A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends

Abstract

:1. Introduction

2. Carbon Family Materials

2.1. Effect of Various Carbon-Based Materials on Flammability of Polymer Composites

2.1.1. Fullerene

2.1.2. Nanotubes

2.1.3. Graphene and Graphene Derivatives

2.1.4. Graphite

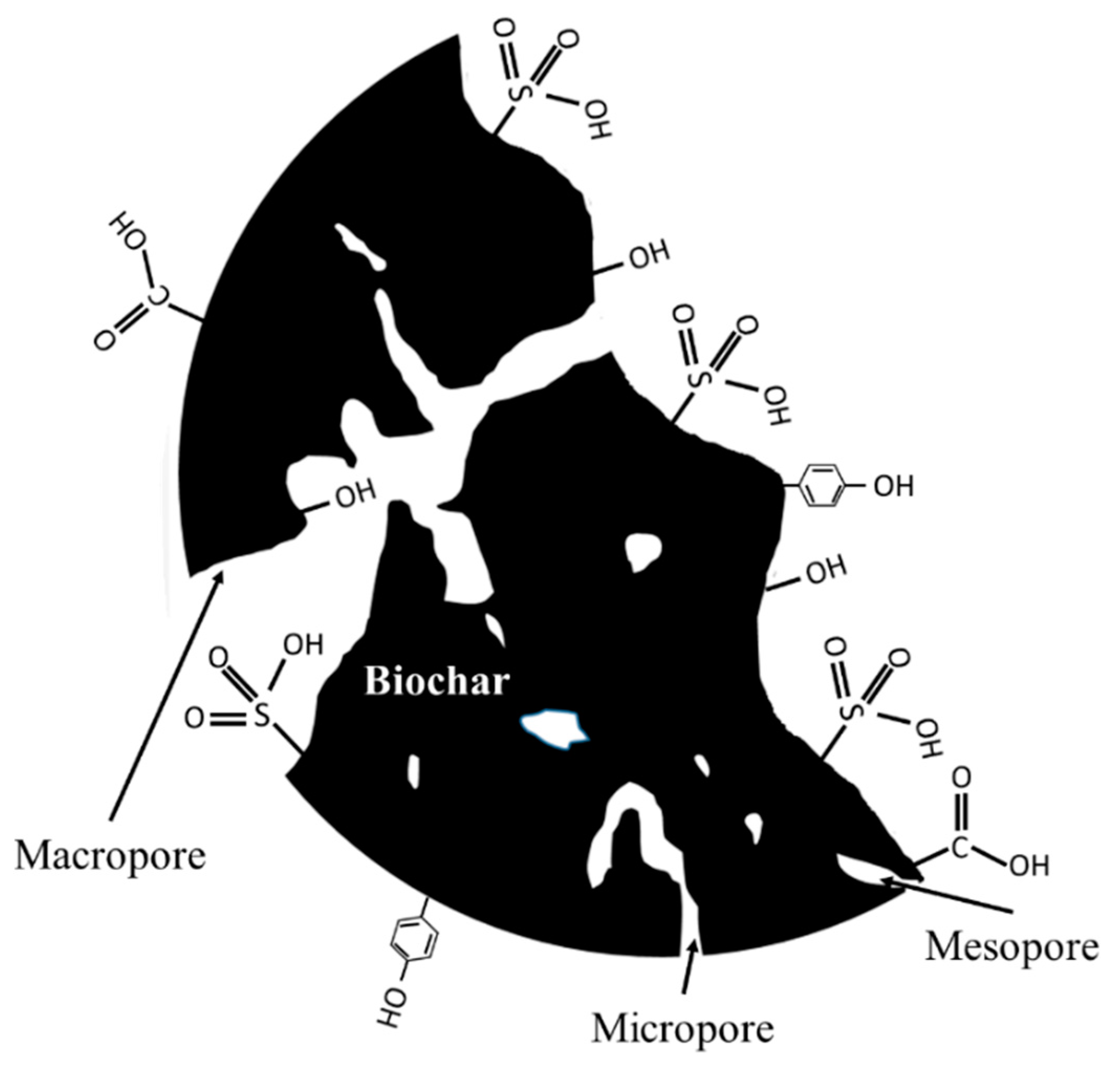

2.1.5. Biochar (BC)

2.1.6. Other Carbon-Based Materials

3. Flammability Measuring Techniques

3.1. LOI Test

3.2. Vertical Burn Test (UL 94)

3.3. Micro-Scale Combustion Calorimetry (MCC)

3.4. Cone Calorimetry

- TTI or tig in s: describes the ease of ignition of the polymeric material by measuring how fast the flaming combustion occurs when the polymeric material is exposed to incident heat flux (in kW/m2) and in oxygen-controlled ambient environment. Hence, polymeric material with a high TTI indicates material that is difficult to be ignited. In the case of flame-retarding polymer composites, sometimes the addition of FRs lead to advance decomposition and, thereby, the reduction of TTI (Table 1. Thus, the shorter TTI is not an indication of worsening flame retardancy of a material.

- HRR in kW/m2: is known as the heat release per unit time and unit surface area during the cone calorimetry test. Mainly, the amount of peak HRR (pHRR) and time taken to reach the pHRR are used to measure the fire performance of polymeric materials.

- Total heat release (THR in kJ/m2): is the total quantity of calorific value released per unit area after the combustion of materials, and this can be determined according to the integration of the HRR vs. time.

- Mass loss rate (MLR in g/s): is the amount of mass loss of polymeric material per unit time during combustion.

4. Conclusions and Scope for Future Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Health Organization. A WHO Plan for Burn Prevention and Care; World Health Organization: Geneva, Switzerland, 2008. [Google Scholar]

- Younis, A. Flammability properties of polypropylene containing montmorillonite and some of silicon compounds. Egypt. J. Pet. 2017, 26, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Fang, L.; Lu, X.; Zeng, J.; Chen, Y.; Tang, Q. Investigation of the Flame-Retardant and Mechanical Properties of Bamboo Fiber-Reinforced Polypropylene Composites with Melamine Pyrophosphate and Aluminum Hypophosphite Addition. Materials 2020, 13, 479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60: Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Ribeiro, B.; Botelho, E.C.; Costa, M.L.; Bandeira, C.F. Carbon nanotube buckypaper reinforced polymer composites: A review. Polímeros 2017, 27, 247–255. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.; Geim, A.K.; Morozov, S.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Gürünlü, B.; Yücedağ, Ç.T.; Bayramoğlu, M.R. Green Synthesis of Graphene from Graphite in Molten Salt Medium. J. Nanomater. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Pan, Y.; Guo, Z.; Ran, S.; Fang, Z. Influence of fullerenes on the thermal and flame-retardant properties of polymeric materials. J. Appl. Polym. Sci. 2019, 137, 47538. [Google Scholar] [CrossRef] [Green Version]

- Krusic, P.J.; Wasserman, E.; Keizer, P.N.; Morton, J.R. Radical reactions of C60. Science 1991, 254, 1183–1185. [Google Scholar] [CrossRef]

- Zuev, V.V. Polymer Nanocomposites Containing Fullerene C60 Nanofillers. Macromol. Symp. 2011, 301, 157–161. [Google Scholar] [CrossRef]

- Zuev, V.V.; Kostromin, S.; Shlykov, A.V. The effect of fullerene fillers on the mechanical properties of polymer nanocomposites. Mech. Compos. Mater. 2010, 46, 147–154. [Google Scholar] [CrossRef]

- Ogasawara, T.; Ishida, Y.; Kasai, T. Mechanical properties of carbon fiber/fullerene-dispersed epoxy composites. Compos. Sci. Technol. 2009, 69, 2002–2007. [Google Scholar] [CrossRef]

- Kausar, A. Adhesion, morphology, and heat resistance properties of polyurethane coated poly (methyl methacrylate)/fullerene-C60 composite films. Compos. Interface 2017, 24, 649–662. [Google Scholar] [CrossRef]

- Song, P.; Zhu, Y.; Tong, L.; Fang, Z. C60reduces the flammability of polypropylene nanocomposites byin situforming a gelled-ball network. Nanotechnology 2008, 19, 225707. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Wang, Z.; Fang, Z. Fabrication of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-decorated fullerene to improve the anti-oxidative and flame-retardant properties of polypropylene. Compos. Part B Eng. 2020, 183, 107672. [Google Scholar] [CrossRef]

- Beyer, G. Short communication: Carbon nanotubes as flame retardants for polymers. Fire Mater. 2002, 26, 291–293. [Google Scholar] [CrossRef]

- Ajayan, P.M. Nanotubes from Carbon. Chem. Rev. 1999, 99, 1787–1800. [Google Scholar] [CrossRef]

- Al Sheheri, S.Z.; Al-Amshany, Z.M.; Al Sulami, Q.A.; Tashkandi, N.Y.; Hussein, M.A.; El-Shishtawy, R.M. The preparation of carbon nanofillers and their role on the performance of variable polymer nanocomposites. Des. Monomers Polym. 2019, 22, 8–53. [Google Scholar] [CrossRef] [Green Version]

- Kausar, A.; Rafique, I.; Anwar, Z.; Muhammad, B. Recent Developments in Different Types of Flame Retardant and Effect on Fire Retardancy of Epoxy Composite. Polym. Technol. Eng. 2016, 55, 1512–1535. [Google Scholar] [CrossRef]

- Patel, P.; A Stec, A.; Hull, R.; Naffakh, M.; Díez-Pascual, A.M.; Ellis, G.; Safronava, N.; Lyon, R.E. Flammability properties of PEEK and carbon nanotube composites. Polym. Degrad. Stab. 2012, 97, 2492–2502. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Du, F.; Winey, K.I.; Groth, K.; Shields, J.R.; Bellayer, S.P.; Kim, H.; Douglas, J.F. Flammability properties of polymer nanocomposites with single-walled carbon nanotubes: Effects of nanotube dispersion and concentration. Polymer 2005, 46, 471–481. [Google Scholar] [CrossRef]

- Wang, X.; Kalali, E.N.; Wan, J.-T.; Wang, D.-Y. Carbon-family materials for flame retardant polymeric materials. Prog. Polym. Sci. 2017, 69, 22–46. [Google Scholar] [CrossRef]

- Guadagno, L.; De Vivo, B.; Di Bartolomeo, A.; Lamberti, P.; Sorrentino, A.; Tucci, V.; Vertuccio, L.; Vittoria, V. Effect of functionalization on the thermo-mechanical and electrical behavior of multi-wall carbon nanotube/epoxy composites. Carbon 2011, 49, 1919–1930. [Google Scholar] [CrossRef]

- Kuan, C.-F.; Chen, W.J.; Li, Y.-L.; Chen, C.-H.; Kuan, H.; Chiang, C.-L. Flame retardance and thermal stability of carbon nanotube epoxy composite prepared from sol–gel method. J. Phys. Chem. Solids 2010, 71, 539–543. [Google Scholar] [CrossRef]

- Gao, F.; Beyer, G.; Yuan, Q. A mechanistic study of fire retardancy of carbon nanotube/ethylene vinyl acetate copolymers and their clay composites. Polym. Degrad. Stab. 2005, 89, 559–564. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Tong, L.; Xu, Z.; Fang, Z. Synergistic effect of carbon nanotube and clay for improving the flame retardancy of ABS resin. Nanotechnology 2007, 18, 375602. [Google Scholar] [CrossRef]

- Vaisman, L.; Marom, G.; Wagner, H.D. Dispersions of Surface-Modified Carbon Nanotubes in Water-Soluble and Water-Insoluble Polymers. Adv. Funct. Mater. 2006, 16, 357–363. [Google Scholar] [CrossRef]

- Schaefer, D.W.; Zhao, J.; Brown, J.M.; Anderson, D.P.; Tomlin, D.W. Morphology of dispersed carbon single-walled nanotubes. Chem. Phys. Lett. 2003, 375, 369–375. [Google Scholar] [CrossRef]

- Martin, C.; Sandler, J.; Shaffer, M.S.P.; Schwarz, M.-K.; Bauhofer, W.; Schulte, K.; Windle, A. Formation of percolating networks in multi-wall carbon-nanotube–epoxy composites. Compos. Sci. Technol. 2004, 64, 2309–2316. [Google Scholar] [CrossRef]

- Beyer, G. Carbon Nanotubes—A New Class of Flame Retardants for Polymers. Int. Polym. Sci. Technol. 2003, 30, 1–6. [Google Scholar] [CrossRef]

- Wen, X.; Tian, N.; Gong, J.; Chen, Q.; Qi, Y.; Liu, Z.; Liu, J.; Jiang, Z.; Chen, X.; Tang, T. Effect of nanosized carbon black on thermal stability and flame retardancy of polypropylene/carbon nanotubes nanocomposites. Polym. Adv. Technol. 2013, 24, 971–977. [Google Scholar] [CrossRef]

- Dai, J.F.; Wang, G.J.; Ma, L.; Wu, C.K. Surface properties of graphene: Relationship to graphene-polymer composites. Rev. Adv. Mater. Sci. 2015, 40, 60–71. [Google Scholar]

- Lee, J.-U.; Yoon, D.; Cheong, H. Estimation of Young’s Modulus of Graphene by Raman Spectroscopy. Nano Lett. 2012, 12, 4444–4448. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

- Szeluga, U.; Pusz, S.; Kumanek, B.; Olszowska, K.; Kobyliukh, A.; Trzebicka, B. Effect of graphene filler structure on electrical, thermal, mechanical, and fire retardant properties of epoxy-graphene nanocomposites—A review. Crit. Rev. Solid State Mater. Sci. 2020, 1–36. [Google Scholar] [CrossRef]

- Huang, G.; Gao, J.; Wang, X.; Liang, H.; Ge, C. How can graphene reduce the flammability of polymer nanocomposites? Mater. Lett. 2012, 66, 187–189. [Google Scholar] [CrossRef]

- Attia, N.F.; El-Aal, N.A.; Hassan, M. Facile synthesis of graphene sheets decorated nanoparticles and flammability of their polymer nanocomposites. Polym. Degrad. Stab. 2016, 126, 65–74. [Google Scholar] [CrossRef]

- Li, K.-Y.; Kuan, C.-F.; Kuan, H.; Chen, C.-H.; Shen, M.-Y.; Yang, J.-M.; Chiang, C.-L. Preparation and properties of novel epoxy/graphene oxide nanosheets (GON) composites functionalized with flame retardant containing phosphorus and silicon. Mater. Chem. Phys. 2014, 146, 354–362. [Google Scholar] [CrossRef]

- Yuan, B.; Fan, A.; Yang, M.; Chen, X.; Hu, Y.; Bao, C.; Jiang, S.; Niu, Y.; Zhang, Y.; He, S.; et al. The effects of graphene on the flammability and fire behavior of intumescent flame retardant polypropylene composites at different flame scenarios. Polym. Degrad. Stab. 2017, 143, 42–56. [Google Scholar] [CrossRef]

- Smith, A.T.; Lachance, A.M.; Zeng, S.; Liu, B.; Sun, L. Synthesis, properties, and applications of graphene oxide/reduced graphene oxide and their nanocomposites. Nano Mater. Sci. 2019, 1, 31–47. [Google Scholar] [CrossRef]

- Tian, P.; Tang, L.; Teng, K.S.; Lau, S.P. Graphene quantum dots from chemistry to applications. Mater. Today Chem. 2018, 10, 221–258. [Google Scholar] [CrossRef]

- Rahimi-Aghdam, T.; Shariatinia, Z.; Hakkarainen, M.; Haddadi-Asl, V. Nitrogen and phosphorous doped graphene quantum dots: Excellent flame retardants and smoke suppressants for polyacrylonitrile nanocomposites. J. Hazard. Mater. 2019, 381, 121013. [Google Scholar] [CrossRef] [PubMed]

- Rahimi-Aghdam, T.; Shariatinia, Z.; Hakkarainen, M.; Haddadi-Asl, V. Polyacrylonitrile/N,P co-doped graphene quantum dots-layered double hydroxide nanocomposite: Flame retardant property, thermal stability and fire hazard. Eur. Polym. J. 2019, 120, 109256. [Google Scholar] [CrossRef]

- Khose, R.V.; Pethsangave, D.A.; Wadekar, P.H.; Ray, A.K.; Some, S. Novel approach towards the synthesis of carbon-based transparent highly effective flame retardant. Carbon 2018, 139, 205–209. [Google Scholar] [CrossRef]

- Wang, G.; Yang, J. Influences of expandable graphite modified by polyethylene glycol on fire protection of waterborne intumescent fire resistive coating. Surf. Coat. Technol. 2010, 204, 3599–3605. [Google Scholar] [CrossRef]

- Ye, L.; Meng, X.-Y.; Ji, X.; Li, Z.-M.; Tang, J.-H. Synthesis and characterization of expandable graphite–poly(methyl methacrylate) composite particles and their application to flame retardation of rigid polyurethane foams. Polym. Degrad. Stab. 2009, 94, 971–979. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.M.; Seong, D.G.; Lee, D. Synergistic improvement of flame retardant properties of expandable graphite and multi-walled carbon nanotube reinforced intumescent polyketone nanocomposites. Carbon 2019, 143, 650–659. [Google Scholar] [CrossRef]

- Hong, L.; Hu, X. Mechanical and Flame Retardant Properties and Microstructure of Expandable Graphite/Silicone Rubber Composites. J. Macromol. Sci. Part B 2016, 55, 175–187. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, L.; Lv, J. Effects of Expandable Graphite and Modified Ammonium Polyphosphate on the Flame-Retardant and Mechanical Properties of Wood Flour-Polypropylene Composites. Polym. Polym. Compos. 2013, 21, 449–456. [Google Scholar] [CrossRef]

- Zhu, H.; Zhu, Q.; Li, J.; Tao, K.; Xue, L.; Yan, Q. Synergistic effect between expandable graphite and ammonium polyphosphate on flame retarded polylactide. Polym. Degrad. Stab. 2011, 96, 183–189. [Google Scholar] [CrossRef]

- Savi, P.; Jose, S.P.; Khan, A.A.; Giorcelli, M.; Tagliaferro, A. Biochar and carbon nanotubes as fillers in polymers: A comparison. In Proceedings of the 2017 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Pavia, Italy, 20–22 September 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef]

- Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymer 2018, 10, 286. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- You, Z.; Li, D. Highly filled bamboo charcoal powder reinforced ultra-high molecular weight polyethylene. Mater. Lett. 2014, 122, 121–124. [Google Scholar] [CrossRef]

- Poulose, A.M.; Elnour, A.Y.; Anis, A.; Shaikh, H.; Al-Zahrani, S.; George, J.; Al-Wabel, M.I.; Usman, A.R.; Ok, Y.S.; Tsang, D.C.; et al. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total. Environ. 2017, 619, 311–318. [Google Scholar] [CrossRef]

- Srinivasan, P.; Sarmah, A.K.; Smernik, R.; Das, O.; Farid, M.; Gao, W.; Smernik, R. A feasibility study of agricultural and sewage biomass as biochar, bioenergy and biocomposite feedstock: Production, characterization and potential applications. Sci. Total. Environ. 2015, 512, 495–505. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Sarmah, A.K. Mechanism of waste biomass pyrolysis: Effect of physical and chemical pre-treatments. Sci. Total. Environ. 2015, 537, 323–334. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K. Value added liquid products from waste biomass pyrolysis using pretreatments. Sci. Total Environ. 2015, 538, 145–151. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.-H.; Kwon, E.E. Biochar as a Catalyst. Renew. Sustain. Energy Rev. 2017, 77, 70–79. [Google Scholar] [CrossRef]

- Byrne, C.; Nagle, D. Carbonization of wood for advanced materials applications. Carbon 1997, 35, 259–266. [Google Scholar] [CrossRef]

- Das, O.; Capezza, J.A.; Mårtensson, J.; Dong, Y.; Neisiany, E.R.; Pelcastre, L.; Jiang, L.; Xu, Q.; Olsson, T.R.; Hedenqvist, S.M. The Effect of Carbon Black on the Properties of Plasticised Wheat Gluten Biopolymer. Molecules 2020, 25, 2279. [Google Scholar] [CrossRef]

- Netravali, A.N.; Mittal, K.L. Interface/Interphase in Polymer Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Fei, B.; Jiang, Z.; Yang, X. Combustion characteristics of bamboo-biochars. Bioresour. Technol. 2014, 167, 94–99. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Enders, A.; Lehmann, J. Short- and long-term flammability of biochars. Biomass Bioenergy 2014, 69, 183–191. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of Pyrolysis Temperature on Biochar Microstructural Evolution, Physicochemical Characteristics, and Its Influence on Biochar/Polypropylene Composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef] [Green Version]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Sarmah, A.K.; Bhattacharyya, D. Development of waste based biochar/wool hybrid biocomposites: Flammability characteristics and mechanical properties. J. Clean. Prod. 2017, 144, 79–89. [Google Scholar] [CrossRef]

- Zhang, Q.; Khan, M.U.; Lin, X.; Cai, H.; Lei, H. Temperature varied biochar as a reinforcing filler for high-density polyethylene composites. Compos. Part B Eng. 2019, 175, 107151. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Kalamkarov, A.L.; Sarmah, A.K.; Bhattacharyya, D. Biochar to the rescue: Balancing the fire performance and mechanical properties of polypropylene composites. Polym. Degrad. Stab. 2017, 144, 485–496. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable biocarbon from pyrolyzed perennial grasses and their effects on impact modified polypropylene biocomposites. Compos. Part B Eng. 2017, 118, 116–124. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Xu, H.; Lu, W.; Ren, X.; Cai, H.; Lei, H.; Huo, E.; Zhao, Y.; Qian, M.; et al. Biochar filled high-density polyethylene composites with excellent properties: Towards maximizing the utilization of agricultural wastes. Ind. Crop. Prod. 2020, 146, 112185. [Google Scholar] [CrossRef]

- Wen, X.; Wang, Y.; Gong, J.; Liu, J.; Tian, N.; Wang, Y.; Jiang, Z.; Qiu, J.; Tang, T. Thermal and flammability properties of polypropylene/carbon black nanocomposites. Polym. Degrad. Stab. 2012, 97, 793–801. [Google Scholar] [CrossRef]

- Yang, H.; Gong, J.; Wen, X.; Xue, J.; Chen, Q.; Jiang, Z.; Tian, N.; Tang, T. Effect of carbon black on improving thermal stability, flame retardancy and electrical conductivity of polypropylene/carbon fiber composites. Compos. Sci. Technol. 2015, 113, 31–37. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Yang, Y.-X.; Zhang, Y.-L.; Wen, X.; Li, N.; Fu, C.; Jian, R.-K.; Li, L.; Wang, D.-Y. A Geometry Effect of Carbon Nanomaterials on Flame Retardancy and Mechanical Properties of Ethylene-Vinyl Acetate/Magnesium Hydroxide Composites. Polymer 2018, 10, 1028. [Google Scholar] [CrossRef] [Green Version]

- Mensah, R.A.; Xu, Q.; Asante-Okyere, S.; Jin, C.; Bentum-Micah, G. Correlation analysis of cone calorimetry and microscale combustion calorimetry experiments. J. Therm. Anal. Calorim. 2018, 136, 589–599. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Te Nijenhuis, K. Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Shrivastava, A. Introduction to Plastics Engineering; William Andrew: Cambridge, MA, USA, 2018; pp. 1–16. [Google Scholar]

- Papaspyrides, C.D.; Kiliaris, P. Polymer Green Flame Retardants; Newnes: Waltham, MA, USA, 2014. [Google Scholar]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.-M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Hsinjin, E.Y. Quantitative Microscale Assessment of Polymer Flammability; Plastics Research: Gansu, China, 2015. [Google Scholar]

- Wan, L.; Deng, C.; Zhao, Z.-Y.; Chen, H.; Wang, Y.-Z. Flame Retardation of Natural Rubber: Strategy and Recent Progress. Polymer 2020, 12, 429. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Jin, C.; Majlingova, A.; Restas, A. Discuss the heat release capacity of polymer derived from microscale combustion calorimeter. J. Therm. Anal. Calorim. 2017, 133, 649–657. [Google Scholar] [CrossRef]

- Xu, Q.; Jin, C.; Majlingova, A.; Zachar, M.; Restas, A. Evaluate the flammability of a PU foam with double-scale analysis. J. Therm. Anal. Calorim. 2019, 135, 3329–3337. [Google Scholar] [CrossRef]

- Standard Test Method for Determining Flammability Characteristics of Plastics and Other Solid Materials Using Microscale Combustion Calorimetry; ASTM D7309; American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Babrauskas, V. Development of the cone calorimeter? A bench-scale heat release rate apparatus based on oxygen consumption. Fire Mater. 1984, 8, 81–95. [Google Scholar] [CrossRef]

- Holborn, P.; Nolan, P.; Golt, J. An analysis of fire sizes, fire growth rates and times between events using data from fire investigations. Fire Saf. J. 2004, 39, 481–524. [Google Scholar] [CrossRef]

| Type of Composites | TTI (s) | % of Ignition Time Delay from Neat Polymer Increased (↑) or Decreased (↓) | pHRR (kW/m2) | % of pHRR Increased (↑) or Decreased (↓) w.r. to Neat Polymer | Time to pHRR (s) | THR (MJ/m2) | LOI (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| PU/PMMA | 70 | --- | 343 | --- | 189 | --- | --- | [13] |

| PU/PMMA/Full-C60 0.5 | 101 | 44% (↑) | 131 | 61.8% (↓) | 150 | --- | --- | |

| Neat PP | 29 | --- | 1054 | --- | --- | 97 | --- | [63] |

| TCP 900 * | 20 | 31% (↓) | 473.68 | 55% (↓) | --- | 86.95 | --- | |

| Neat PP | 29 ± 2 | --- | 1054 ± 120 | --- | 120 ± 18 | 97 ± 14 | 18 ± 0.1 | [69] |

| BC + PP + APP | 14 ± 0 | 51.7% (↓) | 277.82 ± 2.4 | 73.6% (↓) | 120 ± 29.6 | 88.75 ± 0.7 | 22.08 ± 0.1 | |

| Neat PP | 30 | --- | 1261 | --- | 335 | 208 | 18 | [31] |

| PP + 3wt% CB | 20 | 33.3% (↓) | 584 | 53.6% (↓) | 355 | 192 | 22.6 | |

| PP + 3wt% CNT + 5wt% CB | 25 | 16.6% (↓) | 314 | 75.1% (↓) | 70 | 180 | 27.6 | |

| Neat PVA | 18 ± 2 | --- | 373 ± 6 | --- | --- | 58 ± 0.6 | --- | [36] |

| PVA + 3wt% Na-MMT | 20 ± 2 | 11.1% (↑) | 263 ± 7 | 29.4% (↓) | --- | 58 ± 0.4 | --- | |

| PVA + 3wt% MWCNT | 24 ± 2 | 33.3% (↑) | 241 ± 8 | 35.3% (↓) | --- | 52 ± 0.4 | --- | |

| PVA + 3wt% GNS | 33 ± 2 | 83.3% (↑) | 190 ± 6 | 49% (↓) | --- | 45 ± 0.3 | --- | |

| PVA + 5wt% GNS | 45 ± 3 | 150% (↑) | 133 ± 5 | 64.3% (↓) | --- | 38 ± 0.5 | --- | |

| Neat ABS | 43 ± 1.5 | --- | 1385 ± 92 | --- | --- | 145 ± 11 | --- | [37] |

| ABS-MDP | 32 ± 1.5 | 25.5% (↓) | 821 ± 55 | 40.7% (↓) | --- | 97 ± 9 | --- | |

| ABS-GRP-MDP | 18 ± 1 | 58.1% (↓) | 812 ± 54 | 41.3% (↓) | --- | 91 ± 6 | --- | |

| ABS-GRP-MDP- TiO2NP-5 | 35 ± 1.2 | 18.6% (↓) | 720 ± 48 | 48% (↓) | --- | 75 ± 6 | --- | |

| Neat PAN | 10 | --- | 609 | --- | 25 | 9.1 | --- | [42] |

| PAN/NGQDs | 15 | 50% (↑) | 565 | 7.2% (↓) | 30 | 8.5 | --- | |

| PAN/NPGQDs | 20 | 100% (↑) | 515 | 15.4% (↓) | 35 | 7.7 | --- | |

| Neat PAN | 10 | --- | 609 | --- | 25 | 9.1 | --- | [43] |

| PAN/ZnAl LDH | 20 | 100% (↑) | 462 | 24.1% (↓) | 40 | 7.9 | --- | |

| PAN/ZnAl LDH-NPGQD | 25 | 150% (↑) | 435 | 28.5% (↓) | 45 | 7.4 | --- |

| Specific Flaming Characteristics | Rating | ||

|---|---|---|---|

| V-0 | V-1 | V-2 | |

| Total flaming combustion time (in seconds) | |||

| ≤10 | ≤30 | ≤30 |

| ≤50 | ≤250 | ≤250 |

| Flaming and glowing combustion for each specimen after second burner flame application | ≤30 | ≤60 | ≤60 |

| Cotton ignited by flaming drips from any specimen | No | No | Yes |

| Glowing or flaming combustion of any specimen to holding clamp | No | No | No |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babu, K.; Rendén, G.; Afriyie Mensah, R.; Kim, N.K.; Jiang, L.; Xu, Q.; Restás, Á.; Esmaeely Neisiany, R.; Hedenqvist, M.S.; Försth, M.; et al. A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends. Polymers 2020, 12, 1518. https://doi.org/10.3390/polym12071518

Babu K, Rendén G, Afriyie Mensah R, Kim NK, Jiang L, Xu Q, Restás Á, Esmaeely Neisiany R, Hedenqvist MS, Försth M, et al. A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends. Polymers. 2020; 12(7):1518. https://doi.org/10.3390/polym12071518

Chicago/Turabian StyleBabu, Karthik, Gabriella Rendén, Rhoda Afriyie Mensah, Nam Kyeun Kim, Lin Jiang, Qiang Xu, Ágoston Restás, Rasoul Esmaeely Neisiany, Mikael S. Hedenqvist, Michael Försth, and et al. 2020. "A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends" Polymers 12, no. 7: 1518. https://doi.org/10.3390/polym12071518