Patterned Membrane in an Energy-Efficient Tilted Panel Filtration System for Fouling Control in Activated Sludge Filtration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Fabrication, Characterization, and Module Assembly

2.2. Activated Sludge Feed

2.3. Filtration System Configuration

2.4. Filtration Test

2.5. Estimation of Energy Consumption

3. Results and Discussion

3.1. Membrane Fabrication and Characterization

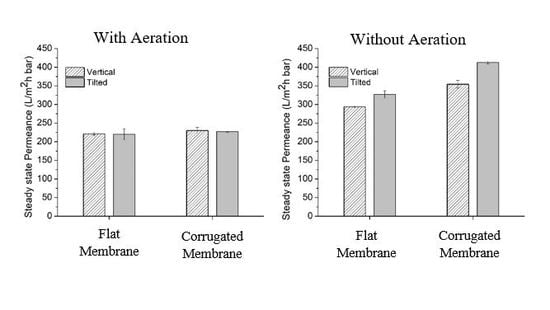

3.2. Effect of Aeration, Corrugation, and Tilting Angle

3.3. Effect of Filtration Cycle Involving Relaxation

3.4. Effect of Aeration Rate

3.5. Effect of Intermittence Aeration

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Judd, S.J. The status of industrial and municipal effluent treatment with membrane bioreactor technology. Chem. Eng. J. 2016, 305, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Bilad, M.R. Membrane bioreactor for domestic wastewater treatment: Principles, challanges and future research directions. Indones. J. Sci. Technol. 2017, 2, 97–123. [Google Scholar] [CrossRef] [Green Version]

- Shamsuddin, N.; Cao, C.; Starov, V.M.; Das, D.B. A comparative study between stirred dead end and circular flow in microfiltration of China clay suspensions. Water Sci. Technol. Water Supply 2016, 16, 481–492. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Kim, K.; Ye, H.; Lee, E.; Shin, C.; McCarty, P.L.; Bae, J. Anaerobic fluidized bed membrane bioreactor for wastewater treatment. Environ. Sci. Technol. 2010, 45, 576–581. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Zamani, F.; Lim, W.; Liao, D.; Wang, Y.; Liu, Y.; Chew, J.W.; Fane, A.G. Effect of mechanical scouring by granular activated carbon (GAC) on membrane fouling mitigation. Desalination 2017, 403, 80–87. [Google Scholar] [CrossRef]

- Wang, J.; Zamani, F.; Cahyadi, A.; Toh, J.Y.; Yang, S.; Wu, B.; Liu, Y.; Fane, A.G.; Chew, J.W. Correlating the hydrodynamics of fluidized granular activated carbon (GAC) with membrane-fouling mitigation. J. Membr. Sci. 2016, 510, 38–49. [Google Scholar] [CrossRef]

- Wang, J.; Wu, B.; Liu, Y.; Fane, A.G.; Chew, J.W. Effect of fluidized granular activated carbon (GAC) on critical flux in the microfiltration of particulate foulants. J. Membr. Sci. 2017, 523, 409–417. [Google Scholar] [CrossRef]

- Akoum, O.A.; Jaffrin, M.Y.; Ding, L.; Paullier, P.; Vanhoutte, C. An hydrodynamic investigation of microfiltration and ultrafiltration in a vibrating membrane module. J. Membr. Sci. 2002, 197, 37–52. [Google Scholar] [CrossRef]

- Bilad, M.R.; Mezohegyi, G.; Declerck, P.; Vankelecom, I.F.J. Novel magnetically induced membrane vibration (MMV) for fouling control in membrane bioreactors. Water Res. 2012, 46, 63–72. [Google Scholar] [CrossRef] [Green Version]

- Braak, E.; Alliet, M.; Schetrite, S.; Albasi, C. Aeration and hydrodynamics in submerged membrane bioreactors. J. Membr. Sci. 2011, 379, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Eliseus, A.; Bilad, M.R.; Nordin, N.A.H.M.; Khan, A.L.; Putra, Z.A.; Wirzal, M.D.H.; Aslam, M.; Aqsha, A.; Jaafar, J. Two-way switch: Maximizing productivity of tilted panel in membrane bioreactor. J. Environ. Manag. 2018, 228, 529–537. [Google Scholar] [CrossRef] [PubMed]

- Wibisono, Y.; Cornelissen, E.R.; Kemperman, A.J.B.; van der Meer, W.G.J.; Nijmeijer, K. Two-phase flow in membrane processes: A technology with a future. J. Membr. Sci. 2014, 453, 566–602. [Google Scholar] [CrossRef]

- Hwang, T.; Oh, Y.-K.; Kim, B.; Han, J.-I. Dramatic improvement of membrane performance for microalgae harvesting with a simple bubble-generator plate. Bioresour. Technol. 2015, 186, 343–347. [Google Scholar] [CrossRef] [PubMed]

- Le-Clech, P.; Chen, V.; Fane, T.A.G. Fouling in membrane bioreactors used in wastewater treatment. J. Membr. Sci. 2006, 284, 17–53. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.; Zhang, H.; Ngo, H.H.; Guo, W.; Zhang, N. The impact of gas slug flow on microfiltration performance in an airlift external loop tubular membrane reactor. RSC Adv. 2016, 6, 109067–109075. [Google Scholar] [CrossRef]

- Cheng, T.-W.; Lin, C.-T. A study on cross-flow ultrafiltration with various membrane orientations. Sep. Purif. Technol. 2004, 39, 13–22. [Google Scholar] [CrossRef]

- Eliseus, A.; Bilad, M.R.; Nordin, N.A.H.M.; Putra, Z.A.; Wirzal, M.D.H. Tilted membrane panel: A new module concept to maximize the impact of air bubbles for membrane fouling control in microalgae harvesting. Bioresour. Technol. 2017, 241, 661–668. [Google Scholar] [CrossRef]

- Eliseus, A.; Putra, Z.A.; Bilad, M.R.; Nordin, N.A.H.M.; Wirzal, M.D.H.; Jaafar, J.; Khan, A.L.; Aqsha. Energy minimization of a tilted panel filtration system for microalgae filtration: Performance modeling and optimization. Algal Res. 2018, 34, 104–115. [Google Scholar] [CrossRef]

- Cheng, T.-W. Influence of inclination on gas-sparged cross-flow ultrafiltration through an inorganic tubular membrane. J. Membr. Sci. 2002, 196, 103–110. [Google Scholar] [CrossRef]

- Bilad, M.R.; Guillen-Burrieza, E.; Mavukkandy, M.O.; Al Marzooqi, F.A.; Arafat, H.A. Shrinkage, defect and membrane distillation performance of composite PVDF membranes. Desalination 2015, 376, 62–72. [Google Scholar] [CrossRef]

- Bilad, M.R.; Marbelia, L.; Laine, C.; Vankelecom, I.F.J. A PVC–silica mixed-matrix membrane (MMM) as novel type of membrane bioreactor (MBR) membrane. J. Membr. Sci. 2015, 493, 19–27. [Google Scholar] [CrossRef]

- Chen, F.; Bi, X.; Ng, H.Y. Effects of bio-carriers on membrane fouling mitigation in moving bed membrane bioreactor. J. Membr. Sci. 2016, 499, 134–142. [Google Scholar] [CrossRef]

- Kharraz, J.A.; Bilad, M.R.; Arafat, H.A. Flux stabilization in membrane distillation desalination of seawater and brine using corrugated PVDF membranes. J. Membr. Sci. 2015, 495, 404–414. [Google Scholar] [CrossRef]

- Marbelia, L.; Bilad, M.R.; Bertels, N.; Laine, C.; Vankelecom, I.F.J. Ribbed PVC–silica mixed matrix membranes for membrane bioreactors. J. Membr. Sci. 2016, 498, 315–323. [Google Scholar] [CrossRef]

- Gronda, A.M.; Buechel, S.; Cussler, E.L. Mass transfer in corrugated membranes. J. Membr. Sci. 2000, 165, 177–187. [Google Scholar] [CrossRef]

- Kharraz, J.A.; Bilad, M.; Arafat, H.A. Simple and effective corrugation of PVDF membranes for enhanced MBR performance. J. Membr. Sci. 2015, 475, 91–100. [Google Scholar] [CrossRef]

- Racz, I.; Wassink, J.G.; Klaassen, R. Mass transfer, fluid flow and membrane properties in flat and corrugated plate hyperfiltration modules. Desalination 1986, 60, 213–222. [Google Scholar] [CrossRef] [Green Version]

- Scott, K.; Mahmood, A.; Jachuck, R.; Hu, B. Intensified membrane filtration with corrugated membranes. J. Membr. Sci. 2000, 173, 1–16. [Google Scholar] [CrossRef]

- Barambu, N.U.; Bilad, M.R.; Wibisono, Y.; Jaafar, J.; Mahlia, T.M.I.; Khan, A.L. Membrane Surface Patterning as a Fouling Mitigation Strategy in Liquid Filtration: A Review. Polymers 2019, 11, 1687. [Google Scholar] [CrossRef] [Green Version]

- Nawi, M.; Izati, N.; Bilad, M.R.; Zolkhiflee, N.; Nordin, N.A.H.; Lau, W.J.; Narkkun, T.; Faungnawakij, K.; Arahman, N.; Mahlia, T.M.I. Development of A Novel Corrugated Polyvinylidene difluoride Membrane via Improved Imprinting Technique for Membrane Distillation. Polymers 2019, 11, 865. [Google Scholar] [CrossRef] [Green Version]

- Mezohegyi, G.; Bilad, M.R.; Vankelecom, I.F.J. Direct sewage up-concentration by submerged aerated and vibrated membranes. Bioresour. Technol. 2012, 118, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Fenu, A.; Roels, J.; Wambecq, T.; De Gussem, K.; Thoeye, C.; De Gueldre, G.; Van De Steene, B. Energy audit of a full scale MBR system. Desalination 2010, 262, 121–128. [Google Scholar] [CrossRef]

- Bilad, M.R.; Declerck, P.; Piasecka, A.; Vanysacker, L.; Yan, X.; Vankelecom, I.F.J. Treatment of molasses wastewater in a membrane bioreactor: Influence of membrane pore size. Sep. Purif. Technol. 2011, 78, 105–112. [Google Scholar] [CrossRef]

- Ndinisa, N.; Fane, A.; Wiley, D.; Fletcher, D. Fouling control in a submerged flat sheet membrane system: Part II—Two-phase flow characterization and CFD simulations. Sep. Sci. Technol. 2006, 41, 1411–1445. [Google Scholar] [CrossRef]

- Wu, J.; Le-Clech, P.; Stuetz, R.M.; Fane, A.G.; Chen, V. Effects of relaxation and backwashing conditions on fouling in membrane bioreactor. J. Membr. Sci. 2008, 324, 26–32. [Google Scholar] [CrossRef]

| Properties (Unit) | Flat Membrane | Corrugated Membrane |

|---|---|---|

| Pore morphology SEM images | Asymmetric | Asymmetric |

| Contact angle (°) | 99 ± 2.39 | 106 ± 3.70 |

| Average pore size (µm) | 0.5 ± 0.02 | 0.78 ± 0.10 |

| Porosity (%) | 41 ± 6.0 | 65 ± 8.1 |

| Thickness (µm) | 228 ± 3.21 | 269 ± 5.32 |

| Clean water permeance (L/m2 h bar) | 550 ± 3.02 | 642 ± 0.32 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osman, A.; Mat Nawi, N.I.; Samsuri, S.; Bilad, M.R.; Shamsuddin, N.; Khan, A.L.; Jaafar, J.; Nordin, N.A.H. Patterned Membrane in an Energy-Efficient Tilted Panel Filtration System for Fouling Control in Activated Sludge Filtration. Polymers 2020, 12, 432. https://doi.org/10.3390/polym12020432

Osman A, Mat Nawi NI, Samsuri S, Bilad MR, Shamsuddin N, Khan AL, Jaafar J, Nordin NAH. Patterned Membrane in an Energy-Efficient Tilted Panel Filtration System for Fouling Control in Activated Sludge Filtration. Polymers. 2020; 12(2):432. https://doi.org/10.3390/polym12020432

Chicago/Turabian StyleOsman, Aisyah, Normi Izati Mat Nawi, Shafirah Samsuri, Muhammad Roil Bilad, Norazanita Shamsuddin, Asim Laeeq Khan, Juhana Jaafar, and Nik Abdul Hadi Nordin. 2020. "Patterned Membrane in an Energy-Efficient Tilted Panel Filtration System for Fouling Control in Activated Sludge Filtration" Polymers 12, no. 2: 432. https://doi.org/10.3390/polym12020432