Effect of Natural Rubber in Polyethylene Composites on Morphology, Mechanical Properties and Biodegradability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

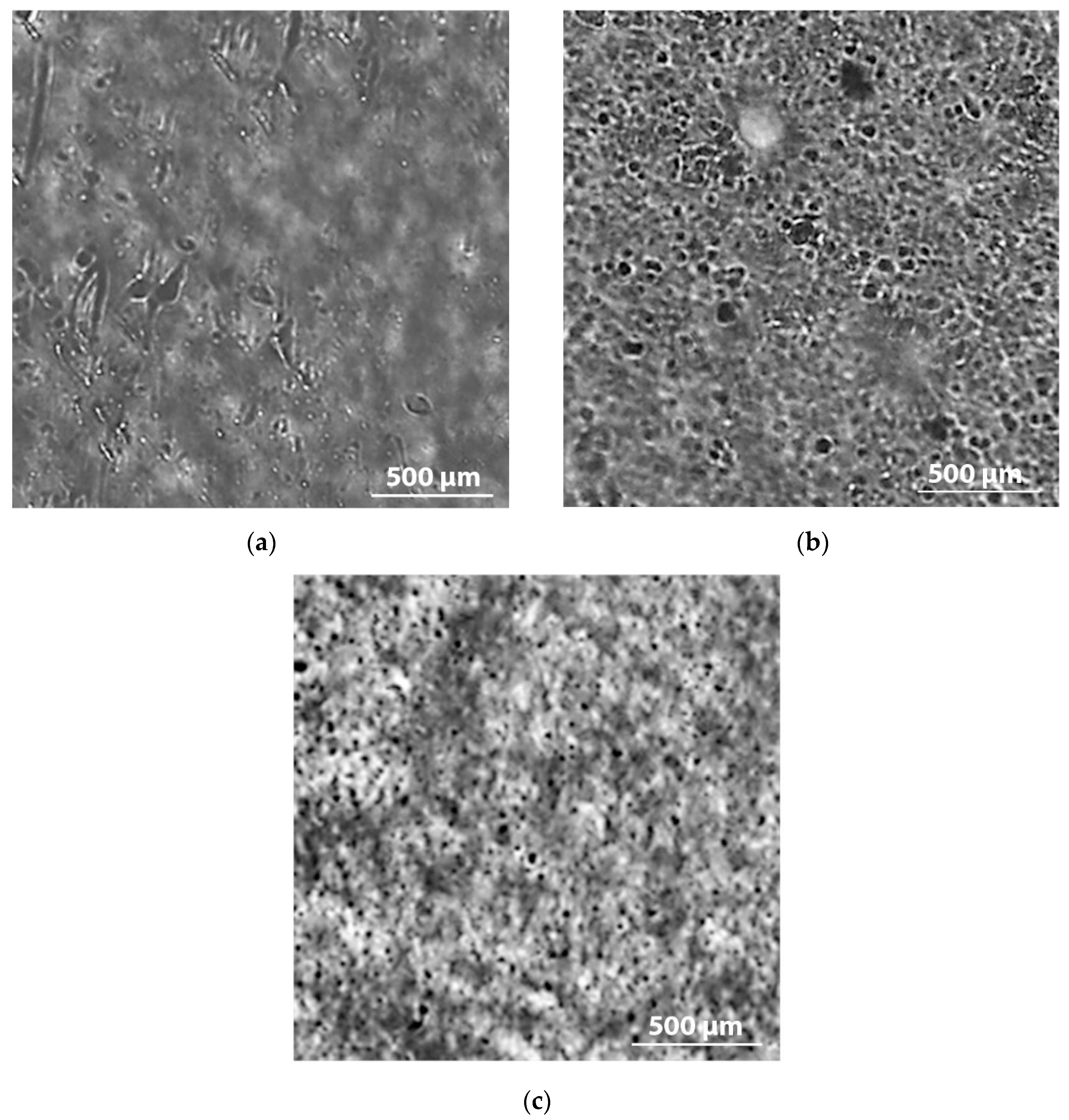

2.2.1. Optical Microscopy

2.2.2. Mechanical Properties (Tensile Test)

2.2.3. Differential Scanning Calorimetry (DSC)

2.2.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.2.5. Kinetics of Water Absorption

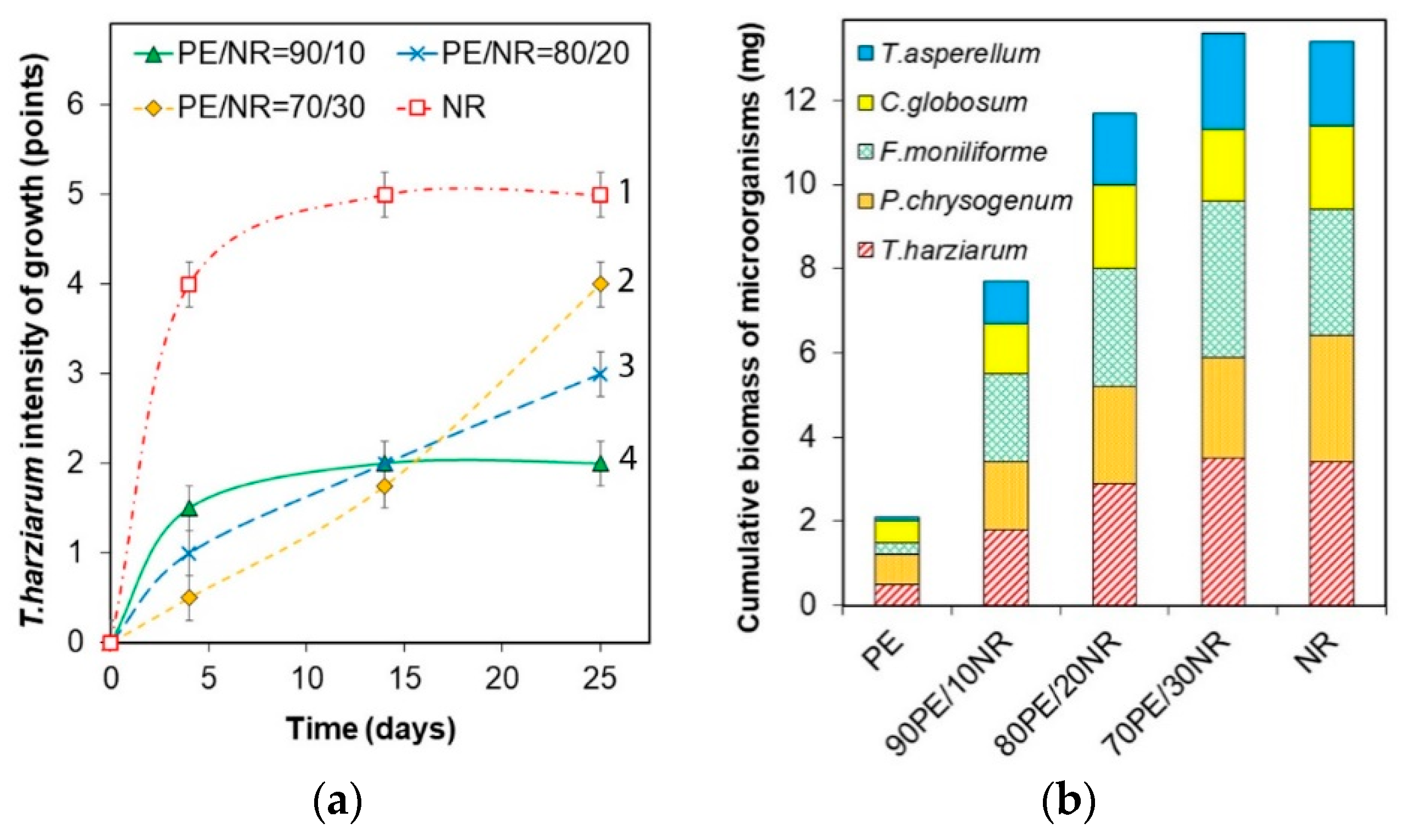

2.2.6. Mycological Test with Mold Fungi

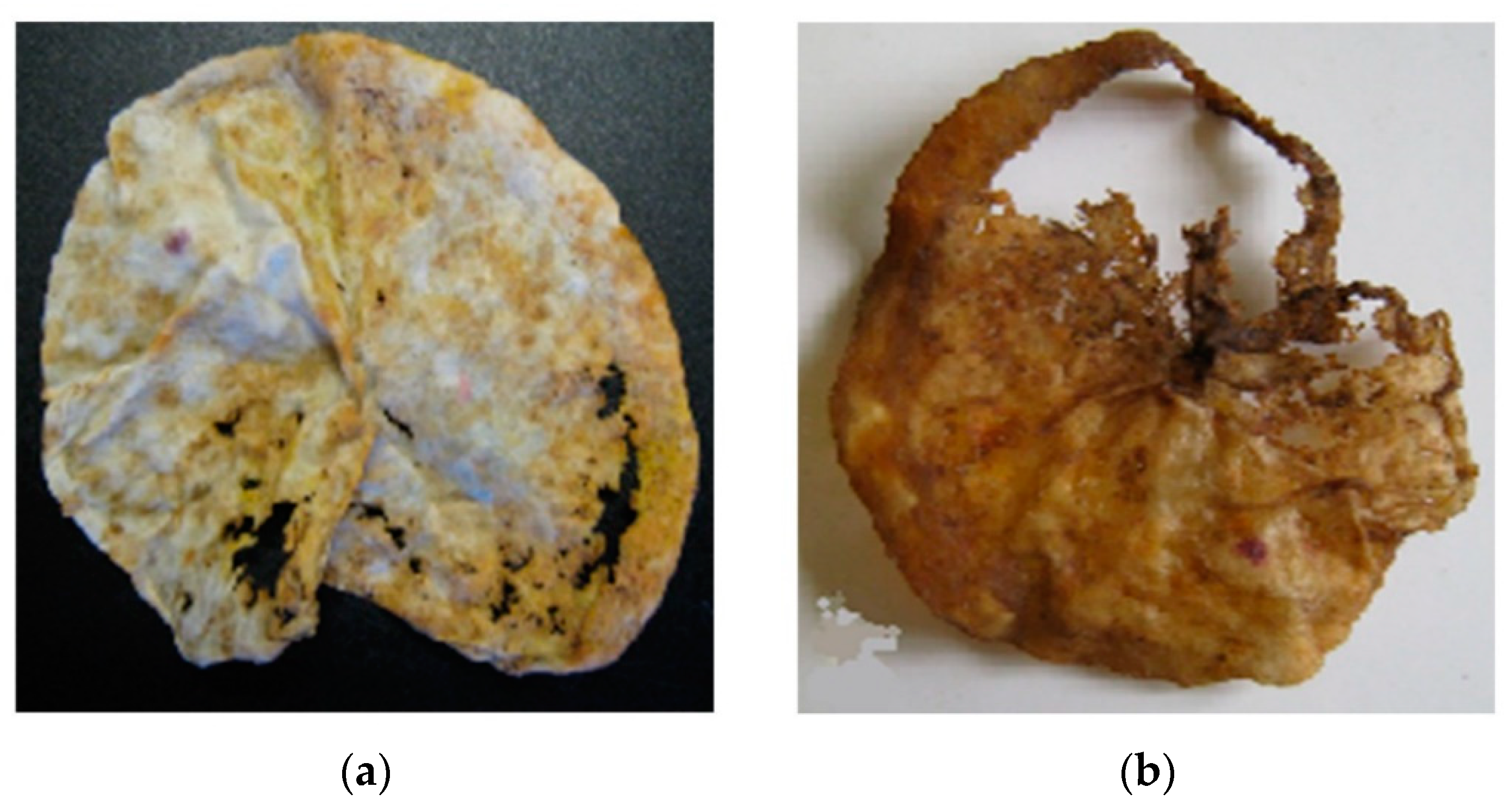

2.2.7. Biodegradability Test in Soil Medium

3. Results

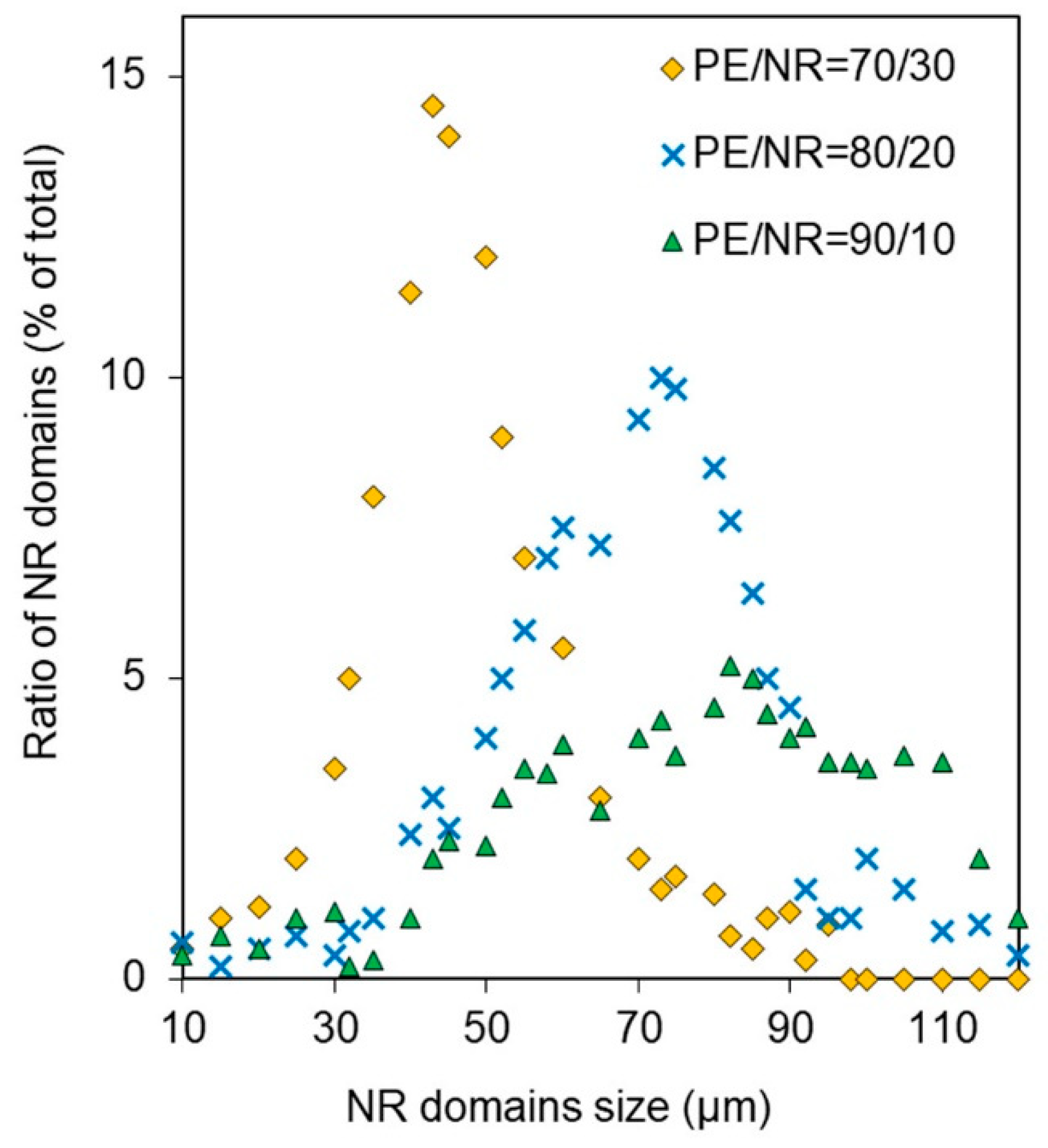

3.1. Structure and Properties

3.2. Degradation Study

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ebnesajjad, S. Handbook of Biopolymers and Biodegradable Plastics, Properties, Processing, and Applications; William Andrew Inc.: New York, NY, USA, 2012. [Google Scholar]

- Karlsson, S.; Albertsson, A.C. Biodegradable polymers and environmental interaction. Polym. Eng. Sci. 1998, 38, 1251–1253. [Google Scholar]

- Makio, H.; Fujita, T. Polyolefins—Challenges for the Future. In Proceedings of the 14th Asia Pacifil Confederation of Chemical Engineering Congress, Singapore, 22–24 February 2012; Research Publishing: Singapore, 2012. [Google Scholar]

- Mittal, V.; Patwary, F. Polypropylene nanocomposites with oxo-degradable pro-oxidant: Mechanical, thermal, rheological, and photo-degradation performance. Polym. Eng. Sci. 2016, 56, 1229–1239. [Google Scholar] [CrossRef]

- Montagna, L.S.; Catto, L.; Forte, M.; Chiellini, E.; Corti, A.; Morelli, A.; Campomanes Santana, R.M. Comparative assessment of degradation in aqueous medium of polypropylene films doped with transition metal free (experimental) and transition metal containing (commercial) pro-oxidant/pro-degradant additives after exposure to controlled UV radiation. Polym. Degrad. Stabil. 2015, 120, 186–192. [Google Scholar] [CrossRef]

- Ol’khov, A.A.; Iordanskii, A.L.; Zaikov, G.E. Morphology and mechanical parameters of biocomposite based on LDPE-PHB. Balk J. Tribol. Assoc. 2014, 20, 101–110. [Google Scholar]

- Sadi, R.K.; Fechine, G.J.M.; Demarquette, N.R. Effect of prior photodegradation on the biodegradation of polypropylene/poly(3-hydroxybutyrate) blends. Polym. Eng. Sci. 2013, 53, 2109–2122. [Google Scholar] [CrossRef]

- Cruz-Navarro, D.S.; Espinosa-Valdemar, R.M.; Beltrán-Villavicencio, M.; Vázquez-Morillas, A. Degradation of Oxo-Degradable-Polyethylene and Polylactic Acid Films Embodied in the Substrate of the Edible Fungus Pleurotus ostreatus. Nat. Resour. J. 2014, 5, 949–957. [Google Scholar]

- Madhu, G.; Bhunia, H.; Bajpai, P.K. Blends of high density polyethylene and poly(L-lactic acid): mechanical and thermal properties. Polym. Eng. Sci. 2014, 54, 2155–2160. [Google Scholar] [CrossRef]

- Podzorova, M.V.; Tertyshnaya, Y.V.; Popov, A.A. Environmentally friendly films based on poly(3-hydroxybutyrate) and poly(lactic acid): A review. Russ. J. Phys. Chem. B 2014, 8, 726–731. [Google Scholar] [CrossRef]

- Ten, E.; Jiang, L.; Zhang, J.; Wolcott, M.P. Mechanical performance of polyhydroxyalkanoate (PHA)-based biocomposites. In Design and Mechanical Performance; Misra, M., Pandey, J.K., Mohanty, A.K., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 39–52. [Google Scholar]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A.; Dutkiewicz, S. In situ generation of sustainable PLA-based nanocomposites by shear induced crystallization of nanofibrillar inclusions. RSC Adv. 2019, 9, 30370–30380. [Google Scholar] [CrossRef] [Green Version]

- Ding, W.; Chen, Y.; Liu, Z.; Yang, S. In situ nano-fibrillation of microinjection molded poly(lactic acid)/poly(ε-caprolactone) blends and comparison with conventional injection molding. RSC Adv. 2015, 5, 92905–92917. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Mastalygina, E.E.; Shatalova, O.V.; Kolesnikova, N.N.; Popov, A.A.; Krivandin, A.V. Modification of isotactic polypropylene by additives of low-density polyethylene and powdered cellulose. Inorg. Mater. Appl. Res. 2016, 7, 58–65. [Google Scholar] [CrossRef]

- Pantyukhov, P.; Kolesnikova, N.; Popov, A. Preparation, structure, and properties of biocomposites based on low-density polyethylene and lignocellulosic fillers. Polym. Compos. 2016, 37, 1461–1472. [Google Scholar] [CrossRef]

- Ayswarya, E.P.; Vidya Francis, K.F.; Renju, V.S.; Thachil, E.T. Rice husk ash—A valuable reinforcement for high density polyethylene. Mater. Des. 2012, 41, 1–7. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Gendy, A.; Kamel, S. Evaluation of corn husk fibers reinforced recycled low density polyethylene composites. Mater. Chem. Phys. 2015, 26, 152–167. [Google Scholar] [CrossRef]

- Singh, N.P.; Aggarwal, L.; Gupta, V.K. Tensile and flexural behavior of hemp fiber reinforced virgin-recycled HDPE matrix composites. Procedia Mater. Sci. 2015, 6, 1696–1702. [Google Scholar] [CrossRef] [Green Version]

- Martínez, E.S.M.; Méndez, M.A.A.; Solís, A.S.; Vieyra, H. Thermoplastic biodegradable material elaborated from unripe banana flour reinforced with metallocene catalyzed polyethylene. Polym. Eng. Sci. 2015, 55, 866–874. [Google Scholar]

- Kaur, I.; Bhalla, T.C.; Deepika, N.; Gautam, N. Study of the biodegradation behavior of soy protein-grafted polyethylene by the soil burial method. Appl. Polym. Sci. 2009, 111, 2460–2469. [Google Scholar] [CrossRef]

- Bode, H.B.; Kerkhoff, K.; Jendrossek, D. Bacterial Degradation of Natural and Synthetic Rubber. Biomacromolecules 2001, 2, 295–303. [Google Scholar] [CrossRef]

- Steinbüchel, L.A. Biodegradation of Natural and Synthetic Rubbers; Wiley-VCH Verlag GmbH & Co. KGaA.: Münster, Germany, 2005. [Google Scholar]

- Yáfiez-Flores, I.G.; Ramos-DeValle, L.F.; Rodriguez-Fernandez, O.S.; Sánchez-Valdez, S. Blends of Polyethylene-Polyisoprene Rubbers: Study of Flow Properties. J. Polym. Eng. 1997, 17, 295–310. [Google Scholar]

- Mastalygina, E.E.; Varyan, I.A.; Kolesnikova, N.N.; Popov, A.A. Structural changes in the low-density polyethylene/natural rubber composites in the aqueous and soil media. AIP Conf. Proc. 2016, 1736, 020097. [Google Scholar]

- Erman, B.; Mark, J.E.; Roland, C.M. Science and Technology of Rubber (Third Edition); Elsevier Inc. Academic Press: Waltham, MA, USA, 2005. [Google Scholar]

- Godowsky, J.K. Thermophysical Research Methods Polymers (Teplofizicheskie Metody Issledovaniya Polimerov); Khimiya: Moscow, Russia, 1976. [Google Scholar]

- Alef, K.; Nannipieri, P. Methods in Applied Soil Microbiology and Biochemistry; Academic Press: London, UK, 1995. [Google Scholar]

- Chen, D.; Shao, H.; Yao, W.; Huang, B. Fourier transform infrared spectral analysis of polyisoprene of a different microstructure. Int. J. Polym. Sci. 2013, 2013, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Mastalygina, E.E.; Popov, A.A. Mechanical properties and stress-strain behaviour of binary and ternary composites based on polyolefins and vegetable fillers. Solid State 2017, 265, 221–226. [Google Scholar] [CrossRef]

- Ting, S.S.; Achmad, N.K.; Ismail, H.; Santiagoo, R.; Noriman Zulkepli, N. Thermal Degradation of High-Density Polyethylene/Soya Spent Powder Blends. J. Polym. Eng. 2015, 35, 437–442. [Google Scholar] [CrossRef]

- Troughton, M.J. Handbook of Plastics Joining: A Practical Guide; William Andrew Inc.: New York, NY, USA, 2008. [Google Scholar]

- Mohan, K. Microbial deterioration and degradation of polymeric materials. J. Biochem. Technol. 2011, 2, 210–215. [Google Scholar]

- Shah, A.A.; Hasan, F.; Shah, Z.; Kanwal, N.; Zeb, S. Biodegradation of natural and synthetic rubbers: A review. Int. Biodeterior. Biodegrad. 2013, 83, 145–157. [Google Scholar] [CrossRef]

- Khvatov, A.V. Structure, properties and biodegradation of compositions based on polyethylene and natural additives. Ph.D. Thesis, Emanuel institute of Biochemical Physics, Russian Academy of Sciences, Moscow, Russia, 2009. [Google Scholar]

- Gumargalieva, K.Z.; Kalinina, I.G.; Semenov, S.A.; Zaikov, G.E. Bio-damages of materials. Adhesion of microorganisms on materials surface. Mol. Cryst. Liq. Cryst. 2008, 486, 213–229. [Google Scholar] [CrossRef]

- Whitehead, K.A.; Deisenroth, T.; Preuss, A.; Liauw, C.M.; Verran, J. The effect of surface properties on the strength of attachment of fungal spores using AFM perpendicular force measurements. Colloids Surf. B Biointerfaces 2011, 82, 483–489. [Google Scholar] [CrossRef]

- Van der Zee, M. Structure-Biodegradability Relationships of 370 Polymeric Materials. Ph.D. Thesis, University Twente, Enschede, The Netherlands, 1997. [Google Scholar]

- Ołdak, D.; Kaczmarek, H.; Buffeteau, T.; Sourisseau, C. Photo- and bio-degradation processes in polyethylene, cellulose and their blends studied by ATR-FTIR and raman spectroscopies. J. Mater. Sci. 2005, 40, 4189–4198. [Google Scholar] [CrossRef]

- Arutchelvi, J.; Sudhakar, M.; Arkatkar, A.; Doble, M.; Bhaduri, S.; Uppara, P.V. Biodegradation of polyethylene and polypropylene. Indian J. Biotechnol. 2008, 7, 9–22. [Google Scholar]

- Usha, R.; Sangeetha, T.; Palaniswamy, M. Screening of Polyethylene Degrading Microorganisms from Garbage Soil. Libyan Agric. Res. Cent. J. Int. 2011, 2, 200–204. [Google Scholar]

- Pramila, R.; Ramesh, K. Biodegradation of low density polyethylene (LDPE) by fungi isolated from municipal landfill area. J. Microbiol. Biotechnol. Res. 2011, 1, 131–136. [Google Scholar]

- Atlas, R.M. Microbial Degradation of Petroleum Hydrocarbons: an Environmental Perspective. Microb. Rev. 1981, 45, 180–209. [Google Scholar] [CrossRef] [Green Version]

- Mastalygina, E.E.; Kolesnikova, N.N.; Popov, A.A.; Olkhov, A.A. Environmental degradation study of multilevel biocomposites based on polyolefins. AIP Conf. Proc. 2015, 1683, 020143. [Google Scholar]

| Parameter | Method | Characterization |

|---|---|---|

| Molecular mass characteristics | Gel filtration chromatography, at 140 °C, 1,2,4-trichlorobenzene as a solvent | Mw = 1.0 × 105, Mn = 1.5 × 104, Mw/Mn = 7.03 |

| MFI (melt flow index) | Capillary viscometry, at 190 °C and load of 2.16 kg | 1.6 ± 0.1 g·10 min−1 |

| Density | Hydrostatic weighing, in ethanol 95 vol% | 0.923 ± 0.001 g·sm−3 |

| Substance | Content, wt% |

|---|---|

| Poly(cis-1,4-isoprene) | 91–96 |

| Protein and amino acids | 2–3 |

| Resins | 2–3 |

| Soot indicator | 0.5 |

| Volatiles | 0.8 |

| Transition metal compounds | <1 |

| Other | <1 |

| Intensity of Growth (Points) | Evaluation |

|---|---|

| 0 | No growth was seen under the microscope. The material does not contain any nutritive component. |

| 1 | No growth was seen by the naked eye but was visible under the microscope. |

| 2 | Growth was visible to the naked eye. 25% of the test sample surface was covered with microorganisms growth. The material contains nutritive components providing a slight growth of microorganisms. |

| 3 | Growth was visible to the naked eye. 50% of the test sample surface was covered with microorganisms growth. |

| 4 | Growth was visible to the naked eye. More than 50% of the test sample surface was covered with microorganisms growth. The material contains enough nutritive components enabling the growth of microorganisms. |

| 5 | Heavy growth covered the entire surface of the test sample. |

| NR, wt% | Initial Samples | Samples after Exposure in Aqueous Medium for 14 Days | Samples after Exposure in Soil Mediumfor 90 Days | |||||

|---|---|---|---|---|---|---|---|---|

| Tm, °C (Δ ± 0.2 °C) | χ, % (Δ ± 1%) | ΔT½, °C (Δ ± 0.2 °C) | Tm, °C( Δ ± 0.2 °C) | χ, %(Δ ± 1%) | ΔT½, °C (Δ ± 0.2 °C) | Tm, °C (Δ ± 0.2 °C) | χ, % (Δ ± 1%) | |

| 0 | 110.0 | 29 | 10.6 | 110.0 | 29 | 10.5 | 110.0 | 29 |

| 10 | 109.5 | 29 | 10.4 | 106.5 | 30 | 11.5 | 108.0 | 29 |

| 20 | 105.5 | 29 | 10.0 | 105.5 | 32 | 13.0 | 108.0 | 32 |

| 30 | 106.0 | 29 | 9.8 | 106.0 | 31 | 12.0 | 107.5 | 34 |

| NR, wt% | Mass Loss, % (after Exposure in Soil for 45 Days) | Mass Loss, % (after Exposure in Soil for 90 Days) | D836/D1463* Initial Samples) | D836/D1463 (after Exposure in Soil for 90 Days) | D1376/D1463** (Initial Samples) | D1376/D1463 (after Exposure in Soil for 90 Days) |

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 10 | 1.3 | 1.3 | – | – | – | – |

| 20 | 1.5 | 1.5 | 0.0920 | 0.0850 | 0.2310 | 0.2180 |

| 30 | 2.7 | 7.2 | 0.1668 | 0.1029 | 0.3409 | 0.2448 |

| 100 | 16.2 | 38.3 | – | – | – | – |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mastalygina, E.; Varyan, I.; Kolesnikova, N.; Gonzalez, M.I.C.; Popov, A. Effect of Natural Rubber in Polyethylene Composites on Morphology, Mechanical Properties and Biodegradability. Polymers 2020, 12, 437. https://doi.org/10.3390/polym12020437

Mastalygina E, Varyan I, Kolesnikova N, Gonzalez MIC, Popov A. Effect of Natural Rubber in Polyethylene Composites on Morphology, Mechanical Properties and Biodegradability. Polymers. 2020; 12(2):437. https://doi.org/10.3390/polym12020437

Chicago/Turabian StyleMastalygina, Elena, Ivetta Varyan, Natalya Kolesnikova, Maria Isabel Cabrera Gonzalez, and Anatoly Popov. 2020. "Effect of Natural Rubber in Polyethylene Composites on Morphology, Mechanical Properties and Biodegradability" Polymers 12, no. 2: 437. https://doi.org/10.3390/polym12020437

APA StyleMastalygina, E., Varyan, I., Kolesnikova, N., Gonzalez, M. I. C., & Popov, A. (2020). Effect of Natural Rubber in Polyethylene Composites on Morphology, Mechanical Properties and Biodegradability. Polymers, 12(2), 437. https://doi.org/10.3390/polym12020437