Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Three-Dimensional Warp Interlock Fabrics

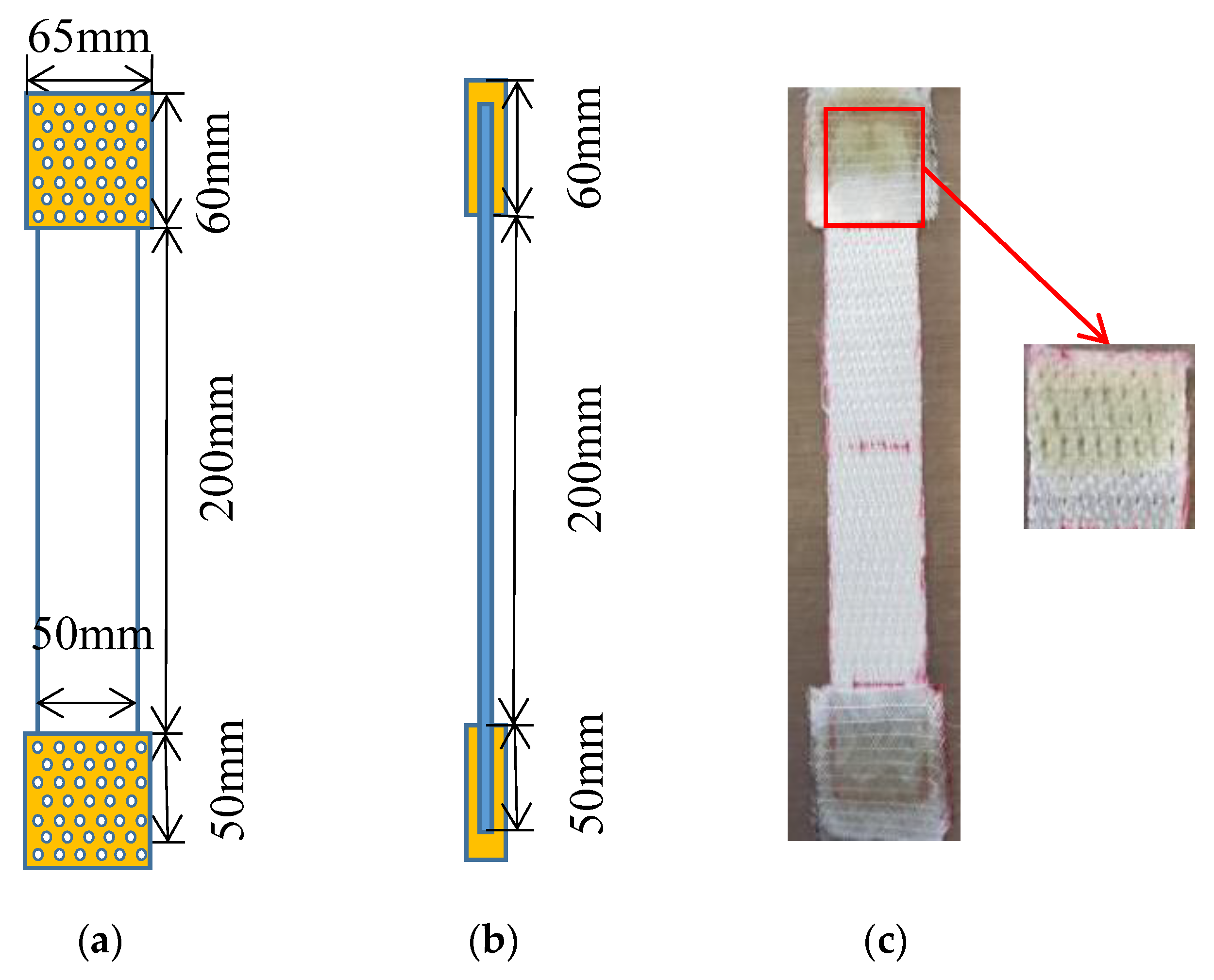

2.2. Tensile Property Characterisation

2.3. Yarn Crimp Test

3. Results and Discussion

3.1. Tensile Behaviour of a Single Yarn

3.2. Yarn Crimp Properties

3.3. Tensile Behaviour of 3DWIFs

3.4. Inter-Yarn Frictions during the Tensile Test of 3DWIFs

3.5. Geometrical Model and the Crimp Angle

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bandaru, A.K.; Sachan, Y.; Ahmad, S.; Alagirusamy, R.; Bhatnagar, N. On the mechanical response of 2D plain woven and 3D angle-interlock fabrics. Compos. Part B Eng. 2017, 118, 135–148. [Google Scholar] [CrossRef]

- Chu, T.L.; Ha-Minh, C.; Imad, A. Analysis of local and global localizations on the failure phenomenon of 3D interlock woven fabrics under ballistic impact. Compos. Struct. 2016, 159, 267–277. [Google Scholar] [CrossRef]

- Hari, B.K.B.; Woven, P.K. Text. Struct. 2010. [CrossRef]

- Yu, B.; Bradley, R.S.; Soutis, C.; Hogg, P.J.; Withers, P.J. 2D and 3D imaging of fatigue failure mechanisms of 3D woven composites. Compos. Part A Appl. Sci. Manuf. 2015, 77, 37–49. [Google Scholar] [CrossRef]

- Cristian, I.; Boussu, F.; Nauman, S. Interesting parameters of 3D warp interlock fabrics influencing the mechanical properties of the final composite structures. In Proceedings of the 10th World Textile Conference (AUTEX 2010), Vilnius, Lithuania, 21–23 June 2010. [Google Scholar]

- Gu, B. 6-Modelling of 3D Woven Fabrics for Ballistic Protection; Elsevier Ltd.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Hou, Y.; Hu, H.; Sun, B.; Gu, B. Strain rate effects on tensile failure of 3-D angle-interlock woven carbon fabric. Mater. Des. 2013, 46, 857–866. [Google Scholar] [CrossRef]

- Dai, S. Mechanical Characterisation and Numerical Modelling of 3D Woven Composites. 2014. Available online: https://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.631626 (accessed on 13 December 2014).

- Kumar, B.; Hu, J. Woven fabric structures and properties. In Engineering of High-Performance Textiles; Woodhead Publishing: Sawston, UK, 2018; pp. 133–151. [Google Scholar] [CrossRef]

- Hu, J. Introduction to three-dimensional fi brous assemblies. 3-D Fibrous Assem. 2008. [Google Scholar] [CrossRef]

- Baozhong, S.; Zhilin, N.; Lvtao, Z.; Bohong, G. Mechanical behaviors of 2D and 3D basalt fiber woven composites under various strain rates. J. Compos. Mater. 2010, 44, 1779–1795. [Google Scholar] [CrossRef]

- Ivanov, D.S.; Lomov, S.V.; Bogdanovich, A.E.; Karahan, M.; Verpoest, I. A comparative study of tensile properties of non-crimp 3D orthogonal weave and multi-layer plain weave E-glass composites. Part 2: Comprehensive experimental results. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1144–1157. [Google Scholar] [CrossRef]

- Adanur, S.; Tam, C.A. On-machine interlocking of 3D laminate structures for composites. Compos. Part B Eng. 1997, 28, 497–506. [Google Scholar] [CrossRef]

- Karahan, M.; Lomov, S.V.; Bogdanovich, A.E.; Verpoest, I. Fatigue tensile behavior of carbon/epoxy composite reinforced with non-crimp 3D orthogonal woven fabric. Compos. Sci. Technol. 2011, 71, 1961–1972. [Google Scholar] [CrossRef]

- Gu, H.; Zhili, Z. Tensile behavior of 3D woven composites by using different fabric structures. Mater. Des. 2002, 23, 671–674. [Google Scholar] [CrossRef]

- Boussu, F.; Picard, S.; Soulat, D. Interesting Mechanical Properties of 3D Warp Interlock Fabrics. In Narrow and Smart Textiles; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Corbin, A.C.; Kececi, A.; Boussu, F.; Ferreira, M.; Soulat, D. Engineering Design and Mechanical Property Characterisation of 3D Warp Interlock Woven Fabrics. Appl. Compos. Mater. 2018, 25, 811–822. [Google Scholar] [CrossRef]

- Dash, A.K.; Behera, B.K. Role of weave design on the mechanical properties of 3D woven fabrics as reinforcements for structural composites. J. Text. Instit. 2017, 109, 952–960. [Google Scholar] [CrossRef]

- Chen, X.; Zanini, I. An experimental investigation into the strucutre and mechanical properties of 3D woven orthogonal structures. J. Text. Instit. 1997, 88, 449–464. [Google Scholar] [CrossRef]

- Nasrun, F.M.Z.; Yahya, M.F.; Ghani, S.A.; Ahmad, M.R. Effect of weft density and yarn crimps towards tensile strength of 3D angle interlock woven fabric. AIP Conf. Proc. 2016, 1774. [Google Scholar] [CrossRef] [Green Version]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Influences of fabric density on mechanical and moulding behaviours of 3D warp interlock para-aramid fabrics for soft body armour application. Compos. Struct. 2018, 204, 402–418. [Google Scholar] [CrossRef]

- Boussu, F.; Cristian, I.; Nauman, S. General definition of 3D warp interlock fabric architecture. Compos. Part B Eng. 2015, 81, 171–188. [Google Scholar] [CrossRef]

- Nauman, S. Geometrical Modelling and Characterization of 3D Warp Interlock Composites and Their on-Line Structural Health Monitoring Using Flexible. 2011. Available online: https://www.theses.fr/2011LIL10010 (accessed on 24 March 2011).

- Kharitonov, A.P.; Maksimkin, A.V.; Mostovaya, K.S.; Kaloshkin, S.D.; Gorshenkov, M.V.; D’yachkova, T.P.; Tkachev, A.G.; Alekseiko, L.N. Reinforcement of bulk ultrahigh molecular weight polyethylene by fluorinated carbon nanotubes insertion followed by hot pressing and orientation stretching. Compos. Sci. Technol. 2015, 120, 26–31. [Google Scholar] [CrossRef]

- Li, B.; Li, M.; Fan, C.; Ren, M.; Wu, P.; Luo, L.; Wang, X.; Liu, X. The wear-resistance of composite depending on the interfacial interaction between thermoplastic polyurethane and fluorinated UHMWPE particles with or without oxygen. Compos. Sci. Technol. 2015, 106, 68–75. [Google Scholar] [CrossRef]

- Holloway, J.L.; Lowman, A.M.; VanLandingham, M.R.; Palmese, G.R. Chemical grafting for improved interfacial shear strength in UHMWPE/PVA-hydrogel fiber-based composites used as soft fibrous tissue replacements. Compos. Sci. Technol. 2013, 85, 118–125. [Google Scholar] [CrossRef]

- Sa, R.; Wei, Z.; Yan, Y.; Wang, L.; Wang, W.; Zhang, L.; Ning, N.; Tian, M. Catechol and epoxy functionalized ultrahigh molecular weight polyethylene (UHMWPE) fibers with improved surface activity and interfacial adhesion. Compos. Sci. Technol. 2015, 113, 54–62. [Google Scholar] [CrossRef]

- Rao, Y.; Farris, R.J. Modeling and experimental study of the influence of twist on the mechanical properties of high-performance fiber yarns. J. Appl. Polym. Sci. 2000, 77, 1938–1949. [Google Scholar] [CrossRef]

- Kirkwood, K.M.; Kirkwood, J.E.; Lee, Y.S.; Egres, R.G.; Wagner, N.J.; Wetzel, E.D. Yarn Pull-Out as a Mechanism for Dissipating Ballistic Impact Energy in Kevlar® KM-2 Fabric: Part I: Quasi-Static Characterization of Yarn Pull-Out. Text. Res. J. 2004, 74, 920–928. [Google Scholar] [CrossRef]

- Hou, Y.; Sun, B.; Gu, B. An analytical model for the ballistic impact of three dimensional angle-interlock woven fabric penetrated by a rigid cylindro-spherical projectile. Text. Res. J. 2011, 81, 1287–1303. [Google Scholar] [CrossRef]

- Pan, N.; Yoon, M.Y. Behavior of Yarn Pullout from Woven Fabrics: Theoretical and Experimental. Text. Res. J. 1993, 63, 629–637. [Google Scholar] [CrossRef]

- Taylor, H.M. 9—Tensile and tearing strength of cotton cloths. J. Text. Instit. Trans 1959, 50, T161–T188. [Google Scholar] [CrossRef]

- Peirce, F.T. 5—The geometry of cloth structure. J. Text. Instit. Trans. 1937, 28, T45–T96. [Google Scholar] [CrossRef]

- Kovar, R. Length of the yarn in plain-weave crimp wave. J. Text. Instit. 2011, 102, 582–597. [Google Scholar] [CrossRef]

- Jung, C.; Ganghoffer, J.-F.; Durand, B. A Generalized Continuum Model for Textile. In Proceedings of the 12th International Conference on Composite Materials (ICCM-12), Paris, France, 5–9 July 1999; pp. 5–9. [Google Scholar]

| Product Family | Linear Density (Tex) | Density (g/cm3) | Elongation (%) | Breaking Strength (N) |

|---|---|---|---|---|

| Spectra® 900 | 135 | 0.97 | 4.12 ± 0.01 | 350.69 ± 6.13 |

| Fabrics | F1 | F2 | F3 | F4 | F5 |

|---|---|---|---|---|---|

| Architecture | A-L 3-2 4 Binding {Twill 4 effect left}-Stuffer | O-L 3-2 4 Binding {Twill 4 effect left}-Stuffer | A-L 5-3 4 Binding {Twill 6 effect left}-Stuffer | O-T 5-4 4 Binding {Twill 6 effect left}-Stuffer | A-T 5-4 4 Binding {Twill 6 effect left}-Stuffer |

| Cross-section weft yarns view |  |  |  |  |  |

| 3D view |  |  |  |  |  |

| Binding step (X) | 3 | 3 | 5 | 5 | 5 |

| Binding depth (Y) | 2 | 2 | 3 | 4 | 4 |

| Fabrics | F1 | F2 | F3 | F4 | F5 |

|---|---|---|---|---|---|

| Warp density (ends/cm) | 10 | ||||

| Weft density (picks/cm) | 42 | ||||

| Thickness (mm) | 2.5 ± 0.3 | 2.1 ± 0.1 | 1.9 ± 0.1 | 1.7 ± 0.1 | 1.6 ± 0.1 |

| Areal weight (g/m2) | 735.8 ± 36.5 | 720.0 ± 12.3 | 688.7 ± 13.2 | 710.6 ± 12.2 | 714.1 ± 9.6 |

| FVF (%) | 30.3 ± 1.5 | 35.3 ± 0.6 | 37.4 ± 0.7 | 40.7 ± 0.7 | 46.0 ± 0.6 |

| N° of Fabrics | F1 | F2 | F3 | F4 | F5 | |

|---|---|---|---|---|---|---|

| Warp yarns crimps/(%) | Binding warp yarns crimps% | |||||

| Inter-ply 0 | 0.85 ± 0.78 | 1.27 ± 0.27 | 1.04 ± 0.53 | 5.78% ± 0.57 | 4.4 ± 1.06 | |

| Inter-ply 1 | 1.20 ± 0.44 | 1.54 ± 0.54 | 0.93 ± 0.57 | - | - | |

| Inter-ply 2 | 1.20 ± 0.62 | 1.49 ± 0.45 | - | - | - | |

| Average value | 1.08 ± 0.61 | 1.43 ± 0.42 | 0.99 ± 0.55 | 5.78% ± 0.57 | 4.4 ± 1.06 | |

| Stuffer warp yarns crimps% | ||||||

| Inter-ply 1 | 0.68 ± 0.28 | 1.23 ± 0.47 | 1.28 ± 0.66 | 4.30 ± 0.58 | 0.8 ± 0.54 | |

| Inter-ply 2 | 0.72 ± 0.52 | 1.20 ± 0.51 | 0.80 ± 0.50 | 4.00 ± 0.02 | 1.33 ± 0.48 | |

| Inter-ply 3 | 0.93 ± 0.74 | 1.13 ± 0.39 | 0.88 ± 0.44 | 4.18 ± 0.35 | 0.73 ± 0.30 | |

| Average value | 0.78 ± 0.51 | 1.19 ± 0.46 | 0.99 ± 0.53 | 4.16 ± 0.32 | 0.95 ± 0.44 | |

| Weft yarns crimps/(%) | Inter-ply 1 | 1.24 ± 0.27 | 0.78 ± 0.49 | 1.23 ± 0.41 | 1.97 ± 0.91 | 1.91 ± 0.36 |

| Inter-ply 2 | 1.64 ± 0.30 | 0.87 ± 0.45 | 1.42 ± 0.46 | 1.76 ± 0.52 | 2.14 ± 0.71 | |

| Inter-ply 3 | 1.80 ± 0.60 | 0.72 ± 0.34 | 1.09 ± 0.40 | 1.78 ± 0.56 | 2.00 ± 0.69 | |

| Inter-ply 4 | 1.38 ± 0.60 | 0.62 ± 0.37 | 1.38 ± 0.59 | 2.03 ± 0.83 | 1.73 ± 0.40 | |

| Average value | 1.52 ± 0.44 | 0.75 ± 0.41 | 1.28 ± 0.47 | 1.89 ± 0.71 | 1.95 ± 0.54 | |

| Parameters | F1 | F2 | F3 | F4 | F5 | |

|---|---|---|---|---|---|---|

| Warp | St (kN) | 11.2 ± 1.1 | 14.2 ± 1.0 | 11.9 ± 0.4 | 11.9 ± 0.2 | 6.0 ± 0.5 |

| ε (%) | 4.97 ± 0.01 | 5.22 ± 0.01 | 5.39 ± 0.01 | 10.15 ± 0.01 | 5.73 ± 0.01 | |

| Weft | St (kN) | 48.46 ± 0.1 | 42.7 ± 1.8 | 50.3 ± 1.8 | 51.7 ± 0.5 | 48.7 ± 3.7 |

| ε (%) | 6.73 ± 0.01 | 7.10 ± 0.01 | 6.68 ± 0.01 | 8.70 ± 0.01 | 8.37 ± 0.01 |

| Fabrics | F1 | F2 | F3 | F4 | F5 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Weft cross-Section |  |  |  |  |  | |||||

| Single binding warp yarn |  |  |  |  |  | |||||

| Cross-linking shape and crimp angles (°) |  | 0 |  | 80 |  | 0 |  | 90 |  | 0 |

| 90 |  | 160 |  | 90 |  | 0 |  | 80 | |

| 0 |  | 80 |  | 0 |  | 180 |  | 0 | |

| 90 |  | 90 |  | 0 |  | 80 | |||

| 90 |  | 0 | |||||||

| Total crimp angles per unit cell (°) | 180 | 320 | 180 | 360 | 160 | |||||

| Total crimp angles in fabric (×360°) | 656.3 | 1166.7 | 437.5 | 875 | 388.9 | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, P.; Boussu, F.; Soulat, D. Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements. Polymers 2020, 12, 1045. https://doi.org/10.3390/polym12051045

Li M, Wang P, Boussu F, Soulat D. Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements. Polymers. 2020; 12(5):1045. https://doi.org/10.3390/polym12051045

Chicago/Turabian StyleLi, Mengru, Peng Wang, François Boussu, and Damien Soulat. 2020. "Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements" Polymers 12, no. 5: 1045. https://doi.org/10.3390/polym12051045

APA StyleLi, M., Wang, P., Boussu, F., & Soulat, D. (2020). Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements. Polymers, 12(5), 1045. https://doi.org/10.3390/polym12051045