Fabrication of Micro-Structured LED Diffusion Plate Using Efficient Micro Injection Molding and Micro-Ground Mold Core

Abstract

:1. Introduction

2. The Optical Design and Light Efficiency Simulation of the Micro-structured LED Diffusion Plate

3. Experimental Details

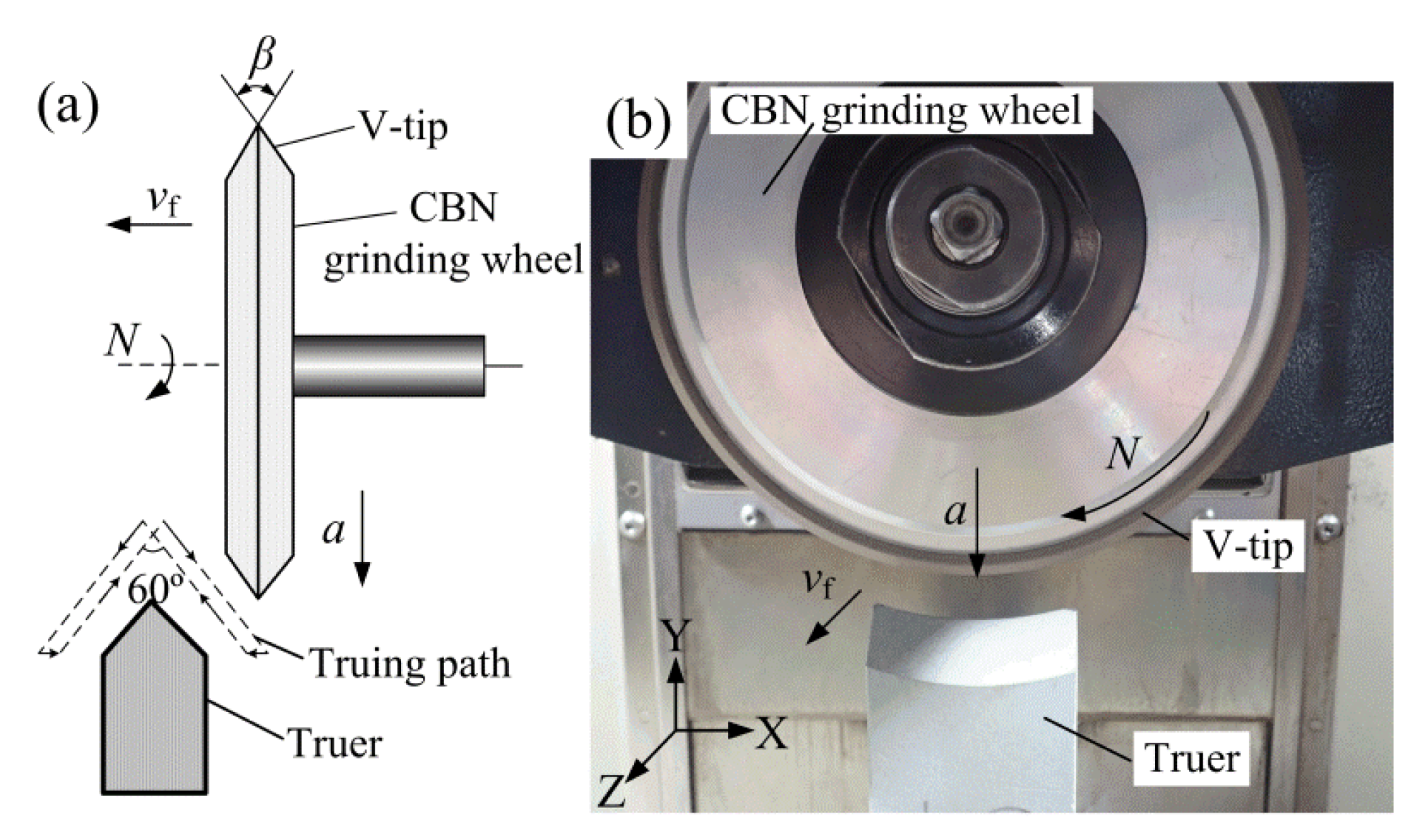

3.1. Precision Truing of the V-Tip CBN Grinding Wheel

3.2. Precision Grinding of the Micro-structured Mold Core

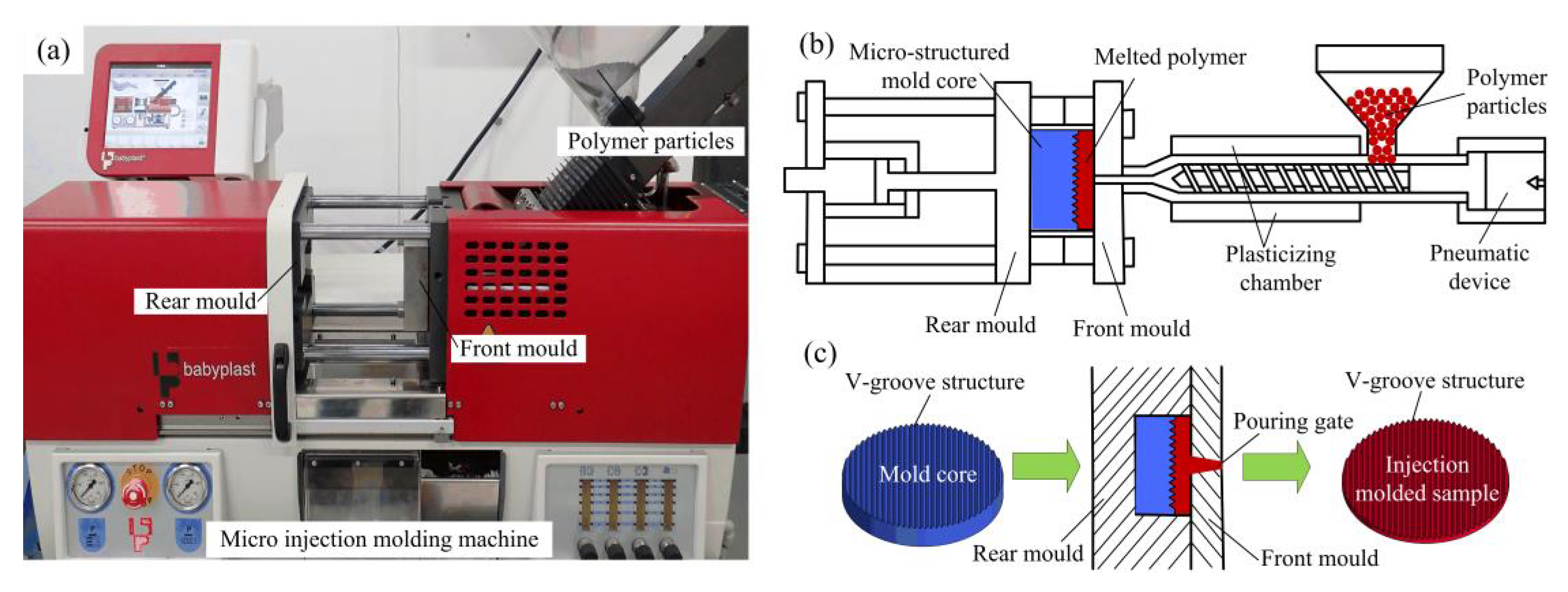

3.3. Micro injection Molding of the Micro-structured LED Diffusion Plate

3.4. Light Efficiency Testing of the Micro-structured LED Diffusion Plate

4. Results and Discussion

4.1. Truing Accuracy of the Grinding Wheel V-Tip

4.2. Photos and Surface Topographies of the Micro-ground Mold Core and the Injection Molded Micro-structured Diffusion Plate

4.3. The Section Profiles of the Micro-structured Mold Core and Diffusion Plate

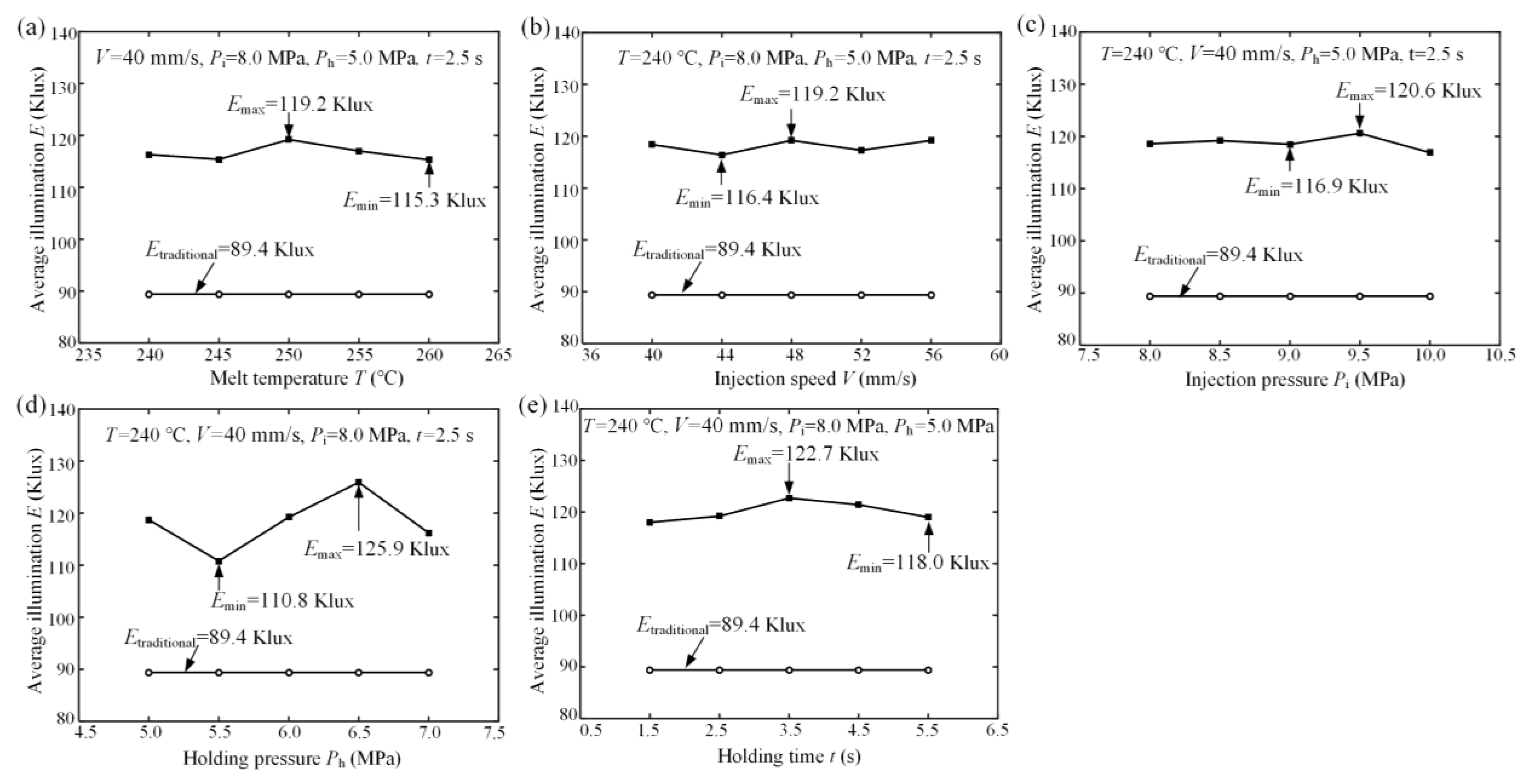

4.4. Light Efficiency Analysis of the Micro-structured LED Diffusion Plate

5. Conclusions

- Through the light efficiency simulation method, the optimal micro-groove parameters, namely V-groove depth and V-groove angle, were designed to be 300 μm and 60°, respectively.

- The machining errors of the V-groove depth and V-groove angle for the micro-ground mold core were 6.2 μm and 0.57°, respectively. The micro-forming errors of the V-groove angle and V-tip radius for the micro-structured diffusion plate in micro injection molding were 0.08° and 0.12 μm, respectively. The shape accuracy of the micro-ground mold core and the replication rate of the micro injection molded diffusion plate were 9.2 μm and 90.26%, respectively.

- The holding pressure has the greatest effect on the light efficiency of the micro-structured diffusion plate. When the melt temperature, injection speed, injection pressure, holding pressure, and holding time were 240 ℃, 40 mm/s, 8.0 MPa, 6.5 MPa, and 2.5 s, respectively, the measured illumination of the micro-structured diffusion plate reached a maximum value of 125.9 Klux, improving the illumination by about 40.82% against the traditional diffusion plate.

- The prediction accuracies of the designed light efficiency simulation method for the traditional and micro-structured diffusion plates are 94.38% and 90.33%, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Ramírez, M.G.; Sirvent, D.; Morales-Vidal, M.; Ortuño, M.; Martínez-Guardiola, F.J.; Francés, J.; Pascual, I. LED-Cured Reflection Gratings Stored in an Acrylate-Based Photopolymer. Polymers 2019, 11, 632. [Google Scholar]

- Lu, L.B.; Zhang, Z.; Guan, Y.C.; Zheng, H.Y. Enhancement of Heat Dissipation by Laser Micro Structuring for LED Module. Polymers. 2018, 10, 886. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chien, C.H.; Chen, C.C.; Chen, T.; Lin, Y.M.; Liu, Y.C. Thermal deformation of microstructure diffuser plate in LED backlight unit. J. Soc. Inf. Display. 2016, 24, 99–109. [Google Scholar] [CrossRef]

- Chien, C.H.; Chen, Z.P. The study of integrated LED-backlight plate fabricated by micromachining technique. Microsyst. Technol. 2009, 15, 383–389. [Google Scholar] [CrossRef]

- Pardo, D.A.; Jabbour, G.E.; Peyghambarian, N. Application of Screen Printing in the Fabrication of Organic Light-Emitting Devices. Adv. Mater. 2020, 12, 1249–1252. [Google Scholar] [CrossRef]

- Weng, C.; Wang, F.; Zhou, M.; Yang, D.; and Jiang, B. Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl. Surf. Sci. 2018, 436, 224–233. [Google Scholar] [CrossRef]

- Liao, Q.H.; Zhou, C.L.; Lu, Y.J.; Wu, X.Y.; Chen, F.M.; Lou, Y. Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM. Polymers 2019, 11, 1591. [Google Scholar] [CrossRef] [Green Version]

- Maghsoudi, K.; Jafari, R.; Momen, G.; Farzaneh, M. Micro-nanostructured polymer surfaces using injection molding: A review. Mater. Today. Commun. 2017, 13, 126–143. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Lucchetta, G. Analysis of the influence of part thickness on the replication of micro-structured surfaces by injection molding. Mater Design. 2016, 95, 219–224. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Parenti, P.; Annoni, M.; Lucchetta, G. Impact of deep cores surface topography generated by micro milling on the demolding force in micro injection molding. J. Mater. Process. Tech. 2017, 246, 211–223. [Google Scholar] [CrossRef]

- Baruffi, F.; Calaon, M.; Tosello, G. Micro-injection moulding in-line quality assurance based on product and process fingerprints. Micromachines 2018, 9, 293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parenti, P.; Masato, D.; Sorgato, M.; Lucchetta, G.; Annoni, M. Surface footprint in molds micromilling and effect on part demoldability in micro injection molding. J. Manuf. Process. 2017, 29, 160–174. [Google Scholar] [CrossRef]

- Sorgato, M.; Masato, D.; Lucchetta, G. Effects of machined cavity texture on ejection force in micro injection molding. Precis. Eng. 2017, 50, 440–448. [Google Scholar] [CrossRef]

- Kim, J.H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Facile fabrication of superhydrophobic surfaces from austenitic stainless steel (AISI 304) by chemical etching. Appl. Surf. Sci. 2018, 439, 598–604. [Google Scholar] [CrossRef]

- Zhou, C.L.; Ngai, T.W.L.; Li, L.J. Wetting behaviour of laser textured Ti3SiC2 surface with micro-grooved structures. J. Mater. Sci. Technol. 2016, 32, 805–812. [Google Scholar]

- Zhou, C.L.; Wu, X.Y.; Lu, Y.J.; Wu, W.; Zhao, H.; Li, L.J. Fabrication of hydrophobic Ti3SiC2 surface with micro-grooved structures by wire electrical discharge machining. Ceram. Int. 2018, 44, 18227–18234. [Google Scholar] [CrossRef]

- Xu, S.L.; Shimada, K.; Mizutani, M.; Kuriyagawa, T. Fabrication of Hybrid micro/nano-textured surfaces using rotary ultrasonic machining with one-point diamond tool. Int. J. Mach. Tools Manuf. 2014, 86, 12–17. [Google Scholar] [CrossRef]

- Wang, J.S.; Zhang, X.D.; Fang, F.Z.; Chen, R.T. Diamond cutting of micro-structure array on brittle material assisted by multi-ion implantation. Int. J. Mach. Tools Manuf. 2019, 137, 58–66. [Google Scholar] [CrossRef]

- Lu, Y.J.; Chen, F.M.; Wu, X.Y.; Zhou, C.L.; Lou, Y.; Li, L.J. Fabrication of micro-structured polymer by micro injection molding based on precise micro-ground mold core. Micromachines. 2019, 10, 253. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.J.; Li, L.J.; Xie, J.; Zhou, C.L.; Guo, R.B. Dry electrical discharge dressing and truing of diamond grinding wheel V-tip for micro-grinding. In Proceedings of the The 5th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering (ICMMCCE 2017), Chongqing, China, 24–25 July 2017; Atlantis Press: Paris, France, 2017. [Google Scholar]

- Li, P.; Xie, J.; Cheng, J.; Jiang, Y.N. Study on weak-light photovoltaic characteristics of solar cell with a microgroove lens array on glass substrate. Opt. Express. 2015, 23, 192–203. [Google Scholar] [CrossRef]

- Kim, D.S.; Kim, D.H.; Jang, J.H. A nanoscale conical polymethyl methacrylate (PMMA) sub-wavelength structure with a high aspect ratio realized by a stamping method. Opt. Express. 2013, 21, 8450–8459. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.J.; Xie, J.; Si, X.H. Study on micro-topographical removals of diamond grain and metal bond in dry electro-contact discharge dressing of coarse diamond grinding wheel. Int. J. Mach. Tools Manuf. 2015, 88, 118–130. [Google Scholar] [CrossRef]

- Xie, J.; Xie, H.F.; Luo, M.J. Dry electro-contact discharge mutual-wear truing of micro diamond wheel V-tip for precision micro-grinding. Int. J. Mach. Tools Manuf. 2012, 60, 44–51. [Google Scholar] [CrossRef]

- Xie, J.; Zhuo, Y.W.; Tan, T.W. Experimental study on fabrication and evaluation of micro pyramid-structured silicon surface using a V-tip of diamond grinding wheel. Precis. Eng. 2011, 35, 173–182. [Google Scholar] [CrossRef]

- Seo, Y.S.; Park, K. Direct patterning of micro-features on a polymer substrate using ultrasonic vibration. Microsyst. Technol. 2012, 18, 2053–2061. [Google Scholar]

- Lu, Y.J.; Chen, F.M.; Wu, X.Y.; Zhou, C.L.; Zhao, H.; Li, L.J.; Tang, Y. Precise WEDM of micro-textured mould for micro-injection molding of hydrophobic polymer surface. Mater. Manuf. Process. 2019, 34, 1342–1351. [Google Scholar] [CrossRef]

| No. | V-Groove Depth h (μm) | V-Groove Angle θ (°) | Illuminance E (Klux) |

|---|---|---|---|

| 1 | 0 | 0 | 94.42 |

| 2 | 100 | 60 | 134.29 |

| 3 | 100 | 90 | 121.64 |

| 4 | 100 | 120 | 103.56 |

| 5 | 100 | 150 | 95.49 |

| 6 | 200 | 60 | 132.82 |

| 7 | 200 | 90 | 123.42 |

| 8 | 200 | 120 | 102.55 |

| 9 | 200 | 150 | 95.22 |

| 10 | 300 | 60 | 138.07 |

| 11 | 300 | 90 | 122.04 |

| 12 | 300 | 120 | 103.63 |

| 13 | 300 | 150 | 94.49 |

| 14 | 400 | 60 | 132.79 |

| 15 | 400 | 90 | 122.02 |

| 16 | 400 | 120 | 102.07 |

| 17 | 400 | 150 | 94.45 |

| CNC Grinding Machine | SMART B818 Ⅲ |

|---|---|

| Grinding wheel | #600 CBN resin-bonded grinding wheel Wheel speed N = 3000 r/min |

| Workpiece | Super-mirror mold steel (S136H) |

| Rough grinding | vf = 1000 mm/min; a = 5 μm, Σa = 290 μm |

| Fine grinding | vf = 1000 mm/min; a = 1 μm, Σa = 10 μm |

| Cooling fluid | Water-soluble coolant |

| V-groove machining parameters | V-groove angle α = 60°, V-groove depth H = 300 μm |

| Process Parameters | Level |

|---|---|

| Melt temperature T (℃) | 240, 245, 250, 255, 260 |

| Injection speed V (mm/s) | 40, 44, 48, 52, 56 |

| Injection pressure Pi (MPa) | 8.0, 8.5, 9.0, 9.5, 10.0 |

| Holding pressure Ph (MPa) | 5.0, 5.5, 6.0, 6.5, 7.0 |

| Holding time T (s) | 1.5, 2.5, 3.5, 4.5, 5.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Luo, W.; Wu, X.; Xu, B.; Wang, C.; Li, J.; Li, L. Fabrication of Micro-Structured LED Diffusion Plate Using Efficient Micro Injection Molding and Micro-Ground Mold Core. Polymers 2020, 12, 1307. https://doi.org/10.3390/polym12061307

Lu Y, Luo W, Wu X, Xu B, Wang C, Li J, Li L. Fabrication of Micro-Structured LED Diffusion Plate Using Efficient Micro Injection Molding and Micro-Ground Mold Core. Polymers. 2020; 12(6):1307. https://doi.org/10.3390/polym12061307

Chicago/Turabian StyleLu, Yanjun, Wang Luo, Xiaoyu Wu, Bin Xu, Chunjin Wang, Jiajun Li, and Liejun Li. 2020. "Fabrication of Micro-Structured LED Diffusion Plate Using Efficient Micro Injection Molding and Micro-Ground Mold Core" Polymers 12, no. 6: 1307. https://doi.org/10.3390/polym12061307