Effect of Radial Moisture Distribution on Frequency Domain Dielectric Response of Oil-Polymer Insulation Bushing

Abstract

:1. Introduction

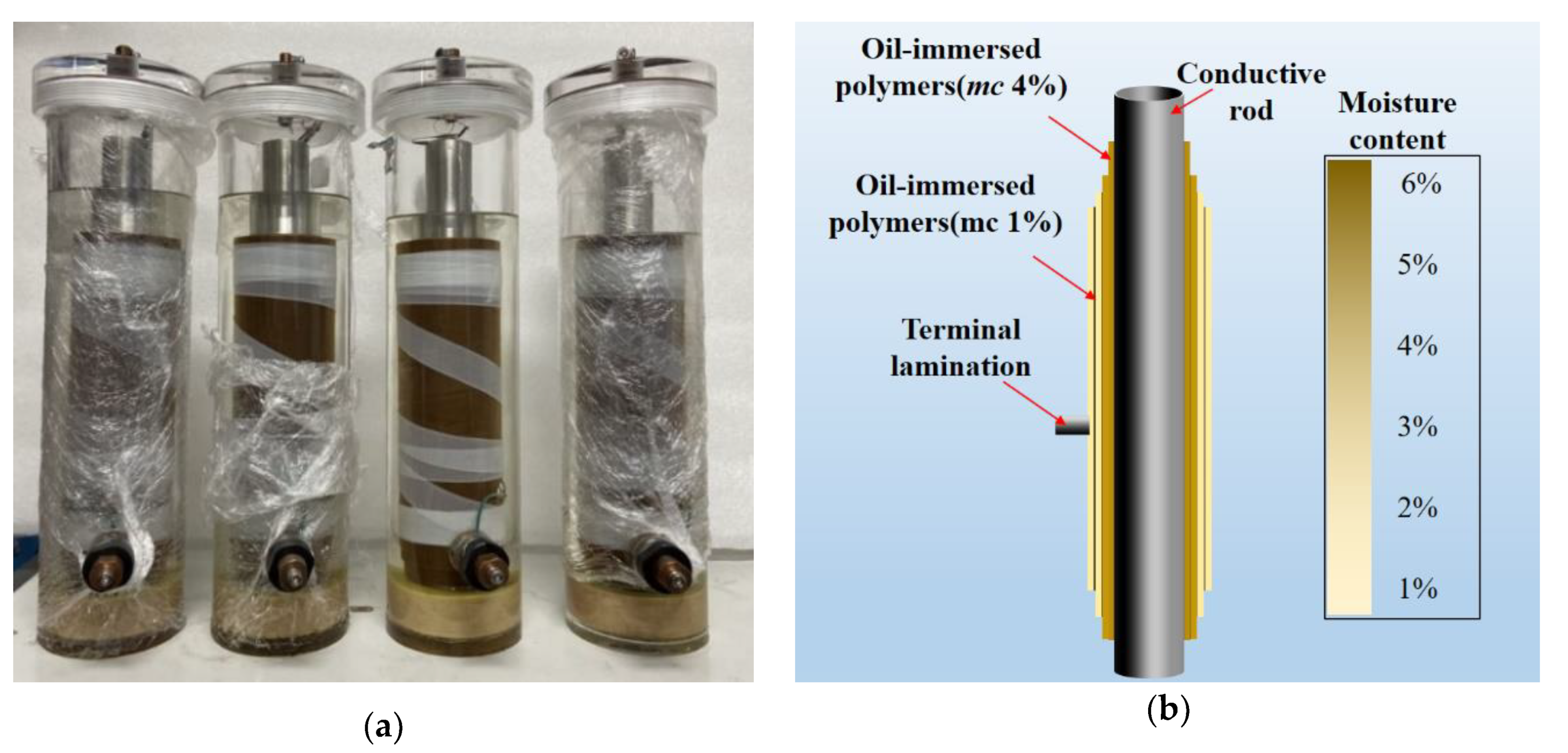

2. Oil-Polymer Sample and Bushing Model

2.1. Oil-Polymer Samples

2.2. Bushing Model

3. Analysis of Measurement Results

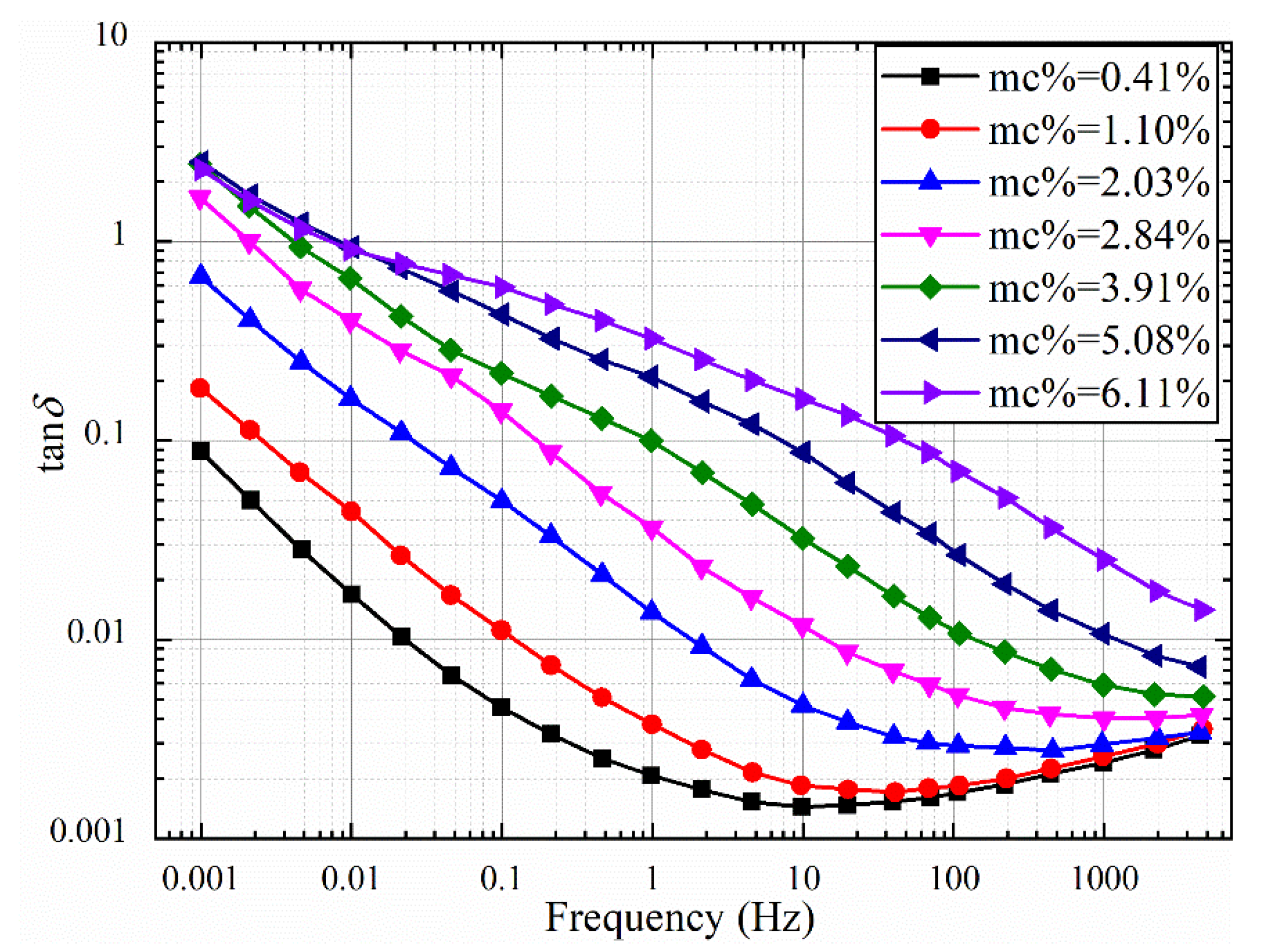

3.1. Oil-Polymer Samples

3.1.1. Uniform Moisture

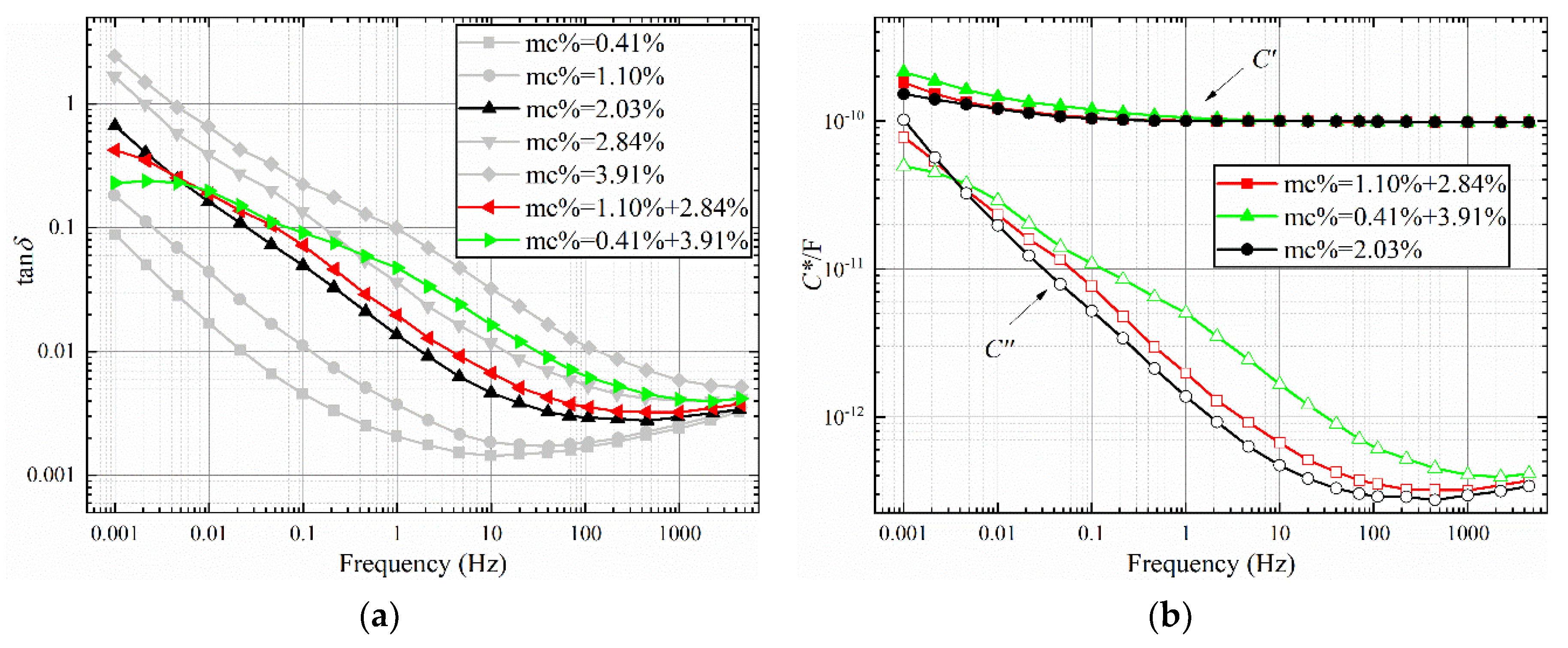

3.1.2. Non-Uniform Moisture

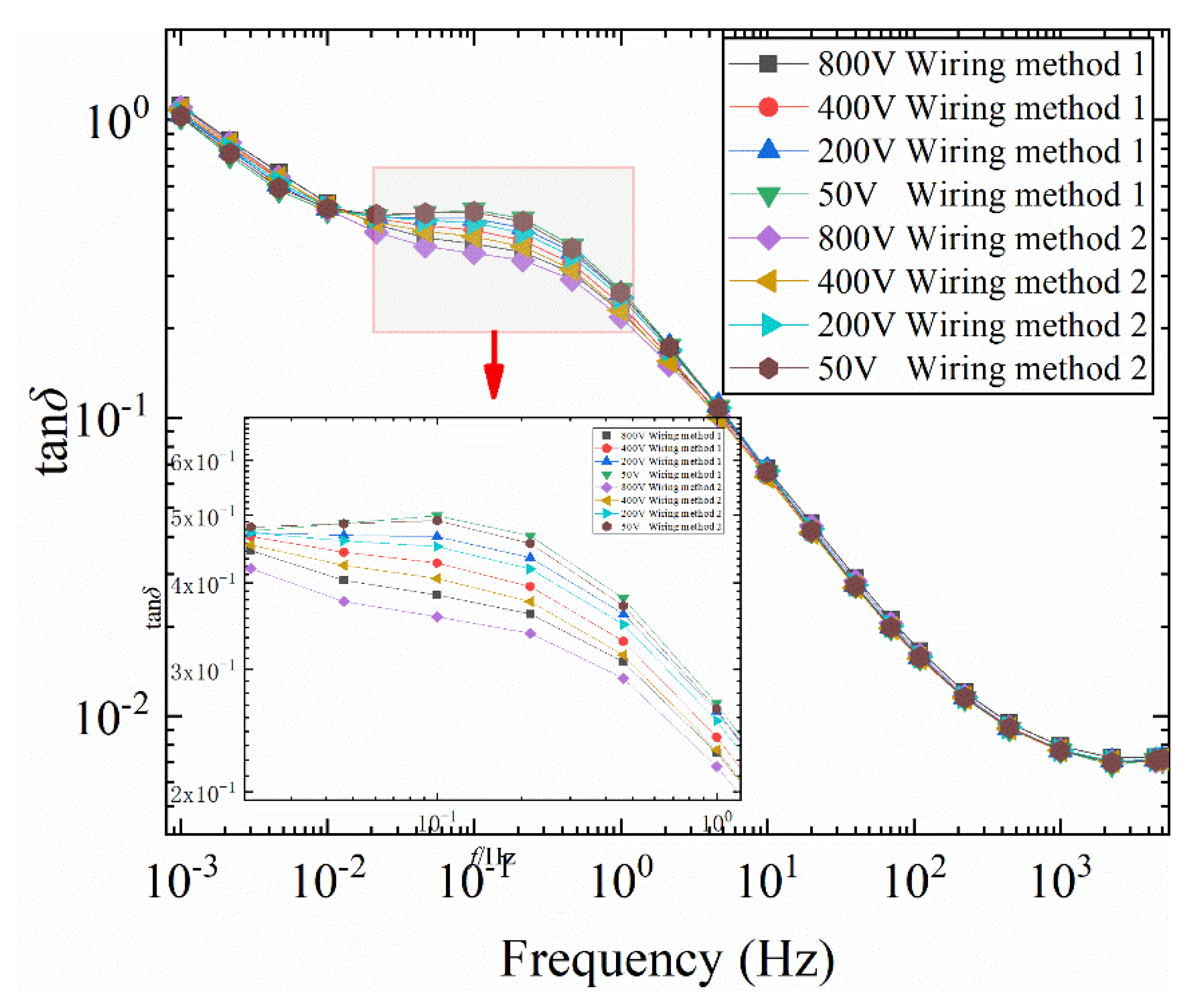

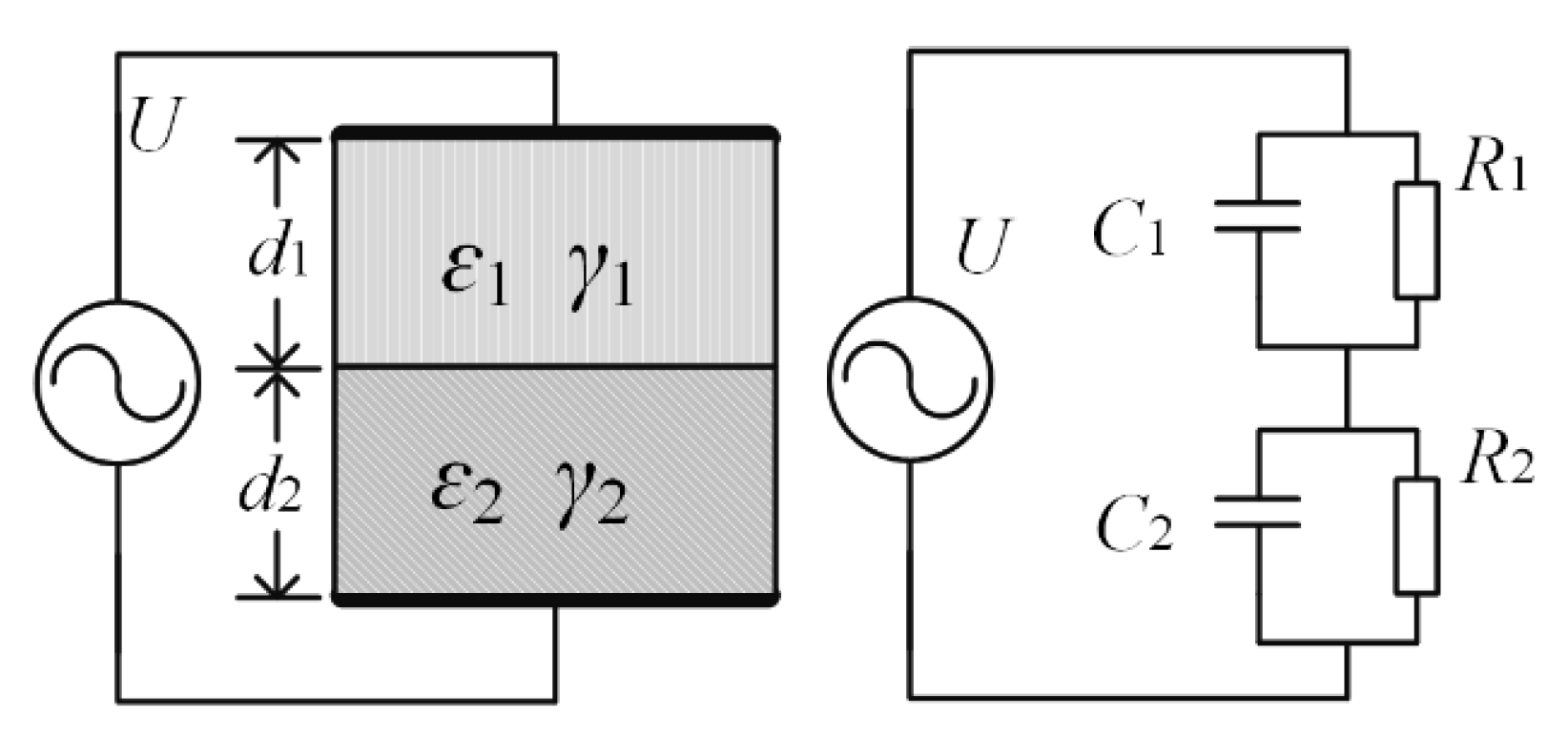

3.2. Bushing Model

3.2.1. Non-Central Symmetric Distribution of Moisture

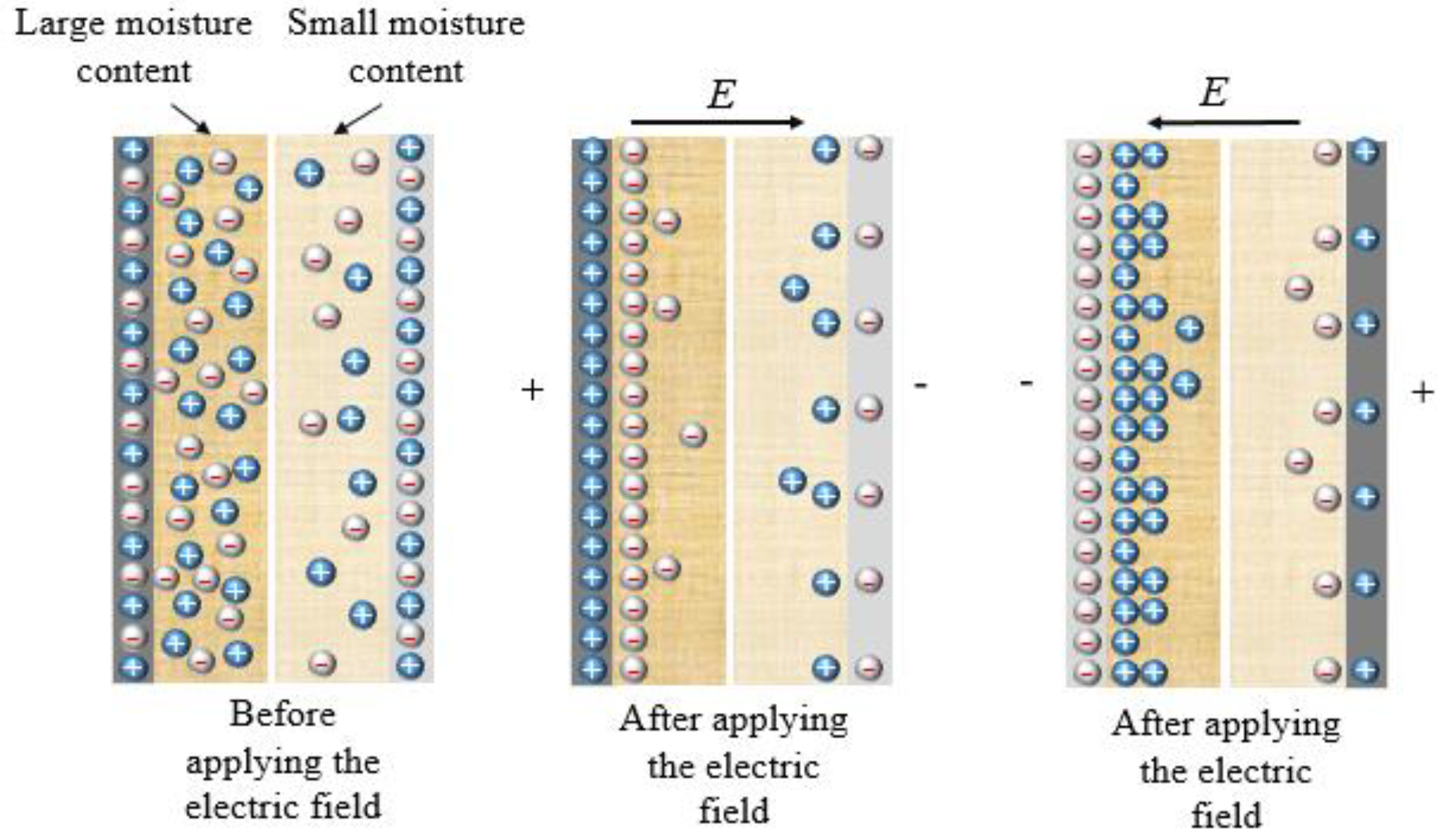

3.2.2. The Influence of Voltage

3.1.3. The Influence of Temperature

4. Discussion

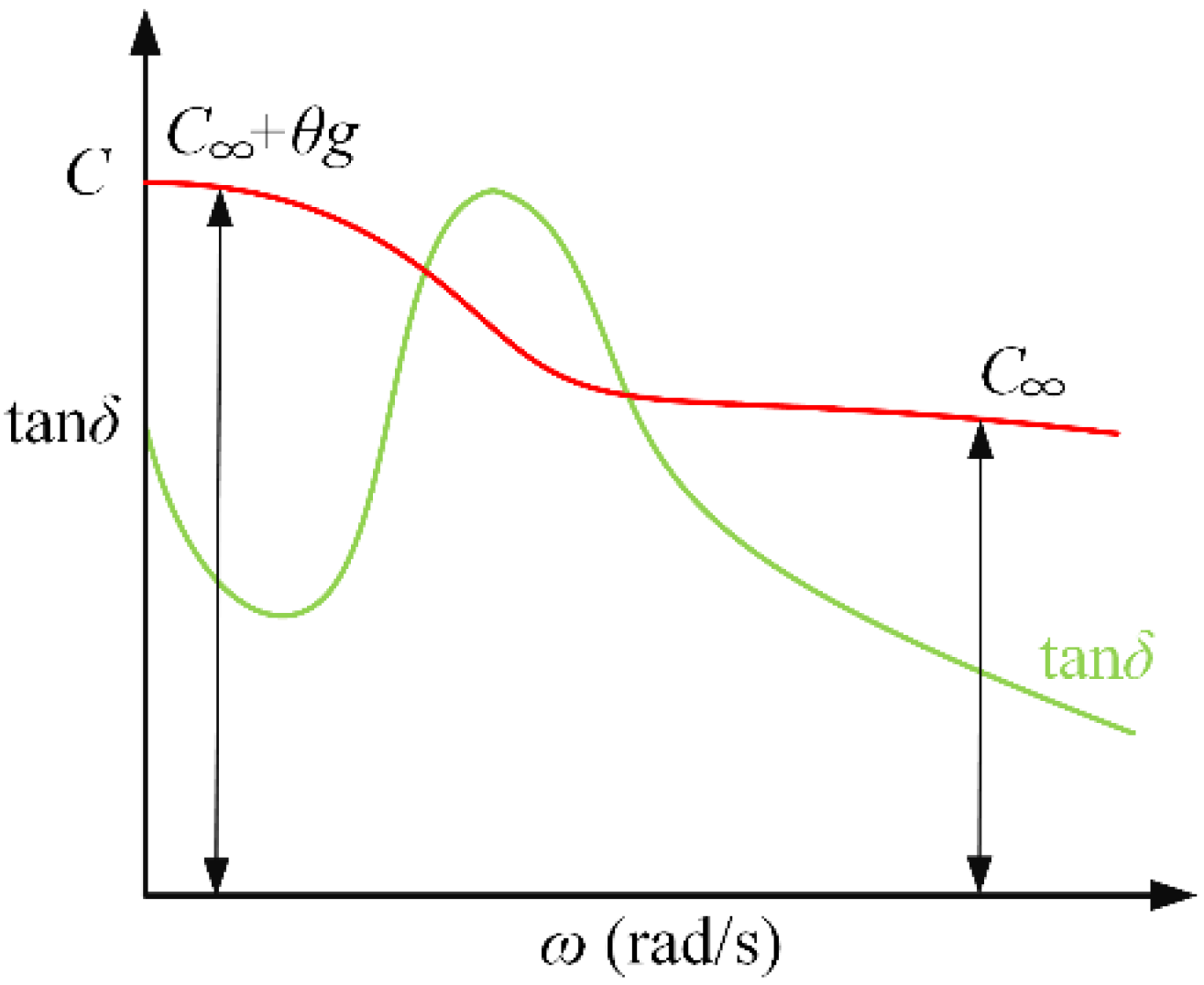

4.1. Non-Uniform Moisture Distribution

4.2. Non-Central Symmetric Distribution of Moisture

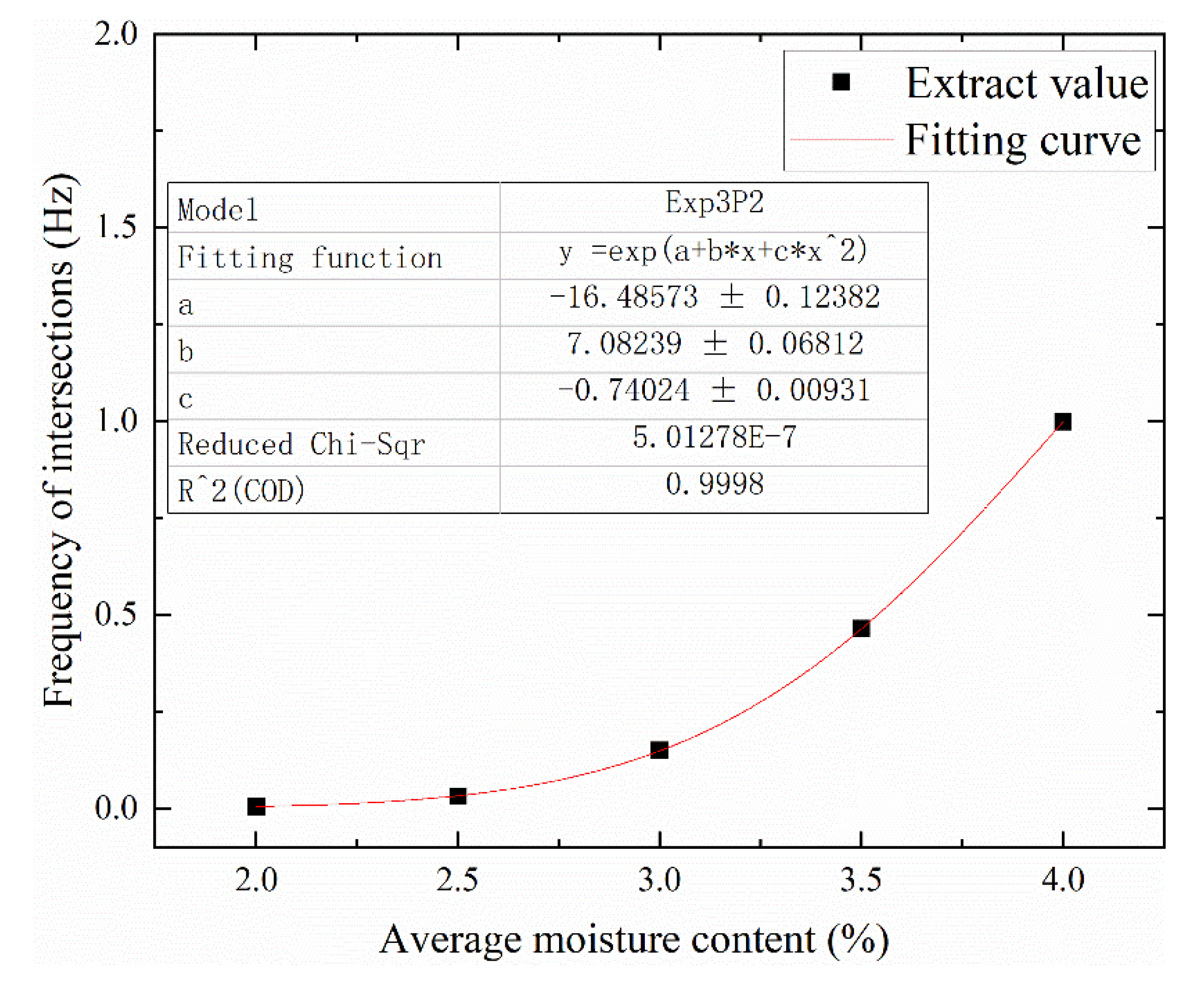

4.3. Assessment Method

5. Conclusions

- (1)

- As the non-uniformity coefficient increases from 0 to 2, the tanδ-f curve of the non-uniform wetted sample fluctuates around the curve of the uniform sample, and shows a loss peak in the high frequency band. For the sample with average moisture content of 2%, 3%, and 4%, the combinations of 0.41% + 3.91%, 0.41% + 6.11%, and 2.03% + 6.11% have the largest fluctuation. There is a common intersection point between the tanδ-f curves of the non-uniform moisture samples with the same average moisture content. For the sample combinations with average water content of 2%, 3%, and 4%, the frequencies corresponding to their intersections are 0.0046 Hz, 0.15 Hz, and 1 Hz, respectively.

- (2)

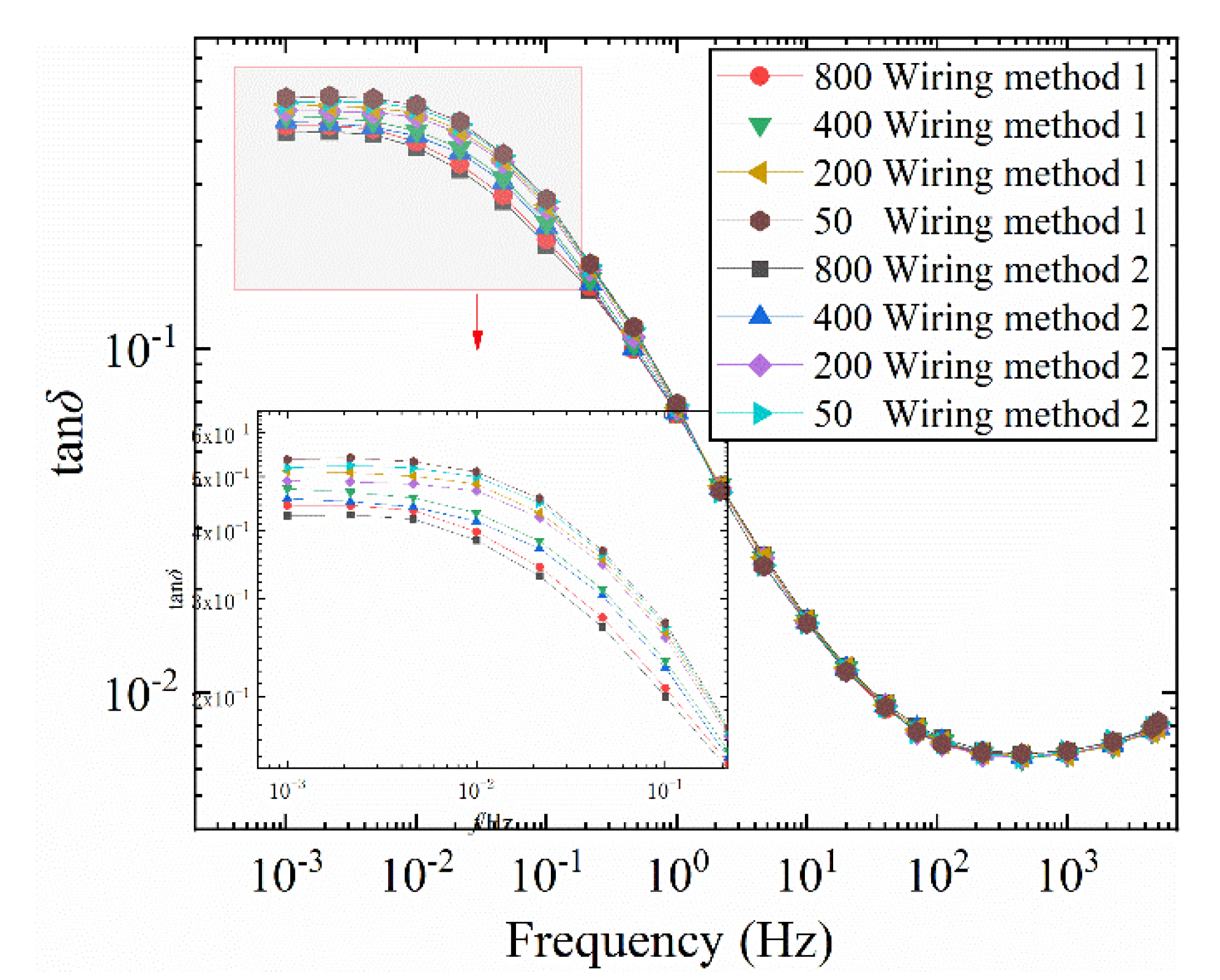

- In the single-cycle FDS test of bushing model, when the positive electrode is first added to the area with higher moisture content, the amplitude of the tanδ-f curve is smaller. The tanδ-f curves under different wiring methods constitute a “ring-shaped” loss peak. As the voltage increases from 50V to 800V, the frequency corresponding to the loss peak of the tanδ-f curve difference decreases from 0.215 Hz to 0.046 Hz at 50 °C. As the temperature decreases from 50 ° C to 30 ° C, the frequency corresponding to the loss peak of the tanδ-f curve difference decreases from 0.046 Hz to below 0.001 Hz at a voltage of 800 V.

Author Contributions

Funding

Conflicts of Interest

References

- Zheng, H.; Lai, B.; Zhang, Y.; Liu, J.; Yang, S. Correction for polarization current curve of polymer insulation materials in transformers considering the temperature and moisture effects. Polymers 2020, 12, 143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Xiao, K.; Chen, B.; Li, Y. Study of the impact of initial moisture content in oil impregnated insulation paper on thermal aging rate of condenser bushing. Energies 2015, 8, 14298–14310. [Google Scholar] [CrossRef]

- Fabre, J.; Pichon, A. Deteriorating Processes and Products of Paper in Oil. Application to Transformers; CIGRE, Report No. 137; CIGRE: Paris, France, 1960. [Google Scholar]

- Liu, J.; Fan, X.; Zhang, Y.; Zheng, H.; Wang, Z.; Zhao, X. A modified aging kinetics model for aging condition prediction of transformer polymer insulation by employing the frequency domain spectroscopy. Polymers 2019, 11, 2082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, Y.; Ma, H.; Saha, T.K.; Ekanayake, C. Understanding moisture dynamics and its effect on the dielectric response of transformer insulation. IEEE Trans. Power Deliv. 2015, 30, 2195–2204. [Google Scholar] [CrossRef] [Green Version]

- Baral, A.; Chakravorti, S. Assessment of non-uniform aging of solid dielectric using system poles of a modified debye model for oil-paper insulation of transformers. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1922–1933. [Google Scholar] [CrossRef]

- Ekanayake, C.; Gubanski, S.; Graczkowski, A.; Walczak, K. Frequency response of oil impregnated pressboard and paper samples for estimating moisture in transformer insulation. IEEE Trans. Power Deliv. 2006, 21, 1309–1317. [Google Scholar] [CrossRef]

- Macdonald, J.R. Theory of ac space-charge polarization effects in photoconductors, semiconductors, and electrolytes. Phys. Rev. 1953, 92, 4–17. [Google Scholar] [CrossRef]

- Frood, D.; Gallagher, T. Space-charge dielectric properties of water and aqueous electrolytes. J. Mol. Liq. 1996, 69, 183–200. [Google Scholar] [CrossRef]

- Chan, J.C.; Hui, M.; Saha, T.K.; Ekanayake, C. Self-adaptive partial discharge signal de-noising based on ensemble empirical mode decomposition and automatic morphological thresholding. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 294–303. [Google Scholar] [CrossRef]

- Oommen, T.V. Moisture equilibrium charts for transformer insulation drying practice. IEEE Trans. Power Appar. Syst. 1984, 103, 3063–3067. [Google Scholar]

- Ojha, S.K.; Purkait, P.; Chakravorti, S. Modeling of relaxation phenomena in transformer oil-paper insulation for understanding dielectric response measurements. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3190–3198. [Google Scholar] [CrossRef]

- Cui, Y.; Ma, H.; Saha, T.; Cui, Y.; Ma, H.; Saha, T. Understanding the effect of non-uniform ageing on dielectric response of transformer insulation. In Proceedings of the IEEE Power and Energy Society 2017 General Meeting, Chicago, IL, USA, 16–20 July 2017. [Google Scholar]

- Zhou, Y.; Hao, M.; Chen, G.; Wilson, G.; Jarman, P. Study of the dielectric response in mineral oil using frequency-domain measurement. J. Appl. Phys. 2014, 115, 124105. [Google Scholar] [CrossRef]

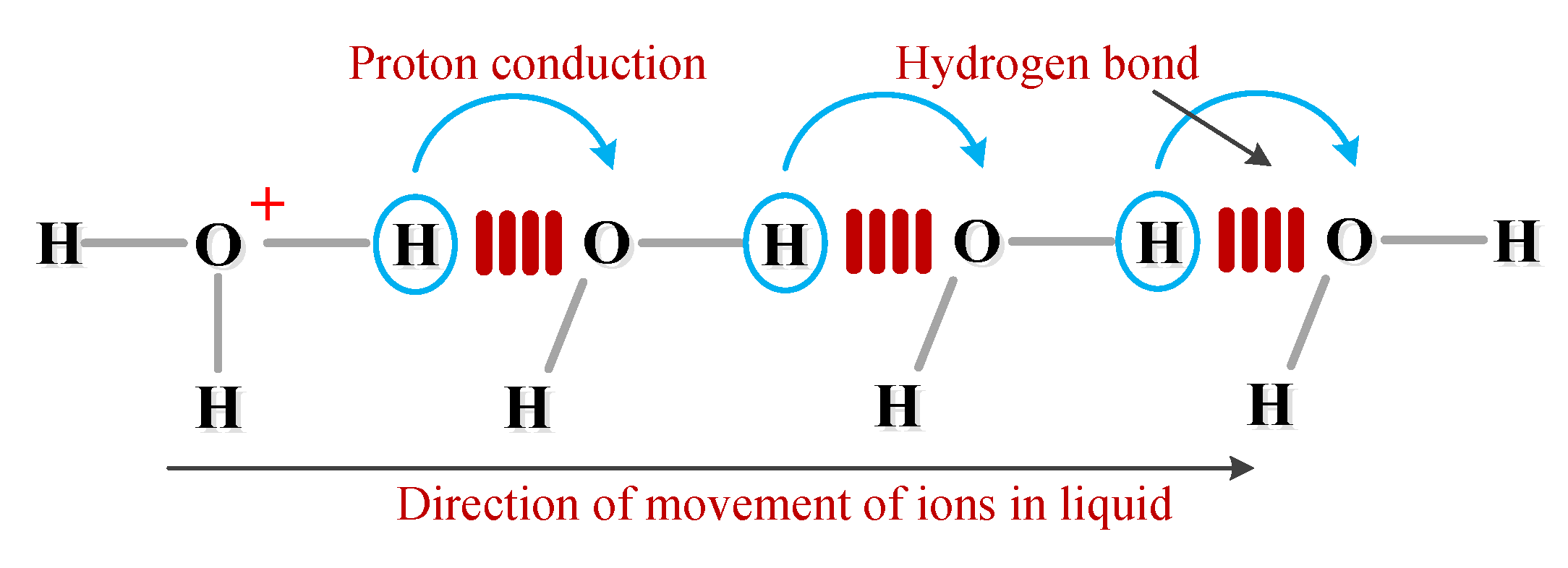

- Hashimoto, T.; Hiwatari, Y. H3O+ and OH− in water. Mol. Sim. 1999, 21, 239–247. [Google Scholar] [CrossRef]

- Tuckerman, M.; Laasonen, K.; Sprik, M.; Parrinello, M. Ab initio molecular dynamics simulation of the solvation and transport of H3O+ and OH− ions in water. J. Phys. Chem. 1995, 99, 5749–5752. [Google Scholar] [CrossRef]

- Garton, C. Dielectric loss in thin films of insulating liquids. J. Inst. Electr. Eng. Part II Power Eng. 1941, 88, 103–120. [Google Scholar] [CrossRef]

- Coelho, R. Physics of Dielectrics for the Engineer; Elsevier: New York, NY, USA, 1979. [Google Scholar]

- Zhang, D.; Yun, H.; Zhan, J.; Sun, X.; He, W.; Niu, C.; Mu, H.; Zhang, G.-J. Insulation condition diagnosis of oil-immersed paper insulation based on non-linear frequency-domain dielectric response. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1980–1988. [Google Scholar] [CrossRef]

| Plate Layer | Thickness (mm) | Upper Plate Difference (mm) | Lower Plate Difference (mm) | Plate Length (mm) |

|---|---|---|---|---|

| 0 | 260 | |||

| 1 | 1.6 | 24 | 6 | 220 |

| 2 | 1.6 | 29 | 8 | 180 |

| 3 | 1.6 | 34 | 8 | 140 |

| 4 | 1.6 | 57 | 16 | 65 |

| Serial Number | Laminate 1 mc (%) | Laminate 1 mc (%) | Laminate 1 mc (%) | Laminate 1 mc (%) | Damp Type |

|---|---|---|---|---|---|

| 1# | 4 | 4 | 1 | 1 | inner |

| 2# | 1 | 1 | 4 | 4 | outer |

| 3# | 1 | 4 | 4 | 1 | middle |

| 4# | 1 | 1 | 1 | 1 | uniform |

| Average Moisture Content (%) | Combination | n |

|---|---|---|

| 2% | 2% + 2% | 0 |

| 1% + 3% | 1 | |

| dry + 4% | 2 | |

| 3# | 3% + 3% | 0 |

| 2% + 4% | 2/3 | |

| dry + 6% | 4/3 | |

| 4# | 4% + 4% | 0 |

| 3% + 5% | 1/2 | |

| 2% + 6% | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Long, G.; Li, Y.; Mu, H.; Zhang, G. Effect of Radial Moisture Distribution on Frequency Domain Dielectric Response of Oil-Polymer Insulation Bushing. Polymers 2020, 12, 1219. https://doi.org/10.3390/polym12061219

Zhang D, Long G, Li Y, Mu H, Zhang G. Effect of Radial Moisture Distribution on Frequency Domain Dielectric Response of Oil-Polymer Insulation Bushing. Polymers. 2020; 12(6):1219. https://doi.org/10.3390/polym12061219

Chicago/Turabian StyleZhang, Daning, Guanwei Long, Yang Li, Haibao Mu, and Guanjun Zhang. 2020. "Effect of Radial Moisture Distribution on Frequency Domain Dielectric Response of Oil-Polymer Insulation Bushing" Polymers 12, no. 6: 1219. https://doi.org/10.3390/polym12061219