Self-Healing Mechanisms for 3D-Printed Polymeric Structures: From Lab to Reality

Abstract

:1. Introduction

2. Conceptual Description of Self-Healing Mechanism and Categories

3. Naturally Inspired Artificial Self-Healing

4. Self-Healing Requirements in Polymeric Structures and Components

5. Existing Self-Healing Mechanisms in 3D Printed Structures

5.1. 3D Printing of Self-Healing Materials

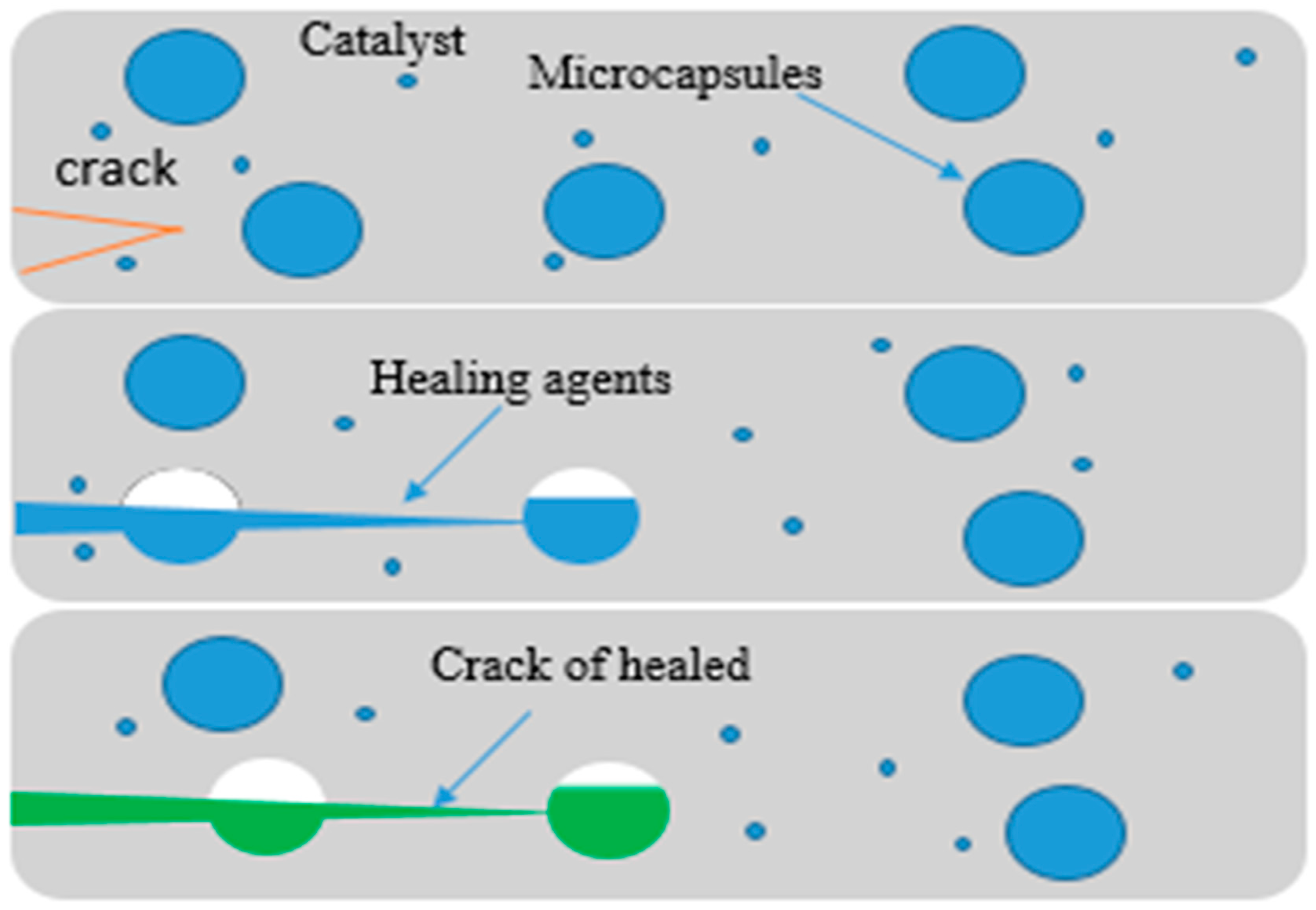

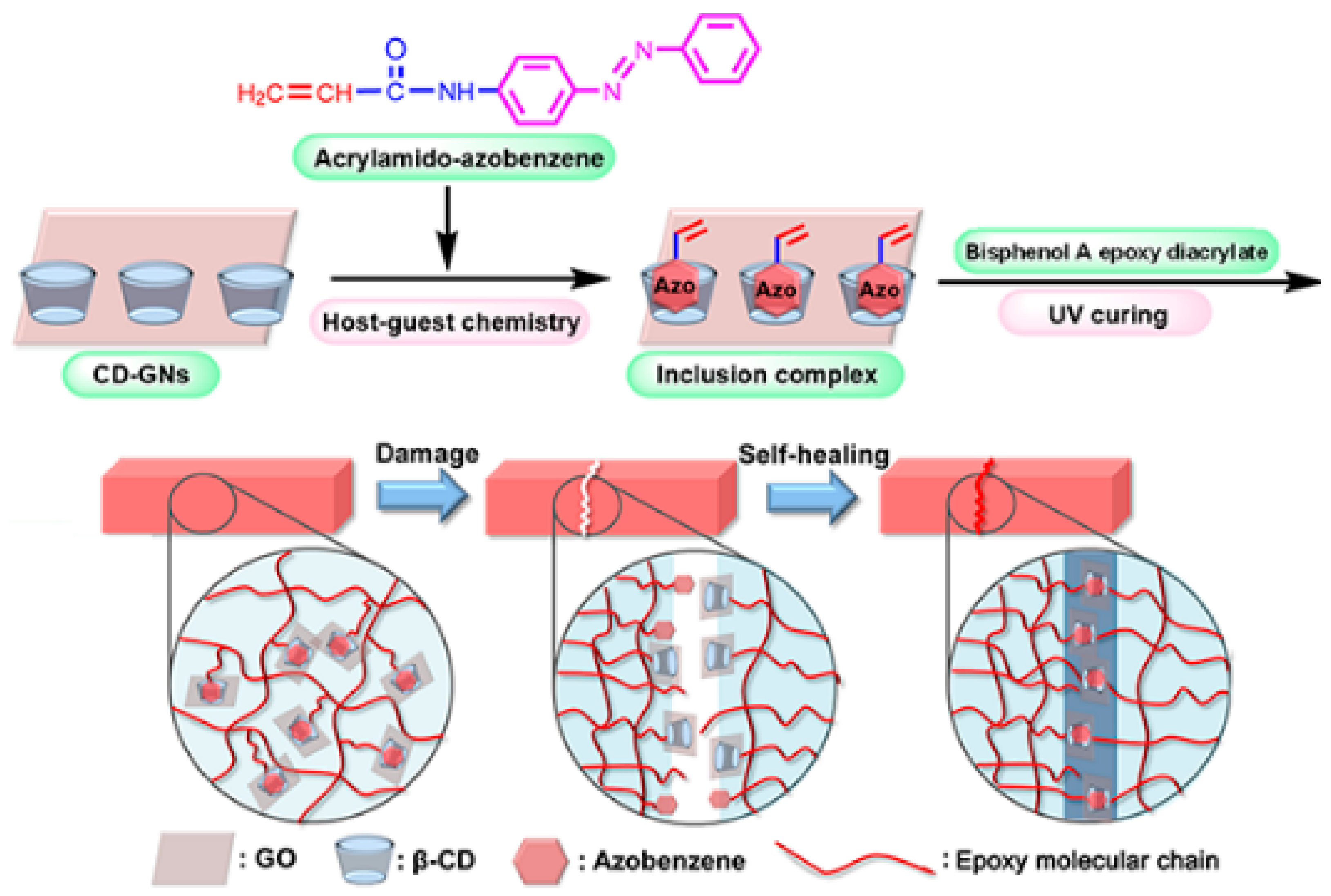

5.2. General Categories of Self-Healing Mechanisms Applicable to 3D Printed Structures

5.3. Healing Mechanism for Different Material Classes

5.4. Focused Efforts Made for Developing Self-Healing in 3D Printed Structures

5.4.1. Working Principle

- The first step comprises the synthesis and functionalization of PHEMA (benzaldehyde-functionalized poly-2 hydroxyethyl methacrylate) with the pendant benzaldehyde group; next, cross-linking with diamine takes place. A delicate rheological tuning of ink formulations and the mapping of printable space is required to prepare printable inks [48].

5.4.2. Self-Healing Mechanism Advantages and Limitations

6. Challenges and Limitations (Identification of the Current Knowledge Gap)

7. Novel Proposal for Self-Healing in 3D Printed Structures

8. Potential Impacts of Smart Self-Healing 3D Printed Structures

8.1. Academic Impact

8.2. Commercial Impact

8.3. Social and Environmental Impact

- The achievement of a sharing economy. This is the anticipated objective of an increasingly competitive economy, in which resources are maximized via the process in which the surplus capacity of services and goods is pooled. This refers to the economy model in which people interact within peer-to-peer (P2P) based activities for sharing access, where all have the same opportunities.

- The achievement of shared value. The objective of shared value is to generate economic value in a manner that additionally forms value for society, by focusing on its specific needs and problems, which represents a new focus for producers to determine business opportunities related to social aspects by concentrating on optimizing the competitive benefit of resolving social problems. This can be accomplished via the preconception of markets and products, the redefinition of profitability within the value chain, and the creation of clusters at the firm’s locations to support the sector.

9. Conclusions and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Madara, S.R.; Raj, N.S.S.; Selvan, C.P. Review of research and developments in self healing composite materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Dubai, UAE, 28–29 November 2018; Volume 346. [Google Scholar] [CrossRef]

- Thao, T.D.P. Quasi-brittle Self-healing Materials: Numerical Modelling and Application in Civile Engineering; National University Singapore: Singapore, 2011; pp. 2–228. [Google Scholar]

- Dry, C.M. Smart multiphase composite materials that repair themselves by a release of liquids that become solids. Smart Struct. Mater. 1994, 2189, 62–70. [Google Scholar] [CrossRef]

- Zhang, F.; Ju, P.; Pan, M.; Zhang, D.; Huang, Y.; Li, G.; Li, X. Self-healing Mechanisms in Smart Protective Coatings: A Review. Corros. Sci. 2018, 144, 74–88. [Google Scholar] [CrossRef]

- Mihashi, H.; Nishiwaki, T. Development of engineered self-healing and self-repairing concrete-state-of-the-art report. J. Adv. Concr. Technol. 2012, 10, 170–184. [Google Scholar] [CrossRef] [Green Version]

- Pelletier, M.M.; Brown, R.; Shukla, A.; Bose, A. Self-healing Concrete with a Microencapsulated Healing Agent; University of Rhode Island: Kingston, NY, USA, 2010. [Google Scholar]

- Wool, R.P. Self-healing materials: A review. R. Soc. Chem. 2008, 4, 400–418. [Google Scholar] [CrossRef]

- Fainleib, A.M.; Purikova, O.H. Self-healing polymers: Approaches of healing and their application. Polym. J. 2019, 41, 4–18. [Google Scholar] [CrossRef]

- Cremaldi, J.C.; Bhushan, B. Bioinspired self-healing materials: Lessons from nature. Beilstein J. Nanotechnol. 2018, 9, 907–935. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. (Oxf.) 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.; Le, T.; Wackrow, R.; Austin, S.; Gibb, A.; Thorpe, A. Development of a viable concrete printing process. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction (ISARC 2011), Seoul, South Korea, 29 June–2 July 2011; pp. 665–670. [Google Scholar] [CrossRef] [Green Version]

- van Tittelboom, K.; de Belie, N. Self-healing in cementitious materials-a review. Materials 2013, 2182–2217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Yang, Y.; Davydovich, D.; Hornat, C.C.; Liu, X.; Urban, M.W. Leaf-Inspired Self-Healing Polymers; Chem. Elsevier Inc.: Amsterdam, The Netherlands, 2018; Volume 4, pp. 1928–1936. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Aïssa, B.; Therriault, D.; Haddad, E.; Jamroz, W. Self-healing materials systems: Overview of major approaches and recent developed technologies. Adv. Mater. Sci. Eng. 2012. [Google Scholar] [CrossRef] [Green Version]

- Zhao, P.C.; Li, W.; Huang, W.; Li, C.H. A self-healing polymer with fast elastic recovery upon stretching. Molecules 2020, 25, 597. [Google Scholar] [CrossRef] [Green Version]

- Memon, H.; Liu, H.; Rashid, M.A.; Chen, L.; Jiang, Q.; Zhang, L.; Wei, Y.; Liu, W.; Qiu, Y. Vanillin-based epoxy vitrimer with high performance and closed-loop recyclability. Macromolecules 2020, 53, 621–630. [Google Scholar] [CrossRef]

- Yuan, D.; Bonab, V.S.; Patel, A.; Yilmaz, T.; Gross, R.A.; Manas-Zloczower, I. Design strategy for self-healing epoxy coatings. Coatings 2020, 10, 50. [Google Scholar] [CrossRef] [Green Version]

- Memon, H.; Wei, Y. Welding and reprocessing of disulfide-containing thermoset epoxy resin exhibiting behavior reminiscent of a thermoplastic. J. Appl. Polym. Sci. 2020. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Serex, L.; Bertsch, A.; Renaud, P. Microfluidics: A new layer of control for extrusion-based 3D printing. Micromachines 2018, 9, 86. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, N.Z.; Shafaghat, A.; Keyvanfar, A.; Majid, M.Z.A.; Ghoshal, S.K.; Yasouj, S.E.M.; Ganiyu, A.A.; Kouchaksaraei, M.S.; Kamyab, H.; Taheri, M.M.; et al. Tests and methods of evaluating the self-healing efficiency of concrete: A review. Constr. Build. Mater. 2016, 112, 1123–1132. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing polymers and polymer composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Trask, R.S.; Williams, H.R.; Bond, I.P. Self-healing polymer composites: Mimicking nature to enhance performance. Bioinspiration Biomim. 2007, 2, 1–12. [Google Scholar] [CrossRef] [PubMed]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Yang, Y.; Urban, M.W. Self-healing polymeric materials. Chem. Soc. Rev. 2013, 42, 7446–7467. [Google Scholar] [CrossRef]

- Ferreira, A.D.B.L.; Nóvoa, P.R.O.; Marques, A.T. Multifunctional material systems: A state-of-the-art review. Compos. Struct. 2016, 151, 3–35. [Google Scholar] [CrossRef]

- Salonitis, K.; Pandremenos, J.; Paralikas, J.; Chryssolouris, G. Multifunctional materials: Engineering applications and processing challenges. Int. J. Adv. Manuf. Technol. 2010, 49, 803–826. [Google Scholar] [CrossRef]

- Mpofu, T.P.; Mawere, C.; Mukosera, M. The Impact and application of 3D printing technology. IJSR 2014, 3, 2148–2152. Available online: https://www.ijsr.net/archive/v3i6/MDIwMTQ2NzU=.pdf (accessed on 20 March 2020).

- Dooley, C.; Taylor, D. Self-healing materials: What can nature teach us? Fatigue Fract. Eng. Mater. Struct. 2017, 40, 655–669. [Google Scholar] [CrossRef]

- Thakur, V.K.; Kessler, M.R. Self-healing polymer nanocomposite materials: A review. Polymer 2015, 69, 369–383. [Google Scholar] [CrossRef] [Green Version]

- van der Zwaag, S. An introduction to material design principles: Damage prevention versus damage management. Self Heal. Mater. 2007. [Google Scholar] [CrossRef]

- Wool, R.P.; O’Connor, K.M. A theory of crack healing in polymers. J. Appl. Phys. 1981, 52, 5953–5963. [Google Scholar] [CrossRef]

- Santana, M.H.; den Brabander, M.; García, S.; van der Zwaag, S. Routes to make natural rubber heal: A review. Polym. Rev. 2018, 58, 585–609. [Google Scholar] [CrossRef]

- Dohler, D.; Michael, P.; Binder, W. Part One Design of Self-Healing Materials. In Self-Healing Polymers: From Principles to Applications; Binder, W., Ed.; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2013; pp. 5–60. [Google Scholar]

- Williams, K.A.; Dreyer, D.R.; Bielawski, C.W. The underlying chemistry of self-healing materials. Mrs Bull. 2008, 33, 759–765. [Google Scholar] [CrossRef]

- Brown, E.N.; White, S.R.; Sottos, N.R. Fatigue crack propagation in microcapsule-toughened epoxy. J. Mater. Sci. 2006, 41, 6266–6273. [Google Scholar] [CrossRef] [Green Version]

- Neuser, S.; Michaud, V. Fatigue response of solvent-based self-healing smart materials. Exp. Mech. 2014, 54, 293–304. [Google Scholar] [CrossRef]

- Mauldin, T.C.; Kessler, M.R. Self-healing polymers and composites. Int. Mater. Rev. 2010, 55, 317–346. [Google Scholar] [CrossRef]

- Hia, I.L.; Vahedi, V.; Pasbakhsh, P. Self-healing polymer composites: Prospects, challenges, and applications. Polym. Rev. 2016, 56, 225–261. [Google Scholar] [CrossRef]

- Wang, Y.; Pham, D.T.; Ji, C. Self-healing composites: A review. Cogent Eng. 2015, 2. [Google Scholar] [CrossRef] [Green Version]

- Burattini, S.; Greenland, B.W.; Chappell, D.; Colquhoun, H.M.; Hayes, W. Healable polymeric materials: A tutorial review. Chem. Soc. Rev. 2010, 39, 1973–1985. [Google Scholar] [CrossRef] [Green Version]

- Cordier, P.; Tournilhac, F.; Soulié-Ziakovic, C.; Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 2008, 451, 977–980. [Google Scholar] [CrossRef] [PubMed]

- Belowich, M.E.; Stoddart, J.F. Dynamic imine chemistry. Chem. Soc. Rev. 2012, 41, 2003–2024. [Google Scholar] [CrossRef] [PubMed]

- Nadgorny, M.; Xiao, Z.; Connal, L.A. 2D and 3D-printing of self-healing gels: Design and extrusion of self-rolling objects. Mol. Syst. Des. Eng. 2017, 2, 283–292. [Google Scholar] [CrossRef]

- Li, G.L.; Schenderlein, M.; Men, Y.; Möhwald, H.; Shchukin, D.G. Monodisperse polymeric core-shell nanocontainers for organic self-healing anticorrosion coatings. Adv. Mater. Interfaces 2014, 1, 1–6. [Google Scholar] [CrossRef]

- He, Y.; Liao, S.; Jia, H.; Cao, Y.; Wang, Z.; Wang, Y. A self-healing electronic sensor based on thermal-sensitive fluids. Adv. Mater. 2015, 27, 4622–4627. [Google Scholar] [CrossRef]

- Tee, B.C.K.; Wang, C.; Allen, R.; Bao, Z. An electrically and mechanically self-healing composite with pressure- and flexion-sensitive properties for electronic skin applications. Nat. Nanotechnol. 2012, 7, 825–832. [Google Scholar] [CrossRef]

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.S.; White, S.R. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585. [Google Scholar] [CrossRef]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A thermally re-mendable cross-linked polymeric material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef]

- MacDonald, E.; Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 2016, 353. [Google Scholar] [CrossRef]

- Darabi, M.A.; Khosrozadeh, A.; Mbeleck, R.; Liu, Y.; Chang, Q.; Jiang, J.; Cai, J.; Wang, Q.; Luo, G.; Xing, M. Skin-inspired multifunctional autonomic-intrinsic conductive self-healing hydrogels with pressure sensitivity, stretchability, and 3D printability. Adv. Mater. 2017, 29, 1–8. [Google Scholar] [CrossRef]

- Zou, Z.; Zhu, C.; Li, Y.; Lei, X.; Zhang, W.; Xiao, J. Rehealable, fully recyclable, and malleable electronic skin enabled by dynamic covalent thermoset nanocomposite. Sci. Adv. 2018, 4, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sijun Liu, L.L. Ultrastretchable and self-healing double-network hydrogel for 3d printing and strain sensor. ACS Appl. Mater. Interfaces 2017, 9, 26429–26437. [Google Scholar]

- Holmes, M. Additive manufacturing continues composites market growth. Reinf. Plast. 2019, 70, 1–6. [Google Scholar] [CrossRef]

- Nadgorny, M.; Collins, J.; Xiao, Z.; Scales, P.J.; Connal, L.A. 3D-printing of dynamic self-healing cryogels with tuneable properties. Polym. Chem. 2018, 9, 1684–1692. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.; Xin, A.; Du, H.; Li, Y.; Wang, Q. Additive manufacturing of self-healing elastomers. NPG Asia Mater. 2019, 11. [Google Scholar] [CrossRef] [Green Version]

- White, S.R.; Moore, J.S.; Sottos, N.R.; Krull, B.P. Restoration of large damage volumes in polymers. Science 2014, 344, 620–623. [Google Scholar] [CrossRef] [PubMed]

- Kamarudin, A.F. Self-Healing Polymer. Polymer Reviews. 2017. Available online: https://www.academia.edu/31139713/Self-Healing_Polymer (accessed on 20 March 2020).

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef]

- Pati, B.P.S.S. SRD self-healing polymer composites based on graphene and carbon nanotubes. In Smart Polymer Nanocomposites: Energy Harvesting, Self-Healing and Shape Memory Applications; Springer: Berlin, Germany, 2017; pp. 119–152. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef] [Green Version]

- Xin, A.D.H. 3-D Printed Tires and Shoes that Self-Repair. PHYS ORG. 2019. Available online: https://phys.org/news/2019-02-d-self-repair.html (accessed on 25 November 2019).

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The boom in 3D-printed sensor technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214. [Google Scholar] [CrossRef]

- Du, Y.; Li, D.; Liu, L.; Gai, G. Recent achievements of self-healing graphene/polymer composites. Polymers 2018, 10, 114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jo, Y.; Jeong, D.W.; Lee, J.O.; Choi, Y.; Jeong, S. 3D-printed origami electronics using percolative conductors. RSC Adv. 2018, 8, 22755–22762. [Google Scholar] [CrossRef] [Green Version]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, A.; Zou, N.; Pei, Z.J. Additive manufacturing for civil infrastructure design and construction: Current state and gaps. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; Volume 1, pp. 1–9. [Google Scholar] [CrossRef]

- Banshiwal, J.K.; Tripathi, D.N. Self-healing polymer composites for structural application. Funct. Mater. 2019, 10, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Deng, G.; Li, F.; Yu, H.; Liu, F.; Liu, C.; Sun, W.; Jiang, H.; Chen, Y. Dynamic hydrogels with an environmental adaptive self-healing ability and dual responsive Sol-Gel transitions. ACS Macro Lett. 2012, 1, 275–279. [Google Scholar] [CrossRef]

- Willocq, B.; Odent, J.; Dubois, P.; Raquez, J.M. Advances in intrinsic self-healing polyurethanes and related composites. RSC Adv. 2020, 10, 13766–13782. [Google Scholar] [CrossRef]

- Raj, S.A.; Muthukumaran, E.; Jayakrishna, K. A case study of 3D printed PLA and its mechanical properties. Mater. Today Proc. 2018, 5, 11219–11226. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Exp. Investig. Âguez 2006, 7, 148–158. [Google Scholar]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanders, P.; Young, A.J.; Qin, Y.; Fancey, K.S.; Reithofer, M.R.; Guillet-Nicolas, R.; Kleatz, F.; Pamme, N.; Chin, J.M. Stereolithographic 3D printing of extrinsically self-healing composites. Sci. Rep. 2019, 9, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Terryn, S.; Mathijssen, G.; Brancart, J.; Lefeber, D.; Assche, G.; van Vanderborght, B. Development of a self-healing soft pneumatic actuator: A first concept. Bioinspiration Biomim. 2015, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, J.S.; Darlington, T.; Starr, A.F.; Takahashi, K.; Riendeau, J.; Hahn, H.T. Multiple healing effect of thermally activated self-healing composites based on Diels-Alder reaction. Compos. Sci. Technol. 2010, 70, 2154–2159. [Google Scholar] [CrossRef]

- Du, P.; Wu, M.; Liu, X.; Zheng, Z.; Wang, X.; Sun, P.; Joncheray, T.; Zhang, Y. Synthesis of linear polyurethane bearing pendant furan and cross-linked healable polyurethane containing Diels-Alder bonds. New J. Chem. 2014, 38, 770–776. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Mechanically Robust, self-healable, and highly stretchable “living” crosslinked polyurethane based on a reversible C-C bond. Adv. Funct. Mater. 2018, 28, 1–8. [Google Scholar] [CrossRef]

- Li, X.; Yu, R.; He, Y.; Zhang, Y.; Yang, X.; Zhao, X.; Huang, W. Self-healing polyurethane elastomers based on a disulfide bond by digital light processing 3D printing. ACS Macro Lett. 2019, 8, 1511–1516. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Rong, M.Z. Intrinsic self-healing of covalent polymers through bond reconnection towards strength restoration. Polym. Chem. 2013, 4, 4878–4884. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, D.; Lu, F.; Yuan, W.; Xu, X.; Zhang, Q.; Liu, H.; Shao, Q.; Guo, Z.; Huang, Y. Multistimuli-responsive intrinsic self-healing epoxy resin constructed by host-guest interactions. Am. Chem. Soc. 2018, 51, 5294–5303. [Google Scholar] [CrossRef]

- Deng, G.; Tang, C.; Li, F.; Jiang, H.; Chen, Y. Covalent cross-linked polymer gels with reversible sol-gel transition and self-healing properties. Macromol. Am. Chem. Soc. 2010, 43, 1191–1194. [Google Scholar] [CrossRef]

- Scott, T.F.; Schneider, A.D.; Cook, W.D.; Bowman, C.N. Chemistry: Photoinduced plasticity in cross-linked polymers. Science 2005, 308, 1615–1617. [Google Scholar] [CrossRef]

- Hager, B.M.D.; Greil, P.; Leyens, C.; van der Zwaag, S.; Schubert, U.S. Self-healing materials. Adv. Mater. 2010, 22, 5424–5430. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, M.; Arun Ramnath, R.; Khan, A.; Khan, A.A.P.; Asiri, A.M. Electrically Conductive Self-Healing Materials: Preparation, Properties, and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 1–13. [Google Scholar] [CrossRef]

- Balazs, A.C. Modeling self-healing materials. Mater. Today 2007, 10, 18–23. [Google Scholar] [CrossRef]

- van Dijk, N.; van der Zwaag, S. Self-healing phenomena in metals. Adv. Mater. Interfaces 2018, 5, 1–13. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G. Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy. Metall. Mater. Trans. A 2006, 37, 3119–3130. [Google Scholar] [CrossRef]

- van der Zwaag, S.; van Dijk, N.H.; Jonkers, H.M.; Mookhoek, S.D.; Sloof, W.G. Self-healing behaviour in Man-made engineering materials: Bioinspired but taking into account their intrinsic character. Philos. Trans. R. Soc. A 2009, 367, 1689–1704. [Google Scholar] [CrossRef]

- Yuan, Y.C.; Yin, T.; Rong, M.Z.; Zhang, M.Q. Self healing in polymers and polymer composites. Concepts, realization and outlook: A review. Express Polym. Lett. 2008, 2, 238–250. [Google Scholar] [CrossRef]

- Brisson, E.R.L.; Xiao, Z.; Levin, L.; Franks, G.V.; Connal, L.A. Facile synthesis of histidine functional poly (N-isopropylacrylamide): Zwitterionic and temperature responsive materials. Polym. Chem. 2016, 7, 1945–1952. [Google Scholar] [CrossRef]

- Brisson, E.R.L.; Xiao, Z.; Franks, G.V.; Connal, L.A. versatile synthesis of amino acid functional polymers without protection group chemistry. Biomacromolecules 2017, 18, 272–280. [Google Scholar] [CrossRef]

- Centre, I.; Materials, A. Innovations in Self—Healing Materials. 2018, pp. 1–10. Available online: https://www.azom.com/article.aspx?ArticleID=15048, (accessed on 21 March 2020).

- Pang, J.W.C.; Bond, I.P. A hollow fibre reinforced polymer composite encompassing self-healing and enhanced damage visibility. Compos. Sci. Technol. 2005, 65, 1791–1799. [Google Scholar] [CrossRef]

- The Engineer. 3D-Printed Rubber Materials Self-Heal When Fractured or Punctured. Tech Trends 2020. 2019. Available online: https://www.theengineer.co.uk/rubber-self-healing/ (accessed on 2 April 2020).

- Saunders, S. 3D Printed Self-Healing Materials Can Fix Sole of Shoe in Two Hours. 3D Print. 2019. Available online: https://3dprint.com/237006/3d-printed-self-healing-material/ (accessed on 30 March 2020).

- Marta., I.; Turri, S.; Levi, M.; Suriano, R. 4D printed thermally activated self-healing and shape memory polycaprolactone-based polymers. Eur. Polym. J. 2018, 101, 169–176. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-printing: A review on current smart materials, technologies, and applications. Int. J. Smart Nano Mater. 2019, 10, 205–224. [Google Scholar] [CrossRef] [Green Version]

- Wu, Q.; Zou, S.; Gosselin, F.P.; Therriault, D.; Heuzey, M.C. 3D printing of a self-healing nanocomposite for stretchable sensors. J. Mater. Chem. C 2018, 6, 12180–12186. [Google Scholar] [CrossRef]

- Donaldson, L. Breakthrough in 3D-printed Self-Healing Materials. Materials Today. 2019. Available online: https://www.materialstoday.com/polymers-soft-materials/news/breakthrough-in-3dprinted-selfhealing-materials/ (accessed on 25 March 2020).

- Ford, S.; Minshall, T. Invited review article: Where and how 3D printing is used in teaching and education. Addit. Manuf. 2018, 25, 131–150. [Google Scholar] [CrossRef]

- Baqasah, H.; He, F.; Zai, B.A.; Asif, M.; Khan, K.A.; Thakur, V.K.; Khan, M.A. In-situ dynamic response measurement for damage quantification of 3D printed ABS cantilever beam under thermomechanical load. Polymers 2019, 11, 2079. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zai, B.A.; Khan, M.A.; Khan, K.A.; Mansoor, A. A novel approach for damage quantification using the dynamic response of a metallic beam under thermo-mechanical loads. J. Sound Vib. 2020, 469, 115134. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.A.; Khan, S.Z.; Asif, M.; Khan, K.A.; Saquib, A.N.; Mansoor, A.; Shahzad, M.; Mujtaba, A. Prediction of Crack Depth and Fatigue Life of an Acrylonitrile Butadiene Styrene Cantilever Beam Using Dynamic Response. J. Test. Eval. 2020, 48, 1520–1536. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.A.; Khan, K.A.; Mansoor, A.; Shah, A.; Shahzad, M. The role of dynamic response parameters in damage prediction. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4620–4636. [Google Scholar] [CrossRef] [Green Version]

- Pirjan, A.; Petrosanu, D.-M. The Impact of 3D Printing Technology on the Society and Economy. J. Inf. Syst. Oper. Manag. 2013. Available online: http://www.rebe.rau.ro/RePEc/rau/jisomg/WI13/JISOM-WI13-A19.pdf (accessed on 20 April 2020).

- Lupton, D. 3d Printing technologies: Social perspectives. SSRN Electron. J. 2017. [Google Scholar] [CrossRef]

| Mechanisms | Type of Materials | Name of Materials | |

|---|---|---|---|

| Polymers & Polymer Composites | Metals | ||

| Encapsulation | ✓ | Polycarbonates, cement, ABS, poly(urea-formaldehyde) and polystyrene | |

| Increase of temperature | ✓ | ✓ | Glass, aluminium |

| Expanding phases | ✓ | ✓ | powder or slurry |

| Separation phases | ✓ | Ionomers, epoxy | |

| Reversible crosslinks | ✓ | × | Diels-Alder reactions, polycyclopendiene |

| Channel transport | ✓ | PLA (Polylactic Acid) | |

| Biological processes | × | Polyurethane (PU) | |

| Electro-chemical process | × | ✓ | Polycarbonates, polyethylene, plastic |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, M.D.; Aria, A.I.; Thakur, V.K.; Khan, M.A. Self-Healing Mechanisms for 3D-Printed Polymeric Structures: From Lab to Reality. Polymers 2020, 12, 1534. https://doi.org/10.3390/polym12071534

Almutairi MD, Aria AI, Thakur VK, Khan MA. Self-Healing Mechanisms for 3D-Printed Polymeric Structures: From Lab to Reality. Polymers. 2020; 12(7):1534. https://doi.org/10.3390/polym12071534

Chicago/Turabian StyleAlmutairi, Mohammed Dukhi, Adrianus Indrat Aria, Vijay Kumar Thakur, and Muhammad A. Khan. 2020. "Self-Healing Mechanisms for 3D-Printed Polymeric Structures: From Lab to Reality" Polymers 12, no. 7: 1534. https://doi.org/10.3390/polym12071534

APA StyleAlmutairi, M. D., Aria, A. I., Thakur, V. K., & Khan, M. A. (2020). Self-Healing Mechanisms for 3D-Printed Polymeric Structures: From Lab to Reality. Polymers, 12(7), 1534. https://doi.org/10.3390/polym12071534