 0.93 | 5.48 ± 0.69 | 647.15 ± 16.79 | - |

| ESD-ABS | 6.57 ± 0.42 | −4.19 ± 0.11 | 2.58 ± 0.09 | 431.70 ± 5.14 | - |

| Cooling (300–30 °C) | |||||

|---|---|---|---|---|---|

| Peak 6 (Recrystallization) | |||||

| Exotherm | |||||

| Ton (°C) | Tm (°C) | Tend (°C) | Extra Tm2 Peak (°C) | ΔH Peak Enthalpies (J/g) | |

| PLA | 117.34 ± 1.95 | 63.75 ± 0.20 | 49.95 ± 1.41 | - | −10.16 ± 2.75 |

| ESD-PLA | 53.04 ± 0.16 | 49.22 ± 0.07 | 38.48 ± 1.23 | - | −7.97 ± 0.20 |

| ABS | 135.18 ± 1.85 | 124.58 ± 0.78 | 92.04 ± 3.10 | - | −5.79 ± 0.37 |

| ESD-ABS | 132.31 ± 1.04 | 123.77 ± 0.11 | 89.32 ± 5.47 | 107.63 ± 0.14 | −6.06 ± 1.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ujfalusi, Z.; Pentek, A.; Told, R.; Schiffer, A.; Nyitrai, M.; Maroti, P. Detailed Thermal Characterization of Acrylonitrile Butadiene Styrene and Polylactic Acid Based Carbon Composites Used in Additive Manufacturing. Polymers 2020, 12, 2960. https://doi.org/10.3390/polym12122960

Ujfalusi Z, Pentek A, Told R, Schiffer A, Nyitrai M, Maroti P. Detailed Thermal Characterization of Acrylonitrile Butadiene Styrene and Polylactic Acid Based Carbon Composites Used in Additive Manufacturing. Polymers. 2020; 12(12):2960. https://doi.org/10.3390/polym12122960

Chicago/Turabian StyleUjfalusi, Zoltan, Attila Pentek, Roland Told, Adam Schiffer, Miklos Nyitrai, and Peter Maroti. 2020. "Detailed Thermal Characterization of Acrylonitrile Butadiene Styrene and Polylactic Acid Based Carbon Composites Used in Additive Manufacturing" Polymers 12, no. 12: 2960. https://doi.org/10.3390/polym12122960

APA StyleUjfalusi, Z., Pentek, A., Told, R., Schiffer, A., Nyitrai, M., & Maroti, P. (2020). Detailed Thermal Characterization of Acrylonitrile Butadiene Styrene and Polylactic Acid Based Carbon Composites Used in Additive Manufacturing. Polymers, 12(12), 2960. https://doi.org/10.3390/polym12122960