1. Introduction

Fibre reinforced composite materials continue to gain progressively larger share in the structures of modern aircraft. The amounts of composite laminates used in the Boeing 787 Dreamliner and Airbus A350 exceed 50% of the vehicle weight [

1,

2]. Since the metal elements are and will be indispensable in aerospace structures, the problem of joining composite and metal elements becomes more and more important as the share of composite elements in the structures increases. The joint used in a composite structure is usually the weakest point of the structure, and thus determines the structural efficiency [

3]. A separate part of this literature review is devoted to the bolted joining of composite and metal elements [

4], as it is the most widely used method of mechanical joining. However, the bolted joining of composite materials has several drawbacks, resulting mainly from the need of drilling holes. The process of drilling disrupts the continuity of the fibres reducing the load carrying capacity [

5,

6,

7] and causes damages (such as delamination, fibre pull-out and microbuckling [

7]). Therefore, the other methods of mechanical joining have been developed and some of them were specially dedicated for joining composite to metals. Those methods include self-piercing riveting, friction riveting, clinching, non-adhesive form-locked joints, pin joints, and loop joints. Some of those methods do not require making holes in cured composite material (non-adhesive form-locked joints, pin joints and loop joints) and thus eliminate the disruption of the fibre continuity and drilling-induced damages, whereas, the others as riveting and clinching disrupt the structure of the composite significantly. Some of the presented methods, including non-adhesive form-locked joints, pin joints, and loop joints, take the advantage of the fibrous nature of the composites in order to transfer loads onto the metal structure in a sophisticated yet clever way. Some of the methods, as self-piercing riveting or form-locked joints, have been successfully developed and employed in commercial applications, whereas, the others, like pin and loop joints, are merely ideas, tested only at the specimen level. Some of the methods present the possibility of joint disassembly without destroying it, whereas some are permanent. Some methods can be used to join any composite and some of them are limited only to the composites with thermoplastic matrix.

The number, diversity, and complexity of mechanical methods of joining composite and metal materials makes the choice of the proper method tedious and difficult. Furthermore, the recent review work on joining FRP composites to metal is moderate. Amancio-Filho and dos Santos described trends in joining of polymers and polymer-metal hybrid structures including bolted joining, clinching, welding and friction riveting [

8]. Kah et al. reviewed techniques for joining metals and polymers in 2014 [

9]. Those methods included adhesive bonding, bolted joining, and welding. In the most comprehensive work, Pramanik et al. presented a review of joining methods of carbon fibre reinforced polymer composites and aluminium alloys, including adhesive bonding, loop joining, self-piercing riveting, bolted joining, clinching and welding [

10]. Dawei et al. provided the most recent works reviewing several mechanical and non-mechanical joining methods, namely: adhesive bonding, bolted joining, pin joining, welding, self-piercing riveting, and clinching [

11,

12]. Since none of those works either focus solely on the mechanical joining methods or cover all the developed methods of mechanical joining, and some of the joining methods have been omitted entirely, the current work presents a review which covers all the mechanical joining methods. The current paper along with its first part [

4] provides a literature review which describes the level of development, and the advantages and disadvantages of mechanical methods of joining composite and metal materials. The current paper omits bolted joining, which is reviewed thoroughly in the first part of this review [

4]. The subsequent sections of the current work describe two methods of riveting used in composite materials: self-piercing riveting and friction riveting, method of joining by mechanical clinching, non-adhesive form-locked joints designed in order to introduce a concentrated force into a composite structure, pin joints which join the composite to metal by arrays of pins protruding from metal elements inserted into composite during curing process and loop joints which consist in entangling reinforcing fibres into loops protruding from metal elements. As those methods vary significantly, the summary section of this paper contains a comparison of those methods with reference to their features, which is important from the point of view of a composite structure designer: possibility of the joint disassembly, damages induced in composite, complication level, weight penalty, range of possible materials to be joined, and the joint strength. This section is divided into subsections which facilitate fast familiarization with the most important conclusions.

3. Mechanical Clinching

Clinching is a method of joining carbon fibre reinforced plastics (CFRP) and ductile materials [

46]. This method was originally developed to join metal sheets including high strength steels and aluminium alloys [

47]. It has been used in automotive [

48]. Then, it has been extended to join many other materials including joining fibre reinforced composites to metal alloys [

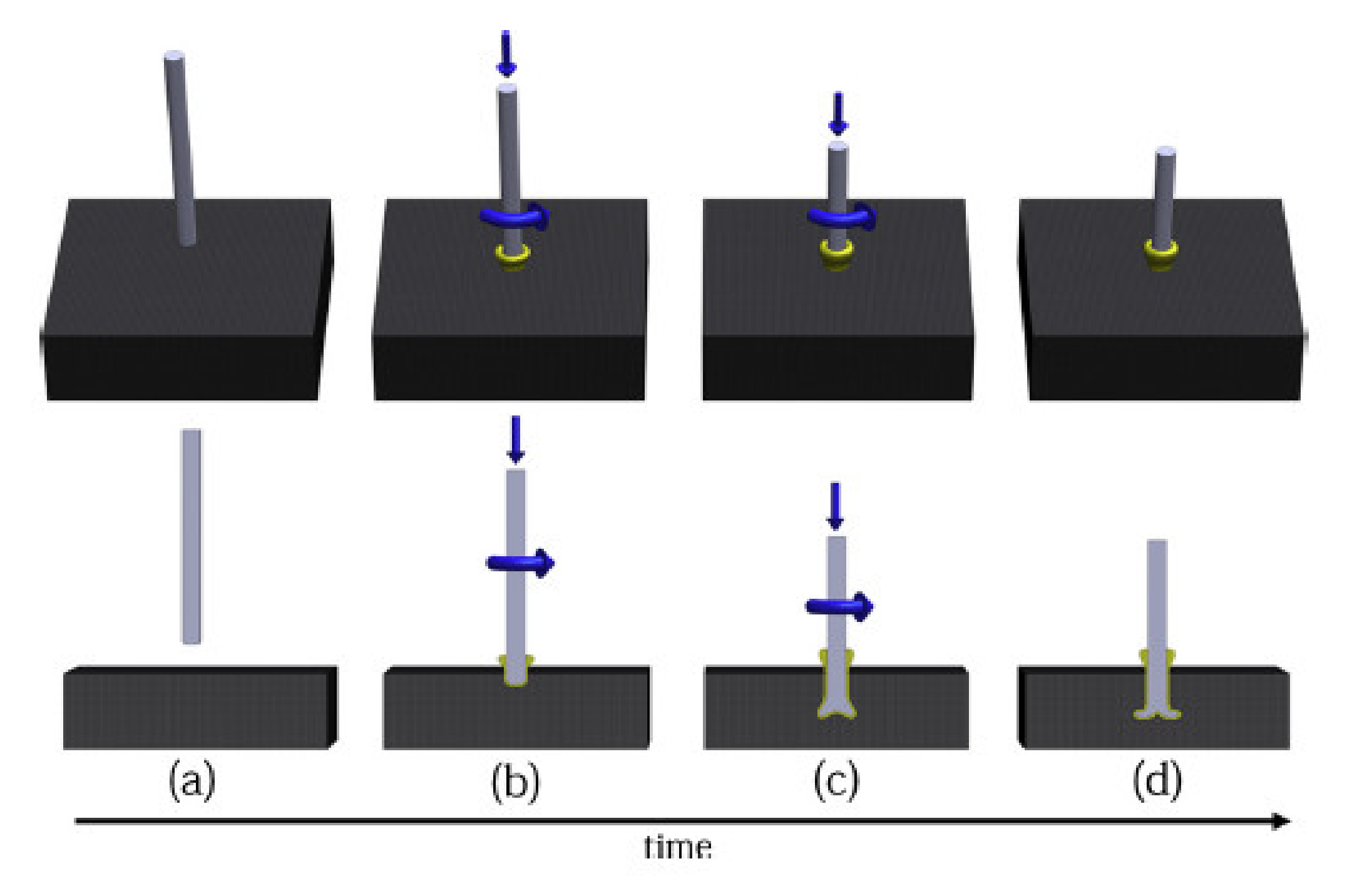

47]. Generally clinching consists in plasticising of either composite or metal sheet in order to build geometrical interlocking, however, it is preferable to place the material with higher ductility (metal) on the punch side, because during clinching the punch-side sheet undergoes severe plastic deformation [

49]. The most common way to perform clinching of composite and metal consists in forcing the metal component into the composite component in order to produce mechanical interlocking (

Figure 9). The composite component is placed on a die and covered with the metal component (

Figure 9a). The punch is positioned over the die cavity and it forces the metal component into the cavity (

Figure 9b). The composite component can have a predrilled hole necessary to assure interlocking as it is presented in

Figure 9 [

46,

48,

50] or the hole can be punched during the clinching process [

47,

49,

51]. The pre-cutting of the hole reduces the material damages compared to punching the hole in composite [

51], however, it also adds additional step to the joining process. The punch is forced further in order to push the metal sheet to fit the die (

Figure 9c) in order to create interlocking joint with undercuts (

Figure 9d) [

46].

Clinching process has the following advantages:

No additional elements are needed. Therefore, it is a fast, low cost, and lightweight process [

47,

49,

52,

53]

Predrilled holes or surface preparation are not necessary in the case of thermoplastic matrices which simplifies the process [

51,

53]

However, it has also disadvantages:

Once the joint is clinched it is impossible to disassembly it without destroying components [

53]

As the process consists in the plastic deformation the joined materials have to exhibit certain ductility, so that not all materials can be subjected to clinching [

46,

49]. It is preferable to place the material with higher ductility on the punch side, because, during clinching, the punch side sheet undergoes severe plastic deformation [

49,

51].

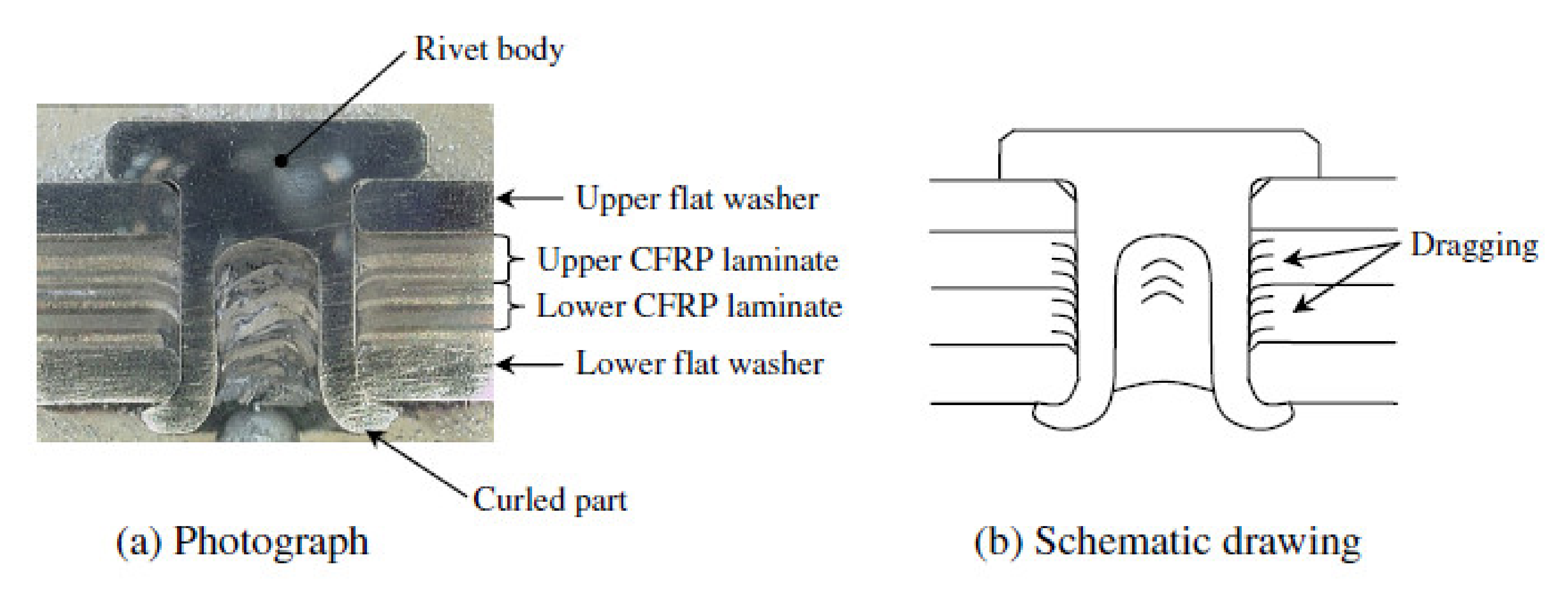

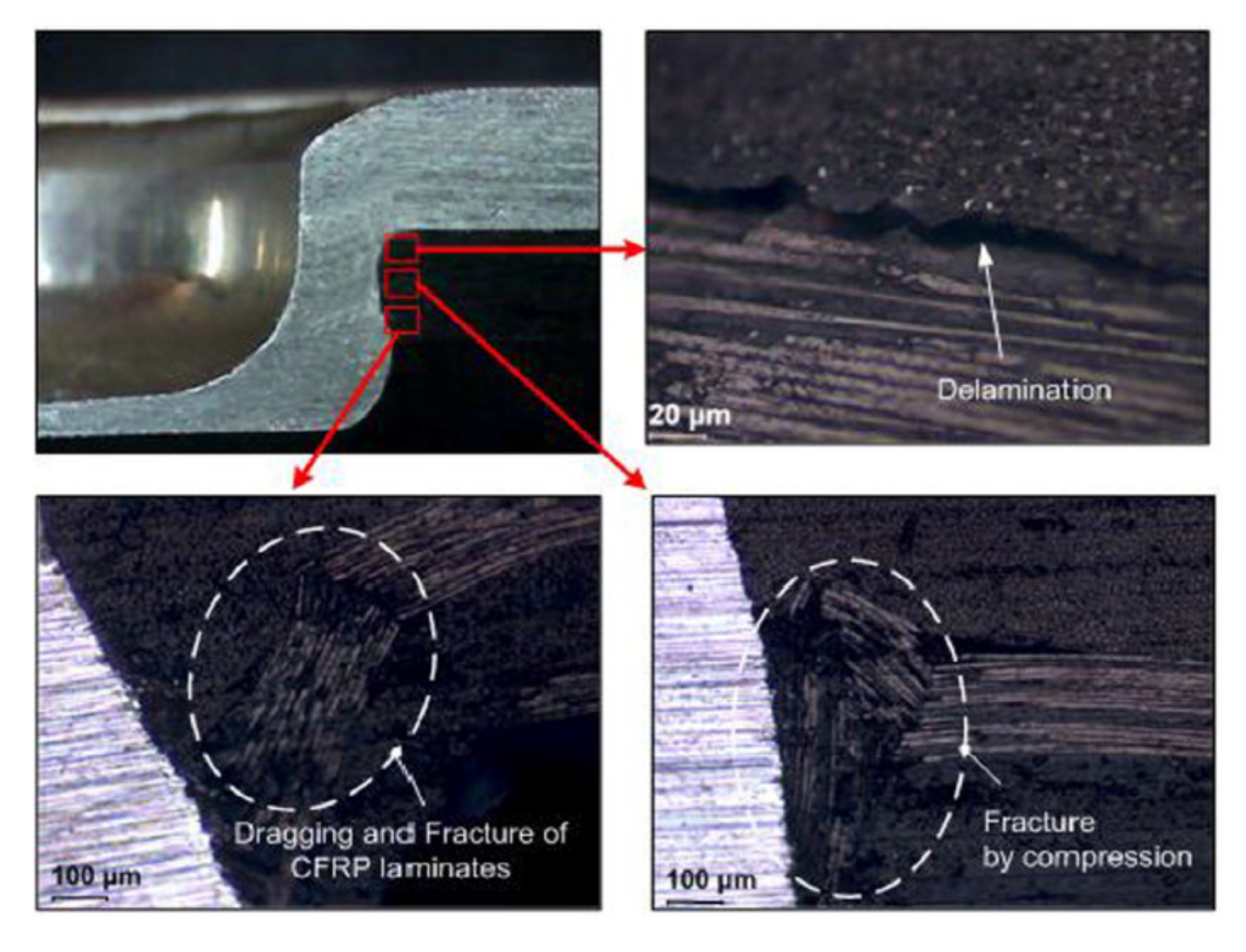

The clinching process can cause some material damage in the composite materials (dragging, delaminations and cracking) (

Figure 10) [

46,

54], especially if the hole is not pre-cut, but punched.

Galvanic corrosion may occur in this joining method if a substrate made of aluminium alloys or steel is used along with a CFRP composite [

22,

23].

Lee et al. conducted single lap shear tests of AA6061 alloy and the CFRP sheets joined by clinching [

54]. The specimens had different composite sheet thickness: 1.0, 1.2, 1.4 or 1.6 mm. The experiments have shown that the failure mode changes with the composite substrate thickness. For 1.0- and 1.2-mm thicknesses the specimens failed by the button separation (pull-out of the metal inclusion from the composite), but for 1.4- and 1.6-mm thicknesses, the failure mode changed to the neck fracture. The failure loads were higher for the higher thicknesses (2.75 kN and 3.34 kN respectively) compared to the lower thicknesses (failure loads 2.0–2.5 kN) [

54]. Lee et al. also investigated experimentally the effect of the tool shape on the hole clinching [

52]. The hole clinching process of joining CFRP laminates with aluminium alloy and high strength steel sheets was studied. It was concluded that [

52]:

The punch diameter has a significant influence on the joint quality: the neck-thickness is decreased and the undercut is increased with the increase of the punch diameter.

The neck formation is also severely influenced by the punch corner radius. Sharp punch corners induce the concentration of deformation at the neck of the upper sheet, which decreases the neck-thickness, so the punches with tight radii are suitable for punching materials which have sufficient ductility, such as SPRC440. Blunt punch corners are suitable for more fragile materials, such as Al6061, and reduce the damage at the neck, but on the other hand, expand the hole in the lower sheet.

The die depth also influences the quality of the joints. When the die is too shallow the undercut creation process is disturbed. On the other hand, too deep a die may cause the fracture of the joint neck in the joining process.

The best failure strength of single lap shear (SLS) specimens (2.69 kN) was achieved for hole clinching process of CFRP laminates and Al6061 with flat die and with sharp punch corner [

52]. The joining of CFRP (carbon fabric preimpreganted with epoxy resin) laminates and SPRC440 steel by the hole-clinching process was also investigated in another work [

48]. Holes of 8.2 mm in diameter were drilled in the composite and the steel was punched into them. In the experiments corner radius of 0.5 mm and three punch diameters, 6.6 mm, 6.8 mm, and 7.0 mm, were used. Single lap shear tests of the specimens were performed. For the joints clinched with the punch diameters 6.6mm and 6.8 mm the average maximum loads were 2.91 kN and 3.36 kN and the failure mode was button separation (pull-out) [

48]. For the punch diameter of 7.0 mm, the maximum load dropped to 2.25 kN and the failure mode changed to neck fracture [

48]. The failure load increased when the punch diameter was increased from 6.6mm to 6.8 mm, because it caused the increase of the undercut and hole expansion [

48]. However, with the further increase of the punch diameter to 7.0 mm the failure load decreased, because the neck became so thin, that it was fractured before the button was pulled out from the composite [

48]. Lambiase and Ko also compared the results of carbon-epoxy composite and aluminium alloy clinching with different punch diameters [

47]. Four punches used in this work had three different diameters (3, 4 or 4.5 mm) and two taper angles (6° or 12°). The holes in the composite materials were not pre-cut, but punched during the clinching process. The results of the strengths of single lap shear specimens clinched with these punches were investigated. During the single lap shear tests, all the examined joints failed by pull-out followed by bearing of CFRP, regardless of the type of punch used [

47]. It was concluded that the punch diameter has significant influence on the joint quality: with the increase of the diameter the undercut is increased, but larger punch diameter induces also more material damage in the CFRP composite. The increase in the taper angle causes greater damage on the CFRP sheet, which is due to the delay in the fibre cut along the developing hole owing to higher hydrostatic stress produced during the offsetting phase [

47]. Reduction of the taper angle from 12° to 6° allowed an increase in the shear strength of 50% [

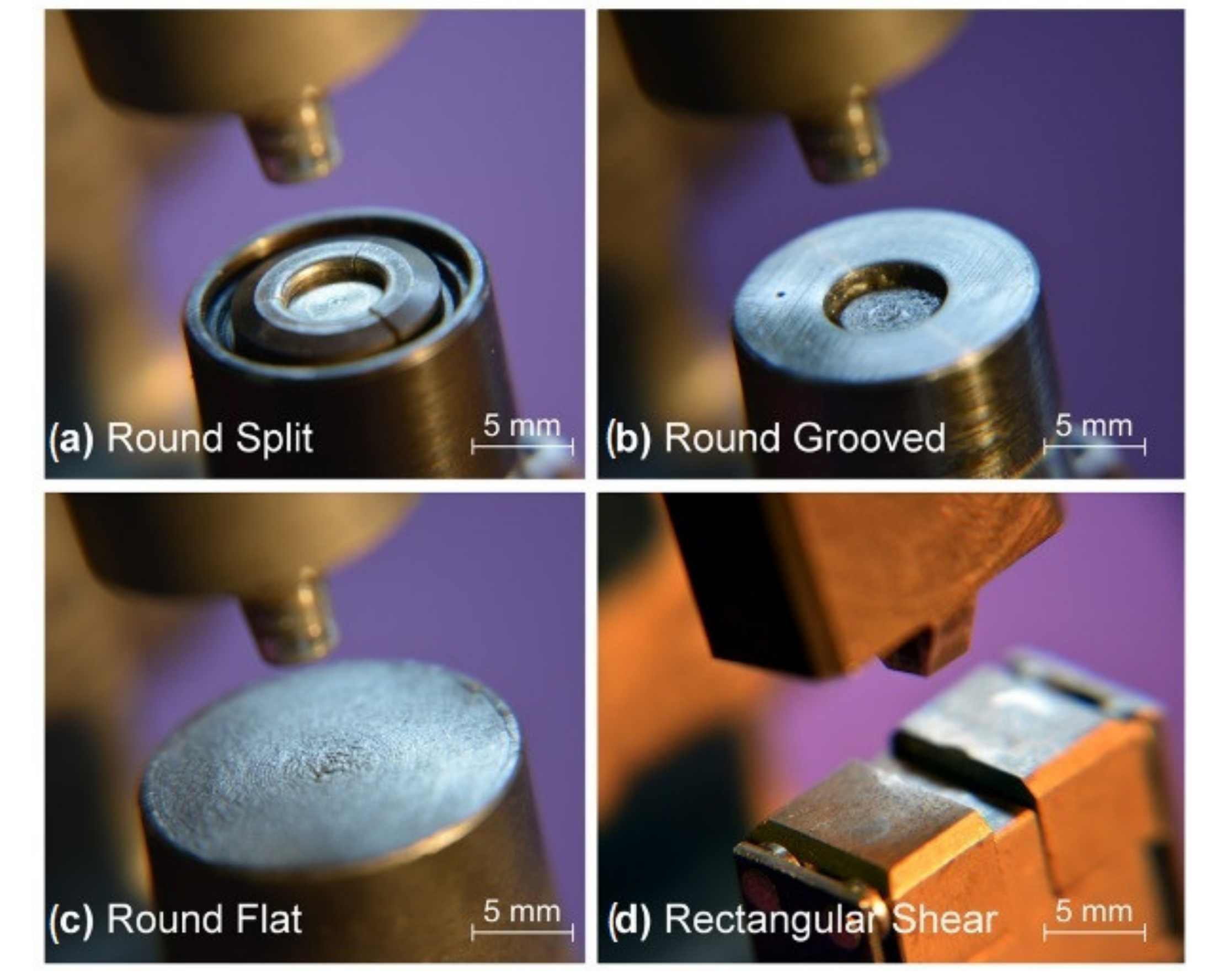

47]. Lambiase et al. also investigated the influence of the die shape on the clinched joint quality [

49]. Different clinching tools were adopted to join aluminium sheets with GFRP sheets by mechanical clinching, namely: a round split (extensible) die, a round grooved die, a round flat die and a rectangular tool (

Figure 11) [

49].

The clinching process was performed without pre-cutting holes in the composite sheet. Single lap shear tests of the specimens were carried out. In the case of the grooved and split dies part of the composite was stuck in the grooves and the splits proving very difficult to be removed, which makes those dies unsuitable for the commercial manufacturing process [

49]. On the other hand, flat dies generally promote small undercuts [

49]. Split dies allow to produce joints of better quality [

49]. In order to prevent the entrapment of the composite material within the splits, a loose sheet of aluminium was placed between the composite and the split die, which successfully prevented this undesirable phenomenon. Single lap shear tests confirmed that the use of the split die yields better results than the use of the flat die. Joints produced with the split die had higher strength than the joints produced with the flat dies (1.9 kN vs. 1.3 and 2.1 kN vs. 0.8 kN) [

49]. The clinched joints failed by pull-out or neck fracture (or combination of both), depending on their geometry features (neck thickness and undercut) [

49]. Lee et al. proposed a new type of hole clinching tool called a spring die [

46]. This tool was designed to improve the hole clinching process of CFRP and aluminium alloy (AA5083). In the spring die two pads supported by a coil spring are employed to improve the formability of ductile materials and to reduce damages to CFRP laminates by increasing the compressive hydrostatic stress during the hole clinching process. The microscopic observations of the clinched joint cross-sections have shown that the spring die is suitable to prevent the fracture and delamination of CFRP laminates, which are main defects in hole clinching process [

46]. Moreover, it was observed that the spring die can prevent the damage accumulation at the neck of the upper sheet by the means of compressive hydrostatic stress [

46].

An investigation which analyses two-stepped clinching based on reshaping deformation that follows mechanical clinching, as a method to improve the mechanical behaviour of clinched connections performed on hybrid metal-composites joints was presented by Lambiase and Ko [

51]. The clinching of AA6024 aluminium alloy and carbon fibre reinforced thermosetting composite was performed. Single lap shear tests were performed in order to verify the effectiveness of the reshaping method. The split die was preferred to a fixed (grooved) one because it generally produces larger undercuts with lower forming forces and enables an easier extraction of composite crumbles from the die cavity [

55]. In the second step (reshaping), the height of the punch was varied in order to produce different punch-die cavity geometries [

51]. Two values of the reshaping force 20.5 kN and 28.8 kN chosen according to the preliminary test results were used. The reshaping step resulted in appearance of several damages in the composite material: buckling, delaminations and cracking [

51]. Those defects resulted in the reduction of the strength of the joint in majority of the reshaped joints. However, under optimal conditions of reshaping (reshaping force 28.8 kN and reshaping depth 0.5 mm) the shear strength was increased by 32% compared to the reference joints. The improvement of the mechanical behaviour is attributed mainly to the increase in undercut [

51]. Lambiase and Paoletti employed a rotating tool in order to join thin aluminium sheets of a carbon–epoxy composite by means of clinching [

50]. The friction-assisted clinching was used to join aluminium alloy component with CFRP composite component. The process was named friction-assisted clinching. The aim of the tool rotation was to soften the aluminium component by friction generated heat and thus reduce the joining forces. According to the achieved results, the employment of friction clinching allowed to increase dramatically the material formability and enabled the production of joints without fractures even with sharp punch tools [

50]. The employment of the rotating tool also enabled a great plunging load reduction. Actually, conventional clinching generally involves forces ranging between 10 kN and 20 kN, while in friction assisted clinching a force of 300 N enabled complete joining [

50]. On the other hand, the time of the process increased to 30 s compared to 1 s time used in conventional clinching [

50]. The specimens were tested in single lap shear experiment. The specimens failed by either pull-out caused by insufficient undercuts or neck fracture caused by insufficient neck thickness [

50]. The clinching process was monitored by an IR camera. Despite high temperatures registered during the process (up to 300 °C), no evident sign of thermal degradation of the epoxy matrix was observed at the CFRP aluminium interface [

50]. This was attributed to the low contact pressure exerted by the aluminium on the CFRP side wall during great part of the process duration.

Apart from the conventional clinching process in which the metal component is plasticized in order to create lock in the hole made in the composite component, there have been several attempts made in order to design different processes, which can be incorporated to the group of ‘mechanical clinching’ methods. In those processes the composite component is the one which is softened to create a lock in the hole of the metal component. Only thermoplastic matrix composites are suitable to be joined by those processes, because the thermoset matrix, once cured, cannot be plasticized again and would crack under high strains required in clinching. Gude et al. developed a method called thermoclinching in order to join steel sheets with glass fabric reinforced polypropylene [

53]. The composite was pre-cut in the joining zone and locally heated to increase its plastic deformation ability, shifted through the pre-punched metal sheet by a tapered pin and compressed from the backside by a die to generate a form-locked joint (

Figure 12a–c). After cooling and solidification, the mould was opened to reveal the geometrical joint (

Figure 12d) [

53].

The joints were tested in single lap shear experiments and failed by either pull out (3kN) or shear (2 kN) of the composite formed lock, depending on its geometrical features [

53]. Abibe et al. proposed a joining method called injection clinching joining (ICJ) [

56,

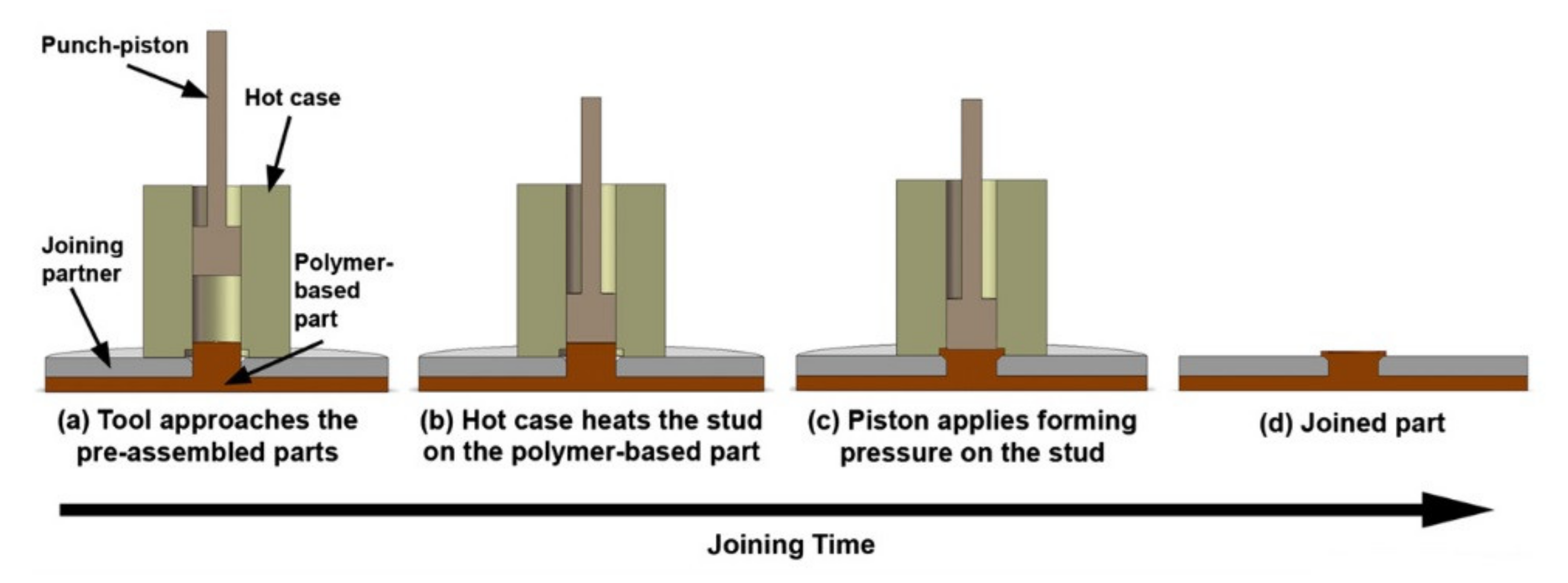

57]. This method starts when a composite part with a protruding stud is pre-assembled with a joining partner that contains a hole, so that the stud fits in the hole. The hot case and punch-piston tool system approaches the pre-assembled parts, with the hot case containing the polymeric stud (

Figure 13a) [

56]. The stud is heated at a certain processing temperature for a predetermined joining time (

Figure 13b), after which the punch-piston pushes the softened polymer into the hole (

Figure 13c) [

56]. Then, the system is cooled under pressure to reduce the polymer thermal relaxation and the joint is consolidated (

Figure 13d). By the end of the process, a joint with no additional parts other than the joining partners and with the polymeric stud working as a rivet to the joint is obtained [

56].

Joints of short glass fibre-reinforced polyamide 6,6 and aluminium alloy were produced using the injection clinching joining process [

56,

57]. The holes in the metal substrate were threaded in order to provide more efficient anchoring of the composite [

57]. The micrographic pictures of the joints revealed that the thermal processing in 250 °C can induce void formation, while processing at 300 °C caused voids on the deformed stud and a large loss of polymer mass [

57]. Single lap shear tests of the joints were performed. The impact of the joining time, processing temperature and drying treatment on the maximum load of a reference sample was investigated [

56]. The reference sample achieved an average maximum load of 942 ± 77 N. Reducing the joining time (from 180 s to 15 s) raised the average value to 1112 ± 102 N, while reducing the processing temperature (from 300 °C to 250 °C) improved the performance to 1807 ± 114 N [

56]. Drying of the composite material yielded a positive effect allowing to achieve 1114 ± 79 N for conditioning 24 h at 60 °C and 1208 ± 77 N for conditioning 24 h at 120 °C [

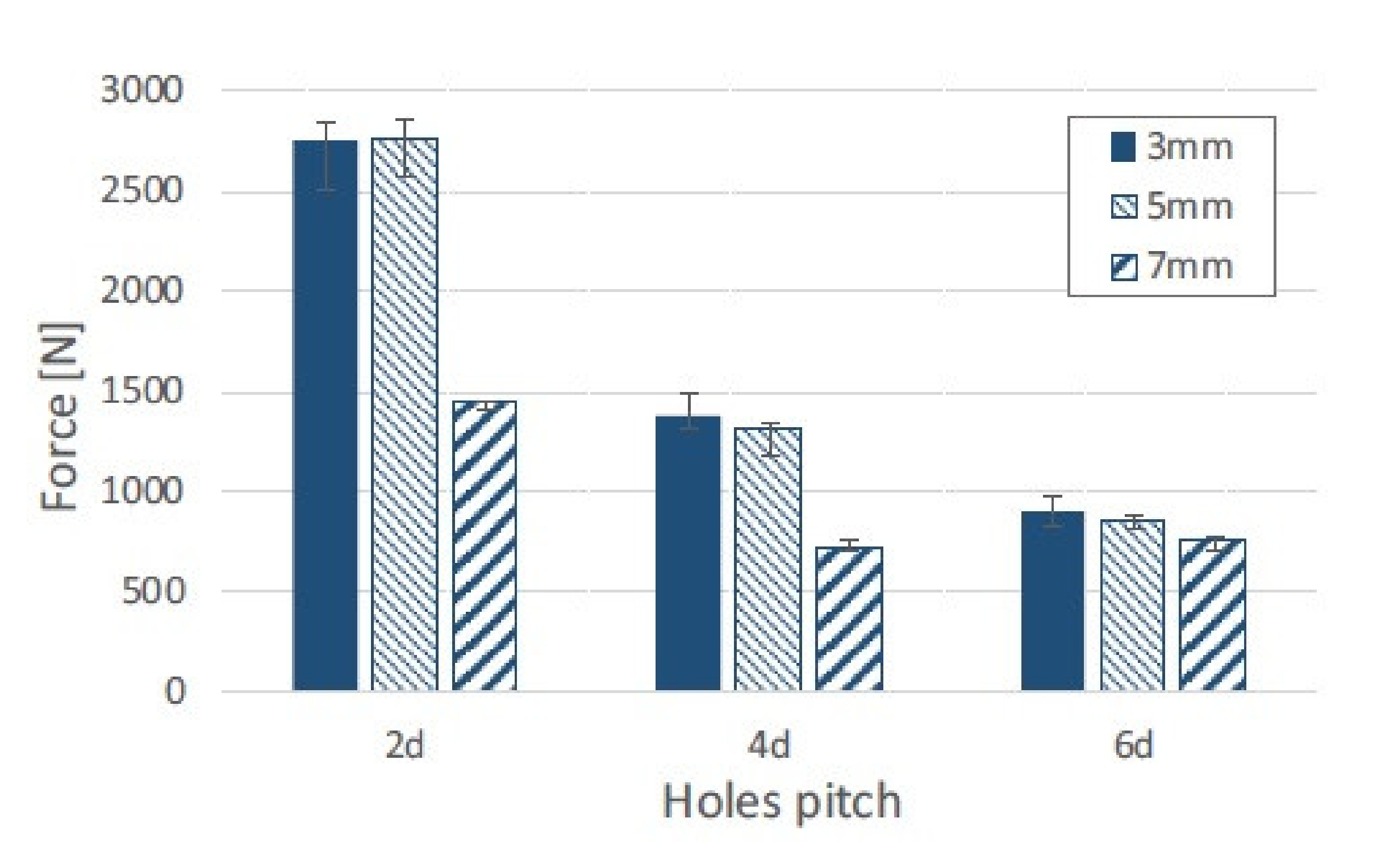

56]. The processing temperature appears to have the most prominent effect on the joint performance. Buffa et al. proposed a new friction stir welding approach to join mechanically AA6082-T6 to self-reinforced polypropylene [

58]. The aluminum sheet was pre-holed along both sides and placed on the top of the composite sheet. A pinless tool was plunged into the aluminium sheet and moved along the longitudinal direction with constant feed rate. The heat generated by the friction force softened the top sheet and was transferred by thermal conduction to the bottom sheet [

58]. Due to the friction heat and the pressure composite extrusions filled the holes in the aluminium sheet. Once cooled down, the extruded polypropylene created a mechanical bond between the aluminium and the composite [

58]. The specimens with different hole diameters and different hole pitch were subjected to shear test. The results of the tests are presented in

Figure 14. The failed specimens with different failure modes are presented in

Figure 15.

It was found that the vertical force on the tool, as well as the tool diameter, rotation, and feed rate, must be carefully selected in order to generate correct heat which does not melt the composite but, at the same time softens it enabling the backward extrusion [

58].

General characteristics of clinching are presented in

Table 4. Applicable standards are:

DVS-EFB 3420:2012-02

DVS-EFB 3450-1:2007-05

4. Non-Adhesive Form-Locked Joint

When large elements are assembled often occurs a need for introducing a concentrated force into a composite structure. In such cases a single massive joint which could withstand the force has to be designed. The simplest example of such a joint is a bolted joint. However, phenomena such as delaminations, fibre pull-outs, and microbuckling [

7], which occur during drilling the hole for the joint in composite, deteriorate its performance [

4]. Moreover, a big hole required for the joint would cause considerable disruption of the load paths by removing significant part of the reinforcing fibres. Those disadvantages prompt engineers to look for better solutions for introducing a concentrated force into a composite structure. An example of such an idea which was developed and successfully used in engineering cases is non-adhesive form-locked joint designed in Warsaw University of Technology [

59]. The joints of this type were used in the PW family of commercial and experimental gliders and motogliders (PW-5, PW-6, and AOS-71) in a fuselage–wing connection (

Figure 16).

The non-adhesive form-locked joint is manufactured along with the composite structure. The hole is cut in dry fabric which is then infused by resin or in uncured prepreg. Metal rings are then fitted to the hole so that the edge of the hole is curled up and locked between them. The structure is then cured in a vacuum bag or in an autoclave. After the curing a screw with a hole in it and a nut are fitted into the hole of the joint in order to clench it (

Figure 16). A bolt is put through the hole in the screw to assembly the structure. This solution ensures that the fibres of the composite are attached to the joint in all directions and clenched in it, which means that, unlike in a traditional bolted joint, where the force is introduced only in the area of contact between the bolt and the composite [

61], the force is distributed in the composite in all directions. The additional advantage of the non-adhesive form-locked joint is the fact that the hole is cut in the fabric before curing, so the delaminations and other damages caused by the hole drilling in the composite can be avoided. Moreover, the joint can be easily assembled and disassembled at will. On the other hand, the disadvantages of the joint include its significant complication level and the mass increased by the presence of additional metal elements such as the holed screw and the nut. The risk of galvanic corrosion is also significant if the elements of the joint placed in carbon fibre reinforced composite are made of steel or aluminium alloys [

22,

23].

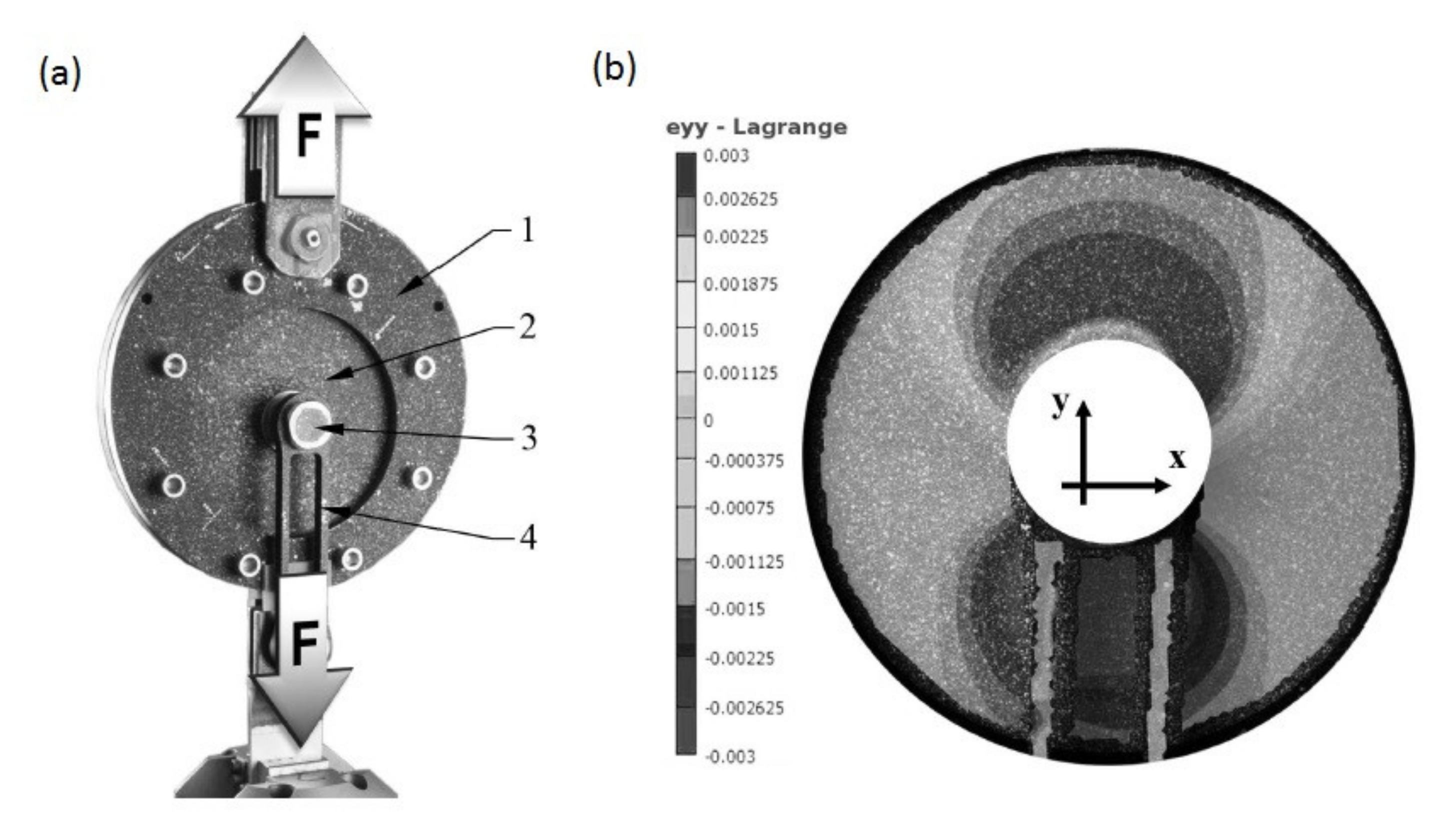

An experimental investigation of the strength of the non-adhesive form-locked joint was carried out by Tomasiewicz and Czarnocki [

60]. The joints made of stainless steel were manufactured in carbon fabric/epoxy specimens consisting of 16 plies cured OOA. After the curing the nut of the joint was tightened with a torque of 75 Nm [

60]. The tensile static tests of two specimens were carried out. A specimen in the testing setup is presented in

Figure 17a. The maximum strength obtained by both specimens was 60–70 kN. The strain field over the laminate plate was determined with the use of the 3D digital image correlation (DIC) method [

60]. The strains in the load direction are presented in

Figure 17b. It can be clearly seen that the concentrated force causes strains in the composite below and above the joint, though the strains below the joint are higher. The significant strains above the joint mean, however, that the stress concentration below the joint is decreased in regard of the equivalent conventional bolted joint.

After the static tests, an inspection of the damage done to the laminate plates was carried out with the help of computed tomography (CT). Several failure modes were distinguished: fiber rupture, matrix cracking, matrix-cracking induced delaminations, and compressive shear [

60].

General characteristics of non-adhesive form-locked joining are presented in

Table 5.

5. Pin Joining

Another method of creating joints between the fibre-reinforced plastic composites and metal parts involves producing metal part with an array of pins protruding vertically from it. Once the array of pins has been prepared, it is necessary to integrate it with the composite material [

62]. During the joint manufacturing the composite plies are placed on the top of the metal, so that their fibres are arranged around the pins and the pins penetrate the fabric layers throughout the thickness with little fibre damage leading to mechanical interlocking of the laminate with the metal structure [

62,

63,

64] (

Figure 18). This allows to achieve a joint without drilling holes in cured composite and without destroying the fibres [

64]. Then the composite is cured. The cure methods suitable for curing pin joints include VARTM [

62,

63,

64] and prepreg technology [

62,

65,

66].

A number of techniques have been used to produce pins on the surface of metallic components for the purpose of hybrid joining [

62]. Those techniques can be broadly categorised as surface restructuring or additive manufacturing (AM) [

62]. A surface restructuring method by an electron beam called Comeld was developed by The Welding Institute [

67]. The main drawbacks of the surface restructuring approach are limited control of pin geometry, excessive damage to the surface caused by the restructuring process and large costs associated with using an electron beam to drive the material across the surface [

62]. Despite those drawbacks this method was used to produce pin joints of titanium and carbon-epoxy composite [

67,

68].

The main advantage of the pin joints is that the joining process does not require manufacturing holes in cured laminate, so problems like delaminations and stress concentrations are mitigated. The metal pins cause very slight disruption of the reinforcing fibres, which may contribute to the good performance of the joint. On the other hand, the disadvantages of the pin joints are following:

The process of manufacturing the pin arrays on the metal substrate is complicated and, therefore, cost and time consuming.

Once the joint is manufactured, it is impossible to disassembly it without destroying it.

Galvanic corrosion may occur in this joining method if a substrate made of aluminium alloys or steel are used along with CFRP composite [

22,

23].

Although the pin joining technique does not cause such strong destruction of the composite fibres as, for instance, hole drilling, it causes certain local disruption of the composite structure such as localised fibre waviness, broken fibres and a resin-rich zones [

69].

Figure 19 shows a picture obtained by computer tomography (CT) of UD composite structure around the pins [

66].

Composite–metal pin joints typically exhibit very low interface strength due to poor pin-composite bonding, which significantly affects joint performance [

69]. The mismatch in thermal expansion coefficient (CTE) between the pins and composite leads to significant debonding at the pin-composite interface during curing in elevated temperature [

70,

71]. The ultrasonic inspection may be used to evaluate the general quality and detect failure of the pin joints [

72].

Parks et al. investigated the strength of single lap shear pin joints of titanium alloys and CFRP composite. The adherends were joined by 6 × 6 array of cylindrical pins protruding from the metal adherent in the area of 25.4 × 25.4 mm overlap [

72]. The limit load was 21% higher and the ultimate load was 650% higher than the ultimate load of a comparable co-cured unpinned joint [

72]. Graham et al. investigated pin joints of glass/epoxy fabric composite and stainless-steel substrate with square 8 × 8 pin arrays and compared them to control co-cured specimens without pins [

62]. Single and double lap joints were subjected to fatigue loading. A 25-gsm glass fibre veil was included at the metallic interface of the prepreg joints in order to graduate the coefficient of thermal expansion (CTE) between the metallic and carbon fibre reinforced polymer adherends [

62]. In both pin and control specimens the fatigue damage initiated at the ends of the overlap [

62]. Damage within the control specimens progressed at an increasing rate following crack initiation. Damage in the hybrid pin joints initiated at a lower number of cycles, but the rate of damage growth reduced considerably as the crack front reached each row of reinforcing pins [

62]. This is likely to be the result of enhanced load transfer through the pins as the bondline is damaged and the more highly stressed ‘joint edge’ effectively moves closer to the pins. This conclusion is supported by the observation that after a period of arrested crack growth, the respective row of pins experiences fatigue failure and the crack front begins to advance as the adhesive is reloaded [

62]. Graham et al. also tested the strength and impact resistance of pin-joined 3-mm thick stainless steel and 2.5-mm thick glass fabric–epoxy composite [

62,

63]. Pin spacing was designed to locate at gaps in the weave architecture of the fabric to minimise fibre disruption. The experimental investigation was conducted using single lap joint specimens. These tests showed increases in strength and impact energy absorption (compared with control specimens—co-cured without pins), in the range of 70–100% and 300–800%, respectively [

62,

63]. The impact energy required to generate visible damage was slightly higher for hybrid joints while the extent of disbonding at higher impact energies was reduced significantly [

62,

63]. Two specimens subjected to similar impact loading, one control and one pin joint, are shown in

Figure 20. It is apparent that, in the case of the pin joined specimen, the crack front has been arrested in a smooth curve bound by a number of pins [

62,

63].

It was also discovered that the pins not only decrease the area damaged by the impact, but also prevent the loss of the residual strength and the propagation of the damaged area. The improvement in mechanical performance results from the load distribution across the joint. As long as the reinforcing pins bridge the two substrates, they are capable of transmitting load and, therefore, reduce the stress intensity at the crack front [

62,

63]. The joint ultimately fails when the pins fracture at the base or are pulled out from the composite [

62,

63].

Uscnik et al. conducted tests of pin joints made of stainless steel and carbon reinforced thermoplastic composite with two kinds of pins manufactured on the surface of the steel substrates: cylinder and ball-headed (

Figure 21) [

64].

Double lap shear specimens were tested in tension. The specimens with cylinder and ball-headed pins exhibited different modes of failure. The cylindrical pins were pulled of the composite material, whereas the ball-headed pins were fractured as the bolt failed. It resulted in higher tensile strength of the joints with the ball-headed pins (150 N) than in the case of the cylindrical pin joints (110 N) [

64]. The performance of titanium and carbon/epoxy prepreg tape composite pin joints with different pin geometries was also investigated by Nguyen et al. [

65]. Four different shapes of pins (

Figure 22) were tested on single pin specimens in pull-out test mode. The highest strength, higher by approximately 20% than for cylindrical pins was achieved for pyramid and helical pins. Lower force increase (by 14%) was obtained for the grooved pins. The mode of failure for cylindrical and grooved pins was pull-out, whereas for pyramid and helical pins, composite failure occurred. This indicates that the use of geometry features increases the pin joint strength, so that the composite strength becomes the limiting factor for joint behaviour in the case of those pin types [

65].

In the same work multi-pinned double cantilever beam (DCB) specimens were tested [

65]. The cylindrical pins were manufactured with inclination angles 0° or 20° from the vertical direction (inclined along or against the crack growth direction). The results have shown that the influence of the pin inclination angle on the increase of the maximum load and fracture toughness in DCB specimens is negligible or may even deteriorate the performance of the specimens in the case of the pins inclined along the crack direction [

65]. Experimental work made by other researchers [

73,

74] revealed significant changes of failure mode and energy absorption for end notched flexure (ENF) specimens under mode II loading when the inclination angle of pins was changed. In those specimens, changing the pin alignment meant that the axial component of the pin load was a compressive load for the case where the pin angle is against the shear load direction [

73,

74]. Tu et al. investigated the influence of the pin inclination in a lap shear metal-composite pin joint by the means of FEM optimisation [

75]. It was concluded that some inclination angles may reduce the stress concentrations and thus improve the joint strength. The optimum angle for the pins is 20° to 30° towards the metal end of the joint [

75]. Nguyen et al. also conducted another research in which the performance of titanium and carbon/epoxy prepreg tape composite pin joints were investigated taking into account the different sizes of cylindrical pins [

69]. Multi-pinned double cantilever beam (DCB) specimens were tested with pins with different aspect ratios of 3.3 (D = 0.5, L = 2) and 6.5 (D = 0.5, L = 4). The DCB specimen with longer pins showed higher opening load and lower fracture toughness. Two aspects of pin joints of carbon fibre reinforced composite and titanium substrates were investigated by Parkes et al. [

66]: the diameter of the pin root and the surface treatment of the titanium substrate. The two types of pins were manufactured: with conical head and with different root diameters, and one was 17% larger than the other. Some specimens were left with raw surface and the others were nano-structured with laser treatment. The specimens were subjected to single lap shear tensile tests. The increase of the pin root resulted in approximately 30% increase of the ultimate strength, whereas, the laser treatment had virtually no effect on the strength. These results are not surprising taking into account that the specimens failed by the fracture of the pins, so the pin root diameter had to have an influence on the ultimate strength. It can be also concluded that in the pin joints the surface treatment is unnecessary if the geometry of the pins is designed so that the joint fails by the fracture of the pins. Wang et al. tested a novel shape of the pins protruding from the metal substrate in the pin joints (

Figure 23) [

67,

68]. The pins had wedged-profiled shape (

Figure 23a). The joints between a titanium alloy and a carbon fibre reinforced polymer (CFRP) were made. The specimens were tested in double-lap shear tests. It was shown that the failure process consists of two main stages: the first stage involves the separation of the interfaces (debonding), the second stage consisted in the failure of the composite involving delamination, fibre fracture and some inter-ply matrix cracking [

67]. In the second work, the results were compared to the results of joints with cylindrical pins (

Figure 23b) [

68].

The cylindrical-pinned joints failed by the pulling out of the pins from the CFRP component [

68]. This resulted in lower failure strength of the specimens (30 kN) compared to the strength of the wedge-pinned joints (73 kN) [

68]. However, the lower strength of the cylindrical-pinned joints may be also influenced by the lower density of the pins (

Figure 23). Xiong et al. investigated the effect of composite orientation on the mechanical properties of the pin joints [

76]. Carbon fabric reinforced epoxy composite was joined with titanium alloy component with protruding wedge-like protrusions similar as in the previous works [

67,

68]. The thickness of the composite adherend was kept constant and the volume content of ±45° ply was increased from 11.1% to 88.9% (the rest of the plies had orientation 0°). The specimens were tested in single lap shear experiments. With the increase of the ±45° plies content the failure mechanism changed from the composite matrix crushing to the combination of the bending, the fracture of pins and composite compression [

76]. With optimum composite orientation (55.6% of 45° plies), the joints damage initiation load was increased by 24.84% and the joint ultimate failure load was increased by 134.5% compared to the reference specimens without protrusions [

76].

General characteristics of pin joining are presented in

Table 6.

6. Loop Joining

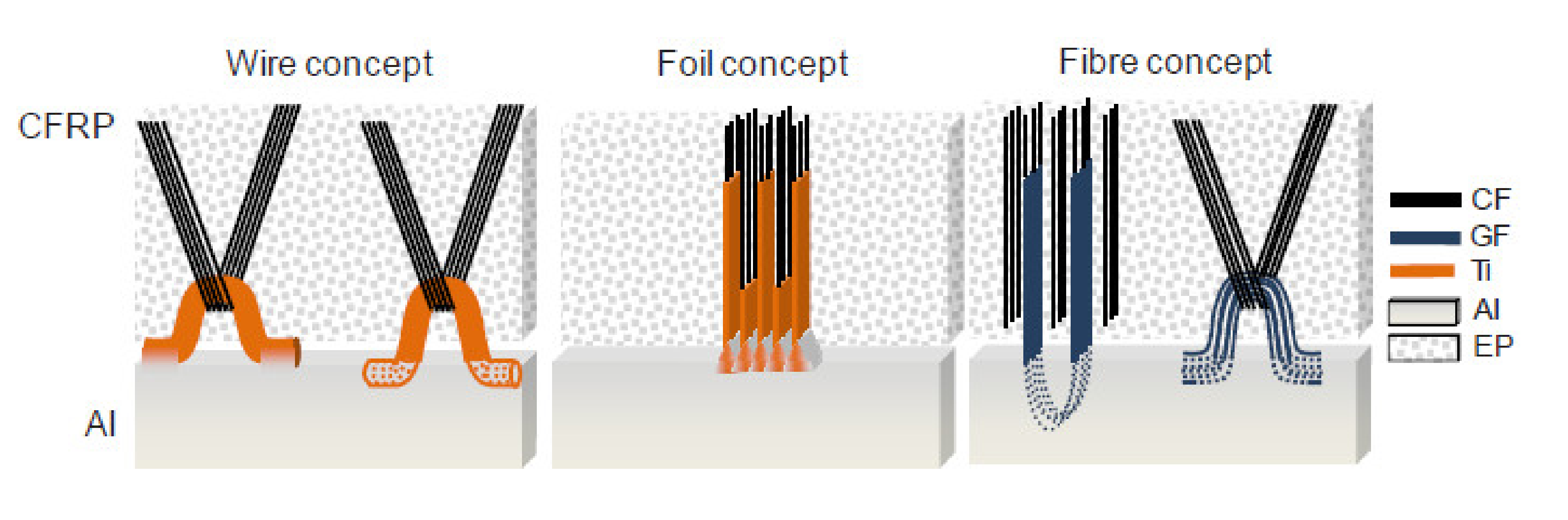

Research group “Schwarz–Silber” funded by German Research Foundation proposed a set of novel ideas for joining carbon fibre reinforced composites with aluminium alloys: wire, foil and fibre concepts [

22,

77,

78] (

Figure 24). Since the majority of the presented techniques include attaching loops to the aluminium alloy substrate, this group of techniques is referred to as ‘loop joining’ in the scope of the present work.

All the joining concepts are focused on separating carbon fibres from aluminium alloy in order to avoid galvanic corrosion, which appears inevitably when those two materials are in contact [

22,

23] and may lead to increased corrosive degradation on the aluminium [

79] followed by a catastrophic failure of carbon/aluminium joints. The corrosion is caused by an electrochemical potential difference between carbon fibres and aluminium alloys [

22] and may be avoided by connecting carbon fibres to the aluminium alloy substrate by transitional elements made of titanium, which reduce the electrochemical potential difference by about two-thirds in comparison to the combination of carbon fibre and aluminium and may be even decreased further by surface treatment of titanium [

22], or even non-conductive materials such as glass and boron fibres [

77]. The wire concept consists in connecting rows of titanium wire loops to the aluminium substrate by welding or casting [

77]. The bundles of carbon fibres are then threaded through those loops. In the foil concept the loops are replaced by titanium foils, which are also connected to the aluminium substrate. The carbon fibres are inserted between the foils and the joint is held together by friction force [

80]. In the fibre concept the titanium is replaced by glass or boron fibres [

77]. All the joints are then embedded in polymeric resin. The presented concepts have some advantages:

The transition elements insulating carbon fibres from aluminium alloy decrease or eliminate the possibility of galvanic corrosion [

22,

77].

The continuity of carbon fibres is not disrupted in any way [

77].

On the other hand, their disadvantages are following:

Joining the transition elements (titanium, glass, or boron fibre) to aluminium substrate is tedious, time consuming and the joint often constitutes the weakest point of the structure [

22,

78,

80,

81].

Glass and boron fibres have often lower strength than carbon fibres. This means that the ultimate strength of carbon reinforced composite structure is reduced to the strength of those fibres if they are used as the insulating elements.

The additional elements in the joints increase the mass of the joint.

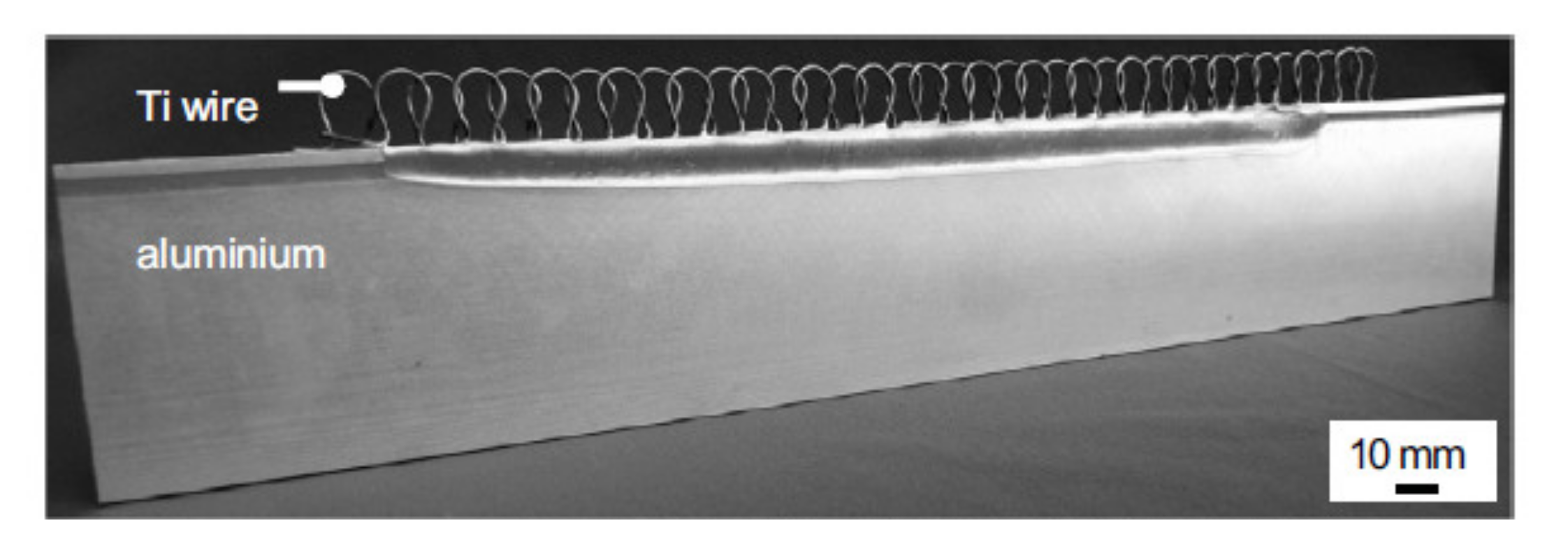

Schumacher et al. investigated the joining of aluminium substrate and carbon fibres by titanium loops [

78]. The loops were joined with the aluminium sheets by laser beam welding, during which the aluminium melts and wets the titanium wire, which stays in solid state [

78]. The specimens with three or five loops were manufactured and a roving bundle was put through each loop and preloaded by a tension force. Subsequently, the rovings as well as the titanium transition structure were impregnated under vacuum by resin [

78]. The specimens were subjected to tensile tests. The failure strengths were 3000 N/25 mm and 8000 N/43 mm respectively. However, all the specimens failed by the fracture of the titanium wire, which makes the results unsuitable for thorough evaluation of the joint strength. Moller et al. also used titanium loops joined to aluminium alloy structure by heat conduction laser beam welding process in order to join it with carbon fibre reinforced composite [

81]. Only the aluminium structure was molten in order to create a bond between the aluminium and the titanium wire [

81]. The titanium wire with a diameter of 0.8 mm was cold-formed to obtain a 2-dimensional loop structure with a principal radius of 2.5 mm. During processing, the laser beam was travelling along the aluminium edge, thus creating a molten aluminium pool. The aluminium wetted the titanium wire structure without melting it [

81]. The resulting aluminium structure with titanium loops is presented in

Figure 25 [

81].

Carbon fibres were threaded through the loops and the structure was impregnated with polymeric resin in order to create CFRP composite. Tensile tests of such specimens were performed. The fracture started with delaminations of the matrix at the interfacial zone to the aluminium structure. The complete failure of the specimens occurred by subsequent failure of the titanium wires close to the aluminium weld. Only in some cases, the fracture path was through the aluminium substrate [

81]. Taking into account that the metal joint failed before the composite, it is very difficult to assess the reliability of such an approach to composite-metal joining. Without increasing strength of the metal-metal joint, the full strength of the composite-material joint cannot be utilised. In the work by Schimanski et al. joints made of titanium wire loops connected with aluminium structure with carbon fibre bundles threaded through them and impregnated by polymeric resin were also investigated [

22]. The investigation was focused on the manufacturing of a titanium–aluminium connection. The process used to join those two components was a combination of diffusion bonding and hot pressing [

22]. The aluminium wire was formed into omega-shaped loops and placed in a 4 mm notch in the aluminium substrate. The whole sample was placed in a vacuum furnace between two plain plungers. To reinforce the contact between the titanium loops and the aluminium sheet, steel foils were placed at the lower and upper side of the aluminium sheet on the notch [

22]. Two process temperatures were used: 480 °C and 540 °C. The mechanical properties of the joints with carbon roving threaded through the loops and embedded in polymeric resin were determined by tensile test. The specimens joined in 480 °C withstood approx. 300 N and the specimens joined in 540 °C, approx. 500 N [

22]. The specimens joined in 480 °C failed by disconnection of the titanium wire from the aluminium substrate after cracking of the matrix (

Figure 26a). The specimens joined in 540 °C failed by fracture of the wire in the vicinity of the substrate (

Figure 26b).

Clausen et al. used glass fibre loops to join carbon fibres to an aluminium alloy substrate [

82]. In the investigated approach glass fibre loops were integrated with an aluminium alloy part, carbon fibre bundles were threaded through the loops, and the joint was impregnated by epoxy resin (

Figure 27) [

82].

In the scope of the work, however, no tensile tests were performed in order to measure the strength of the joint. An assumption that the glass fibre loop joint is by 50% lighter than a bolted joint in aluminium/carbon fibre reinforced structure was made [

82], however, no reasoning behind it was presented. Lang et al. investigated loops made of different fibres (boron, S-glass, and E-glass) which could be used for joining carbon fibre reinforced and aluminium structures [

77]. Firstly, ‘dry’ specimens of selected fibres looped with different carbon fibres are tested for tensile failure strength. The pair of fibres for which the highest strength was achieved, S-glass fibre and HTS 24k carbon fibre, was selected for further tensile tests, in which the specimens were embedded in epoxy matrix. Before embedding the fibres in the resin, the carbon fibre loops were pre-tensioned with different forces (4, 20, 50, 80 and 100 N) [

77]. The tensile strength increases steadily with the increasing pretension load from less than 2200 N for 4 N of pretension to over 2800 N for 100 N of pretension (

Figure 28) [

77].

The first fibre failures were predominantly located in carbon fibres [

77]. This indicates the importance of using for the loop materials with a strength similar to or higher than the strength of joined carbon fibres. Otherwise, the loop fails first, deteriorating the performance of the carbon fibre reinforced structure.

Woizeschke and Schumacher investigated the joining of aluminium alloy and carbon fibres with the use of titanium foil concept [

80]. A laser beam was used to melt aluminium alloy which wetted the titanium foil surface. The foils 0.6 mm thick are made of pure titanium. The joint manufacturing process is presented in

Figure 29. Firstly, the titanium foils are stacked alternately with CFRP prepreg plies (

Figure 29a). The pure titanium side of the joint is then sealed by the laser welding in order to insulate the carbon fibres (

Figure 29b). The welded titanium is then placed in a 2 mm deep groove made in the aluminium alloy substrate and the assembly is again welded by a laser beam (

Figure 29c). Finally, the joint is compressed and subjected to elevated temperature in order to cure CFRP prepreg (

Figure 29d) [

80].

The manufactured specimens were subjected to tensile tests. Three different failure modes occurred [

80]. Three of five specimens fractured within the Al–Ti fusion zone, with the failure located at the front side of the titanium. One specimen failed at the Ti–CFRP interface by delamination and one at both Al–Ti and Ti–CFRP interfaces. However, failing of the Al–Ti interface at the front side of the titanium laminate has been detected in all specimens [

80]. Hence, a modification of the Al–Ti joining zone would be necessary to make the entire specimen suitable for higher loads [

80].

General characteristics of loop joining are presented in

Table 7.

7. Additive Manufacturing

As mentioned in

Section 5, additive manufacturing (AM) can be used to manufacture pins array for pin joints. AM techniques vary considerably, but the principle is the same, to ‘build up’ features by sequentially adding layers of material to a substrate [

62]. AM techniques based on metal-powder processing allow reasonable control of pin geometry and do not generally cause excessive damage to the existing surface [

62]. Two common types of metal powder processing are applicable in pins manufacturing: selective laser melting (SLM) and laser metal deposition (LMD) [

62]. SLM utilises a metal powder bed, over which a laser spot is focused to selectively melt layers of the material [

62]. The SLM technique was utilised by Nguyen et al. to print an array of pins from Ti-64 [

65]. LMD works by blowing metal powder into the focal point of a high-power laser [

62]. The LMD technique was used to form arrays of protruding pins on stainless steel substrates by Graham et al. [

62]. For research purposes these techniques are in many aspects ideal, but they remain a costly option for industry [

62]. Cold metal transfer (CMT) is a relatively modern AM technique that allows droplets of molten metal wire to be deposited onto a metal substrate in progressive layers. Uscnik et al. developed a CMT method which consisted in arc-welding of one end of a wire to the metal substrate and then tearing the wire by applying resistive heating and tensile force [

64]. Thus, pieces of welded wire formed an array of pins, with expected shapes and dimensions, integrally attached to the metal [

64]. It is generally possible to perform each of those surface restructuring or additive manufacturing processes on a range of metals including steel, aluminium, and titanium alloys [

62].

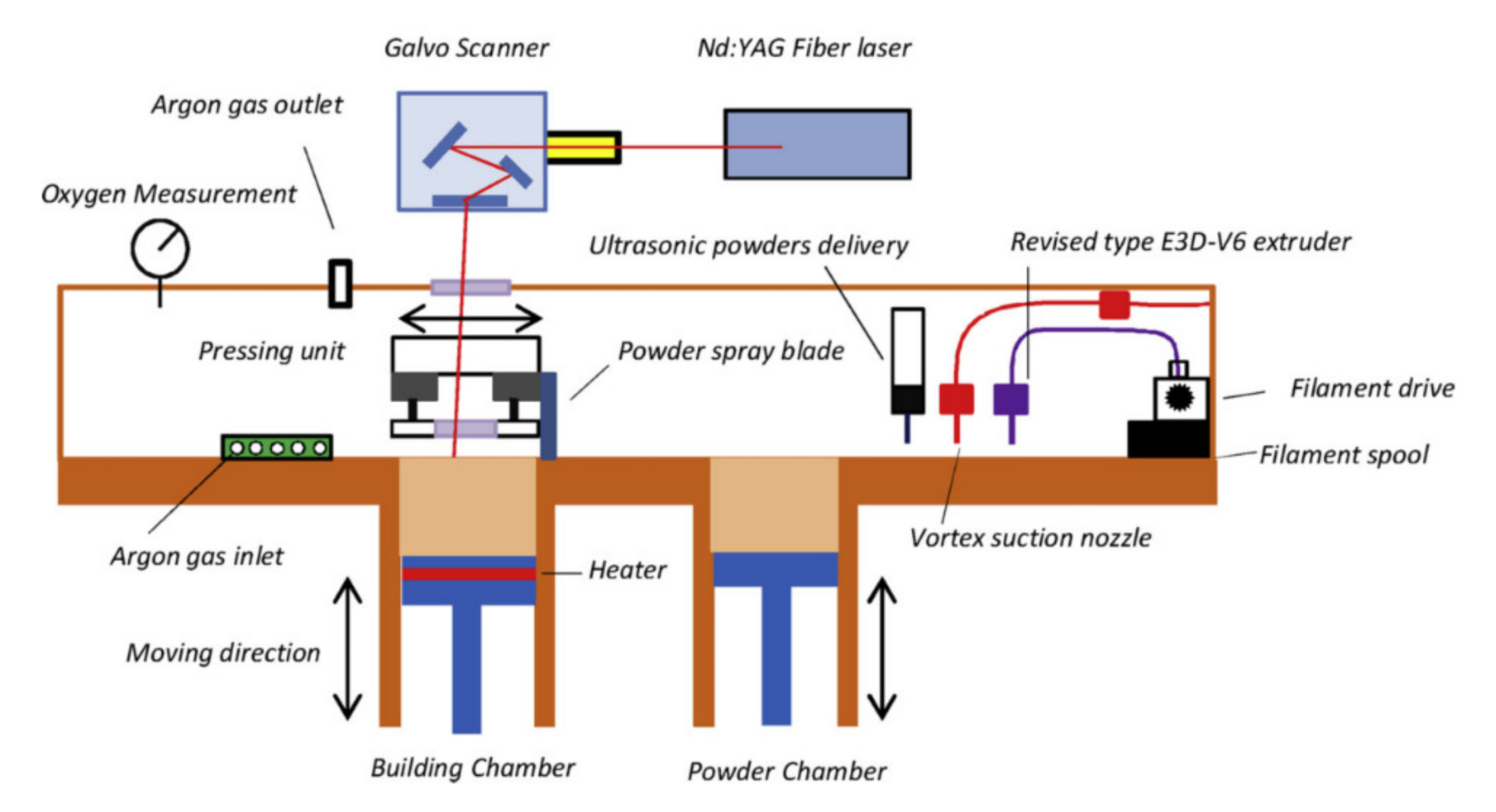

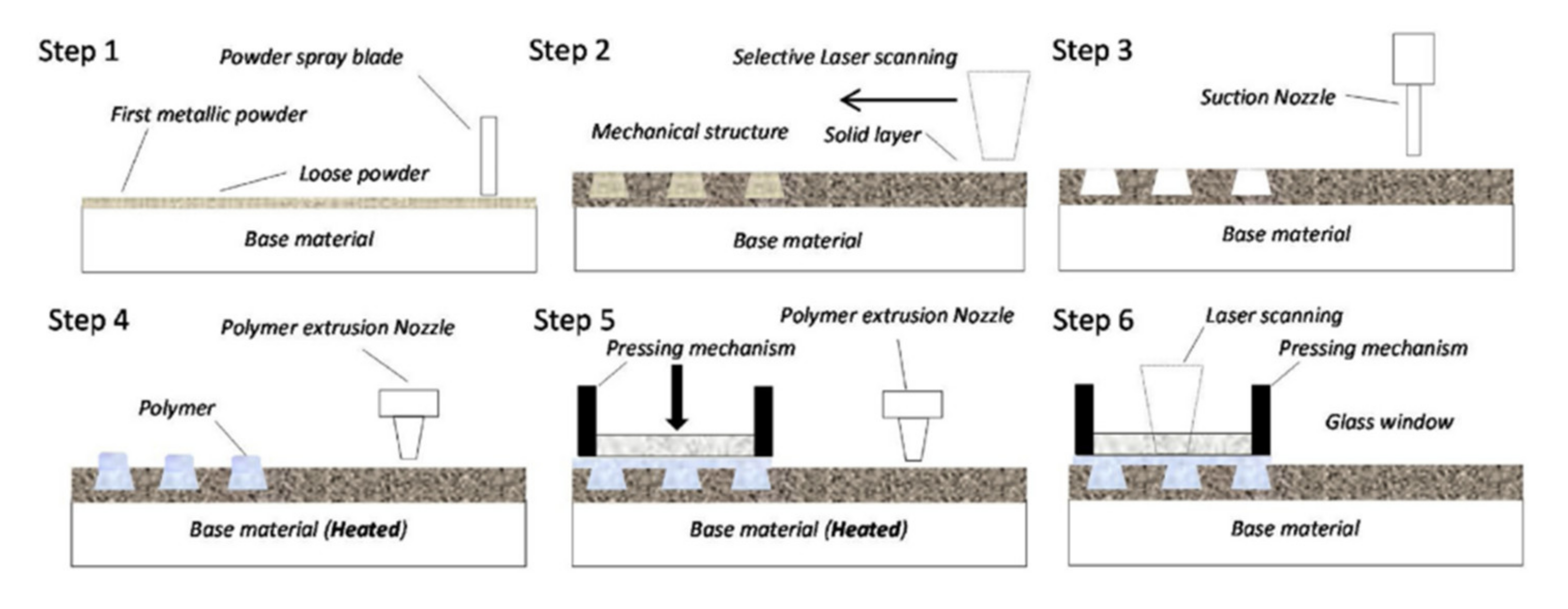

Additive manufacturing of both metallic and polymer composite is possible if short fibres are used to reinforce the polymer. Yuan-Hui Chueh et al. developed a method of integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects [

83]. Laser-based powder bed fusion is used to manufacture array of metallic interlocking structures with predefined shapes on the metallic base. Then, polymer or reinforced polymer is extruded and pressed between these structures thus creating mechanical joint. In the course of polymer extrusion metallic base is heated facilitating penetration of the array with polymer. Pressing is performed with glass window with laser assist to improve the contact between interlocking structures and polymer. The printing system developed to manufacture joined metallic and polymer parts is presented in

Figure 30 and

Figure 31, which show the sequence of manufacturing. So far, pure metal polymer joints were manufactured and tested, but authors claim that composite made of polymer reinforced by short fibres can be also joined with metallic parts this way. Manufactured samples were investigated to reveal their strength. Two types of experiments were performed: shear tests and tensile tests. Samples were made of stainless steel, polyethene terephthalate (PET). Arrays of interlocking structures for shear tests had dimensions of 21 × 20mm whereas arrays for tensile tests had dimensions of 10 × 21 mm. Three shapes of interlocking structures were tested: “root contact”, “tree-shaped contact” and “interlocking contact” (

Figure 32). In all cases, the shear strength of the joint appeared smaller than tensile strength. It did not exceed 18 MPa, whereas tensile strength exceeded 20 MPa for “root contact” and 22 MPa for two other shapes if interlocking structures. Moreover, tensile tests usually ended with fracture inside the polymer component whereas shear tests ended with fracture of polymer at the top if interlocking structure.

General characteristics of interlock joining with the application of integrated laser-based powder bed fusion and fused filament fabrication are presented in

Table 8An attempt to deposit melted metal (copper) at the top of polymer component was also presented in [

83], but resulting joint strength appeared week. Laser energy small enough not to damage the polymer appeared not large enough to sinter the cooper powder well enough. Metal components can be manufactured after polymer ones if electroforming is applied instead [

84]. It is possible because electroforming does not require high temperatures to deposit metals. Matsuzaki et al. investigated manufacturability of hybrid metal-polymer parts with application of fused filament fabrication and electroforming. They deposited one layer of polylactic acid (PLA) filament on top of the aluminium plate and then deposited copper in “moulds” created this way. This procedure was repeated several times allowing to build metal-polymer structure as high as 3.8 mm. To prevent coper deposition on other surfaces of an aluminium plate, it was covered by masking tape. In the areas where PLA and cooper were deposited, the aluminium plate was covered with conducting adhesive to prevent PLA from separating during plating process. Two types of pins were investigated “ordinary shaped” where metal pins were converging with height and “overhung shaped” where metal pins dimensions were growing with height. First type appeared more difficult to make because coper was deposited faster at edges of the metallic part then in its centre because higher concentration of the current around the edges. As a result, the thickness of the cooper at the edges was greater than the thickness of the PLA after each iteration leading to the collisions with printer head depositing PLA in the following step. This was not the case in the “overhung shaped” pins because printer head was not supposed to deposit PLA on the top of copper. It was enough to assume the ratio of the of metallic pin diameter increase to the PLA layer thickness to be smaller than ¾ to prevent copper layer against growing over the PLA layer. It was expanding radially instead. This phenomenon seems advantageous because it could allow for the production of effective interlocking structures if this method was applied to manufacture a metal–polymer connection. Unfortunately, authors investigated manufacturability only without any strength measurements, and therefore the strength of such a structure remains unknown. It seems reasonable to assume that PLA could be mixed with short fibres in this method, however it also seems like fibres would not reinforce the connection since they would not protrude from one layer to the following one inside the interlocking structure. Therefore, it seems like the strength of the connection would be similar for both pure PLA and PLA reinforced with short fibres. Moreover, it is not clear how strong the connection between the aluminium plate and the copper component of the interlocking structure is. However, other combinations of metals can be also applied.

General characteristics of pin joining with application of fused filament fabrication and electroforming are presented in

Table 9.

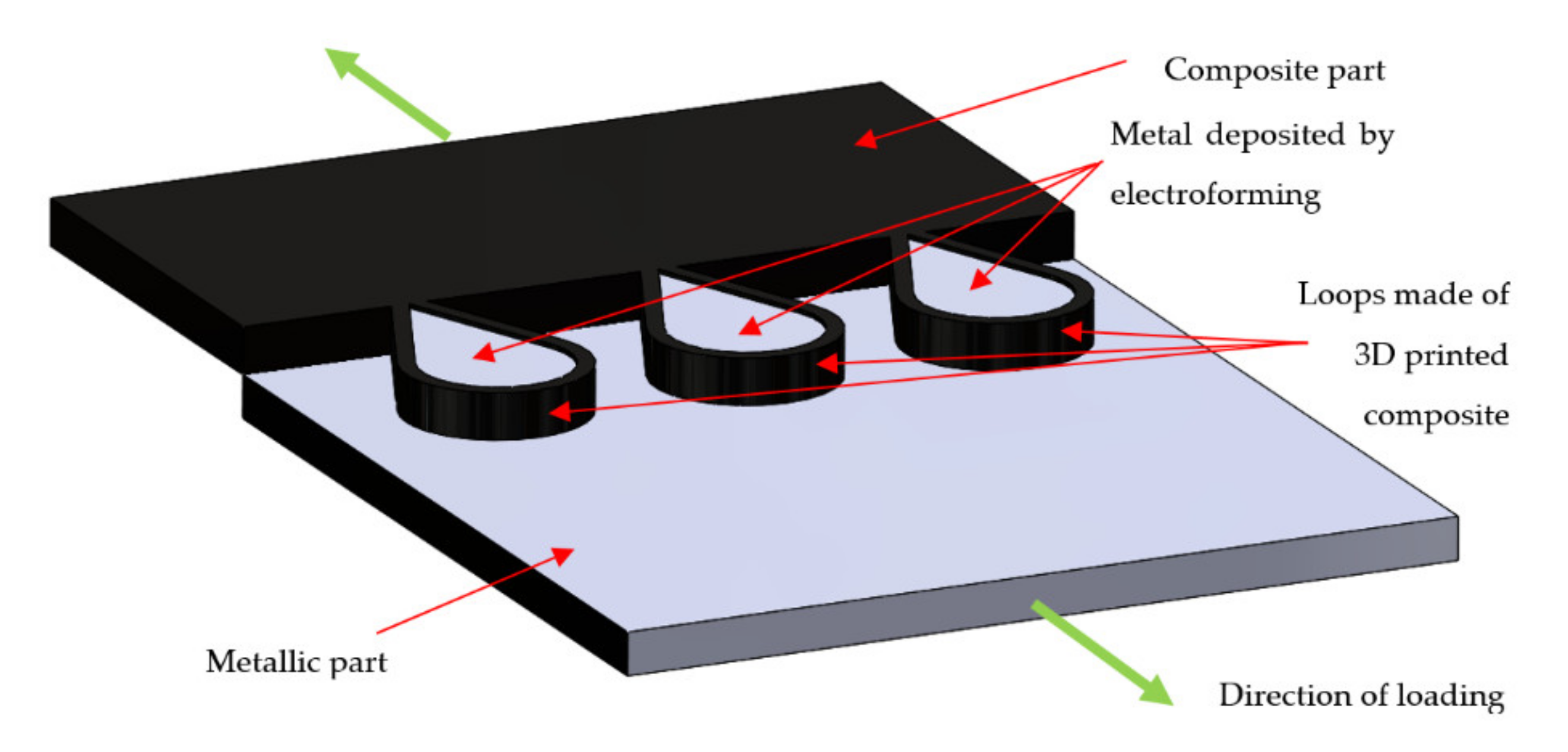

It seems reasonable to combine electroforming [

84] with loop joining [

77,

80] and 3D printing of continuous carbon fiber [

85] or 3D printing of continuous-fiber composites by in-nozzle impregnation [

86]. In both these methods polylactic acid reinforced by continuous carbon fibers was used to manufacture various parts including sandwich panels. To connect such a composite part with metallic part, the continuous carbon fiber composite part could be printed in the neighborhood of the metallic part with carbon loops extending from the composite part and touching the metallic part. Then the electroforming could be used to fill the composite loop with metal (

Figure 33). The thickness of the loops can be increased by the following layers of the carbon fiber impregnated with polymer printed on the top of previous layers of the loop followed by the following electroforming sequences. At the end, the loops can be completely covered by the metal in the electroforming process. This idea would allow to create quite strong connection between composite part with metallic part with application of additive manufacturing only. Unfortunately, no publications on the application of such a method have been found. General characteristics of loop joining with application of 3D printing of continuous-fiber composites and electroforming are presented in

Table 10.