Mechanical and Dynamic Behavior of an Elastic Rubber Layer with Recycled Styrene-Butadiene Rubber Granules

Abstract

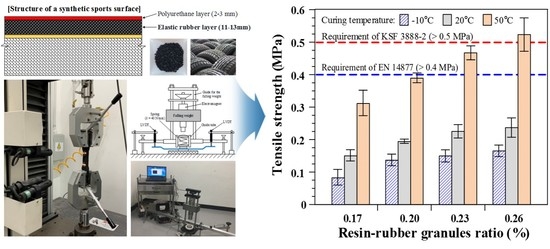

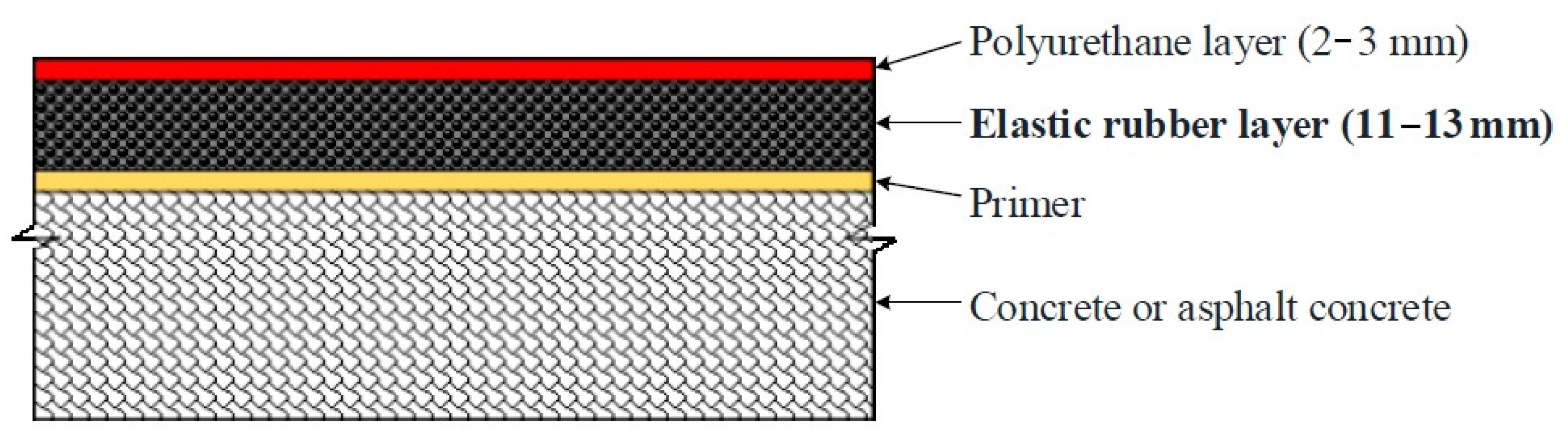

:1. Introduction

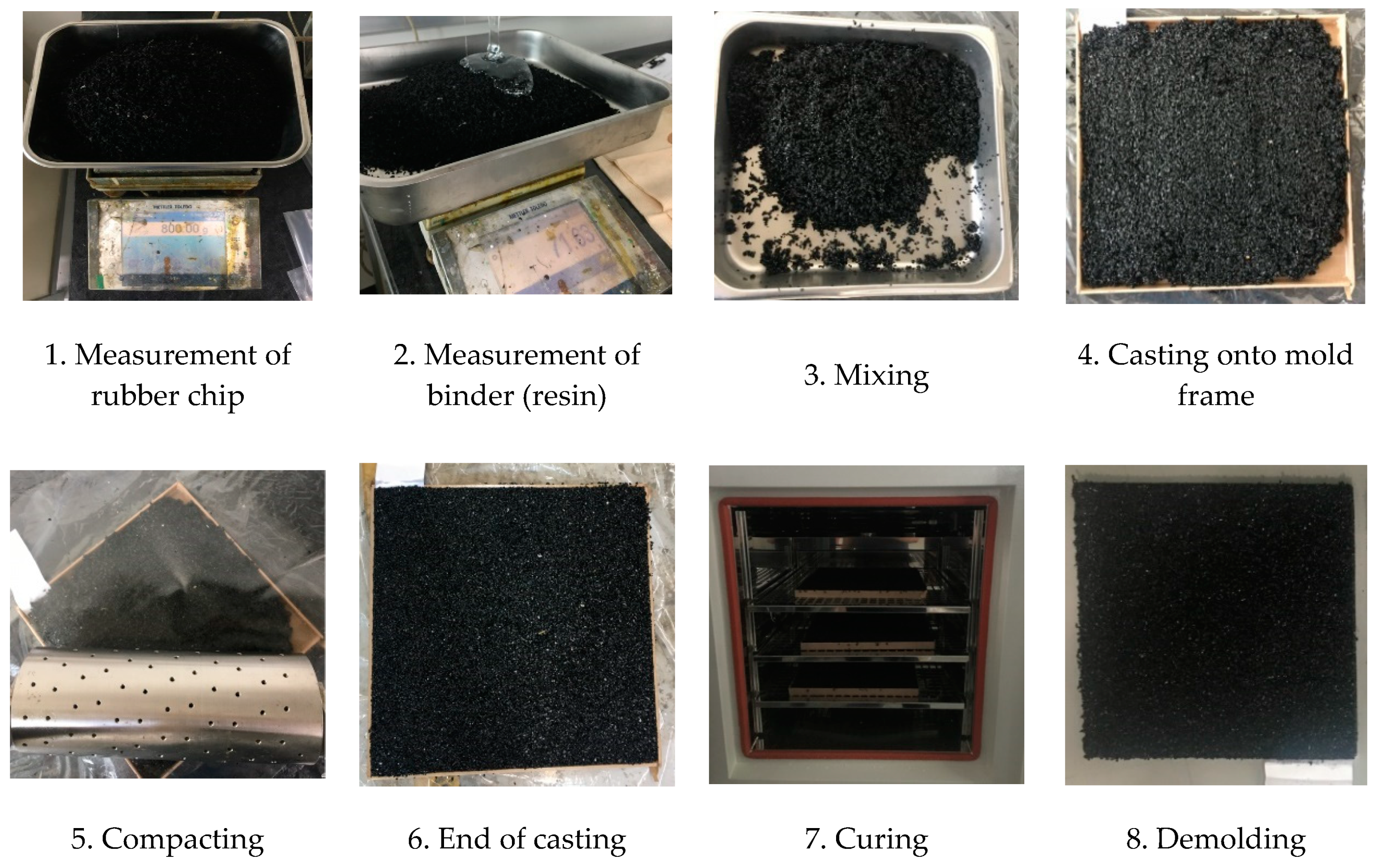

2. Experimental Program

2.1. Materials

2.2. Test Specimens and Variables

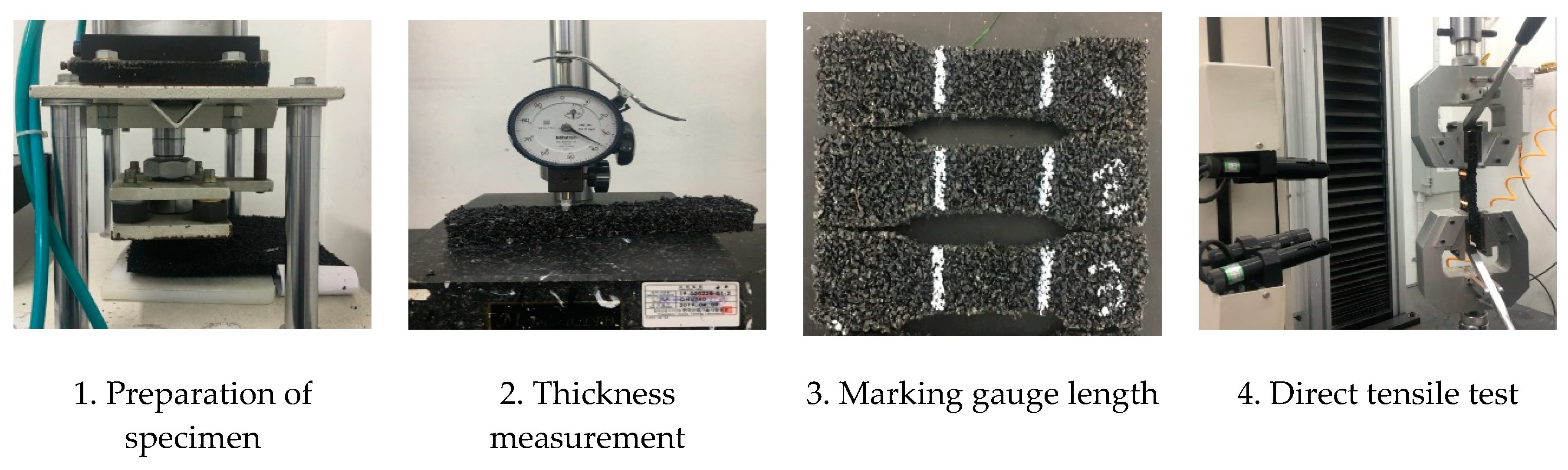

2.3. Test Setup and Procedure

2.3.1. Direct Tensile Test

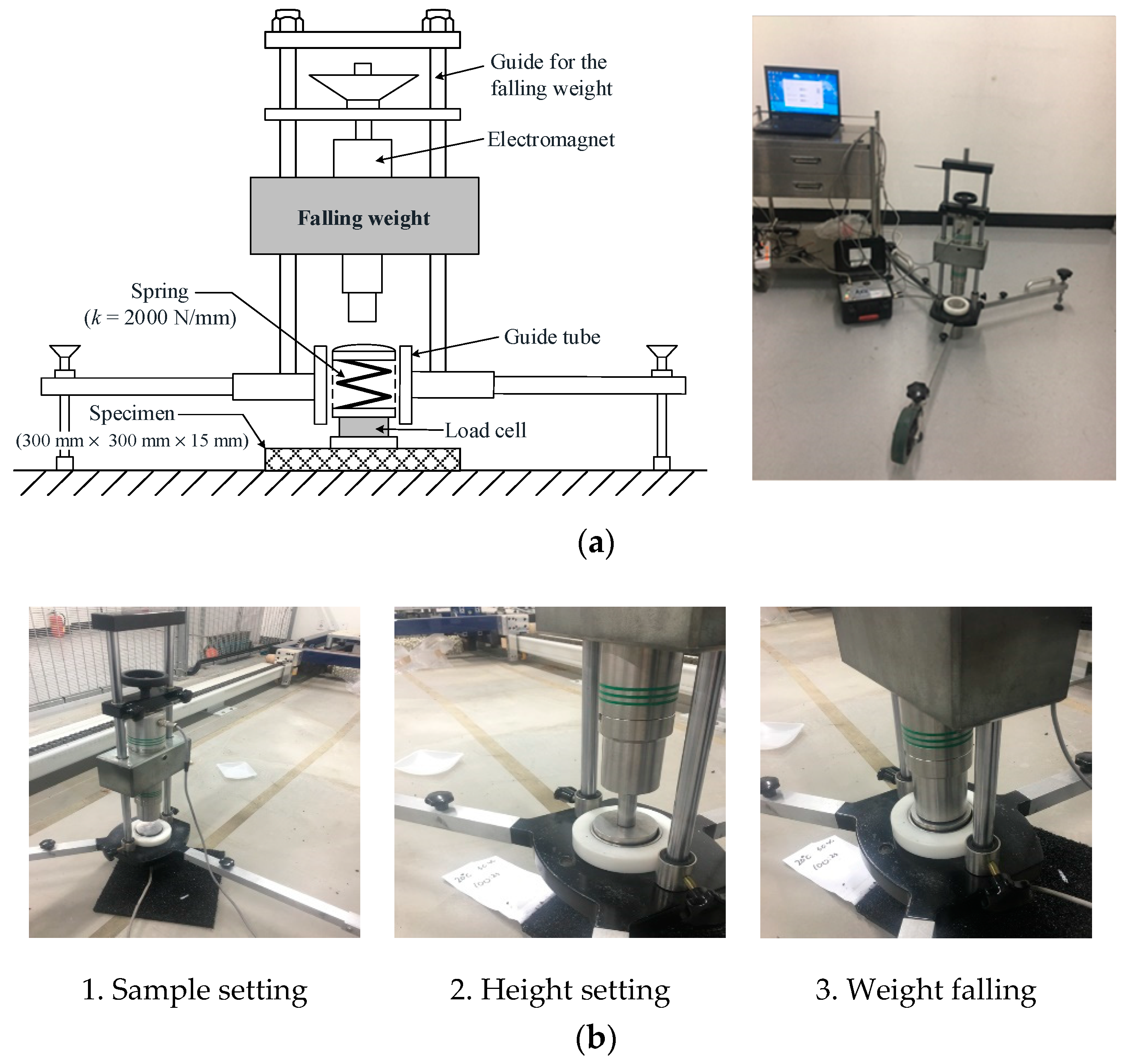

2.3.2. Shock Absorption Test

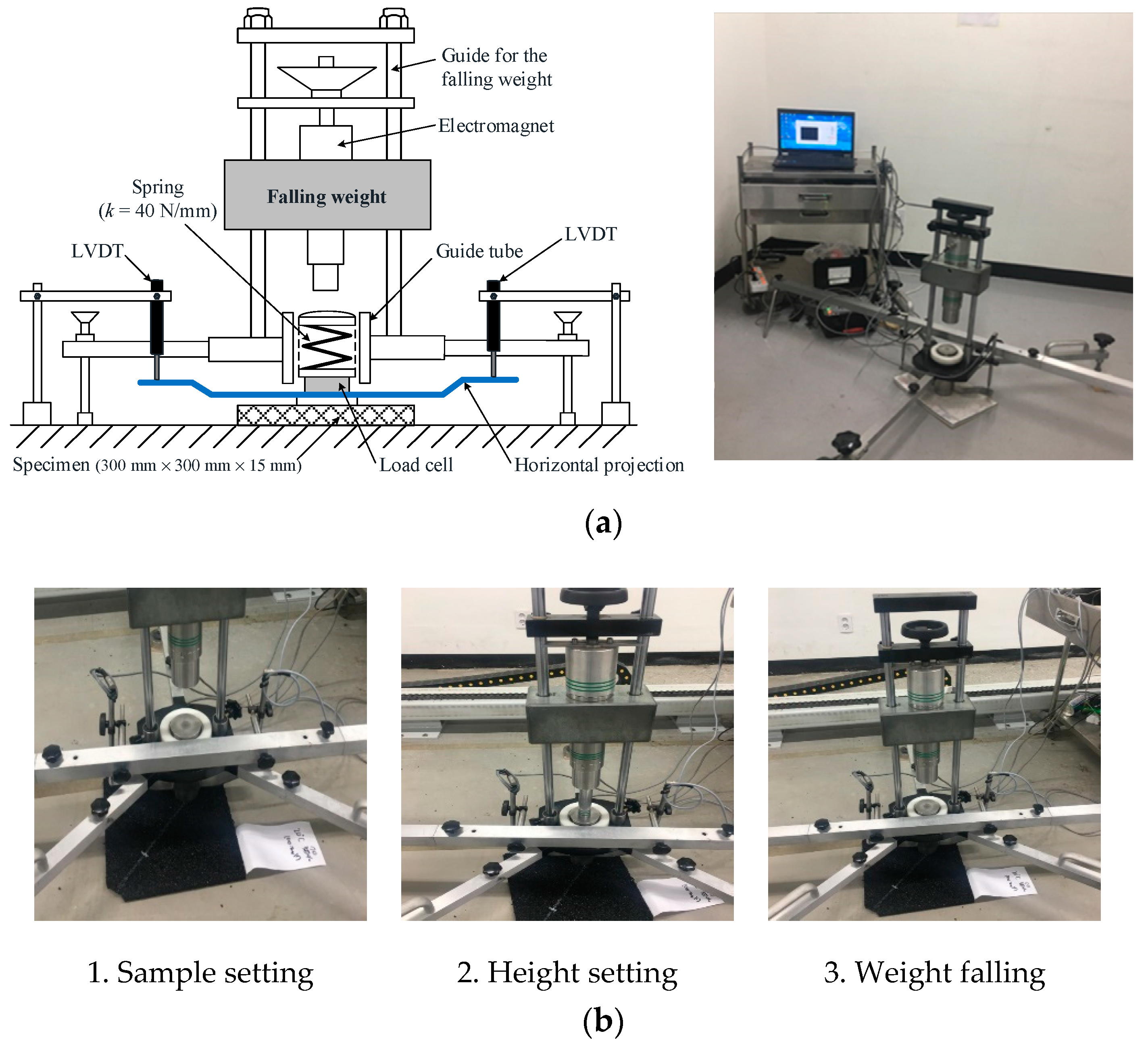

2.3.3. Vertical Deformation Test

3. Test Results and Discussion

3.1. Effects of the Number of Compactions

3.2. Effect of the Curing Age

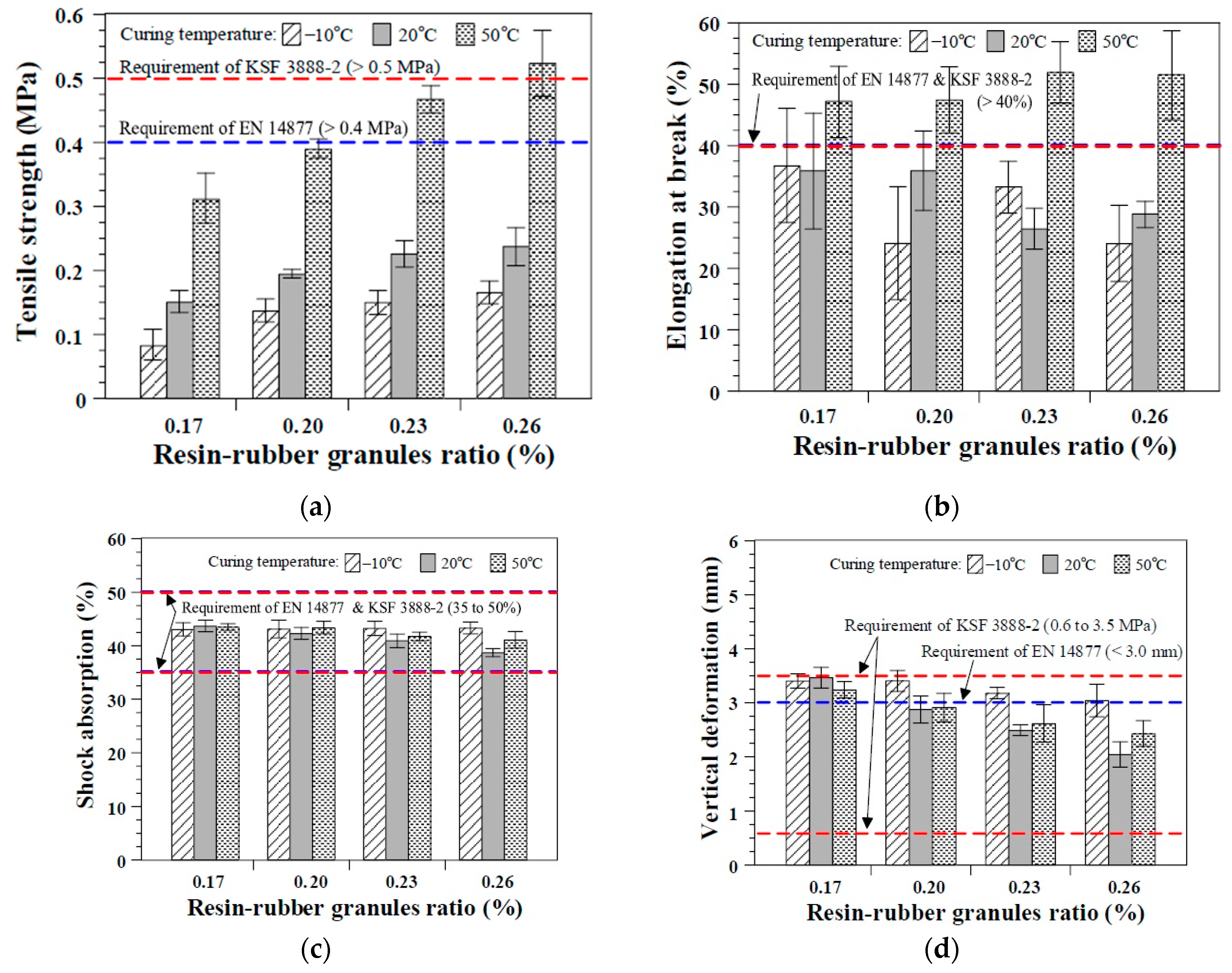

3.3. Effects of the Curing Temperature and Resin–Rubber Granule Ratio

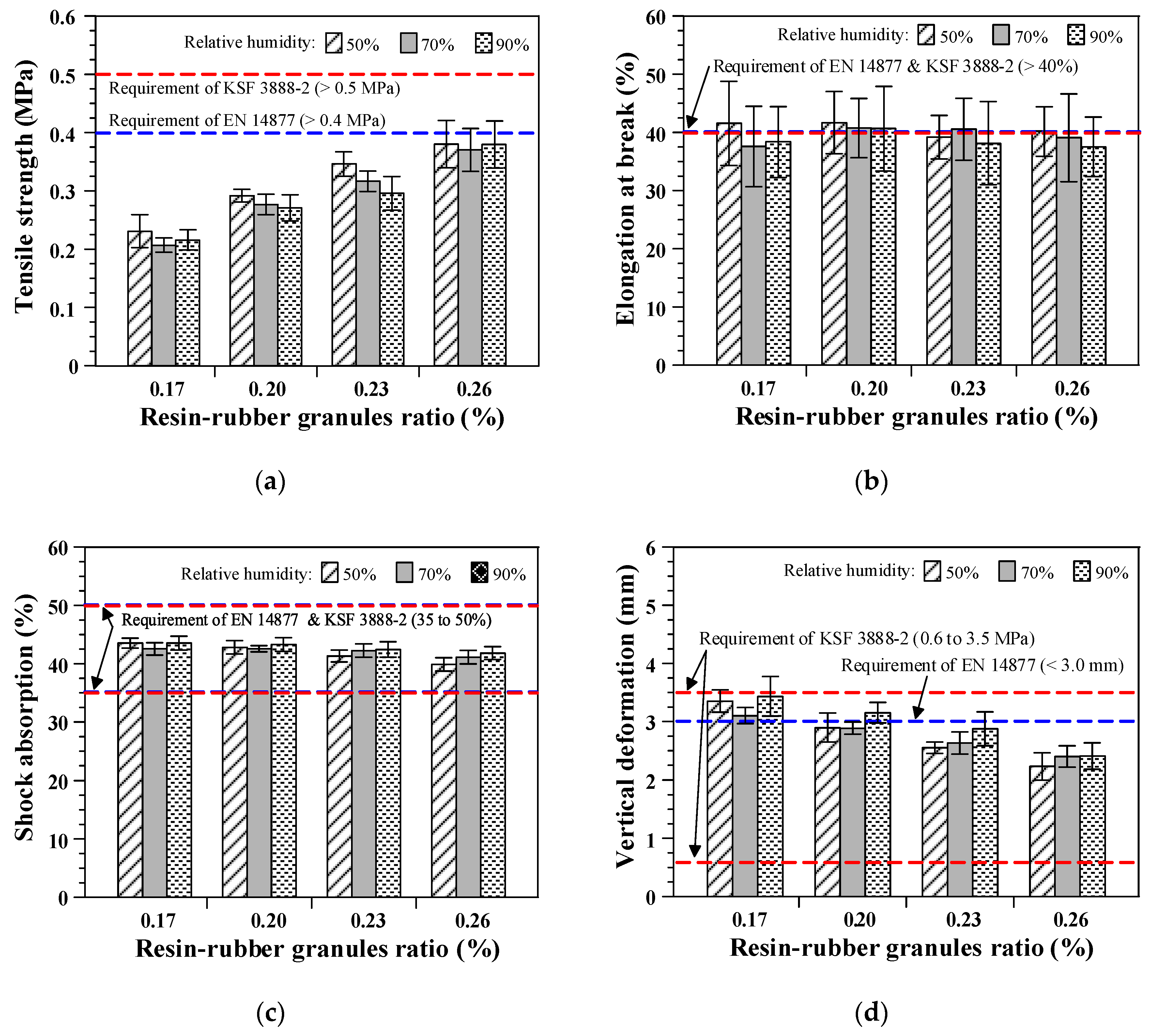

3.4. Effects of the Relative Humidity and Resin–Rubber Granule Ratio

4. Conclusions

- (1)

- The tensile strength increased to 163% when the number of compactions was 100, compared with that when the number of compaction cycles was 10. However, shock absorption and vertical deformation decreased by 82% and 77%, respectively, when the compaction number was 100 compared with those when the number of compactions was 10;

- (2)

- The tensile strength increased, whereas the elongation at break decreased with an increasing curing period owing to progressive hardening of the urethane resin. Furthermore, a higher curing temperature accelerated the hardening and strength development of urethane resin at an early age. The shock absorption and vertical deformation remained unchanged, regardless of the curing age;

- (3)

- The tensile properties, including both the tensile strength and elongation at break, significantly increased with increasing the curing temperature from 20 to 50 °C. However, the effects of the curing temperature on the shock absorption and vertical deformation of the elastic rubber layers were not significant;

- (4)

- The tensile strength improved, but the vertical deformation decreased, as the resin–rubber granule ratio increased. The elongation at break and shock absorption were not significantly affected by the amount of resin used for mixing;

- (5)

- The effects of the relative humidity conditions on the mechanical and dynamic behaviors of the elastic rubber layer with recycled SBR granules were not significant. A relative humidity of over 50% is sufficient for providing the moisture required for hardening the urethane binder;

- (6)

- The curing temperature has a more pronounced effect on the mechanical properties of the elastic rubber layer with recycled SBR granules than other parameters related to the making or curing of the elastic rubber layer;

- (7)

- Elastic rubber layers with SBR only satisfied the performance requirements specified in the standards for resin–rubber granule ratios above 23% and curing at 50 °C. Therefore, a sufficient amount of resin with a sufficiently high curing temperature is required to obtain reasonable tensile properties of the elastic rubber layer containing recycled SBR.

Author Contributions

Funding

Conflicts of Interest

References

- Benanti, M.; Andena, L.; Briatico-Vangosa, F.; Pavan, A. Viscoelastic behavior of athletics track surfaces in relation to their force reduction. Polym. Test. 2013, 32, 52–59. [Google Scholar] [CrossRef]

- Andena, L.; Ciancio, A.; Briatico-Vangosa, F.; Mariani, S.; Pavan, A. On the relationship between force reduction, loading rate and energy absorption in athletics tracks. Proceedings of the Institution of Mechanical Engineers, Part P. J. Sports Eng. Technol. 2018, 232, 71–78. [Google Scholar]

- Colino, E.; Sánchez-Sánchez, J.; García-Unanue, J.; Ubago-Guisado, E.; Haxaire, P.; Le Blan, A.; Gallardo, L. Validity and reliability of two standard test devices in assessing mechanical properties of different sport surfaces. Polym. Test. 2017, 62, 61–67. [Google Scholar] [CrossRef]

- Tagliabue, S.; Andena, L.; Pavan, A.; Marenghi, A.; Testa, E.; Frassine, R. Ageing in athletics tracks: A multi-technique experimental investigation. Polym. Test. 2018, 69, 293–301. [Google Scholar] [CrossRef]

- Kang, K.-W.; Lee, S.-P. An analysis for optimization of rubber granule layer in synthetic surfaced track using response surface methodology. J. Korea Acad. Ind. Coop. Soc. 2010, 11, 787–794. [Google Scholar]

- Park, W.-K. An analysis of coherence and resilience depending on materials mixing ratio in elastic landscape pavement. J. Korean Inst. Landsc. Archit. 2010, 38, 93–101. [Google Scholar]

- Hong, C.W. Examination of color difference in elastic pavement that uses EPDM chip using ultraviolet ray accelerated weathering test. J. Korean Soc. Civil. Eng. 2011, 31, 91–98. [Google Scholar]

- Park, D.-K.; Hong, Y.-J.; Jeong, K.-M.; Kim, J.-K. Development of rubber composite materials using waste EPDM. Elastom. Compos. 2012, 47, 121–128. [Google Scholar] [CrossRef] [Green Version]

- Park, J.-C. A Study on Elastic Pavement Materials Using Recycled Rubber Elastomers; Changwon National University: Changwon, Korea, 2012. [Google Scholar]

- Choi, S.-K.; Jun, M.-H.; Lee, D.-H. Study on the safety of playground flooring made of polyolefin foam waste and rubber paving. J. Korean Recycle. Constr. Resour. Inst. 2013, 1, 246–254. [Google Scholar] [CrossRef] [Green Version]

- Ko, H.-B.; Ko, M.-Y. An experimental study on the basic properties of elastic paving materials. J. Korea Acad. Ind. Coop. Soc. 2015, 16, 5021–5028. [Google Scholar]

- Choi, J.-J.; Lee, K.-H.; Moon, S.-K. Characteristics of elastic paving material made of sawdust and urethane resin mixture. J. Korea Acad. Ind. Coop. Soc. 2017, 18, 673–680. [Google Scholar]

- Fleming, P.; Young, C.; Carré, M. Mechanical testing and characterisation of sports surfaces. Sci. Eng. Sport Surf. 2015, 3, 26–69. [Google Scholar]

- Farhang, B.; Araghi, F.R.; Bahmani, A.; Moztarzadeh, F.; Shafieian, M. Landing impact analysis of sport surfaces using three-dimensional finite element model. Proceedings of the Institution of Mechanical Engineers, Part P. J. Sports Eng. Technol. 2015, 230, 180–185. [Google Scholar]

- KS M 6519:2018. Method of Analysis for Rubber Goods; Korean Standard Association: Seoul, Korea, 2018. [Google Scholar]

- KS F 3888-2:2016. Outdoor Sports Facilities-Elastic Paving Materials; Korean Standard Association: Seoul, Korea, 2016. [Google Scholar]

- World Athletics. Track and Field Facilities Manual; IAAF: Quai Antoine, Monaco, 2019. [Google Scholar]

- BS EN 12230:2003. Surfaces for Sports Areas—Determination of Tensile Properties of Synthetic Sports Surfaces; British Standards Institution: London, UK, 2003. [Google Scholar]

- Silva, R.; Rodrigues, J.; Pinto, V.; Ferreira, M.; Russo, R.; Pereira, C. Evaluation of shock absorption properties of rubber materials regarding footwear applications. Polym. Test. 2009, 28, 642–647. [Google Scholar] [CrossRef]

- BS EN 14808:2005. Surface for Sports Areas—Determination of Shock Absorption; British Standards Institution: London, UK, 2005. [Google Scholar]

- Shorten, M.; Himmelsbach, J. Shock attenuation of sports surfaces. In The Engineering of Sport IV: Proceedings of the 4th International Conference on The Engineering of Sport; Blackwell Science: Oxford, UK, 2002; pp. 1–5. [Google Scholar]

- BS EN 14809:2005. Surface for Sports Areas—Determination of Vertical Deformation; British Standards Institution: London, UK, 2005. [Google Scholar]

- Harrington, D.; Abdo, F.; Adaska, W.; Hazaree, C.V.; Ceylan, H.; Bektas, F. Guide for Roller-Compacted Concrete Pavements; National Concrete Pavement Technology Center Institute for Transportation Iowa State University: Ames, IA, USA, 2010. [Google Scholar]

- Chung, G.W.; Song, S.H.; Lee, S.W. Analysis of relationship between compressive strength and compaction ratio of roller-compacted concrete pavement. J. Korean Soc. Civil. Eng. 2016, 36, 1117–1123. [Google Scholar] [CrossRef] [Green Version]

- BS EN 14877:2013. Synthetic Surfaces for Outdoor Sports Areas–Specification; British Standards Institution: London, UK, 2013. [Google Scholar]

- Oertel, G. Polyurethane Handbook; Elsevier: New York, NY, USA, 1986; Volume 30, p. 51. [Google Scholar]

- Hepburn, C. Polyurethane Elastomers; Springer Science & Business Media: Cham, Switzerland, 2012. [Google Scholar]

- Kim, S.M. Study on the Preparation and Physical Properties of Polyurethane Adhesive; Pukyong National University: Busan, Korea, 2017. [Google Scholar]

| Specimen | Temperature (°C) | Relative Humidity (%) | Rubber Chip Weight (g) | Resin Weight (g) | Curing Period (Days) | Number of Compactions |

|---|---|---|---|---|---|---|

| 20-50-10T | 20 ± 2 | 50 ± 5 | 800 | 184 | 7 | 10 |

| 20-50-20T | 20 | |||||

| 20-50-30T | 30 | |||||

| 20-50-40T | 40 | |||||

| 20-50-50T | 50 | |||||

| 20-50-60T | 60 | |||||

| 20-50-80T | 80 | |||||

| 20-50-100T | 100 |

| Specimen | Temperature (°C) | Relative Humidity (%) | Rubber Chip Weight (g) | Resin Weight (g) | Curing Period (Days) | Number of Compactions |

|---|---|---|---|---|---|---|

| 20-50-1D | 20 ± 2 | 50 ± 5 | 800 | 184 | 1 | 40 |

| 20-50-3D | 3 | |||||

| 20-50-5D | 5 | |||||

| 50-50-1D | 50 ± 2 | 1 | ||||

| 50-50-3D | 3 | |||||

| 50-50-5D | 5 |

| Specimen | Temperature (°C) | Relative Humidity (%) | Rubber Chip Weight (g) | Resin Weight (g) | Curing Period (Days) | Number of Compactions |

|---|---|---|---|---|---|---|

| −10-0-17B | −10 ± 2 | - | 800 | 136 | 7 | 40 |

| −10-0-20B | 160 | |||||

| −10-0-23B | 184 | |||||

| −10-0-26B | 208 | |||||

| 20-50-17B | 20 ± 2 | 50 ± 5 | 136 | |||

| 20-50-20B | 160 | |||||

| 20-50-23B | 184 | |||||

| 20-50-26B | 208 | |||||

| 20-70-17B | 70 ± 5 | 136 | ||||

| 20-70-20B | 160 | |||||

| 20-70-23B | 184 | |||||

| 20-70-26B | 208 | |||||

| 20-90-17B | 90 ± 5 | 136 | ||||

| 20-90-20B | 160 | |||||

| 20-90-23B | 184 | |||||

| 20-90-26B | 208 | |||||

| 50-50-17B | 50 ± 2 | 50 ± 5 | 136 | |||

| 50-50-20B | 160 | |||||

| 50-50-23B | 184 | |||||

| 50-50-26B | 208 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Shin, H.-O.; Yoo, D.-Y. Mechanical and Dynamic Behavior of an Elastic Rubber Layer with Recycled Styrene-Butadiene Rubber Granules. Polymers 2020, 12, 3022. https://doi.org/10.3390/polym12123022

Kim S, Shin H-O, Yoo D-Y. Mechanical and Dynamic Behavior of an Elastic Rubber Layer with Recycled Styrene-Butadiene Rubber Granules. Polymers. 2020; 12(12):3022. https://doi.org/10.3390/polym12123022

Chicago/Turabian StyleKim, Seongdo, Hyun-Oh Shin, and Doo-Yeol Yoo. 2020. "Mechanical and Dynamic Behavior of an Elastic Rubber Layer with Recycled Styrene-Butadiene Rubber Granules" Polymers 12, no. 12: 3022. https://doi.org/10.3390/polym12123022

APA StyleKim, S., Shin, H.-O., & Yoo, D.-Y. (2020). Mechanical and Dynamic Behavior of an Elastic Rubber Layer with Recycled Styrene-Butadiene Rubber Granules. Polymers, 12(12), 3022. https://doi.org/10.3390/polym12123022