3.1. Effect of Process Parameters on Filler Network

Generally, the interaction between fillers is characterized by the Payne effect, that is, a phenomenon in which the storage modulus gradually decreases with the increase of strain at a constant temperature and frequency [

42]. Therefore, the Payne effect is usually quantified with

. In this experiment, it was calculated according to the following formula:

Notably, the smaller the Payne effect, the less the network structure between fillers, indicating that fillers are better dispersed in the rubber. The range analysis of the orthogonal experiments based on the Payne effect test results is shown in

Table 4, and the change trend of the Payne effect with various factors is shown in

Figure 3.

As shown in

Table 4, based on the comparison between range (factor) and range (error), it can be concluded that other factors have a great influence on Payne effect, except for the initial mixing rotor speed, the initial mixing temperature and the reactive barrel temperature. The barrel temperature of the extruding zone has the greatest influence on the Payne effect. Specifically,

Figure 3d shows that the Payne effect decreases first and then increases with the barrel temperature of the extruding zone gradually increases from 120 °C. When the barrel temperature of the extruding zone reaches about 126 °C, the force between fillers is the smallest and the fillers are best dispersed. This is because the temperature of the rubber compound has reached above 145 °C before passing through the extruding zone. Additionally, the rubber compound reaches a continuous exothermic state due to the previous mechanochemical action. Therefore, the barrel of the extruding zone creates a cooling effect on the rubber compound. However, when the temperature reduction of the barrel is severe, the temperature of the rubber compound decreases rapidly, the silanization reaction speed slows down, and the silica without coupling effect agglomerates in large quantities under the action of polarity. As the temperature of the rubber increases, both of the silanization reaction rate and the hydrophobicity degree of the silica improves and the interaction between rubber and fillers increases, resulting in a decrease in the Payne effect. However, if the barrel temperature in the extruding zone is too high and consequently causes the rubber temperature to reach above 155 °C, the S element contained in TESPT will prematurely crosslink with rubber, forming the silane–rubber bond and the rubber–rubber bond shown in

Figure 4. As a result, the Mooney viscosity of the rubber is increased by these bonds, and the movement of the rubber molecular chain is obstructed, resulting in a bad influence on the dispersion of fillers and enhance the Payne effect. Therefore, the proper barrel temperature of the extruding zone is the key to reduce the interaction between fillers.

According to the range analysis, the filling factor of the initial mixing module is the second major factor that affects the Payne effect. As shown in

Figure 3b, when the value of the filling factor is small, because the rubber compound keeps in a state of discontinuous flow in the internal mixer, only a small amount of it is forced to pass through the gap between the rotor edge and the inner wall of the internal mixer. As a result, the rubber compound is subjected to less effective shear force, resulting in a higher Payne effect. With the increase of the filling factor, the shear action on the rubber compound enhances and the network between the filler breaks. However, when the filling factor is too high, it is difficult for the fillers to bite and accumulate at the feeding port of the internal mixer. Additionally, since the rotor has a limited turning and folding effect on the rubber compound, the fillers are hard disperse and mix, resulting in undesired filler dispersion effects. As shown in the experimental results, the Payne effect is found to be the lowest when the filling factor is around 0.77.

In addition to the above two factors, the Payne effect is affected by the initial mixing time, the speed of the reaction rotor, and the temperature of the feeding barrel, which basically have the same importance. As shown in

Figure 3b, with the extension of the initial mixing time, the Payne effect first decreases and then increases, reaching its minimum value at around 95 s. Firstly, with the extension of mixing time, the wettability and dispersion of the filler are promoted by the high temperature softening and the input of mechanical energy of the rubber, leading to the reduction of the Payne effect. Nevertheless, the continued extension of mixing time increases the network structure of the filler. The reasons for this can be divided into two aspects: one is that the increase in material fluidity leads to a reduction in the dispersion of mechanical forces, the other is that the initial mixing temperature is far from the starting temperature of the silanization reaction, so the surface of the silica has not been modified. In addition, the high temperature exacerbates the polar agglomeration of silica, resulting in an increase in the filler network. This situation gradually improves with continued mechanical dispersion and silanization.

The reaction time and the strength of the mechanical force are determined by the speed of the reaction rotor. As shown in

Figure 3c, the optimal speed of the reaction rotor is 30 rpm. When the speed is too low, the dispersion force of the dual rotor is low, the contact area between carbon black and TESPT is small, and the degree of modification of silica cannot be promoted with a long reaction time. With the increase of the rotation speed, the dispersion and reaction reach the optimal balance.

As shown in

Figure 3c, the filler network structure reaches its lowest point at a feeding barrel temperature of 150 °C. When the barrel temperature in the feeding zone is too low, the silanization reaction of the rubber cannot start immediately, and the total reaction time decreases, resulting in a low degree of silanization of silica, agglomeration of unmodified silica, and a high Payne effect. As the temperature gradually increases, the reaction degree increases, while the filler aggregation decreases. When the barrel temperature in the feeding zone is too high, scorching of the rubber occurs too early due to the S contained in TESPT, thus hindering the dispersion and reaction of the filler and enhancing the Payne effect again.

Other process parameters have little effect on Payne effect. In general, according to the analysis of the test results of the Payne effect, the best process parameters for preparing NR/carbon black/silica composite materials by serial modular continuous mixing method are (in descending order of major and minor): extruding barrel temperature 126 °C, filling factor 0.77, reactive mixing rotor speed 30 rpm, feeding barrel temperature 150 °C, initial mixing time 95 s, reactive barrel temperature 145 °C, initial mixing rotor speed 48 rpm, initial mixing temperature 30 °C.

3.2. Effect of Process Parameters on Tensile Strength

The tensile strength is one of the important indicators to measure the quality of rubber. The range analysis of orthogonal experiments based on the tensile strength test results is shown in

Table 5, and the change trend of the tensile strength with various factors is shown in

Figure 5.

According to the range analysis, the filling factor, reactive mixing rotor speed and feeding barrel temperature have significant influence on tensile strength, of which the filling factor is the most important. As shown in

Figure 5b, as the filling factor increases, the tensile strength first increases and then decreases, with a peak at 0.78. The reason is that the mechanical force of the rotor on the rubber material is small at low filling factors, which causes poor dispersion results and poor filler reinforcement effect. On the other hand, an excessively high filling amount will increase the difficulty of the biting and dispersion of the filler and reduce the reinforcing effect. Therefore, a suitable filling factor is needed to ensure the good dispersion and reinforcing effect of the filler.

The speed of the reaction rotor is the second most important factor that affects the tensile strength. As shown in

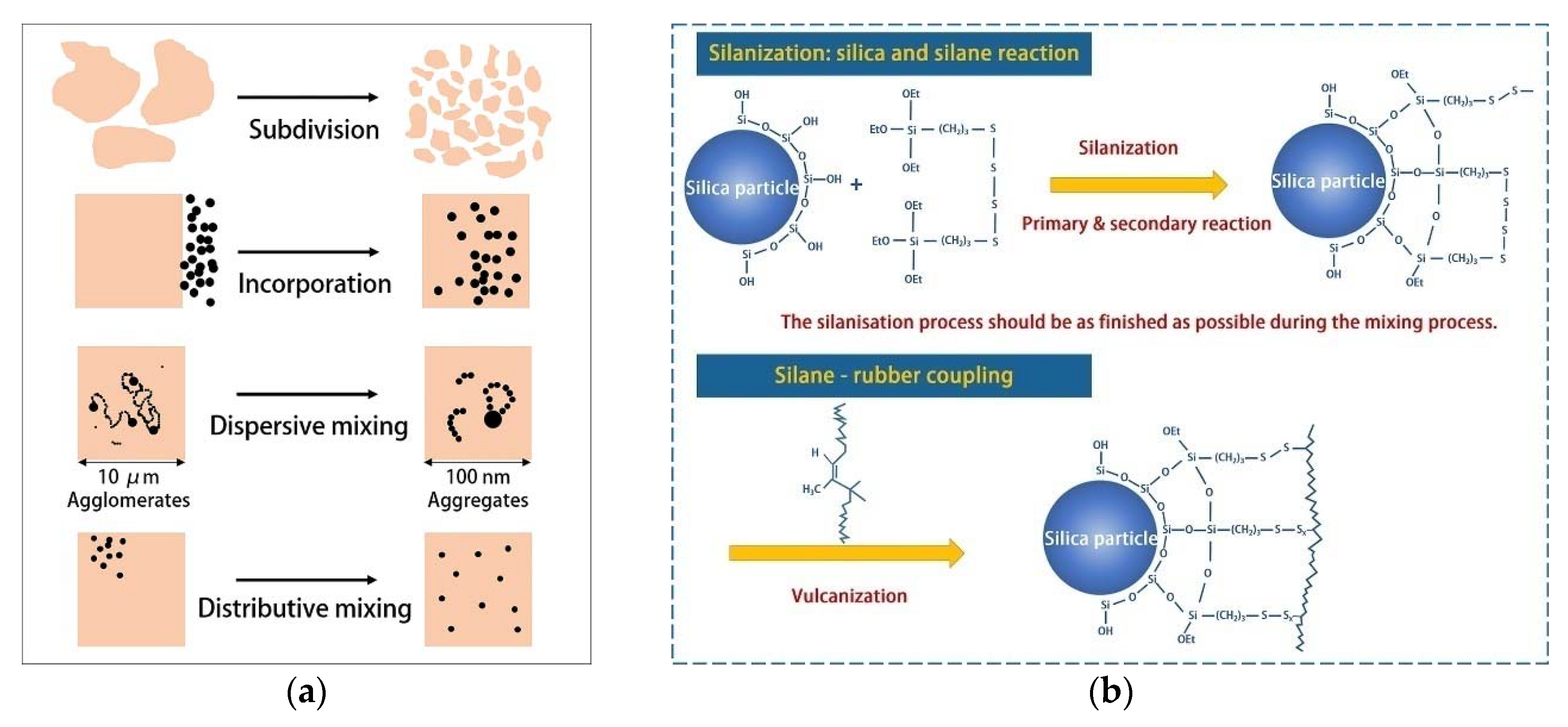

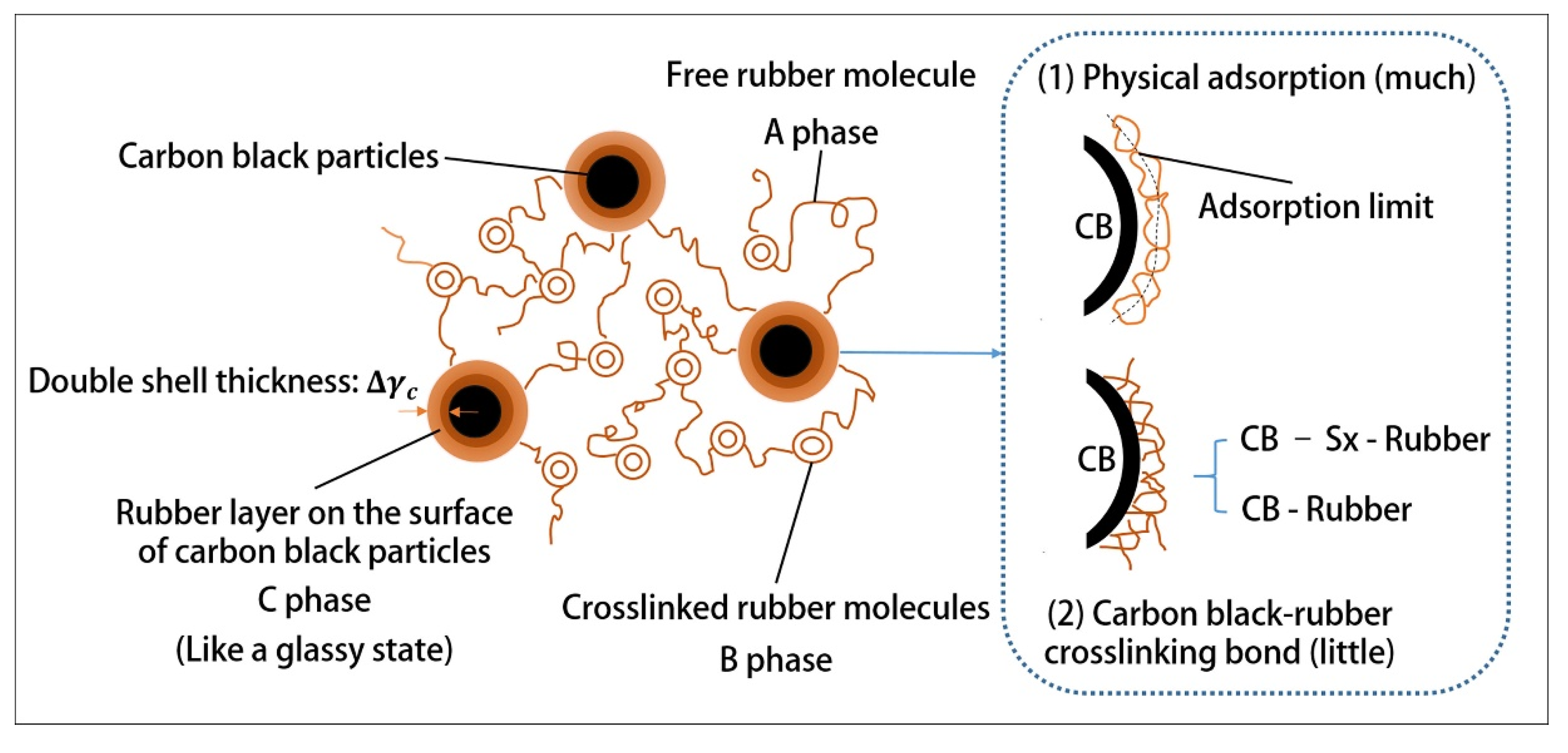

Figure 5c, the tensile strength is the biggest when the speed of the reaction rotor reaches 40 rpm. In this formula, there are two supplements, carbon black and silica, which hold different reinforcement mechanism. Specifically, as shown in

Figure 6, the rubber filled with carbon black contains three phases, ABC, of which the C phase plays the role of a skeleton, acting as the key to reinforcement. Most of the C phases are formed by the physical adsorption of carbon black, while a small part is formed by chemical bonding [

43]. However, the reinforcing effect of silica is achieved by chemical reaction in

Figure 2b, forming a chemical bonding of silica–silane–rubber. Therefore, the reinforcing effect of the filler in the formula is influenced by interaction of the dispersion of the filler and the degree of silanization reaction. On the one hand, the shear force is affected by the reaction speed, showing that the faster the speed, the greater the mechanical dispersion force. On the other hand, the silanization reaction of silica is affected by the reaction speed, showing that the faster the speed, the shorter the reaction time. As a result, an equilibrium point is necessary to achieve the optimal reinforcing effect. As shown in the experimental results, the optimal rotor speed is 40 rpm. Notably, in comparison to

Figure 3c, when the speed of the reaction rotor reaches 30 rpm, the lowest Payne effect is achieved, but the optimal reinforcing effect cannot be produced. It can be inferred that due to the high breakage degree of the rubber molecular chain at 40 rpm, more reactive free radicals are generated, resulting in the formation of the C phase through combination with the active point on the surface of carbon black, resulting in higher tensile strength.

The feeding barrel temperature is the third factor that has an important effect on tensile strength. As shown in

Figure 5c, with increasing feeding barrel temperature, the tensile strength first increases and then decreases, and reaching a peak at about 145 °C. This is because the degree of silanization reaction and the chain breakage degree at high temperature of the rubber are affected by the feeding barrel temperature, which then affects the tensile strength. Specifically, excessive low temperature is not conducive to the silanization reaction, resulting in the reduction of the silica reinforcing effect. On the other hand, excessive temperature will cause excessive chain breakage of the rubber under high-temperature oxidation, reducing the strength of the rubber.

The degree of effect of the remaining process parameters on the tensile strength is basically the same. According to the analysis of the test results of tensile strength, the best process parameters for preparing NR/carbon black/silica composite materials by serial modular continuous mixing method are (in descending order of major and minor): filling factor 0.78, reactive mixing rotor speed 40 rpm, feeding barrel temperature 145 °C, extruding barrel temperature 120 °C, initial mixing rotor speed 40 rpm, initial mixing temperature 30 °C, initial mixing time 90 s, reactive barrel temperature 145 °C.

3.3. Effect of Process Parameters on Chemical Reinforcement

The reinforcement index M300/M100 (300% modulus divided by 100% modulus) has a positive correlation with the rubber chemically bonded with vulcanizate. The interfacial area available for chemical bonding of the polymer is the dominant factor for reinforcement [

44]. For silica/carbon black/NR composites, the chemical reinforcement mainly comes from silica, because the reinforcement of carbon black mainly depends on the principle of physical adsorption. The optimal silica reinforcement process conditions are obtained by analyzing the effect of process parameters on the reinforcement index M300/M100. The range analysis of orthogonal experiments based on the tensile strength test results is shown in

Table 6, and the change trend of the tensile strength with various factors is shown in

Figure 7.

According to

Table 6, through the comparison between range (factor) and range (error), it can be concluded that all factors have an impact on M300/M00. The initial mixing speed occupies the most important factor that affects M300/M100. The

Figure 7a shows that as the initial mixing speed increases, the M300/M100 increases first and then decreases, and the peak value appears at around 45 rpm. In the initial mixing stage of serial continuous mixing, the rubber does not undergo silanization reaction due to the low temperature. The dispersion of the fillers is affected by the speed of the initial mixing, resulting in the variation of the reinforcement index. Specifically, the rubber is subjected to low mechanical force at low speeds, leading to a poor dispersion effect of the fillers. With increasing rotation speed, the mechanical dispersion effect is improved. The silanization reaction occurs quickly after the initial mixing rubber enters the reaction module, resulting in an enhancement of chemical bonding. However, when the rotation speed is excessive high, the dispersion of the filler decreases, resulting in a reduction in reinforcement index. As shown in

Figure 3a, the change in the Payne effect also proves that the dispersion of the filler becomes worse when the initial mixing speed is excessively high. This can be attributed to the following two reasons: On the one hand, the Mooney viscosity of the rubber is sharply reduced by the high speed. Although it is beneficial to the infiltration and distribution of the filler, the mechanical dispersion of the filler agglomerates is weakened. On the other hand, the polar agglomeration of the unmodified silica is exacerbated due to the increase of temperature. Therefore, the reinforcing index is reduced by the increase of the filler aggregates network.

The temperature of the reaction barrel, the speed of the reaction rotor, and the temperature of the feeding barrel are also factors that have a great effect on the reinforcement index M300/M100. The three factors are directly related to the silanization reaction and affect the degree of silanization. According to

Figure 7d, as the temperature of the reactive barrel increases, the reinforcement index first increases and then rapidly decreases, reaching a maximum at about 140 °C. Similarly, the temperature of the feeding barrel has the same trend, with a peak at about 147 °C, as shown in

Figure 7c. This is because whether the temperature of the rubber is suitable for the silanization reaction is determined by these two factors. The proper temperature of the barrel can promote the silanization reaction and improve the reinforcement index. Furthermore,

Figure 7c shows that the reinforcement index increases first with the increase of the speed of the reaction rotor, and then remains stable. When the speed is excessive low (below 30 rpm), the mechanical dispersion force is small. The contact area between silica and TESPT is small, and the degree of the silica modification cannot be improved by a long reaction time. With the increase in rotation speed, the degree of dispersion and reaction degree are improved. When the speeds of the reaction rotor are 30/40/50 rpm, respectively, the reinforcement indexes reach the highest and basically the same.

Other process parameters have little effect on reinforcement index M300/M100. In general, according to the analysis of the test results of M300/M100, the best process parameters for preparing NR/carbon black/silica composite materials by serial modular continuous mixing method are (in descending order of major and minor): initial mixing rotor speed 45 rpm, reactive barrel temperature 140 °C, reactive mixing rotor speed 30–50 rpm, feeding barrel temperature 147 °C, initial mixing temperature 40–60 °C, initial mixing time 100 s, filling factor 0.68, extruding barrel temperature 128 °C.

3.4. Effect of Process Parameters on Tear Strength

The tear resistance of the rubber and the chipping resistance and anti-collapse ability of the tire can be improved by the addition of silica. In this paper, the effect of process parameters on the tear strength is studied. The range analysis of orthogonal experiments based on the tear strength test results is shown in

Table 7, and the change trend of the tear strength with various factors is shown in

Figure 8.

According to the analysis in

Table 7, the range (error) is 2.71, indicating that other factors have a certain influence on tear strength except the initial mixing rotor speed. The filling factor has the greatest influence on the tear strength. When the filling factor is around 0.75, the tear strength reaches its maximum value, which is similar to the trend shown in the Payne effect. It can be inferred that the tear strength is changed by the variation of the filler dispersion. The specific cause analysis is shown in

Section 3.1.

The initial mixing temperature is the second most important factor that affects the tear strength.

Figure 8a shows that as the initial mixing temperature increases, the tear strength first gradually increases, and then decreases, reaching a peak at 50 °C. In addition to the filler reinforcement, the tear strength is also greatly affected by crosslinking density. According to

Figure 3a, when the initial mixing temperature is increased from 30 to 50 °C, the Payne effect increases slightly, which has little effect on the tear strength. However, with the increase of temperature, the S in TESPT will undergo an early vulcanization reaction with rubber, forming a silane–rubber or rubber–rubber bond, which increases the crosslinking density and improve the tear strength. Additionally, when the mixing temperature is raised to 60 °C, the filler aggregates increase significantly, as shown in

Figure 3a. Furthermore, the high-temperature oxidation chain breakage of the rubber intensifies, and the degree of tear strength decreases under the combined effect.

The extruding barrel temperature, the reactive barrel temperature and the feeding barrel temperature are the third, fourth, and fifth factors that affect the tear strength. The temperature of the rubber in the reactive mixing module is affected by these three factors. As shown in

Figure 8c,d, when the extruding barrel temperature, the reactive barrel temperature, and the feeding barrel temperature reach 128, 140 and 147 °C, respectively, the optimal reinforcement index and tear strength are obtained. At this point, the temperature of the material can be kept between 145 and 155 °C, providing a suitable temperature for silanization. Therefore, the tear strength is greatly affected by the degree of silica silanization.

According to the analysis of the test results of tear strength, the best process parameters for preparing NR/carbon black/silica composite materials by serial modular continuous mixing method are (in descending order from major to minor): filling factor 0.75, initial mixing temperature 50 °C, extruding barrel temperature 128 °C, reactive barrel temperature 140 °C, feeding barrel temperature 147 °C, initial mixing time 110 s, reactive mixing rotor speed 30 rpm, initial mixing rotor speed 30 rpm.

3.5. Optimal Preparation Process Paraments of NR/Carbon Black/Silica Composite

Because complex physical and chemical changes occur in rubber composite materials during mixing, the different properties of materials will show different trends when the mixing process parameters are changed. Therefore, it is not possible to achieve optimal values for all the properties at the same time when mixing. In this paper, the four properties of filler–filler interaction, tensile strength, chemical reinforcing effect and tear strength are comprehensively considered, and the optimal process parameters are analyzed. The selection of the optimal process parameters corresponding to each property are summarized in

Table 8, and the order of the degree of influence of the parameters on the performance is marked. Based on the principle of giving priority to important effects, the optimal series modular continuous mixing process parameters of reinforcing natural rubber composite materials with silica/carbon black are determined:

Initial mixing rotor speed 45 rpm, initial mixing temperature 50 °C, filling factor 0.77, initial mixing time 95 s, reactive mixing rotor speed 40 rpm, feeding barrel temperature 147 °C, reactive barrel temperature 140 °C, extruding barrel temperature 128 °C.