Sound Absorption Properties of Perforated Recycled Polyurethane Foams Reinforced with Woven Fabric

Abstract

:1. Introduction

2. Theoretical Background

2.1. Johnson–Champoux–Allard Model

Estimation of JCA Parameters

2.2. Olny and Boutin Model

2.3. Pieren’s Model

2.4. Delany and Bazley Model

3. Numerical Model for Porous Media

4. Materials and Methods

4.1. Polyurethane Foam and Textile Fabric Materials

4.2. Drilling Configurations and Methods

4.3. Experimental Methodology

4.3.1. Sound Absorption Coefficient

4.3.2. Airflow Resistivity

5. Results and Discussion

5.1. Effect of Perforation Rate and Aperture Size On the Sound Absorption

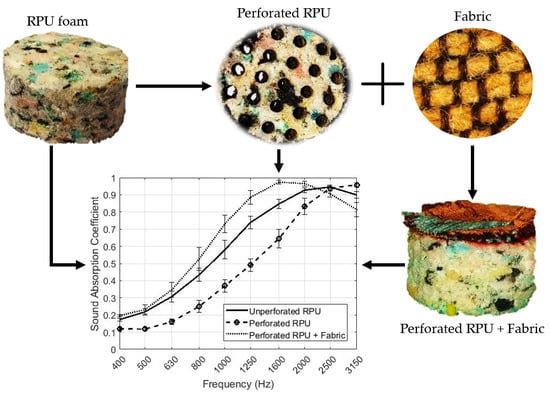

5.2. Effect of the Textile Fabric over a RPU Foam on Acoustic Absorption

5.3. Comparison of Predicted and Measured Values

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Berglund, B.; Lindvall, T.; Schwela, D.H. World Health Organization. Guidelines for community noise; WHO: Geneva, Switzerland, 1999. [Google Scholar]

- Hamernik, R.P.; Ahroon, W.A. Interrupted noise exposures: Threshold shift dynamics and permanent effects. J. Acoust. Soc. Am. 1998, 103, 3478–3488. [Google Scholar] [CrossRef] [PubMed]

- Ramis, J.; Alba, J.; del Rey, R.; Escuder, E.; Sanchís, V.J. New absorbent material acoustic base on kenaf’s fiber. Materiales de Construcción 2010, 60, 133–143. [Google Scholar] [CrossRef]

- Ramis, J.; del Rey, R.; Alba, J.; Godinho, L.; Carbajo, J. A model for acoustic absorbent materials derived from coconut fiber. Materiales de construcción 2014, 64, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Rey Tormos, R.; Alba Fernández, J.; Uris Martínez, A.; Candelas Valiente, P. WOOL4BUILD: Improved isolation material for eco-building based on natural wool. Revista de Acústica 2017, 48, 3–10. [Google Scholar]

- Atiénzar, R.; Bonet, M.Á.; Payà, J.; del Rey, R.; Picó, R. Sound absorption of doped cotton textile fabrics with microcapsules. Revista de Acústica 2019, 50, 20–31. [Google Scholar]

- Yang, W.; Dong, Q.; Liu, S.; Xie, H.; Liu, L.; Li, J. Recycling and Disposal Methods for Polyurethane Foam Wastes. Procedia Environ. Sci. 2012, 16, 167–175. [Google Scholar] [CrossRef]

- Gama, N.; Silva, R.; Carvalho, A.; Ferreira, A.; Barros-Timmons, A. Sound absorption properties of polyurethane foams derived from crude glycerol and liquefied coffee grounds polyol. Polym. Test. 2017, 62, 13–22. [Google Scholar] [CrossRef]

- Del Rey, R.; Alba, J.; Arenas, J.; Sanchis, V.J. An empirical modelling of porous sound absorbing materials made of recycled foam. Appl. Acoust. 2012, 73, 604–609. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, Y. The acoustic property study of polyurethane foam with addition of bamboo leaves particles. Polym. Compos. 2016, 39, 1370–1381. [Google Scholar] [CrossRef]

- Delany, M.E.; Bazley, E.N. Acoustical properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Johnson, D.L.; Koplik, J.; Dashen, R. Theory of dynamic permeability and tortuosity in fluid-saturated porous media. J. Fluid Mech. 1987, 176, 379–402. [Google Scholar] [CrossRef]

- Allard, J.F.; Champoux, Y. New empirical equations for sound propagation in rigid frame fibrous materials. J. Acoust. Soc. Am. 1992, 91, 3346–3353. [Google Scholar] [CrossRef]

- Voronina, N. Acoustical properties of fibrous materials. Appl. Acoust. 1994, 42, 165–174. [Google Scholar] [CrossRef]

- Umnova, O.; Attenborough, K.; Ho–Chul, S.; Cummings, A. Deduction of tortuosity and porosity from acoustic reflection and transmission measurements on thick samples of rigid-porous materials. Appl. Acoust. 2005, 66, 607–624. [Google Scholar] [CrossRef]

- Zhang, C.H.; Li, J.Q.; Hu, Z.; Zhu, F.L.; Huang, Y.D. Correlation between the acoustic and porous cell morphology of polyurethane foam: Effect of interconnected porosity. Mater. Design 2012, 41, 319–325. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Rusu, T.; Vasile, O. The influence of perforations on the surface of a sound absorbing material on the sound absorption coefficient. Rom. J. Acoust. Vib. 2013, 10, 59–62. [Google Scholar]

- Chevillotte, F. Controlling sound absorption by an upstream resistive layer. Appl. Acoust. 2012, 73, 56–60. [Google Scholar] [CrossRef]

- Lou, C.-W.; Huang, S.-Y.; Huang, C.-H.; Pan, Y.-J.; Yan, R.; Hsieh, C.-T.; Lin, J.-H. Effects of structure design on resilience and acoustic absorption properties of porous flexible-foam based perforated composites. Fibers Polym. 2015, 16, 2652–2662. [Google Scholar] [CrossRef]

- Lin, J.-H.; Chuang, Y.-C.; Li, T.-T.; Huang, C.-H.; Huang, C.-L.; Chen, Y.-S.; Lou, C.-W. Effects of Perforation on Rigid PU Foam Plates: Acoustic and Mechanical Properties. Materials 2016, 9, 1000. [Google Scholar] [CrossRef] [Green Version]

- Xia, X.; Zhang, Z.; Zhao, W.; Li, C.; Ding, J.; Liu, C.; Liu, Y. Acoustic properties of closed-cell aluminum foams with different macrostructures. J. Mater. Sci. Technol. 2017, 33, 1227–1234. [Google Scholar] [CrossRef]

- Atalla, N.; Sgard, F.; Olny, X.; Panneton, R. Acoustic absorption of macro-perforated porous materials. J. Sound Vib. 2001, 243, 659–678. [Google Scholar] [CrossRef]

- Olny, X.; Boutin, C. Acoustic wave propagation in double porosity media. J. Acoust. Soc. Am. 2003, 114, 73–89. [Google Scholar] [CrossRef] [PubMed]

- Zwikker, C.; Kosten, C.W. Sound Absorbing Materials; Elsevier: New York, NY, USA, 1949. [Google Scholar]

- Sgard, F.C.; Olny, X.; Atalla, N.; Castel, F. On the use of perforations to improve the sound absorption of porous materials. Appl. Acoust. 2005, 66, 625–651. [Google Scholar] [CrossRef]

- Carbajo, J.; Prieto, A.; Ramis, J.; Río-Martín, L. A non-parametric fluid-equivalent approach for the acoustic characterization of rigid porous materials. Appl. Math. Model. 2019, 76, 330–347. [Google Scholar] [CrossRef]

- Ekici, B.; Kentli, A.; Kucuk, H. Improving Sound Absorption Property of Polyurethane Foams by Adding Tea-Leaf Fibers. Arch. Acoust. 2012, 37, 515–520. [Google Scholar] [CrossRef]

- Del Rey, R.; Alba, J.; Llopis, A.; Guillén, I. Aplicación de Nanopapel Para la Mejora de Prestaciones Acústicas. 45° Congreso español de acústica (2014), 8° Congreso ibérico de Acústica–European Symposium on Smart Cities and Environmental Acoustics; Sociedad Española de Acústica: Madrid, Spain, 2014; ISSN 1240-7441. [Google Scholar]

- Segura Alcaraz, M.P.; Bonet-Aracil, M.; Segura Alcaraz, J.G.; Montava Seguí, I. Sound absorption of textile material using a microfibers resistive layer. IOP Conf. Ser.: Mater. Sci. Eng. 2017, 254, 072022. [Google Scholar] [CrossRef]

- Pieren, R. Sound absorption modeling of thin woven fabrics backed by an air cavity. Text. Res. J. 2012, 82, 864–874. [Google Scholar] [CrossRef]

- Romero-García, V.; Theocharis, G.; Richoux, O.; Pagneux, V. Use of complex frequency plane to design broadband and sub-wavelength absorbers. J. Acoust. Soc. Am. 2016, 139, 3395–3403. [Google Scholar] [CrossRef] [Green Version]

- ISO 10534-2. Determination of Sound Absorption Coefficient and Impedance in Impedances Tubes. Part 2: Transfer-Function Method. Acoustics; Comite Europeen de Normalisation: Brussels, Belgium, 1998. [Google Scholar]

- Ingard, K.U.; Dear, T.A. Measurement of Acoustic Flow Resistance. J. Sound Vib. 1985, 103, 567–572. [Google Scholar] [CrossRef]

- Jayabal, S.; Natarajan, U. Drilling analysis of coir-fiber-reinforced polyester composites. B. Mater. Sci. 2011, 34, 1563–1567. [Google Scholar] [CrossRef]

- Radovanović, M.; Dašić, P. Research on surface roughness by laser cut. The Annals of “Dunărea de Jos” University of Galaţi, Fascicle VIII: ISSN 1221–4590. Tribology 2006, 12, 84–88. [Google Scholar]

- Del Rey, R.; Alba, J.; Blanes, M.; Marco, B. The acoustic absorption of textile curtains on the function of the fullness. Materiales de Construcción 2013, 63, 569–580. [Google Scholar] [CrossRef] [Green Version]

| Configuration | D (mm) | a (mm) | No. of holes | ||

|---|---|---|---|---|---|

| a) | 5 | 5 | 4 | 15.8 | 5 |

| b) | 4.5 | 5 | 6 | 23.8 | 2 |

| c) | 21 | 20 | 4 | 7.9 | 21 |

| d) | 20.25 | 20 | 6 | 11.9 | 9 |

| Fabric Type | t (cm) | ||

|---|---|---|---|

| T1 | 0.18 | 398 | 204250 |

| T2 | 0.14 | 478 | 270274 |

| Foam Type | σ | ∅ | Λ (µm) | (µm) | d (µm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Unperforated | 182 | 1250 | 20.420.5 | 0.88 | 1.07 | 52.1 | 104.2 | 25 | |

| 5%4 mm | 153 | 0.05 | |||||||

| 5%6 mm | 165 | 0.05 | |||||||

| 20%4 mm | 130 | 0.2 | |||||||

| 20%6 mm | 132 | 0.2 |

| Fabrics | ||||||||

|---|---|---|---|---|---|---|---|---|

| T1 | 0.1101 | 0.6283 | 0.1846 | 0.7027 | 0.0455 | 0.8173 | 0.0733 | 0.7487 |

| T2 | 0.0984 | 0.7225 | 0.2191 | 0.6716 | 0.0431 | 1.0000 | 0.0899 | 0.2333 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atiénzar-Navarro, R.; del Rey, R.; Alba, J.; Sánchez-Morcillo, V.J.; Picó, R. Sound Absorption Properties of Perforated Recycled Polyurethane Foams Reinforced with Woven Fabric. Polymers 2020, 12, 401. https://doi.org/10.3390/polym12020401

Atiénzar-Navarro R, del Rey R, Alba J, Sánchez-Morcillo VJ, Picó R. Sound Absorption Properties of Perforated Recycled Polyurethane Foams Reinforced with Woven Fabric. Polymers. 2020; 12(2):401. https://doi.org/10.3390/polym12020401

Chicago/Turabian StyleAtiénzar-Navarro, Roberto, Romina del Rey, Jesús Alba, Víctor J. Sánchez-Morcillo, and Rubén Picó. 2020. "Sound Absorption Properties of Perforated Recycled Polyurethane Foams Reinforced with Woven Fabric" Polymers 12, no. 2: 401. https://doi.org/10.3390/polym12020401

APA StyleAtiénzar-Navarro, R., del Rey, R., Alba, J., Sánchez-Morcillo, V. J., & Picó, R. (2020). Sound Absorption Properties of Perforated Recycled Polyurethane Foams Reinforced with Woven Fabric. Polymers, 12(2), 401. https://doi.org/10.3390/polym12020401