Moisture Prediction of Transformer Oil-Immersed Polymer Insulation by Applying a Support Vector Machine Combined with a Genetic Algorithm

Abstract

:1. Introduction

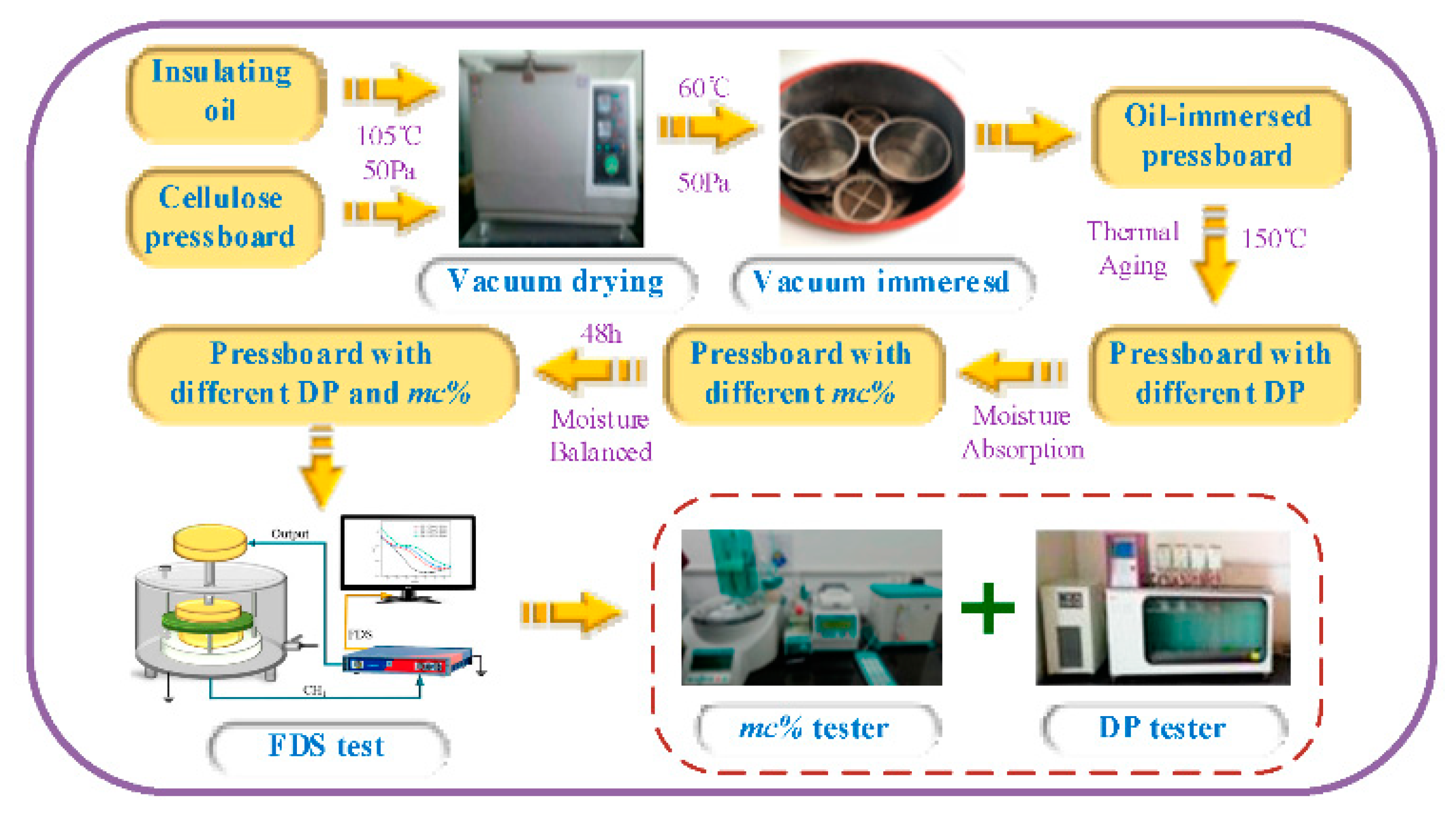

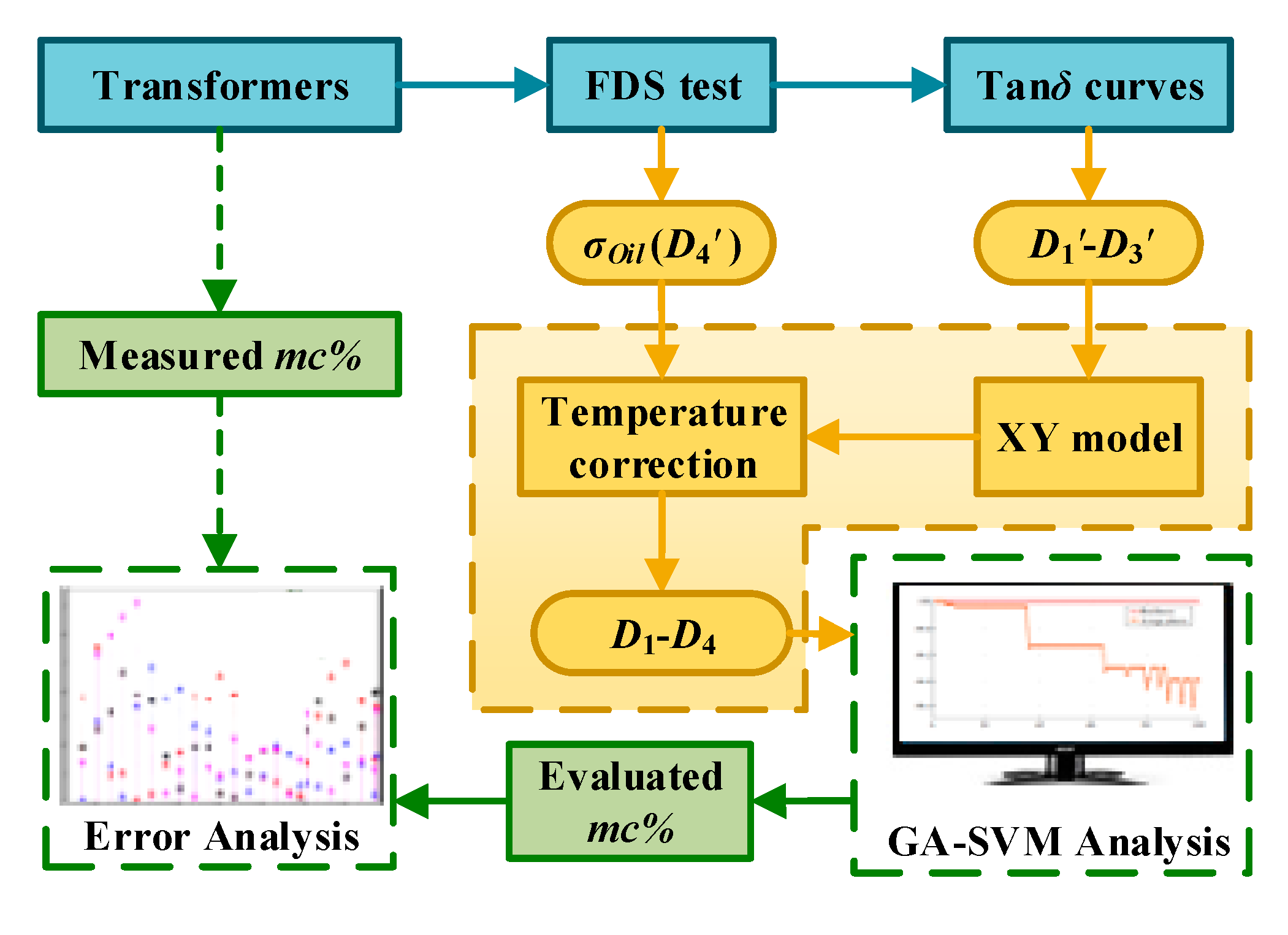

2. Sample Preparation and Frequency Response Test

3. Acquisition of Fitting Fingerprints

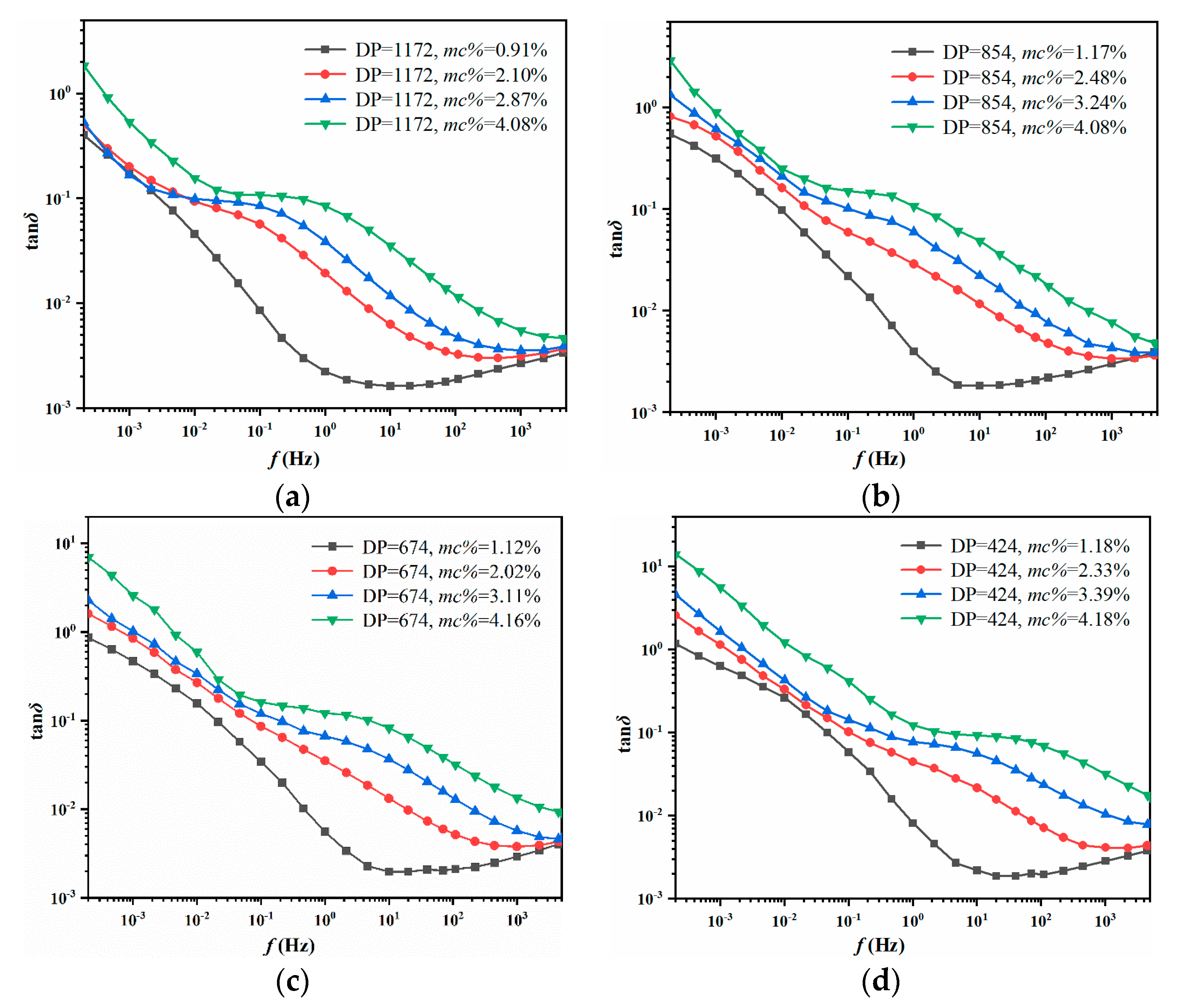

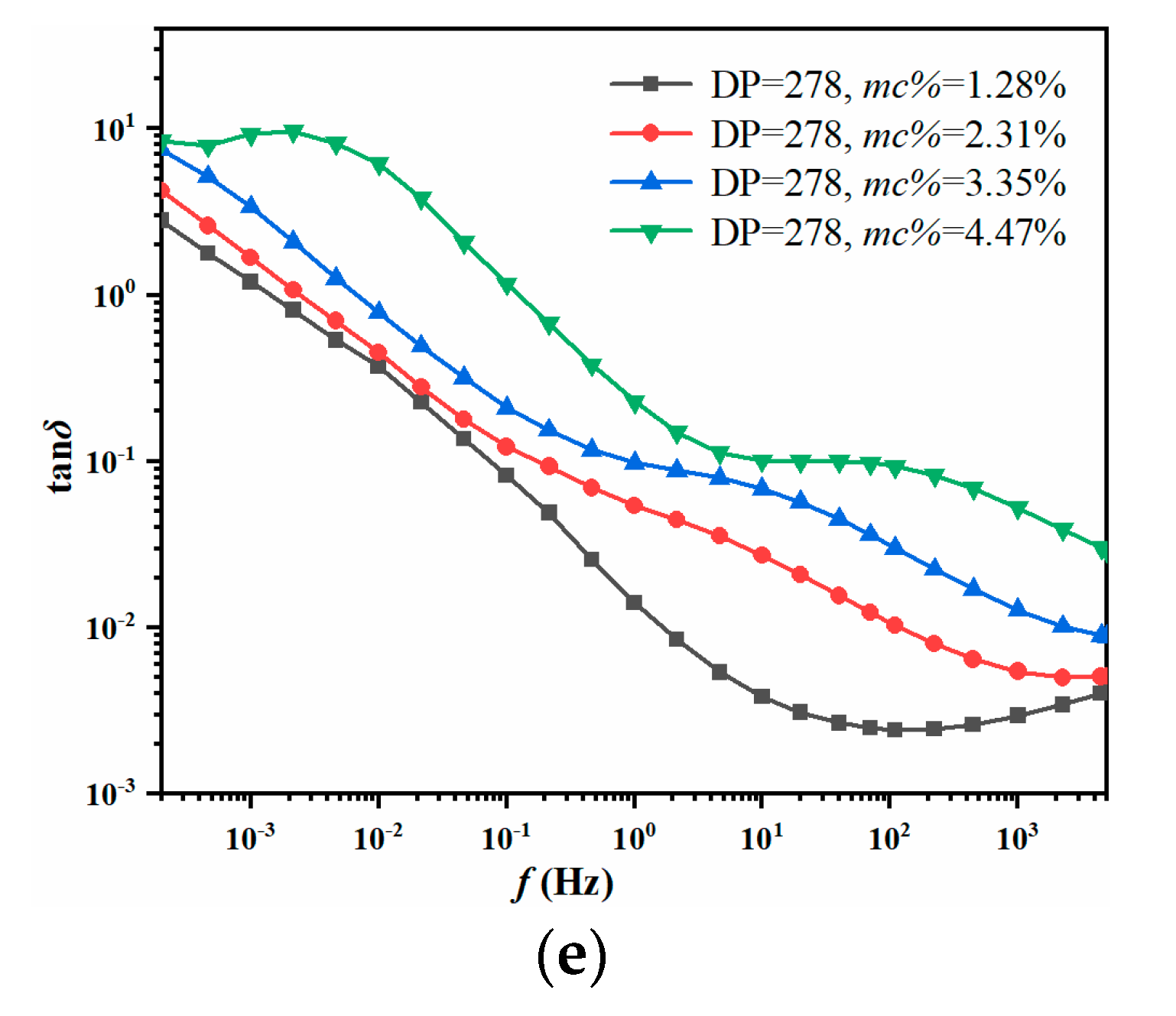

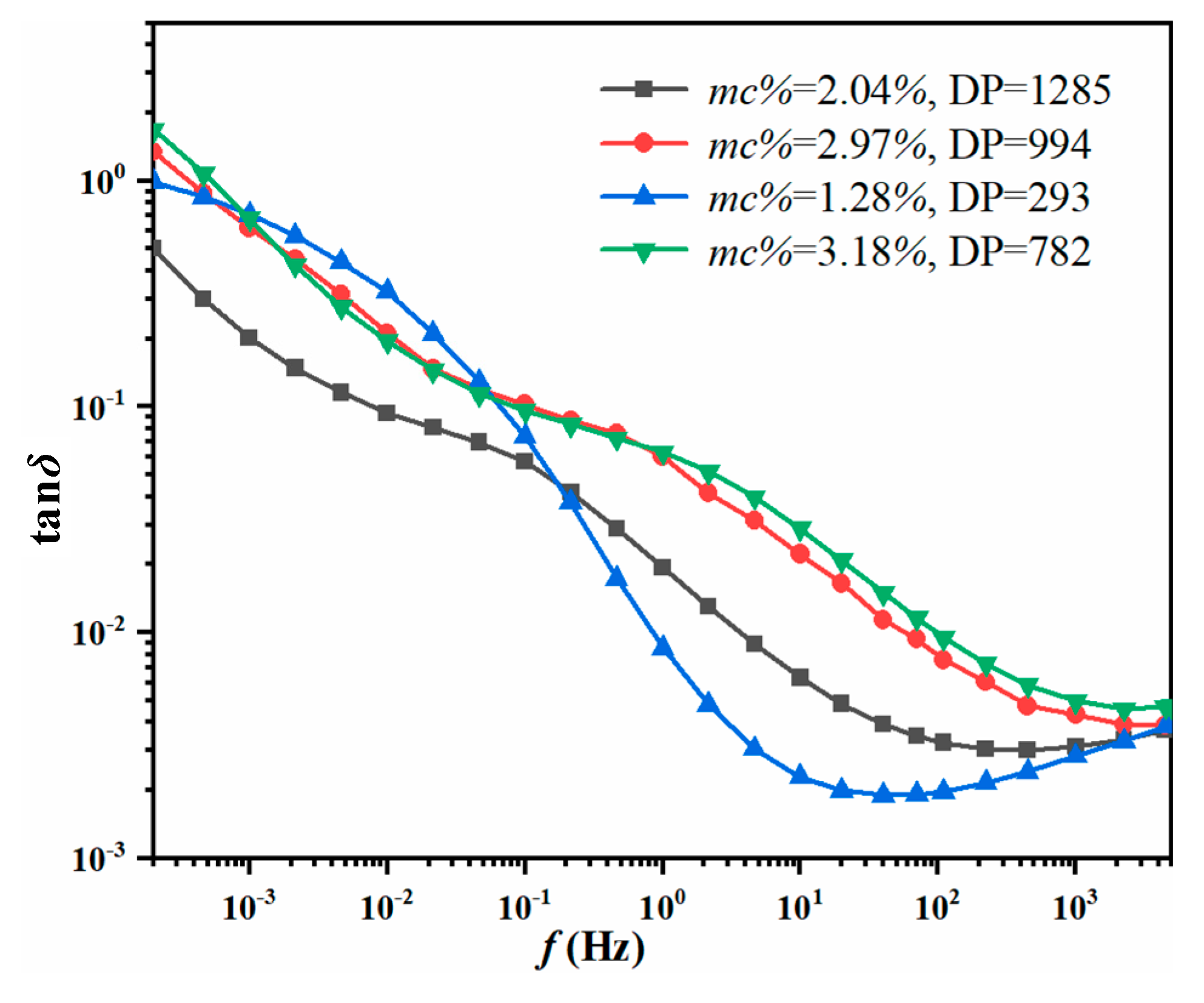

3.1. Analysis of FDS Curves

3.2. Construction of Fitting Analysis Model

- The fitting fingerprints Fi is defined as the dependent variable Zi, i = 1, 2, 3, 4, which is set to represent the integral value of tanδ curves. Moreover, the value of DP and mc% are defined as independent variable X and Y, respectively, which make an obvious impact on the shape of tanδ curves;

- Determining the types of fitting functions to build the model with the higher goodness of fitting. Two types of functions (Power 2D and Rational Taylor) are selected to realize the construction of the fitting analysis model in this work. Moreover, the values of Fi cannot be negative, the fitting functions are thus added with an absolute operation;

- The 20 groups of original data shown in Table 3 are brought into the determined functions so the fitting analysis model is constructed;

- Adjust the parameters of the model. The values of parameters can largely determine the goodness of the model. After experiments and adjustments, the parameters of the model are decided and the fitting analysis model is established. Finally, the goodness of Fi (i = 1–4) reach to 0.988, 0.983, 0.999, and 0.989, respectively. The surface of the fitting analysis model is shown in Figure 3, and its parameters and formulates are displayed in Table 4.

4. Construction of the GA-SVM Moisture Content Prediction Model

4.1. The Introduction of SVM

4.2. The Introduction of GA

- C and g should be firstly defined, and then operate binary-coded.

- Generating an initial population containing M individuals, where M is the number of individuals in the initial population.

- Calculating the fitness of individuals in the population by Equation (11):where, NT and NF represent the number of correctly classified and incorrectly classified samples, respectively.

- Ranking the individuals based on the fitness, then judging whether the termination condition meets the required level; if so, end the iteration, if not, go to step V.

- Generating the progeny by genetic operators. Then, go to step III.

4.3. Prediction Model of the Moisture Content Based on GA-SVM

4.3.1. Construction of Sample Set

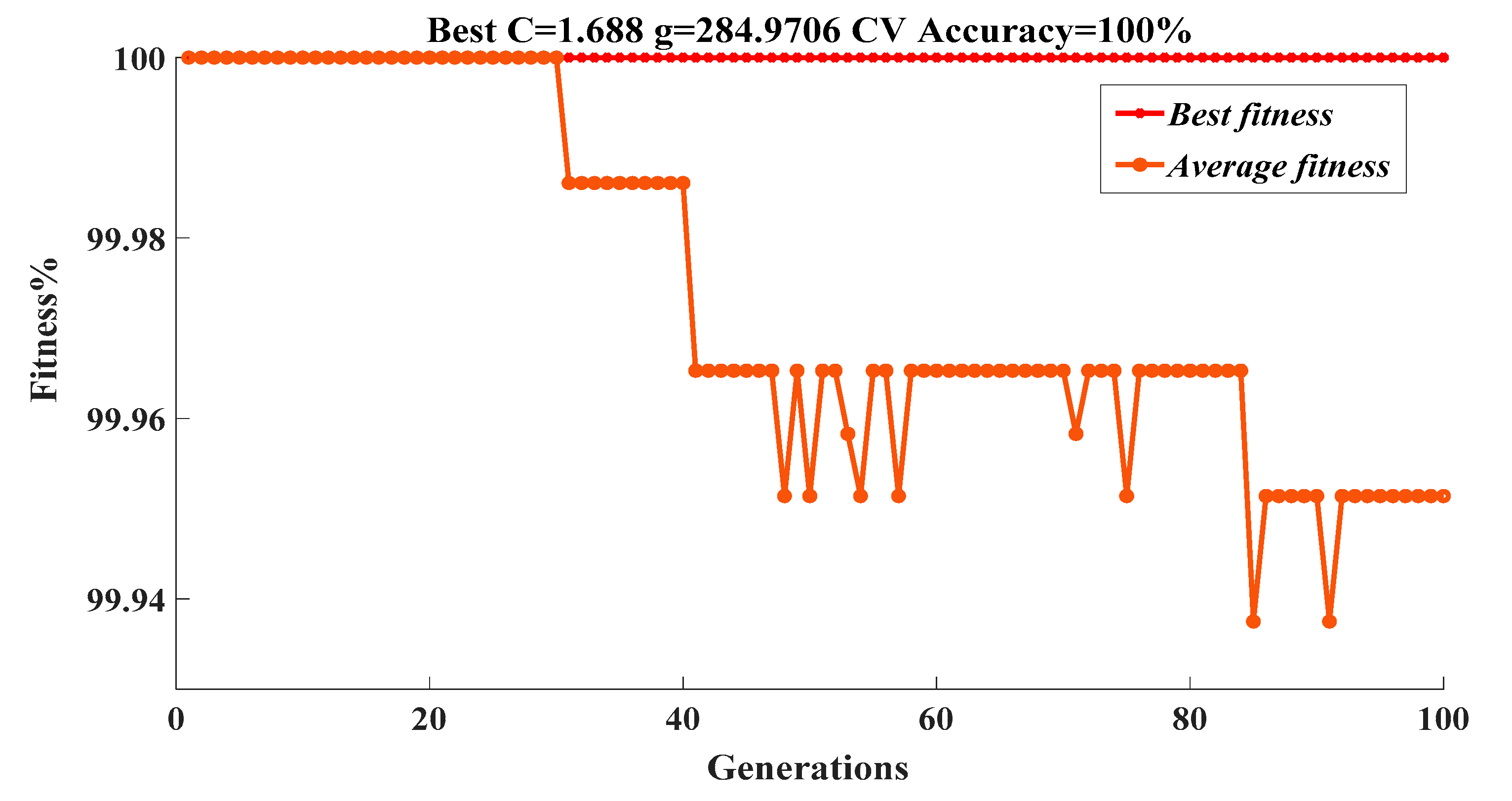

4.3.2. Model Building and Parameter Optimization

4.3.3. Controlled Trial

5. Feasibility Verification of the GA-SVM Model for Moisture Prediction

5.1. Verification under Laboratory Conditions

5.2. Verification under Field Conditions

- Testing the complex capacitance Ctot*(ω) of the above field transformers. The complex dielectric constant εtot*(ω) is calculated by the formula εtot*(ω) = Ctot*(ω)/C0.

- In this work, the structure parameters X and Y of the tested transformers are obtained by the commercial dielectric response analyzer, i.e., DIRANA/OMICRON. The DIRANA could access the preset curve that is most similar to the measured curve by using match technique. Then, the obtained structure parameters (X and Y) of the preset curve is approximatively regarded as the tested sample’s parameters. The analysis results of X and Y are shown in Table 10.

- The XY model is utilized to calculate the εPB*(ω) of transformer oil-immersed pressboards, as shown in Equation (14).

- Correcting the influence caused by various test temperatures. The FDS data of field transformers is measured at 30 °C, 29 °C, and 30 °C, respectively, while the data of the reported GA-SVM model is measured at 45 °C. Therefore, the shift factor αT shown in Equation (15) is applied to realize the temperature correction of the FDS data at different test temperatures.where Ea represents the activation energy (Ea =113kJ/mol). R represents a gas constant and R = 8.314 J/(mol·K). Tref represents the reference temperature (Tref = 318.15 K). T represents the test temperature (T1 = 303.15 K; T2 = 302.15 K; T3 = 303.15 K). Then, the shift factor αT1, αT2, αT3 is calculated (αT1 = 8.28; αT2 = 9.60; αT3 = 8.28). Above all, the temperature correction of the measured FDS data is realized. The corrected tanδ curves are shown in Figure 9, where the scattered points are uncorrected data, and the curves are corrected by the shift factor. The dielectric fingerprints D1–D3 can be extracted from these correct curves by using Equation (1). Besides, it has been proved in studies [24,30] that the temperature correction of σoil can be achieved by multiplying the shift factor αT, in that way, D4 = σoil × αT. Above all, the dielectric fingerprints are obtained and shown in Table 11.

- Get the dielectric fingerprints D1–D4 inputted to the reported GA-SVM model. The mc% prediction of the field transformers is realized, and the results are shown in Table 12. The prediction mc% in Table 12 is from GA-SVM and the measured mc% is from DIRANA. It can be seen that the same moisture level is given for Field 1 and Field 3. As for Field 2, the number of operating years is 8. Considering that the normal operating life of the transformer is 30 years, the Field 2 transformer is still lying in the early-term stage. Therefore, the predicted results of DIRANA and GA-SVM are both within a reasonable range.

6. Conclusions

- A group of dielectric fingerprints D1–D4, sensitive to the moisture content inside the transformer oil-immersed insulation, can be obtained by the presented analysis.

- A small number of samples are difficult to realize the training of the SVM multi-classifier, so a fitting analysis model is proposed in this paper to expand the number of training samples. Consequently, the heavy work of preparing a great number of oil-immersed pressboards is replaced and the training set with adequate fitting fingerprints is obtained easily.

- In the course of the construction of the moisture prediction model, the genetic algorithm is utilized to optimize the key parameters of the SVM. It has been proved that the GA-SVM performs better than the SVM on the classification of the training set.

- The feasibility and accuracy of the moisture prediction model based on the GA-SVM are proved by the laboratory and field experiments. The reported GA-SVM achieves the correct classification of the moisture levels of the lab samples, and the average relative error of the lab sample is 6.46%. As for the field transformer, considering the measured results of DIRANA and the operating years, the predicted values of GA-SVM is within a reasonable range.

Author Contributions

Funding

Conflicts of Interest

References

- Xie, Y.M.; Ruan, J.J.; Shi, Y.; Jin, S.; Tian, Y.; Zhu, L. Inversion Detection Method for Resistivity of Oil-Immersed Paper in Transformer. IEEE Trans. Power Deliv. 2019, 34, 1757–1765. [Google Scholar] [CrossRef]

- Emsley, A.M. Kinetics and mechanisms of the low-temperature degradation of cellulose. Cellulose 1994, 1, 26–56. [Google Scholar] [CrossRef]

- Zheng, H.B.; Lai, B.H.; Zhang, Y.Y.; Liu, J.; Yang, S. Correction for Polarization Current Curve of Polymer Insulation Materials in Transformers Considering the Temperature and Moisture Effects. Polymers 2020, 12, 143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Emsley, A.M. On the kinetics of degradation of cellulose. Cellulose 1997, 4, 1–5. [Google Scholar] [CrossRef]

- Zhang, D.N.; Long, G.W.; Li, Y.; Mu, H.; Zhang, G. Effect of Radial Moisture Distribution on Frequency Domain Dielectric Response of Oil-Polymer Insulation Bushing. Polymers 2020, 12, 1219. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.W.; Hao, J.; Liao, R.J.; Chen, X.; Cheng, L.; Liu, M. Comparative Study on the Thermal-Aging Characteristics of Cellulose Insulation Polymer Immersed in New Three-Element Mixed Oil and Mineral Oil. Polymers 2019, 11, 1292. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.F.; Fan, X.H.; Zhang, Y.Y.; Zheng, H.B.; Zhu, M.Z. Quantitative evaluation for moisture content of cellulose insulation material in paper/oil system based on frequency dielectric modulus technique. Cellulose 2020, 27, 1–14. [Google Scholar] [CrossRef]

- Yang, L.J.; Zou, T.T.; Deng, B.F.; Zhang, H.; Mo, Y.; Peng, P.; Zhang, H. Assessment of Oil-Paper Insulation Aging Using Frequency Domain Spectroscopy and Moisture Equilibrium Curves. IEEE Access 2019, 7, 45670–45678. [Google Scholar] [CrossRef]

- Liu, J.F.; Fan, X.H.; Zhang, Y.Y.; Zheng, H.B.; Jiao, J. Temperature Correction to Frequency Dielectric Modulus and Activation Energy Prediction of Immersed Cellulose Insulation. IEEE Trans. Dielectr. Electr. Insul. 2019, 27, 956–963. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjou, H.; Meghnefi, F.; Farzaneh, M.; Setayeshmehr, A.; Borsi, H.; Gockenbach, E. On the frequency domain dielectric response of oil-paper insulation at low temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 799–807. [Google Scholar] [CrossRef]

- Xia, G.Q.; Wu, G.N.; Gao, B.; Yin, H.J.; Yang, F.B. A New Method for Evaluating Moisture Content and Aging Degree of Transformer Oil-Paper Insulation Based on Frequency Domain Spectroscopy. Energies 2017, 10, 1195. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.F.; Fan, X.H.; Zhang, Y.Y.; Zheng, H.B.; Zhu, M.Z. Aging evaluation and moisture prediction of oil-immersed cellulose insulation in field transformer using frequency domain spectroscopy and aging kinetics model. Cellulose 2020. [Google Scholar] [CrossRef]

- Lelekakis, N.; Martin, D.; Wijaya, J. Ageing rate of paper insulation used in power transformers Part 2: Oil/paper system with medium and high oxygen concentration. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 2009–2018. [Google Scholar] [CrossRef]

- Suleiman, A.A.; Muhamad, N.A.; Bashir, N.; Murad, N.S.; Arief, Y.Z.; Phung, B.T. Effect of moisture on breakdown voltage and structure of palm based insulation oils. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2119–2126. [Google Scholar] [CrossRef]

- Zhang, D.N.; Hao, Y.; Zhan, J.Y.; Sun, X.; He, W.; Niu, C.; Mu, H.; Zhang, G. Insulation condition diagnosis of oil-immersed paper insulation based on non-linear frequency-domain dielectric response. IEEE Trans. Dielectr. Electr. Insul 2018, 25, 1980–1988. [Google Scholar] [CrossRef]

- Gao, J.; Yang, L.J.; Wang, Y.Y.; Liu, X.; Lv, Y.; Zheng, H. Condition diagnosis of transformer oil-paper insulation using dielectric response fingerprint characteristics. IEEE Trans. Dielectr. Electr. Insul 2016, 23, 1207–1218. [Google Scholar] [CrossRef]

- Linhjell, D.; Lundgaard, L.E.; Gafvert, U. Dielectric response of mineral oil impregnated cellulose and the impact of aging. IEEE Trans. Dielectr. Electr. Insul 2007, 14, 156–169. [Google Scholar] [CrossRef]

- Wang, L.; Tang, C.; Zhu, S.P.; Zhou, S.L. Terahertz Time Domain Spectroscopy of Transformer Insulation Paper after Thermal Aging Intervals. Materials 2018, 11, 2124. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.M.; Wang, Z.J. Study on broadband loss characteristics of oil-immersed papers for fast transient modeling of power transformer. IEEE Trans. Dielectr. Electr. Insul 2013, 20, 564–570. [Google Scholar] [CrossRef]

- Fei, S.W.; Zhang, X.B. Fault diagnosis of power transformer based on support vector machine with genetic algorithm. Expert Syst. Appl. 2009, 36, 11352–11357. [Google Scholar] [CrossRef]

- Han, H.; Wang, H.J.; Dong, X.C. Transformer Fault Dignosis Based on Feature Selection and Parameter Optimization. Energy Procedia 2011, 12, 662–668. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.Y.; Li, X.; Zheng, H.B.; Yao, H.; Liu, J.; Zhang, C.; Peng, H.; Jiao, J. A Fault Diagnosis Model of Power Transformers Based on Dissolved Gas Analysis Features Selection and Improved Krill Herd Algorithm Optimized Support Vector Machine. IEEE Access 2019, 7, 102803–102811. [Google Scholar] [CrossRef]

- Li, J.Z.; Zhang, Q.G.; Wang, K.; Wang, J.; Zhou, T.; Zhang, Y. Optimal dissolved gas ratios selected by genetic algorithm for power transformer fault diagnosis based on support vector machine. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1198–1206. [Google Scholar] [CrossRef]

- Liu, J.F.; Fan, X.H.; Zhang, Y.Y.; Zheng, H.B.; Zhang, C.H. Condition prediction for oil-immersed cellulose insulation in field transformer using fitting fingerprint database. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 279–287. [Google Scholar] [CrossRef]

- Koch, M.; Prevost, T. Analysis of dielectric response measurements for condition assessment of oil-paper transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1908–1915. [Google Scholar] [CrossRef]

- Jadav, R.B.; Ekanayake, C.; Saha, T.K. Understanding the impact of moisture and ageing of transformer insulation on frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 369–379. [Google Scholar] [CrossRef]

- Liao, R.J.; Liu, J.F.; Yang, L.J.; Wang, K.; Hao, J.; Ma, Z.; Gao, J.; Lv, Y. Quantitative analysis of insulation condition of oil-paper insulation based on frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 322–334. [Google Scholar] [CrossRef]

- Cherkassky, V. The Nature of Statistical Learning Theory. IEEE Trans. Neural Netw. 1997, 8, 1564. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.B.; Wang, J.Z.; Zhang, K.Q. Short-term electric load forecasting based on singular spectrum analysis and support vector machine optimized by Cuckoo search algorithm. Electr. Power Syst. Res. 2017, 146, 270–285. [Google Scholar] [CrossRef]

- Verma, H.C.; Baral, A.; Pradhan, A.K.; Chakravorti, S. A method to estimate activation energy of power transformer insulation using time domain spectroscopy data. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3245–3253. [Google Scholar] [CrossRef]

| Cellulosic Pressboard | Insulating Oil | ||

|---|---|---|---|

| Brand | T4 transformer pressboard | Brand | Karamay No.25 naphthenic mineral oil |

| Thickness | 1.05 mm | Tan δ | 4 × 10−4 |

| Tensile strength | Machine Direction: 138.8 MPa, Cross-Machine Direction: 97.1 MPa | Pour point | ≤−45 °C |

| Density | 1.09 g/cm3 | Flash point | 135 °C |

| mc% | 1.0% | 1.5% | 2.0% | 2.5% | 3.0% | 3.5% | 4.0% | 4.5% |

|---|---|---|---|---|---|---|---|---|

| Tag | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 |

| Damp State | Well Dry | Dry | Slightly Damped | Damped | Moderately Damped | Quiet Damped | Severely Damped | Extremely Damped |

| No. | Insulation Information | Dielectric Fingerprint | ||||

|---|---|---|---|---|---|---|

| DP | mc% | D1 | D2 | D3 | D4 | |

| 1 | About 1172 | 0.91 | 1.88 | 21.30 | 12.47 | 0.06 |

| 2 | 2.10 | 11.41 | 27.32 | 13.84 | 3.50 | |

| 3 | 2.87 | 22.00 | 33.55 | 14.87 | 11.00 | |

| 4 | 4.08 | 55.24 | 62.62 | 19.50 | 38.00 | |

| 5 | About 854 | 1.17 | 2.67 | 23.89 | 14.36 | 0.15 |

| 6 | 2.48 | 18.55 | 32.79 | 14.06 | 5.80 | |

| 7 | 3.24 | 35.98 | 44.83 | 15.85 | 19.00 | |

| 8 | 4.08 | 70.53 | 91.23 | 22.51 | 330.00 | |

| 9 | About 674 | 1.12 | 3.47 | 22.70 | 14.44 | 0.39 |

| 10 | 2.02 | 22.03 | 35.72 | 16.23 | 7.80 | |

| 11 | 3.11 | 50.17 | 67.23 | 19.53 | 25.00 | |

| 12 | 4.16 | 102.56 | 163.36 | 42.06 | 530.00 | |

| 13 | About 424 | 1.18 | 4.76 | 22.20 | 13.79 | 0.56 |

| 14 | 2.33 | 31.72 | 41.80 | 16.88 | 9.70 | |

| 15 | 3.39 | 67.24 | 124.22 | 34.23 | 31.00 | |

| 16 | 4.18 | 105.98 | 392.64 | 88.70 | 770.00 | |

| 17 | About 279 | 1.28 | 8.25 | 23.82 | 14.47 | 0.72 |

| 18 | 2.31 | 39.01 | 59.43 | 20.42 | 17.00 | |

| 19 | 3.35 | 82.62 | 156.31 | 40.30 | 56.00 | |

| 20 | 4.47 | 152.11 | 604.64 | 149.71 | 1200.00 | |

| Equation: | |||||

| A0 | 6.759 | A3 | 8.401 | Precision | 10−6 |

| A1 | −0.418 | A4 | 2.217 | R-Square | 0.988 |

| A2 | 0.462 | A5 | −0.221 | ||

| Equation: | |||||

| A0 | 26.39 | A3 | −78.58 | Precision | 10−6 |

| A1 | −2.092 | A4 | 4.910 | R-Square | 0.983 |

| A2 | −0.0033 | A5 | 80.42 | ||

| Equation: | |||||

| A0 | 10.57 | A5 | −3.3 × 10−5 | Precision | 10−6 |

| A1 | −0.0019 | A6 | 1.7 × 10−7 | ||

| A2 | −0.519 | A7 | −1.2 × 10−10 | R-Square | 0.999 |

| A3 | −1.337 | A8 | −0.467 | ||

| A4 | 0.238 | A9 | 0.055 | ||

| Equation: | |||||

| A0 | −28.50 | A3 | 0.0098 | Precision | 10−6 |

| A1 | 4.6 × 10−6 | A4 | 7.888 | R-Square | 0.989 |

| A2 | 2.229 | A5 | −1.3 × 10−9 | ||

| Pressboard I | Pressboard II | ||

|---|---|---|---|

| Brand | T4 pressboard | Brand | Common pressboard |

| Thickness | 1 mm | Thickness | 2 mm |

| Tensile strength | Machine Direction: 138.8 MPa, Cross-Machine Direction: 97.1 MPa | Tensile strength | Machine Direction:150.0 MPa, Cross-Machine Direction: 57.1 MPa |

| Density | 1.09 g/cm3 | Density | 1.17 g/cm3 |

| Testing Samples | mc% | DP |

|---|---|---|

| Lab. 1 | 2.04% | 1285 |

| Lab. 2 | 2.97% | 994 |

| Lab. 3 | 1.28% | 293 |

| Lab. 4 | 3.18% | 782 |

| No. | Dielectric Fingerprints | |||

|---|---|---|---|---|

| D1 | D2 | D3 | D4 | |

| Lab. 1 | 12.04 | 27.32 | 13.84 | 0.58 |

| Lab. 2 | 37.12 | 44.83 | 15.85 | 6.62 |

| Lab. 3 | 5.20 | 22.00 | 13.84 | 1.10 |

| Lab. 4 | 42.93 | 53.93 | 18.74 | 76.00 |

| No. | Predicted mc% | Measured mc% | T/F | P. E |

|---|---|---|---|---|

| Lab. 1 | 2.0%(M3) | 2.04%(M3) | T | 1.96% |

| Lab. 2 | 3.0%(M5) | 2.97%(M5) | T | 1.01% |

| Lab. 3 | 1.5%(M2) | 1.28%(M2) | T | 17.19% |

| Lab. 4 | 3.0%(M5) | 3.18%(M5) | T | 5.66% |

| No. | Voltage Level | Test Voltage | Test Temperature | σ (T) | Service Record | |

|---|---|---|---|---|---|---|

| Field 1 | 110 kV | 200 V | 30 °C | 2.1 pS/m | 1 years | |

| Field 2 | 110 kV | 200 V | 29 °C | 6.3 pS/m | 8 years | |

| Field 3 | 220 kV | 200 V | 30 °C | 220 pS/m | 14 years |

| No. | X | Y |

|---|---|---|

| Field 1 | 0.27 | 0.20 |

| Field 2 | 0.29 | 0.24 |

| Field 3 | 0.30 | 0.14 |

| No. | Dielectric Fingerprints | |||

|---|---|---|---|---|

| D1 | D2 | D3 | D4 | |

| Field 1 | 1.65 | 14.64 | 5.93 | 17.33 |

| Field 2 | 5.01 | 21.77 | 8.75 | 60.35 |

| Field 3 | 4.81 | 11.63 | 4.89 | 181.5 |

| No. | Predicted mc% | Measured mc% |

|---|---|---|

| Field 1 | 1.0%(M1) | 0.7%(M1) |

| Field 2 | 1.5%(M2) | 1.2%(M1) |

| Field 3 | 1.0%(M1) | 0.8%(M1) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, J.; Fan, X.; Liu, J.; Zhang, H. Moisture Prediction of Transformer Oil-Immersed Polymer Insulation by Applying a Support Vector Machine Combined with a Genetic Algorithm. Polymers 2020, 12, 1579. https://doi.org/10.3390/polym12071579

Zhang Y, Li J, Fan X, Liu J, Zhang H. Moisture Prediction of Transformer Oil-Immersed Polymer Insulation by Applying a Support Vector Machine Combined with a Genetic Algorithm. Polymers. 2020; 12(7):1579. https://doi.org/10.3390/polym12071579

Chicago/Turabian StyleZhang, Yiyi, Jiaxi Li, Xianhao Fan, Jiefeng Liu, and Heng Zhang. 2020. "Moisture Prediction of Transformer Oil-Immersed Polymer Insulation by Applying a Support Vector Machine Combined with a Genetic Algorithm" Polymers 12, no. 7: 1579. https://doi.org/10.3390/polym12071579