Electro-active Variable-Stiffness Corrugated Structure Based on Shape-Memory Polymer Composite

Abstract

:1. Introduction

2. Experimental Section

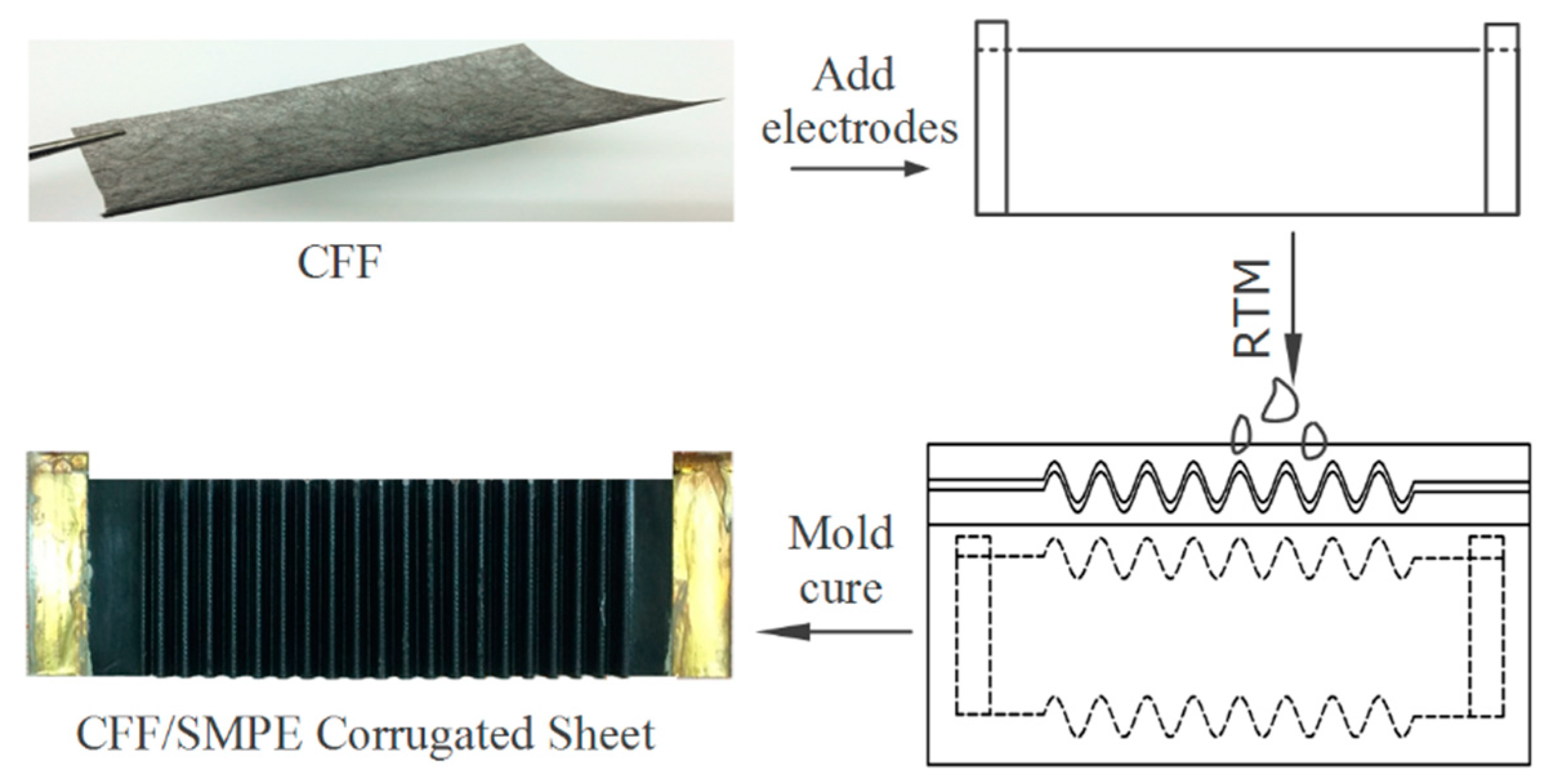

2.1. Fabrication of Corrugated Sheets

2.2. Characterization Methods

2.2.1. Dynamic Mechanical Properties

2.2.2. Quasi-Static Mechanical Properties

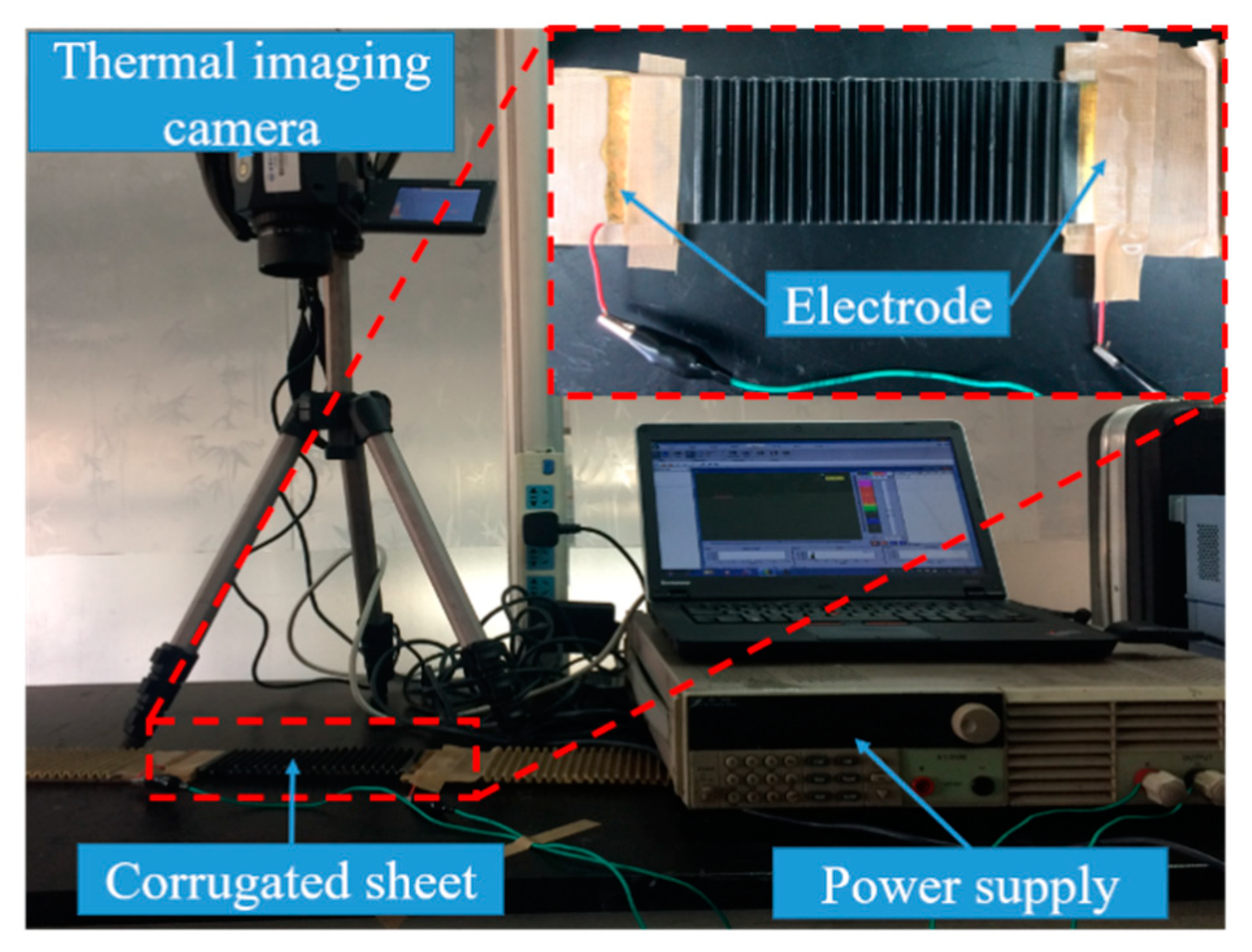

2.2.3. Temperature Distribution

2.2.4. Shape-Memory Effect

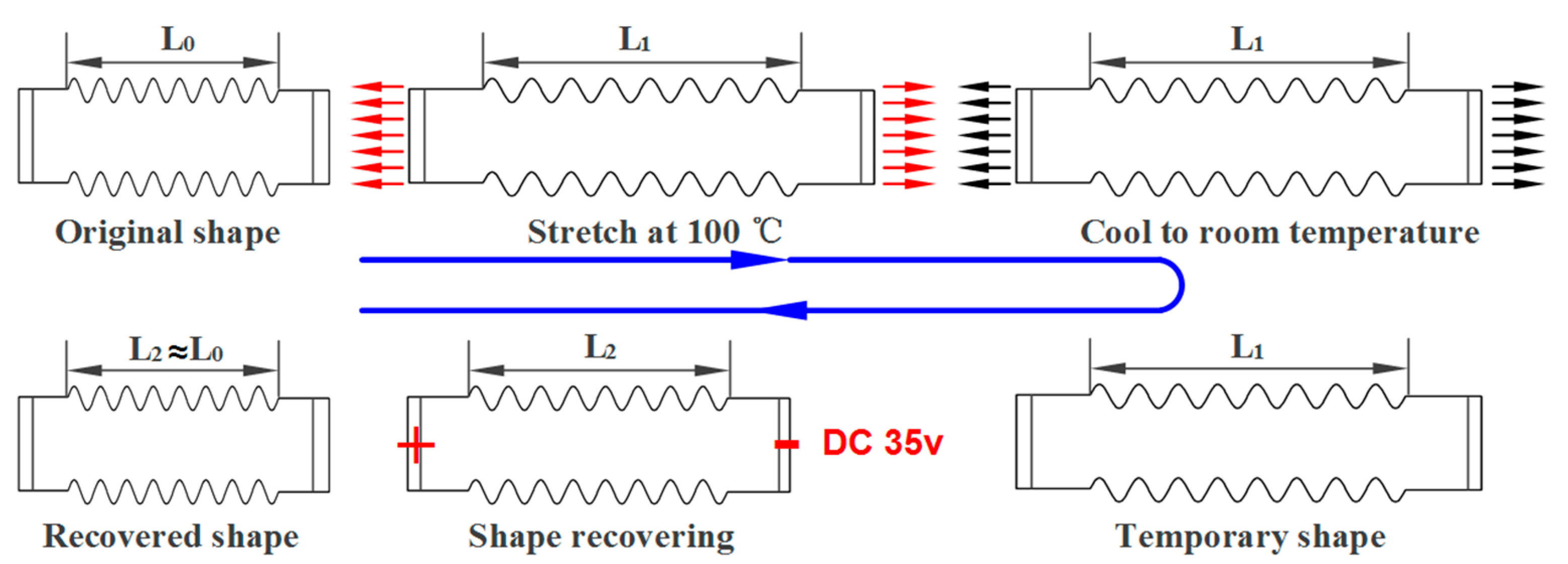

3. Results and Discussion

3.1. Thermal Mechanical Properties

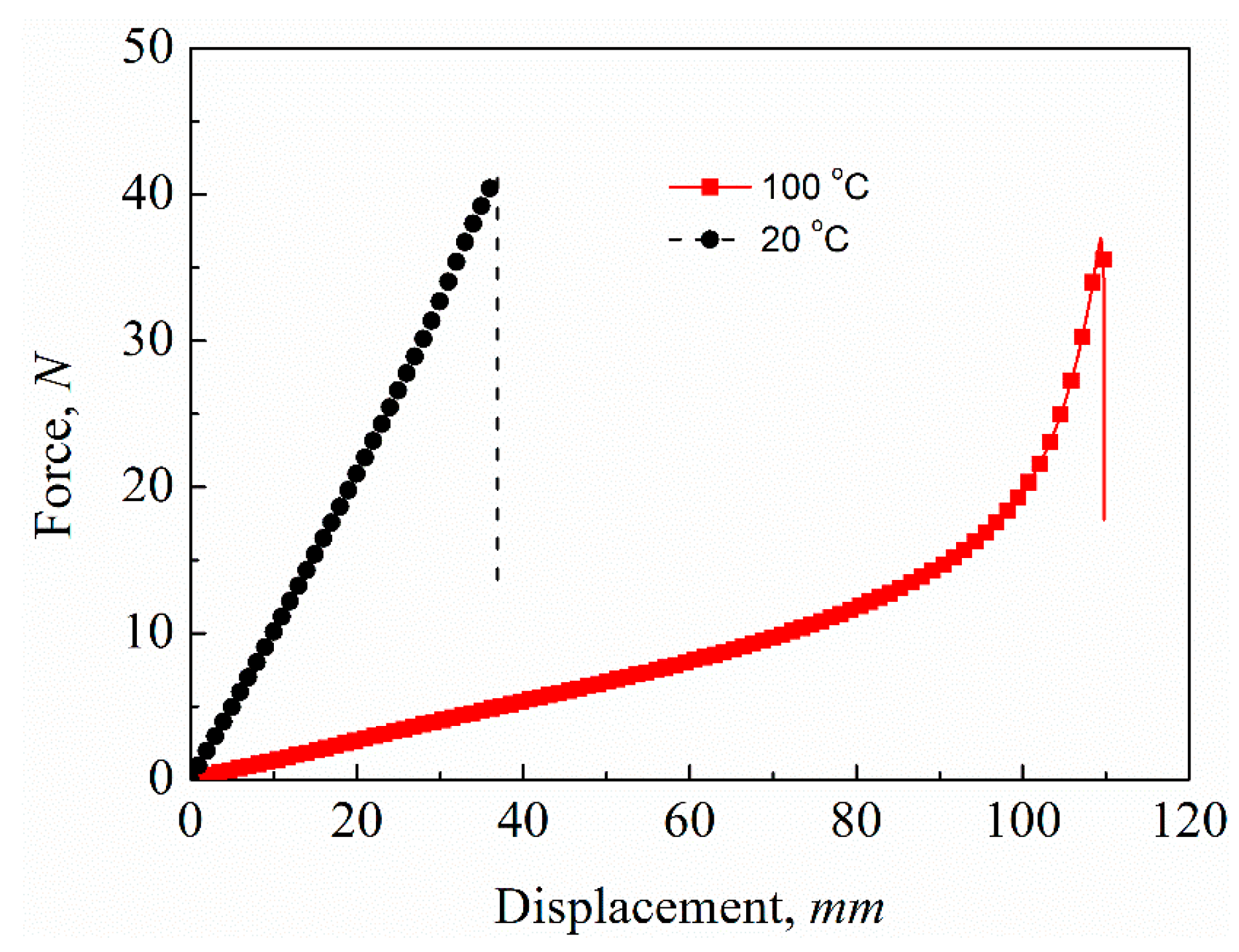

3.2. Quasi-Static Mechanical Properties

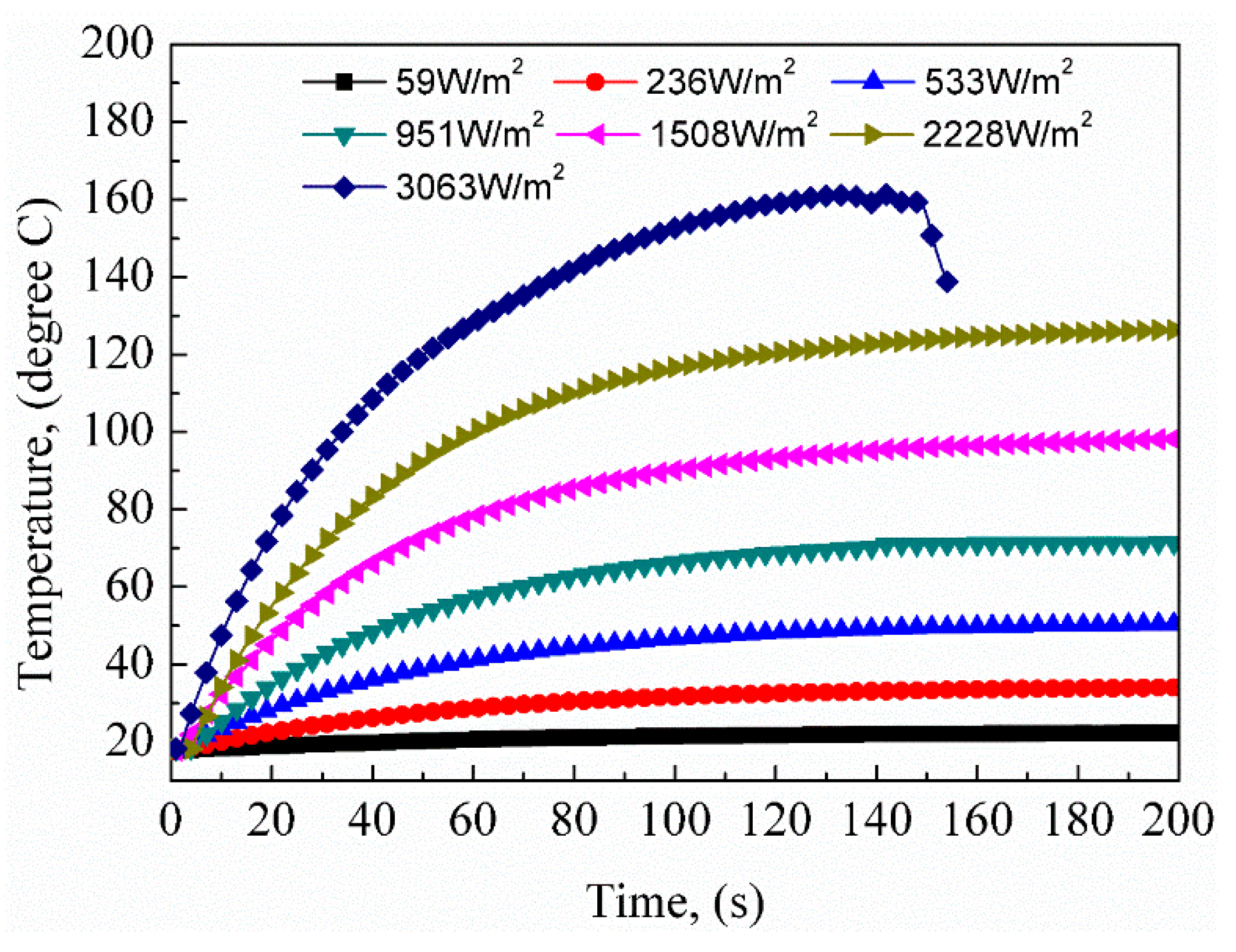

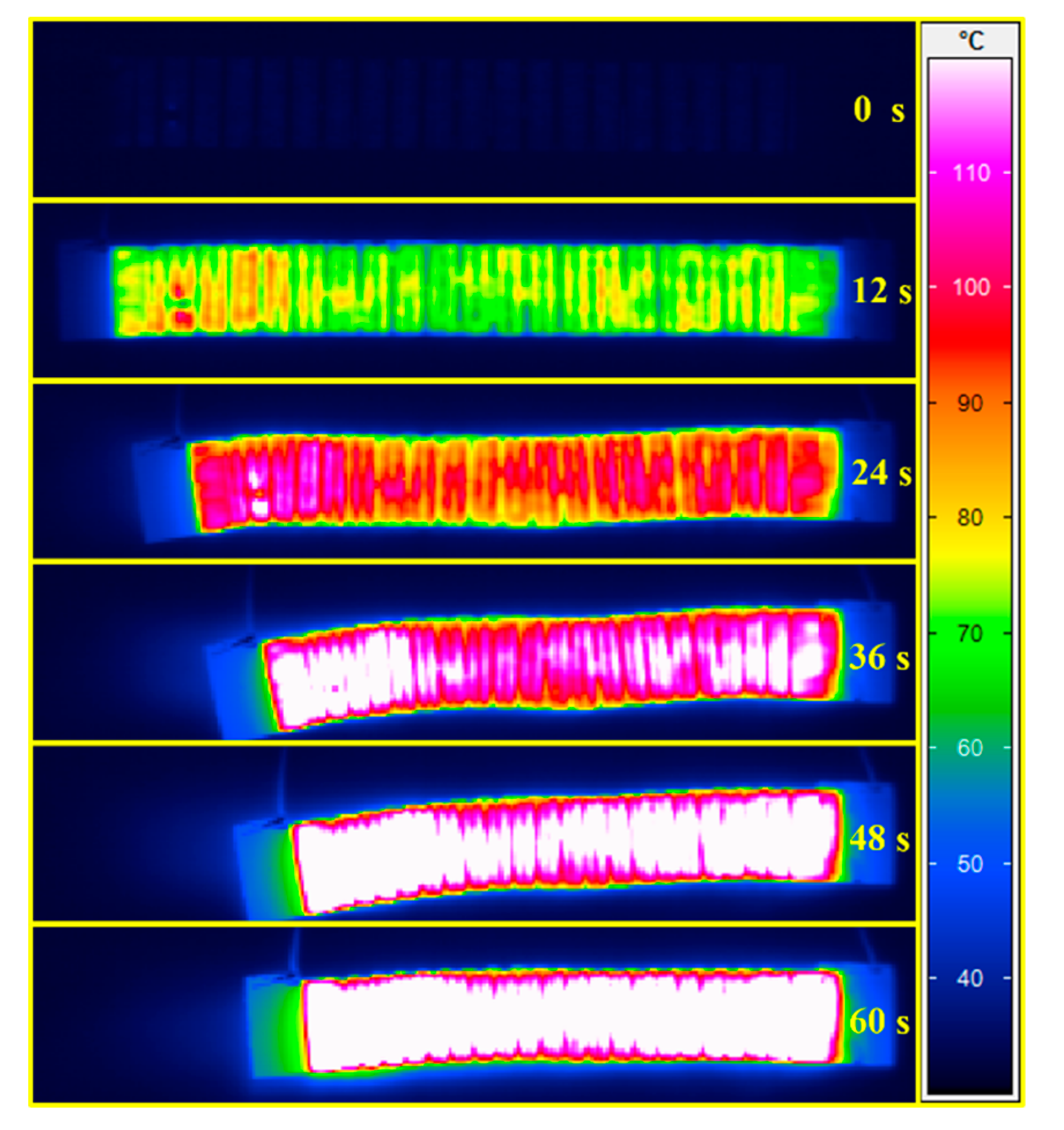

3.3. Electrical Heating Performance

3.4. Shape-Memory Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Armando, R. Morphing Aircraft Technology Survey. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8 January 2007; p. 1258. [Google Scholar]

- Barbarino, S.; Bilgen, O.; Ajaj, R.M.; Friswell, M.I.; Inman, D.J. A review of morphing aircraft. J. Intell. Mater. Syst. Struct. 2011, 22, 823–877. [Google Scholar] [CrossRef]

- Jha, A.K.; Kudva, J.N. Morphing aircraft concepts, classifications, and challenges. In Proceedings of the SPIE—Smart Structures and Materials 2004: Industrial and Commercial Applications of Smart Structures Technologies, San Diego, CA, USA, 29 July 2004; pp. 213–224. [Google Scholar]

- Weisshaar, T.A. Morphing Aircraft Systems: Historical Perspectives and Future Challenges. J. Aircr. 2007, 50, 337–353. [Google Scholar] [CrossRef]

- Vasista, S.; Riemenschneider, J.; Mendrock, T.; Monner, H.P. Pressure-driven morphing devices for 3D shape changes with multiple degrees-of-freedom. In Proceedings of the ASME 2018 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS 2018, San Antonio, TX, USA, 10–12 September 2018. [Google Scholar]

- Kuder, I.K.; Arrieta, A.F.; Raither, W.E.; Ermanni, P. Variable stiffness material and structural concepts for morphing applications. Prog. Aerosp. Sci. 2013, 63, 33–55. [Google Scholar] [CrossRef]

- Keihl, M.M.; Bortolin, R.S.; Sanders, B.; Joshi, S.; Tidwell, Z. Mechanical properties of shape memory polymers for morphing aircraft applications. In Proceedings of the SPIE—Smart Structures and Materials 2005: Industrial and Commercial Applications of Smart Structures Technologies; Society of Photo Optical: Bellingham, WA, USA, 2005; pp. 143–151. [Google Scholar]

- Hemmelgarn, C.D.; Havens, E. Adaptive wing structures. In Proceedings of the SPIE-Smart Structures and Materials 2005: Industrial and Commercial Applications of Smart Structures Technologies; Society of Photo Optical: Bellingham, WA, USA, 2005; pp. 225–233. [Google Scholar]

- Sun, J.; Liu, Y.; Leng, J. Mechanical properties of shape memory polymer composites enhanced by elastic fibers and their application in variable stiffness morphing skins. J. Intell. Mater. Syst. Struct. 2015, 26, 2020–2027. [Google Scholar] [CrossRef]

- McKnight, G.; Doty, R.; Keefe, A.; Herrera, G.; Henry, C. Segmented reinforcement variable stiffness materials for reconfigurable surfaces. J. Intell. Mater. Syst. Struct. 2010, 21, 1783–1793. [Google Scholar] [CrossRef]

- Kumar, K.S.; Biju, R.; Nair, C.R. Progress in shape memory epoxy resins. React. Funct. Polym. 2013, 73, 421–430. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Meng, H.; Li, G. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Huang, R.; Qi, X.; Dong, P.; Fu, Q. Facile preparation of rapidly electro-active shape memory thermoplastic polyurethane/polylactide blends via phase morphology control and incorporation of conductive fillers. Polymer 2017, 114, 28–35. [Google Scholar] [CrossRef]

- Koerner, H.; Price, G.; Pearce, N.A.; Alexander, M.; Vaia, R.A. Remotely actuated polymer nanocomposites[mdash]stress-recovery of carbon-nanotube-filled thermoplastic elastomers. Nat. Mater. 2004, 3, 115–120. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Ansari, R. Thermal conductivity of shape memory polymer nanocomposites containing carbon nanotubes: A micromechanical approach. Compos. Pt. B-Eng. 2019, 162, 167–177. [Google Scholar] [CrossRef]

- Tang, Z.H.; Kang, H.L.; Wei, Q.Y.; Guo, B.C.; Zhang, L.Q.; Jia, D.M. Incorporation of graphene into polyester/carbon nanofibers composites for better multi-stimuli responsive shape memory performances. Carbon 2013, 64, 487–498. [Google Scholar] [CrossRef]

- Wang, E.L.; Wu, Y.L.; Islam, M.Z.; Dong, Y.B.; Zhu, Y.F.; Liu, F.Y.; Fu, Y.Q.; Xu, Z.H.; Hu, N. A novel reduced graphene oxide/epoxy sandwich structure composite film with thermo-, electro- and light-responsive shape memory effect. Mater. Lett. 2019, 238, 54–57. [Google Scholar] [CrossRef]

- Huang, C.J.; Peng, J.S.; Cheng, Y.R.; Zhao, Q.; Du, Y.; Dou, S.X.; Tomsia, A.P.; Wagner, H.D.; Jiang, L.; Cheng, Q.F. Ultratough nacre-inspired epoxy-graphene composites with shape memory properties. J. Mater. Chem. A 2019, 7, 2787–2794. [Google Scholar] [CrossRef]

- Schmidt, A.M. Electromagnetic activation of shape memory polymer networks containing magnetic nanoparticles. Macromol. Rapid Commun. 2006, 27, 1168–1172. [Google Scholar] [CrossRef]

- Arun, D.I.; Kumar, K.S.S.; Kumar, B.S.; Chakravarthy, P.; Dona, M.; Santhosh, B. High glass-transition polyurethane-carbon black electro-active shape memory nanocomposite for aerospace systems. Mater. Sci. Technol. 2019, 35, 596–605. [Google Scholar] [CrossRef]

- Du, J.; Zhang, Z.L.; Liu, D.B.; Ren, T.B.; Wan, D.C.; Pu, H.T. Triple-stimuli responsive shape memory effect of novel polyolefin elastomer/lauric acid/carbon black nanocomposites. Compos. Sci. Technol. 2019, 169, 45–51. [Google Scholar] [CrossRef]

- Leng, J.; Huang, W.; Lan, X.; Liu, Y.; Du, S. Significantly reducing electrical resistivity by forming conductive Ni chains in a polyurethane shape-memory polymer/carbon-black composite. Appl. Phys. Lett. 2008, 92, 204101. [Google Scholar] [CrossRef]

- Lu, H.B.; Gou, J.H. Fabrication and electroactive responsive behavior of shape-memory nanocomposite incorporated with self-assembled multiwalled carbon nanotube nanopaper. Polym. Adv. Technol. 2012, 23, 1529–1535. [Google Scholar] [CrossRef]

- Kwok, N.; Hahn, H.T. Resistance Heating for Self-healing Composites. J. Compos. Mater. 2007, 41, 1635–1654. [Google Scholar] [CrossRef]

- Perkins, D.A.; Reed, J.L.; Havens, E. Morphing wing structures for loitering air vehicles. In Proceedings of the 45th AIAA Structures, Structural Dynamics & Materials Conference, Palm Springs, CA, USA, 19–22 April 2004; p. 1888. [Google Scholar]

- Bye, D.R.; McClure, P.D. Design of a morphing vehicle. In Proceedings of the 48th AIAA Structures Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007; p. 1728. [Google Scholar]

- Gong, X.; Liu, L.; Liu, Y.; Leng, J. An electrical-heating and self-sensing shape memory polymer composite incorporated with carbon fiber felt. Smart Mater. Struct. 2016, 25, 035036. [Google Scholar] [CrossRef]

- Dayyani, I.; Shaw, A.D.; Saavedra Flores, E.I.; Friswell, M.I. The Mechanics of Composite Corrugated Structures: A Review with Applications in Morphing Aircraft. Compos. Struct. 2015, 133, 358–380. [Google Scholar] [CrossRef] [Green Version]

- Yokozeki, T.; Takeda, S.-i.; Ogasawara, T.; Ishikawa, T. Mechanical properties of corrugated composites for candidate materials of flexible wing structures. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1578–1586. [Google Scholar] [CrossRef]

- Wang, C.; Xia, Y.; Friswell, M.I.; Saavedra Flores, E.I. Predicting global strain limits for corrugated panels. Compos. Struct. 2020, 231, 111472. [Google Scholar] [CrossRef]

- Golzar, M.; Ghabezi, P. Corrugated Composite Skins. Mech. Compos. Mater. 2014, 50, 137–148. [Google Scholar] [CrossRef]

- Thill, C.; Etches, J.; Bond, I.; Potter, K.; Weaver, P. Corrugated composite structures for aircraft morphing skin applications. In Proceedings of the 18th International Conference of Adaptive Structures and Technologies, Ottawa, ON, Canada; Curran Associates Inc: Nice, France, 2008. [Google Scholar]

- Dayyani, I.; Friswell, M.I.; Khodaparast, H.H.; Woods, B.K. The Design of a Corrugated Skin for the FishBAC Compliant Structure. In Proceedings of the 22nd AIAA/ASME/AHS Adaptive Structures Conference—SciTech Forum and Exposition 2014, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- Dayyani, I.; Friswell, M.I.; Ziaei-Rad, S.; Flores, E.I.S. Equivalent models of composite corrugated cores with elastomeric coatings for morphing structures. Compos. Struct. 2013, 104, 281–292. [Google Scholar] [CrossRef]

- Thill, C.; Etches, J.A.; Bond, I.P.; Potter, K.D.; Weaver, P.M.; Wisnom, M.R. Investigation of trapezoidal corrugated aramid/epoxy laminates under large tensile displacements transverse to the corrugation direction. Compos. Part A Appl. Sci. Manuf. 2010, 41, 168–176. [Google Scholar] [CrossRef]

- Kharati-koopaee, M.; Fallahzadeh-abarghooee, M. Effect of corrugated skins on the aerodynamic performance of the cambered airfoils. Eng. Comput. (Swans. Wales) 2018, 35, 1567–1582. [Google Scholar] [CrossRef]

- Takahashi, H.; Yokozeki, T.; Hirano, Y. Development of variable camber wing with morphing leading and trailing sections using corrugated structures. J. Intell. Mater. Syst. Struct. 2016, 27, 2827–2836. [Google Scholar] [CrossRef]

- Dayyani, I.; Khodaparast, H.H.; Woods, B.K.S.; Friswell, M.I. The design of a coated composite corrugated skin for the camber morphing airfoil. J. Intell. Mater. Syst. Struct. 2015, 26, 1592–1608. [Google Scholar] [CrossRef]

- Xia, Y.; Ajaj, R.M.; Friswell, M.I. Design and Optimisation of Composite Corrugated Skin for a Span Morphing Wing. In Proceedings of the 22nd AIAA/ASME/AHS Adaptive Structures Conference, National Harbor, MD, USA, 13–17 January 2014; p. 0762. [Google Scholar]

- Ursache, N.M.; Melin, T.; Isikveren, A.T.; Friswell, M.I. Technology Integration for Active Poly-Morphing Winglets Development. In Proceedings of the ASME 2008 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Ellicott City, MD, USA, 28–30 October 2008; pp. 775–782. [Google Scholar]

- Thill, C.; Etches, J.A.; Bond, I.P.; Potter, K.D.; Weaver, P.M. Composite corrugated structures for morphing wing skin applications. Smart Mater. Struct. 2010, 19, 124009. [Google Scholar] [CrossRef]

- Leng, J.; Wu, X.; Liu, Y. Effect of a linear monomer on the thermomechanical properties of epoxy shape-memory polymer. Smart Mater. Struct. 2009, 18, 095031. [Google Scholar] [CrossRef]

- Xie, F.; Huang, C.; Wang, F.; Huang, L.; Weiss, R.; Leng, J.; Liu, Y. Carboxyl-terminated polybutadiene–poly (styrene-co-4-vinylpyridine) supramolecular thermoplastic elastomers and their shape memory behavior. Macromolecules 2016, 49, 7322–7330. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Agarwal, G.; Patnaik, A.; Sharma, R.K. Comparative investigations on three-body abrasive wear behavior of long and short glass fiber-reinforced epoxy composites. Adv. Compos. Mater. 2014, 23, 293–317. [Google Scholar] [CrossRef]

- George, J.; Bhagawan, S.; Thomas, S. Thermogravimetric and dynamic mechanical thermal analysis of pineapple fibre reinforced polyethylene composites. J. Therm. Anal. Calorim. 1996, 47, 1121–1140. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Hassan, A.; Rahman, N.A.; Yahya, R. Extrusion and injection-molding of glass fiber/MAPP/polypropylene: Effect of coupling agent on DSC, DMA, and mechanical properties. J. Reinf. Plast. Compos. 2011, 30, 1223–1232. [Google Scholar] [CrossRef]

- López-Manchado, M.A.; Biagiotti, J.; Kenny, J.M. Comparative study of the effects of different fibers on the processing and properties of polypropylene matrix composites. J. Thermoplast. Compos. Mater. 2002, 15, 337–353. [Google Scholar] [CrossRef]

- Gong, X.; Liu, L.; Scarpa, F.; Leng, J.; Liu, Y. Variable stiffness corrugated composite structure with shape memory polymer for morphing skin applications. Smart Mater. Struct. 2017, 26, 035052. [Google Scholar] [CrossRef] [Green Version]

| Temperature (°C) | Tensile Stiffness (N/mm) | Force at Break (N) | Displacement at Break (mm) |

|---|---|---|---|

| 20 °C | 1.04 ± 0.06 | 41.59 ± 4.99 | 36.36 ± 2.27 |

| 100 °C | 0.15 ± 0.03 | 36.74 ± 1.37 | 108.39 ± 1.19 |

| Temperature (°C) | Bending Stiffness (N∙m2) | Force at Break (N) | Displacement at Break (mm) |

|---|---|---|---|

| 20 °C | 0.412 ± 0.016 | 151.76 ± 3.34 | 2.28 ± 0.06 |

| 100 °C | 0.076 ± 0.001 | 18.00 ± 1.90 | 6.15 ± 1.58 |

| DC Voltage (V) | Heat Flux Density (W/m2) | Equilibrium Temperature (°C) | Heat Time (s) |

|---|---|---|---|

| 5 | 59 | 23 ± 1.6 | 100 ± 8.4 |

| 10 | 236 | 32 ± 3.7 | 105 ± 5.4 |

| 15 | 533 | 49 ± 2.1 | 116 ± 8.0 |

| 20 | 951 | 67 ± 2.5 | 123 ± 8.2 |

| 25 | 1508 | 92 ± 5.7 | 132 ± 7.3 |

| 30 | 2228 | 123 ± 6.7 | 143 ± 13.1 |

| 35 | 3063 | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, X.; Xie, F.; Liu, L.; Liu, Y.; Leng, J. Electro-active Variable-Stiffness Corrugated Structure Based on Shape-Memory Polymer Composite. Polymers 2020, 12, 387. https://doi.org/10.3390/polym12020387

Gong X, Xie F, Liu L, Liu Y, Leng J. Electro-active Variable-Stiffness Corrugated Structure Based on Shape-Memory Polymer Composite. Polymers. 2020; 12(2):387. https://doi.org/10.3390/polym12020387

Chicago/Turabian StyleGong, Xiaobo, Fang Xie, Liwu Liu, Yanju Liu, and Jinsong Leng. 2020. "Electro-active Variable-Stiffness Corrugated Structure Based on Shape-Memory Polymer Composite" Polymers 12, no. 2: 387. https://doi.org/10.3390/polym12020387

APA StyleGong, X., Xie, F., Liu, L., Liu, Y., & Leng, J. (2020). Electro-active Variable-Stiffness Corrugated Structure Based on Shape-Memory Polymer Composite. Polymers, 12(2), 387. https://doi.org/10.3390/polym12020387