Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments

Abstract

:1. Introduction

1.1. Techniques for Welding Thermoplastics

1.2. Thermal Welding Methods

1.3. Recent Work for Welding Thermoplastics

2. Ultrasonic Weld for Polymers

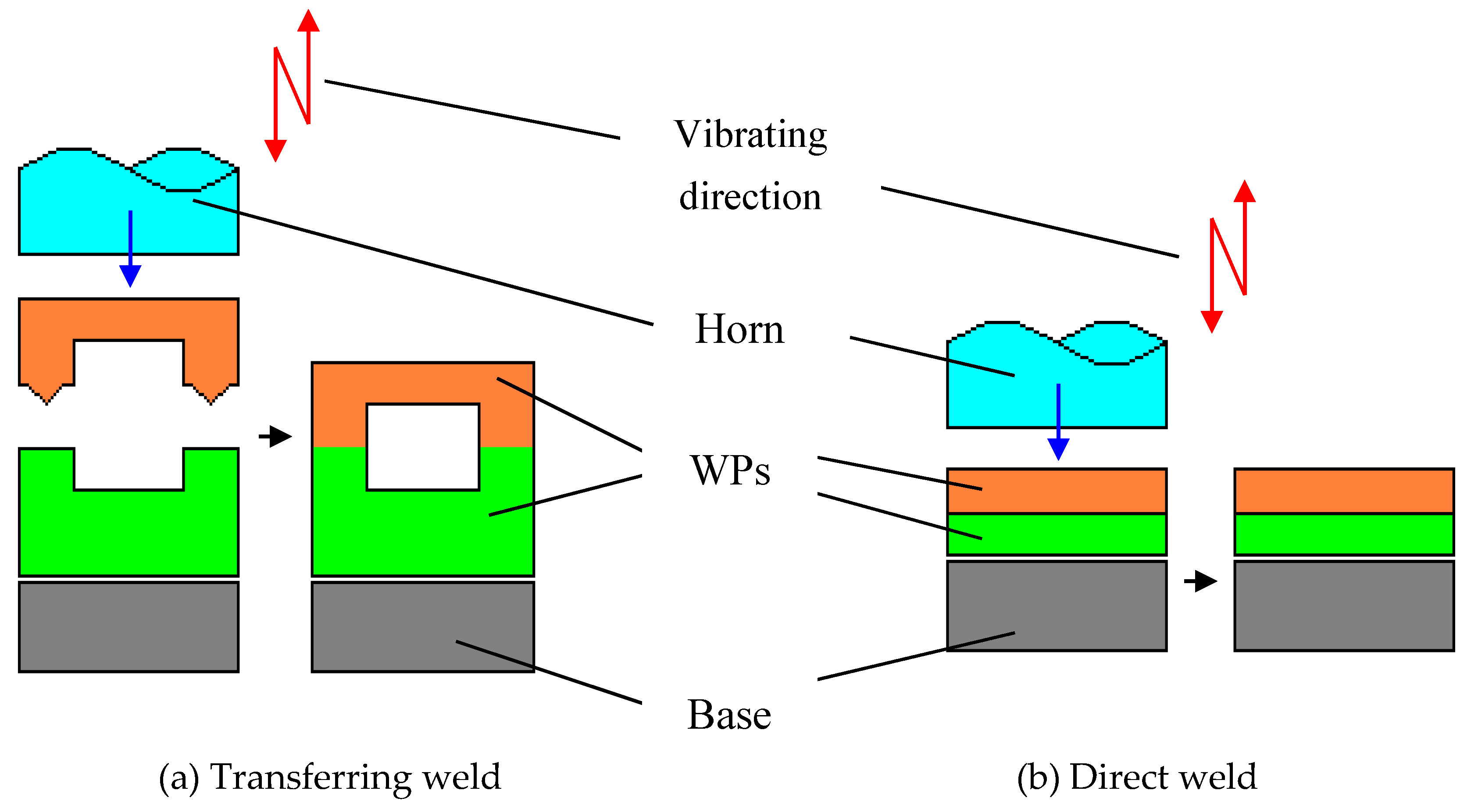

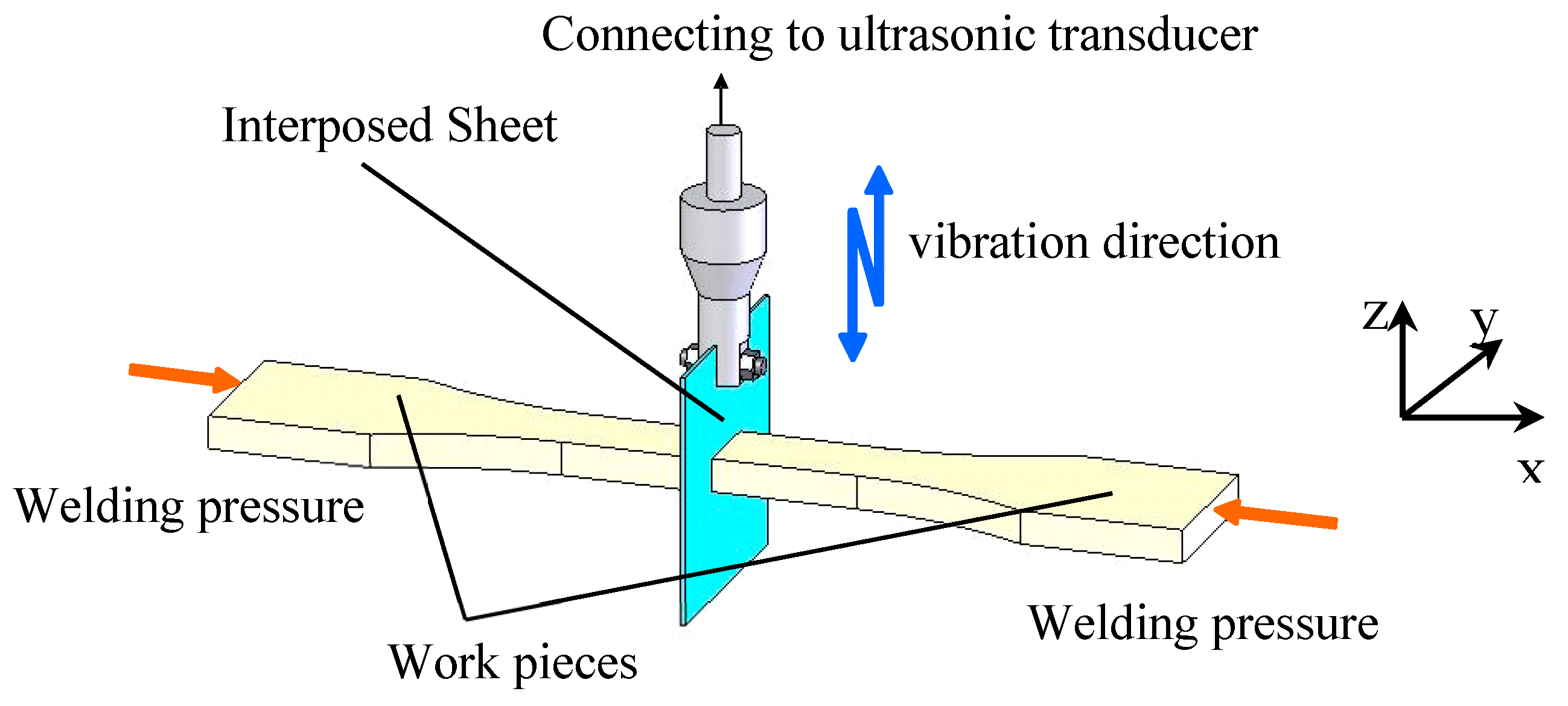

2.1. Ultrasonic Weld Methods

2.2. Weld Between Dissimilar Polymers

2.3. New Ultrasonic Welding Application for Polymers

3. Ultrasonic TWTP Technology of PC and PMMA

3.1. IPS Preparation for Ultrasonic TWTP Between PC and PMMA

3.2. Mechanical Properties of IPS for Ultrasonic TWTP Between PC and PMMA

3.3. Welded Strength of Ultrasonic TWTP Between PC and PMMA

3.4. Interfacial Structures Analysis

4. Ultrasonic TWTP Technology of PLA and POM

4.1. Welded Strength for Ultrasonic TWTP Between PLA and POM

4.2. Interfacial Structure and Mechanism Analysis

5. Ultrasonic TWTP Technology of PLA and PMMA

5.1. IPS Preparation for Ultrasonic TWTP Between PLA and PMMA

5.2. Mechanical Properties of IPS for Ultrasonic TWTP Between PLA and PMMA

5.3. Welded Strength of Ultrasonic TWTP Between PLA and PMMA

6. Molecular Interdiffusion Analysis of Ultrasonic TWTP Technology

Interdiffusion Analysis of Ultrasonic TWTP

7. Conclusions and Work in Future

Author Contributions

Funding

Conflicts of Interest

References

- Red, C. The outlook for thermoplastics in aerospace composites, 2014–2023. High Perform. Compos. 2014, 22, 54–63. [Google Scholar]

- Ajay, K.; Jayashree, B. Investigations on performance and failure mechanisms of high temperature thermoplastic polymers as adhesives. Int. J. Adhes. Adhes. 2016, 70, 90–101. [Google Scholar]

- Villegas, I.F.; Moser, L.; Yousefpour, A.; Mitschang, P.; Bersee, H.E.N. Process and performance evaluation of ultrasonic, induction and resistance welding of advanced thermoplastic composites. J. Thermoplast. Compos. 2012, 26, 1007–1024. [Google Scholar] [CrossRef]

- Ulisses, H.R.; Inés, F.; Elisa, V. Ultrasonic Molding Technology: Recent Advances and Potential Applications in the Medical Industry. Polymers 2019, 11, 667. [Google Scholar]

- Kellomaki, M.; Tormala, P. Ultrasonic moulding of bioabsorbable polymers and polymer/drug composites. J. Mater. Sci. Lett. 1997, 16, 1786–1789. [Google Scholar] [CrossRef]

- Whiteside, B.; Babenko, M.; Tuinea-Bobe, C.; Brown, E.; Coates, P. Ultrasonic injection moulding: A study of thermal behaviour and nanofeature replication. In Proceedings of the 16th International Conference of the European Society for Precision Engineering and Nanotechnology, Nottingham, UK, 30 May–3 June 2016. [Google Scholar]

- Yuka, S.; Yukihiro, N.; Fai, U.; Akikazu, M. Dissimilar Materials Bonding Using Epoxy Monolith. ACS Omega 2018, 3, 7532–7541. [Google Scholar]

- Kunkun, C.; Yansong, Z.; Hongze, W. Effect of acoustic softening on the thermal-mechanical process of ultrasonic welding. Ultrasonics 2017, 75, 9–21. [Google Scholar]

- Rutz, B.H.; Berg, J.C. A Review of the Feasibility of Lightening Structural Polymeric Composites with Voids without Compromising Mechanical Properties. Adv. Colloid Interface Sci. 2010, 160, 56–75. [Google Scholar] [CrossRef]

- Byrne, M.T.; Gunko, Y.K. Recent Advances in Research on Carbon Nanotube-Polymer Composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; Heerden, D.J.; Kuiper, P.; Wit, H. Recycling of Composite Materials. Chem. Eng. Process. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Botelho, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. A Review on the Development and Properties of Continuous Fiber/Epoxy/Aluminum Hybrid Composites Fore Aircraft Structures. Mater. Res. 2006, 9, 247–256. [Google Scholar] [CrossRef]

- Denis, S. Contact mechanism between dissimilar materials under plastic deformation. Comptes Rendus Mécanique 2019, 347, 588–600. [Google Scholar]

- Packham, D.E. Surface Energy, Surface Topography and Adhesion. Int. J. Adhes. Adhes. 2003, 23, 437–448. [Google Scholar] [CrossRef] [Green Version]

- Puka’nszky, B. Interfaces and Interphases in Multicomponent Materials: Past, Present, Future. Eur. Polym. J. 2005, 41, 645–662. [Google Scholar] [CrossRef]

- Awaja, F.; Gilbert, M.; Kelly, G.; Fox, B.; Pigram, P.J. Adhesion of Polymers. Prog. Polym. Sci. 2009, 34, 948–968. [Google Scholar] [CrossRef]

- Mohan, P.A. Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym. Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Kalita, D.; Netravali, A.N. Interfaces in Green Composites: A Critical Review. Rev. Adhes. Adhes. 2015, 3, 386–443. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and Application of Epoxy Resins: A Review. J. Int. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Surface Treatment of Materials for Adhesive Bonding, 2nd ed.; Elsevier: Oxford, UK, 2014; pp. 95–138. [Google Scholar]

- Yamabe, H. Stabilization of the Polymer-Metal Interface. Prog. Org. Coat. 1996, 28, 9–15. [Google Scholar] [CrossRef]

- Bhaskar, P.; Peter, H.F. Thermoplastic Vibration Welding: Review of Process Phenomenology and Processing-structure-property Interrelationships. Polym. Eng. Sci. 2010, 51, 1–22. [Google Scholar]

- Baldan, A. Adhesively-Bonded Joints and Repairs in Metallic Alloys, Polymers and Composite Materials: Adhesives, Adhesion Theories and Surface Pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Christoph, L.; Markus, M.; Dietmar, D. Influence of Radiation Cross-linking of Polyamide 66 on the Characteristics of the Vibration Welding Process. Polym. Eng. Sci. 2015, 55, 2493–2499. [Google Scholar]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic Metal Welding of Aluminium Sheets to Carbon Fibre Reinforced Thermoplastic Composites. Adv. Eng. Mater. 2009, 11, 35–39. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane Coupling Agents Used for Natural Fiber/Polymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Baldan, A. Adhesion Phenomena in Bonded Joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Jiang, B.; Zou, Y.; Liu, Y.; Wu, W. Characterization of the Fluidity of the Ultrasonic Plasticized Polymer Melt by Spiral Flow Testing under Micro-Scale. Polymers 2019, 11, 357. [Google Scholar] [CrossRef] [Green Version]

- Moreno-Couranjou, M.; Manakhov, A.; Boscher, N.D.; Pireaux, J.J.; Choquet, P. A Novel Dry Chemical Path Way for Diene and Dienophile Surface Functionalization toward Thermally Responsive Metal-Polymer Adhesion. ACS Appl. Mater. Interfaces 2013, 5, 8446–8456. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Takahashi, M.; Katayama, S. Laser Direct Joining of Carbon Fiber Reinforced Plastic to Zinc-Coated Steel. Mater. Des. 2013, 47, 179–188. [Google Scholar] [CrossRef]

- Ozcan, M.; Koc-Dundar, B. Composite-Composite Adhesion in Dentistry: A Systematic Review and Meta-Analysis. J. Adhes. Sci. Technol. 2014, 28, 2209–2229. [Google Scholar] [CrossRef]

- Breto, R.; Chiminelli, A.; Duvivier, E.; Lizaranzu, M.; Jimenez, M.A. Finite Element Analysis of Functionally Graded Bond-Lines for Metal/Composite Joints. J. Adhes. 2015, 91, 920–936. [Google Scholar] [CrossRef]

- Füllbrandt, M.; Kesal, D.; von Klitzing, R. Multiscaling Approach for Non-Destructive Adhesion Studies of Metal/Polymer Composites. ACS Appl. Mater. Interfaces 2015, 7, 16247–16256. [Google Scholar] [CrossRef] [PubMed]

- Kang, T.; Oh, D.; Heo, J.; Lee, H.K.; Choy, S.; Hawker, C.J.; Hwang, D.S. Formation, Removal, and Reformation of Surface Coatings on Various Metal Oxide Surfaces Inspired by Mussel Adhesives. ACS Appl. Mater. Interfaces 2015, 7, 24656–24662. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Cullis, T.; Inkson, B. Bottom-up Nanoconstruction by the Welding of Individual Metallic Nanoobjects Using Nanoscale Solder. Nano Lett. 2009, 9, 91–96. [Google Scholar]

- Russell, U.; Sana, Q.; Michael, J.; Kaushal, R. Gold Nanorod-Collagen Nanocomposites as Photothermal Nanosolders for Laser Welding of Ruptured Porcine Intestines. ACS Biomater. Sci. Eng. 2015, 1, 805–815. [Google Scholar]

- Ge, T.; Grest, G.S.; Robbins, M.O. Structure and Strength at Immiscible Polymer Interfaces. ACS Macro. Lett. 2013, 2, 882–886. [Google Scholar] [CrossRef] [Green Version]

- Hua, Q.; Mosto, B. Determination of Mutual Diffusion Coefficients at Nonsymmetric Polymer/Polymer Interfaces from Rheometry. Macromolecules 2000, 33, 6588–6594. [Google Scholar]

- Oliveira, P.H.F.; Amancio-Filho, S.T.; Dos Santos, J.F.; Hage, E., Jr. Preliminary study on the feasibility of friction spot welding in PMMA. Mater. Lett. 2010, 64, 2098–2101. [Google Scholar] [CrossRef] [Green Version]

- Rothesier, J. Joining of Plastics; Hanser Gardner: München, Germany, 1999. [Google Scholar]

- Balázs, M.; Tibor, C. Polymer joints. Period. Polytech. Mech. Eng. 2002, 46, 117–126. [Google Scholar]

- Bonten, C.; Schmachtenberg, E. A new hypothesis to describe the mechanisms acting in a welded joint of semicrystalline thermoplastics. Polym. Eng. Sci. 2001, 41, 475–483. [Google Scholar] [CrossRef]

- Barnes, T.A.; Pashby, I.R. Joining techniques for aluminium spaceframes used in automobiles: Part II—Adhesive bonding and mechanical fasteners. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar] [CrossRef]

- Negin, A.; Natalie, L.J.; David, R.M. Welding methods for joining thermoplastic polymers for the hermetic enclosure of medical devices. Med. Eng. Phys. 2010, 32, 690–699. [Google Scholar]

- Niu, M.C.Y. Composite Airframe Structures, Practical Design Information and Data, 2nd ed.; Hong Kong Conmilit Press: Hong Kong, China, 2000. [Google Scholar]

- Parmley, R.O. Standard Handbook of Fastening and Joining, 3rd ed.; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- McGrath, G. Not sticking to tradition-a guide to adhesive bonding. Bulletin 3 (TWI) 1991, 32, 64–67. [Google Scholar]

- Kalpakjian, S. Manufacturing Engineering and Technology, Chapter 30, 2nd ed.; Addison-Wesley: Boston, MA, USA, 1992. [Google Scholar]

- Shroeder, K.J. Adhesives for Structural Bonding of Aluminium Vehicles. In Proceedings of the International Conference on Body Engineering, Body Assembly and Manufacturing, Detroit, MI, USA, 26–29 September 1994; Volume 10, pp. 10–30. [Google Scholar]

- Zhao, T.; Palardy, G.; Villegas, I.F.; Rans, C.; Martinez, M.; Benedictus, R. Mechanical behavior of thermoplastic composites spot-welded and mechanically fastened joints: A preliminary comparison. Compos. Part B Eng. 2017, 112, 224–234. [Google Scholar] [CrossRef] [Green Version]

- Radakovic, D.J.; Tumuluru, M. An evaluation of the cross-tension test of resistance spot welds in high-strength dual-phase steels. Weld. J. 2012, 91, 8–15. [Google Scholar]

- Xintian, L.; Songlin, Z.; Jinzhi, F.; Hu, H.; Jun, C.; Lihui, Z. Reliability Analysis and Evaluation of Automobile Welding. Struc. Qual. Reliab. Eng. Inter. 2014, 30, 1293–1300. [Google Scholar]

- Komatsu, Y.; Ari, T.; Abe, H.; Sato, M.; Nakazawa, Y. Application of all aluminium automotive body for Honda NSX; SAE Technical Series; Report No. 910548; SAE: Warrendale, PA, USA, 1991. [Google Scholar]

- Ellison, T.M. No-emission dry paint films. CHEMTECH (ACS) 1995, 25, 36–39. [Google Scholar]

- Graff, G. In-mould colour coating readies for industry debut. Mod. Plast. 1995, 72, 52–53. [Google Scholar]

- Hartung, M.; Hintze-Bruning, H.; Oslowski, H.J. Painting of plastics. Kunstst. Plast Eur. 1996, 86, 23–25. [Google Scholar]

- Nastas, C. In-Mold Painting and Priming of Plastic Parts Using Paint Film Laminate Technology; Society of Manufacturing Engineers Technical Paper; Report No. FC94-157; SME: Southfield, MI, USA, 1994. [Google Scholar]

- Tavakoli, S.M.; Pullen, D.A.; Dunkerton, S.B. A review of adhesive bonding techniques for joining medical materials. Assem. Autom. 2005, 25, 100–105. [Google Scholar] [CrossRef]

- Haque, R.; Durandet, Y. Strength prediction of self-pierce riveted joint in cross-tension and lap-shear. Mater. Design. 2016, 108, 666–678. [Google Scholar] [CrossRef]

- Sacristan, M.; Planta, X.; Morell, M.; Puiggali, J. Eects of ultrasonic vibration on the micro-molding processing of polylactide. Ultrason. Sonochem. 2014, 21, 376–386. [Google Scholar] [CrossRef] [PubMed]

- Baldan, A. Review: Adhesively-bonded joint in metallic alloys, polymers and composite materials, Mechanical and environmental durability performance. J. Mater. Sci. 2004, 39, 4729–4797. [Google Scholar] [CrossRef]

- Reitz, W.E.; Oman, R.M. How to join plastics. Adv. Mater. Process. 2000, 158, 49–52. [Google Scholar]

- Shim, M.J.; Kim, S.W. Characteristics of polymer welding by healing process. Mater. Chem. Phys. 1997, 48, 90–93. [Google Scholar] [CrossRef]

- Watson, M.N.; Murch, M.G. Recent developments in hot plate welding of thermoplastics. Polym. Eng. Sci. 1989, 29, 1382–1386. [Google Scholar] [CrossRef]

- Nonhof, C.J. Optimization of hot plate welding for series and mass production. Polym. Eng. Sci. 1996, 36, 1184–1195. [Google Scholar] [CrossRef]

- Poopat, B.; Benatar, A.; Park, J.B. Comparative study of contact and non-contact hot plate welding of HDPE. In Proceedings of the 58th Annual Technical Conference of the Society of Plastics Engineers-Plastics the Magical Solution (ANTEC 2000), Orlando, FL, USA, 7–11 May 2000; pp. 1117–1121. [Google Scholar]

- Koutras, N.; Villegas, I.F.; Benedictus, R. Influence of temperature on the strength of resistance welded glass fibre reinforced PPS joints. Compos. Part A Appl. Sci. Manuf. 2018, 105, 57–67. [Google Scholar] [CrossRef]

- Jones, I. Laser welding for plastic components. Assem. Autom. 2002, 22, 129–135. [Google Scholar] [CrossRef]

- Troughton, M.J. Handbook of Plastics Joining: A Practical Guide, 2nd ed.; The Welding Institute: Cambridge, UK, 2008. [Google Scholar]

- Potente, H.; Becker, F.; Fiegler, G.; Korte, J. Investigations towards application of a new technique on laser transmission welding. Weld. World 2001, 45, 15–20. [Google Scholar]

- Acherjee, B.; Misra, D.; Bose, D.; Venkadeshwaran, K. Prediction of weld strength and seam width for laser transmission welding of thermoplastic using response surface methodology. Opt. Laser Technol. 2009, 41, 956–967. [Google Scholar] [CrossRef]

- Georgiev, G.L.; Baird, R.J.; McCullen, E.F.; Newaz, G.; Auner, G.; Patwa, R. Chemical bond formation during laser bonding of Teflon FEP and titanium. Appl. Surf. Sci. 2009, 255, 7078–7083. [Google Scholar] [CrossRef]

- Grewell, D.; Benatar, A. Welding of plastics: Fundamentals and new developments. Int. Polym. Process. 2007, 22, 43–60. [Google Scholar] [CrossRef] [Green Version]

- Stokes, V.K. Vibration welding of thermoplastics. 2. Analysis of the welding process. Polym. Eng. Sci. 1988, 28, 728–739. [Google Scholar] [CrossRef]

- Zhao, T.; Broek, C.; Palardy, G.; Villegas, I.F.; Benedictus, R. Towards robust sequential ultrasonic spot welding of thermoplastic composites: Welding process control strategy for consistent weld quality. Compos. Part A Appl. Sci. Manuf. 2018, 109, 355–367. [Google Scholar] [CrossRef] [Green Version]

- Levy, A.; Le Corre, S.; Chevaugeon, N.; Poitou, A. A level set based approach for the finite element simulation of a forming process involving multiphysics coupling: Ultrasonic welding of thermoplastic composites. Eur. J. Mech. A-Solids 2011, 30, 501–509. [Google Scholar] [CrossRef] [Green Version]

- Stokes, V.K.; Hobbs, S.Y. Vibration welding of ABS to itself and to polycarbonate, poly(butylene terephthalate), poly(ether imide) and modified poly(phenylene oxide). Polymer 1993, 34, 1222–1231. [Google Scholar] [CrossRef]

- Cakmak, M.; Robinette, J.; Schaible, S. Structure development and dynamics of vibration welding of poly(ethylene naphthalate) from amorphous and semicrystalline precursors. J. Appl. Polym. Sci. 1998, 70, 89–108. [Google Scholar] [CrossRef]

- Chung, Y.M.; Kamal, M.R. Morphology of PA-6 vibration welded joints and its effects on weld strength. Polym. Eng. Sci. 2008, 48, 240–248. [Google Scholar] [CrossRef]

- Marczis, B.; Czigány, T. Low and high-speed mechanical investigation of mirror-welded polymer construction elements. Műanyag és Gumi 2003, 40, 127–130. [Google Scholar]

- Vijay, K.S. A phenomenological study of the hot-tool welding of thermoplastics Part 2: Unfilled and glass-filled poly(butylene terephthalate). Polymer 2000, 41, 4317–4343. [Google Scholar]

- Vijay, K.S. A phenomenological study of the hot-tool welding of thermoplastics Part 3: Polyetherimide. Polymer 2001, 42, 775–792. [Google Scholar]

- Vijay, K.S. A phenomenological study of the hot-tool welding of thermoplastics. 4: Weld strength data for several blends. Polymer 2001, 42, 7477–7493. [Google Scholar]

- Li, Y.; Lee, T.H.; Wang, C.; Wang, K.; Tan, C.; Banu, M.; Hu, S.J. An artificial neural network model for predicting joint performance in ultrasonic welding of composites. Procedia CIRP 2018, 76, 85–88. [Google Scholar] [CrossRef]

- Kaifeng, W.; Yang, L.; Mihaela, B.; Jingjing, L.; Weihong, G.; Haris, K. Effect of interfacial preheating on welded joints during ultrasoniccomposite welding. J. Mater. Process. Technol. 2017, 246, 116–122. [Google Scholar]

- Wei, D.; ChuanSong, W. Effect of ultrasonic vibration exerted at the tool on friction stir welding process and joint quality. J. Manuf. Process. 2019, 42, 192–201. [Google Scholar]

- Zhong, Y.B.; Wu, C.S.; Padhy, G.K. Effect of ultrasonic vibration on welding load, temperature andmaterial flow in friction stir welding. J. Mater. Process. Technol. 2017, 239, 273–283. [Google Scholar] [CrossRef]

- Vijay, K.S. Experiments on the induction welding of thermoplastics. Polym. Eng. Sci. 2003, 43, 1523–1541. [Google Scholar]

- Mitschang, P.; Rudolf, R.; Neitzel, M. Continuous Induction Welding Process, Modelling and Realisation. J. Thermoplas. Compos. Mater. 2002, 15, 127–153. [Google Scholar] [CrossRef]

- Potente, H.; Karger, O.; Fielger, G. Laser and Microwave Welding-The Applicability of New Process Principles. Macromole. Mater. Eng. 2002, 287, 734–744. [Google Scholar] [CrossRef]

- Kagan, V.A.; Bray, R.G.; Kuhn, W.P. Laser Transmission Welding of Semi-Crystalline Thermoplastics-Part I: Optical Characterization of Nylon Based Plastics. J. Reinf. Plas. Compos. 2002, 21, 1101–1122. [Google Scholar] [CrossRef]

- J Dutta, M.; Manna, I. Laser material process. Int. Mater. Rev. 2011, 56, 341–388. [Google Scholar] [CrossRef]

- Bhaskar, P.; Peter, H.F. A Simple Analytical Model for Estimation of Melt Film Variables in Thermoplastic Vibration Welding. Polym. Eng. Sci. 2014, 54, 499–511. [Google Scholar]

- Marczis, B.; Czigány, T. Interrelationships between welding parameters of hot-Gas welded polypropylene. Polym. Eng. Sci. 2006, 46, 1173–1181. [Google Scholar] [CrossRef]

- Umbrecht, F.; Muller, D.; Gattiker, F.; Boutry, C.M.; Neuenschwander, J.; Sennhauser, U. Solvent assisted bonding of polymethylmethacrylate: Characterization using the response surface methodology. Sens. Actuators A Phys. 2009, 156, 121–128. [Google Scholar] [CrossRef] [Green Version]

- Potente, H.; Fiegler, G.; Haferkamp, H.; Fargas, M.; von Busse, A.; Bunte, J. An Approach to Model the Melt Displacement and Temperature Profiles during the Laser Through-Transmission Welding of Thermoplastics. Polym. Eng. Sci. 2006, 46, 1565–1575. [Google Scholar] [CrossRef]

- David, A.G.; Benatar, A. Comparison of Orbital and Linear Vibration Welding of Thermoplastics. Polym. Eng. Sci. 2009, 49, 1410–1420. [Google Scholar]

- David, C.B.; Geraldine, M.; Bruce, L.; Reza, R.; François, B.; Liam, M.G.; Jake, E.B. Ultrasonic Phosphate Bonding of Nanoparticles. Adv. Mater. 2013, 25, 5953–5958. [Google Scholar]

- Qiu, J.H.; Tsuboi, A.; Izumi, K.; Wu, H.; Guo, S.Y.; Huang, Y.D. Effects of Interfacial Morphology on the Welding Strength of Injection-Molded Polyamide. Polym. Eng. Sci. 2007, 47, 2164–2171. [Google Scholar] [CrossRef]

- Park, S.; Kim, M.; Baek, S.-K.; Park, J.-H.; Choi, S.-O. Spray-Formed Layered Polymer Microneedles for Controlled Biphasic Drug Delivery. Polymers 2019, 11, 369. [Google Scholar] [CrossRef] [Green Version]

- Tsuboi, A.; Izumi, K.; Qiu, J.H. Injection molded joining of polymer processing products. Japan Patent Pending 2005-131902, 26 May 2005. [Google Scholar]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef] [Green Version]

- Jiang, B.; Peng, H.; Wu, W.; Jia, Y.; Zhang, Y. Numerical simulation and experimental investigation of the viscoelastic heating mechanism in ultrasonic plasticizing of amorphous polymers for micro injection molding. Polymers 2016, 8, 199. [Google Scholar] [CrossRef]

- Olmo, C.; Amestoy, H.; Casas, M.T.; Martinez, J.C.; Franco, L.; Sarasua, J.R.; Puiggali, J. Preparation of nanocomposites of poly(ɛ-caprolactone) and multi-walled carbon nanotubes by ultrasound micro-molding. influence of nanotubes on melting and crystallization. Polymers 2017, 9, 322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.C.; Isaac, S.C. Welding immiscible polymers with a supercritical fluid. Langmuir 2007, 23, 12192–12195. [Google Scholar] [CrossRef]

- Truckenmüller, R.; Ahrens, R.; Cheng, Y.; Fischer, G.; Saile, V. An ultrasonic welding based process for building up a new class of inert fluidic microsensors and –actuators from polymers. Sens. Actuators A Phys. 2006, 132, 385–392. [Google Scholar] [CrossRef]

- Li, D.; Soar, R. Influence of sonotrode texture on the performance of an ultrasonic consolidation machine and the interfacial bond strength. J. Mater. Process Technol. 2009, 209, 1627–1634. [Google Scholar] [CrossRef]

- Benatar, A.; Ewaran, R.V.; Nayar, S.K. Ultrasonic Welding of Thermoplastics: Near-Field; Report MR8902; Edison Welding Institute: Columbus, OH, USA, 1989. [Google Scholar]

- Benatar, A.; Zhang, C. Ultrasonic Welding of Thermoplastics, Part II: Far-Field; Report MR8903; Edison Welding Institute: Columbus, OH, USA, 1989. [Google Scholar]

- Liu, S.J.; Lin, W.F.; Chang, B.C.; Wu, G.M.; Hung, S.W. Optimizing the joint strength of ultrasonically welded thermoplastics. Adv. Polym. Technol. 1999, 18, 125–135. [Google Scholar] [CrossRef]

- Chuah, Y.K.; Chien, L.H.; Chang, B.C.; Liu, S.J. Effects of the shape of the energy director on far-field ultrasonic welding of thermoplastics. Polym. Eng. Sci. 2000, 40, 157–167. [Google Scholar] [CrossRef]

- Grewell, D.; Benatar, A.; Park, J.B. Plastics and Composites Welding Handbook; Carl Hanser: Munich, Germany, 2003. [Google Scholar]

- Vera, M.; Danilo, M.; Andrea, C.; Massimo, C. Ultrasonic waves for materials evaluation in fatigue, thermal and corrosion damage: A review. Mech. Syst. Signal Process. 2019, 120, 32–42. [Google Scholar]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Research Annals; Japan Science and Technology Agency: Tokyo, Japan, 2007.

- Amancio Filho, S.T.; Dos Santos, J.F. Joining of polymers and polymer-metal hybrid structures: Recent developments and trends. Polym. Eng. Sci. 2009, 49, 1461–1476. [Google Scholar] [CrossRef]

- Rink, M. Device for producing bonded parts. U.S. Patent 005940949, 24 August 1999. [Google Scholar]

- Kweon, J.; Jung, J.; Kim, T.; Choi, J.; Kim, D. Failure of carbon composite-to-aluminum joints with combined mechanical fastening and adhesive bonding. Compos. Struc. 2006, 75, 192–198. [Google Scholar] [CrossRef]

- Ageorges, C.; Le, Y.; Hou, M. Advances in fusion bonding techniques for joining thermoplastic matrix composites: A review. Compos. Part A Appl. Sci. Manuf. 2001, 32, 839–857. [Google Scholar] [CrossRef]

- Steven, H.M.; Scott, T.H.; John, W.G.; Cynthia, L.T.L.; James, M.M. Scaling issues in resistance-welded thermoplastic composite joints. Adv. Polym. Technol. 1997, 16, 279–295. [Google Scholar]

- Christophe, A.; Lin, Y.; Meng, H. Experimental investigation of the resistance welding for thermoplastic-matrix composites. Part I: Heating element and heat transfer. Compos. Sci. Technol. 2000, 60, 1027–1039. [Google Scholar]

- Rudolf, R.; Mitschang, P.; Neitzel, M. Induktionsschweißen gewebeverstärkter Faser-Kunststoff-Venbunde. Schweißen und Schneiden. 2001, 53, 690–695. [Google Scholar]

- Wang, K.; Shriver, D.; Li, Y.; Banu, M.; Hu, S.J.; Xiao, G.; Arinez, J.; Fan, H.T. Characterization of weld attributes in ultrasonic welding of short carbon fiber reinforced thermoplastic composites. J. Manuf. Process. 2017, 29, 124–132. [Google Scholar]

- Villegas, I.F.; Valle Grande, B.; Bersee, H.E.N.; Benedictus, R. A comparative evaluation between flat and traditional energy directors for ultrasonic welding of CF/PPS thermoplastic composites. Compos. Interfaces 2015, 22, 717–729. [Google Scholar] [CrossRef]

- Benatar, A.; Gutowski, T.G. Ultrasonic welding of PEEK graphite APC-2 composites. Polym. Eng. Sci. 1989, 29, 1705–1721. [Google Scholar] [CrossRef]

- Villegas, I.F. Strength development versus process data in ultrasonic welding of thermoplastic composites with flat energy directors and its application to the definition of optimum processing parameters. Compos. A Appl. Sci. Manuf. 2014, 65, 27–37. [Google Scholar] [CrossRef]

- Villegas, I.F. In situ monitoring of ultrasonic welding of thermoplastic composites through power and displacement data. J. Thermoplast. Compos. Mater. 2015, 28, 66–85. [Google Scholar] [CrossRef]

- Villegas, I.F.; Bersee, H.E.N. Ultrasonic welding of advanced thermoplastic composites: An investigation on energy-directing surfaces. Adv. Polym. Tech. 2010, 29, 112–121. [Google Scholar] [CrossRef]

- Chakrapani, S.K.; Howard, A.; Barnard, D. Influence of surface roughness on the measurement of acoustic nonlinearity parameter of solids using contact piezoelectric transducers. Ultrasonics 2018, 84, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Palardy, G.; Villegas, I.F. On the effect of flat energy directors thickness on heat generation during ultrasonic welding of thermoplastic composites. Compos. Interface 2017, 24, 203–214. [Google Scholar] [CrossRef] [Green Version]

- Villegas, I.F.; Palardy, G. Ultrasonic welding of CF/PPS composites with integrated triangular energy directors: Melting, flow and weld strength development. Compos. Interfaces 2017, 24, 515–528. [Google Scholar] [CrossRef] [Green Version]

- Harras, B.; Cole, K.C.; Vu-Khanh, T. Optimization of the ultrasonic welding of PEEK carbon composites. J. Reinf. Plast. Compos. 1996, 15, 174–182. [Google Scholar] [CrossRef]

- Liu, S.J.; Chang, I.T.; Hung, S.W. Factors affecting the joint strength of ultrasonically welded polypropylene composites. Polym. Compos. 2001, 22, 132–141. [Google Scholar] [CrossRef]

- Liu, S.J.; Chang, I.T. Optimizing the weld strength of ultrasonically welded nylon composites. J. Compos. Mater. 2002, 36, 611–624. [Google Scholar] [CrossRef]

- Genevieve, P.; Huajie, S.; Arthur, L.; Steven, L.; Irene, F. A study on amplitude transmission in ultrasonic welding of thermoplastic composites. Compos. Part, A. Appl. Manuf. 2018, 113, 339–349. [Google Scholar]

- Levy, A.; Le, C.; Fernandez, V. Modeling of the heating phenomena in ultrasonic welding of thermoplastic composites with flat energy directors. J. Mater. Process. Technol. 2014, 214, 1361–1371. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb waves for identification of damage in composite structure: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 1–27. [Google Scholar] [CrossRef]

- Singher, L.; Segal, Y.; Segal, E. Considerations in bond strength evaluation by ultrasonic guided waves. J. Acoust Soc. Am. 1994, 96, 2497–2505. [Google Scholar] [CrossRef]

- Singher, L. Bond strength measurement by ultrasonic guided waves. Ultrasonics 1997, 35, 305–315. [Google Scholar] [CrossRef]

- Pedro, O.; Irene, F.; Roger, M.; Rinze, B. Diagnostic of manufacturing defects in ultrasonically welded thermoplastic composite joints using ultrasonic guided waves. NDT E Int. 2019, 107, 102126. [Google Scholar]

- Natesh, M.; Yun, L.; Vendan, S.A.; Kumar, K.A.R.; Gao, L.; Niu, X.; Peng, X.; Garg, A. Experimental and numerical procedure for studying strength and heat generation responses of ultrasonic welding of polymer blends. Measurement 2019, 132, 1–10. [Google Scholar] [CrossRef]

- Tao, W.; Su, X.; Wang, H.; Zhang, Z.; Li, H.; Chen, J. Influence mechanism of welding time and energy director to the thermoplastic composite joints by ultrasonic welding. J. Manufac. Process. 2019, 37, 196–202. [Google Scholar] [CrossRef]

- Chan, W.X.; Ng, S.H.; Li, K.H.H.; Park, W.T.; Yoon, Y.J. Micro-ultrasonic welding using thermoplastic-elastomeric composite film. J. Mater. Process. Technol. 2016, 236, 183–188. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, G.; Wu, Y. Proposal of Ultrasonic Welding Technique and Weld Performances Applied to Polymers. Polym. Eng. Sci. 2009, 49, 1755–1759. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, J. Inter-diffusion analysis based on novel ultrasonic welding method with inserting interposed sheet. Polym. Eng. Sci. 2011, 51, 103–108. [Google Scholar] [CrossRef]

- Zhang, G. Study on Interfacial Structures and Weld strength of Polymers Based on Novel Ultrasonic Weld. Ph.D. Thesis, Akita Prefectural University, Akita, Japan, March 2011. [Google Scholar]

- Qiu, J.; Zhang, G.; Asao, M.; Zhang, M.; Feng, H.; Wu, Y. Study on the novel Ultrasonic weld properties of heterogeneous polymers between PC and PMMA. Int. J. Adhes. Adhes. 2010, 30, 729–734. [Google Scholar] [CrossRef]

- Zhang, G.H.; Qiu, J.H.; Shao, L.; Fu, X. Molecular interdiffusion of hauling theory between dissimilar polymers based on novel USW. Adv. Mate. Res. 2011, 221, 289–294. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, J.; Shao, L.; Liu, M.; Zhang, M.; Wu, Y. Ultrasonic Weld Properties of Heterogeneous Polymers: Polylactide and Poly (methyl methacrylate). J. Mater. Process. Technol. 2010, 211, 1358–1363. [Google Scholar] [CrossRef]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

| Advantages | Disadvantages |

|---|---|

| Reopen ability of WPs | Augmented stress concentration |

| Convenient technology and machinery | Loosening of WPs due to creep or stress relaxation |

| Controllable volume capability | Crazing and cracking |

| Joint of dissimilar materials | Enclosure limitation |

| Assurance of structural integrity by well-known prediction methods and analysis | residual stresses due to the differences between WPs |

| Ease of joint inspection | Loss of properties due to moisture |

| Little surface preparation and cleaning is required | Need to access both sides of the part, increased number of process steps |

| Repair or replacement of pieces is facilitated | Weight penalty due to thicker sections and fasteners |

| Advantages | Disadvantages |

|---|---|

| Dissimilar materials bonding ability | Difficulty to disassemble |

| Good as repair method | Requiring good surface preparation |

| No holes required | Assembly rate limitations |

| Assembly of thin or flexible substrates | Resistant only to shear loading |

| Low stress concentration | High buying and disposal costs |

| Good surface finishing | Temperature sensitivity |

| Weight reduction | Adhesive may suffer thermal and environmental degradation |

| Sealing | Difficulty in predicting bond failure |

| Improvement of fatigue resistance | Emission control |

| Advantages | Disadvantages |

|---|---|

| High production rates | Sample size limitations (maximum of 0.23 m × 0.3 m) |

| Energy efficiency | Usually only for compatible thermoplastics |

| Design freedom | Noise concerns |

| Ease of assembly | Expensive equipment |

| Embedding of extra pieces | |

| No filler materials needed |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, J.; Zhang, G.; Sakai, E.; Liu, W.; Zang, L. Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments. Polymers 2020, 12, 759. https://doi.org/10.3390/polym12040759

Qiu J, Zhang G, Sakai E, Liu W, Zang L. Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments. Polymers. 2020; 12(4):759. https://doi.org/10.3390/polym12040759

Chicago/Turabian StyleQiu, Jianhui, Guohong Zhang, Eiichi Sakai, Wendi Liu, and Limin Zang. 2020. "Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments" Polymers 12, no. 4: 759. https://doi.org/10.3390/polym12040759

APA StyleQiu, J., Zhang, G., Sakai, E., Liu, W., & Zang, L. (2020). Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments. Polymers, 12(4), 759. https://doi.org/10.3390/polym12040759