Progressive Failure and Energy Absorption of Chopped Bamboo Fiber Reinforced Polybenzoxazine Composite under Impact Loadings

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Pretreatment of Bamboo Fibers

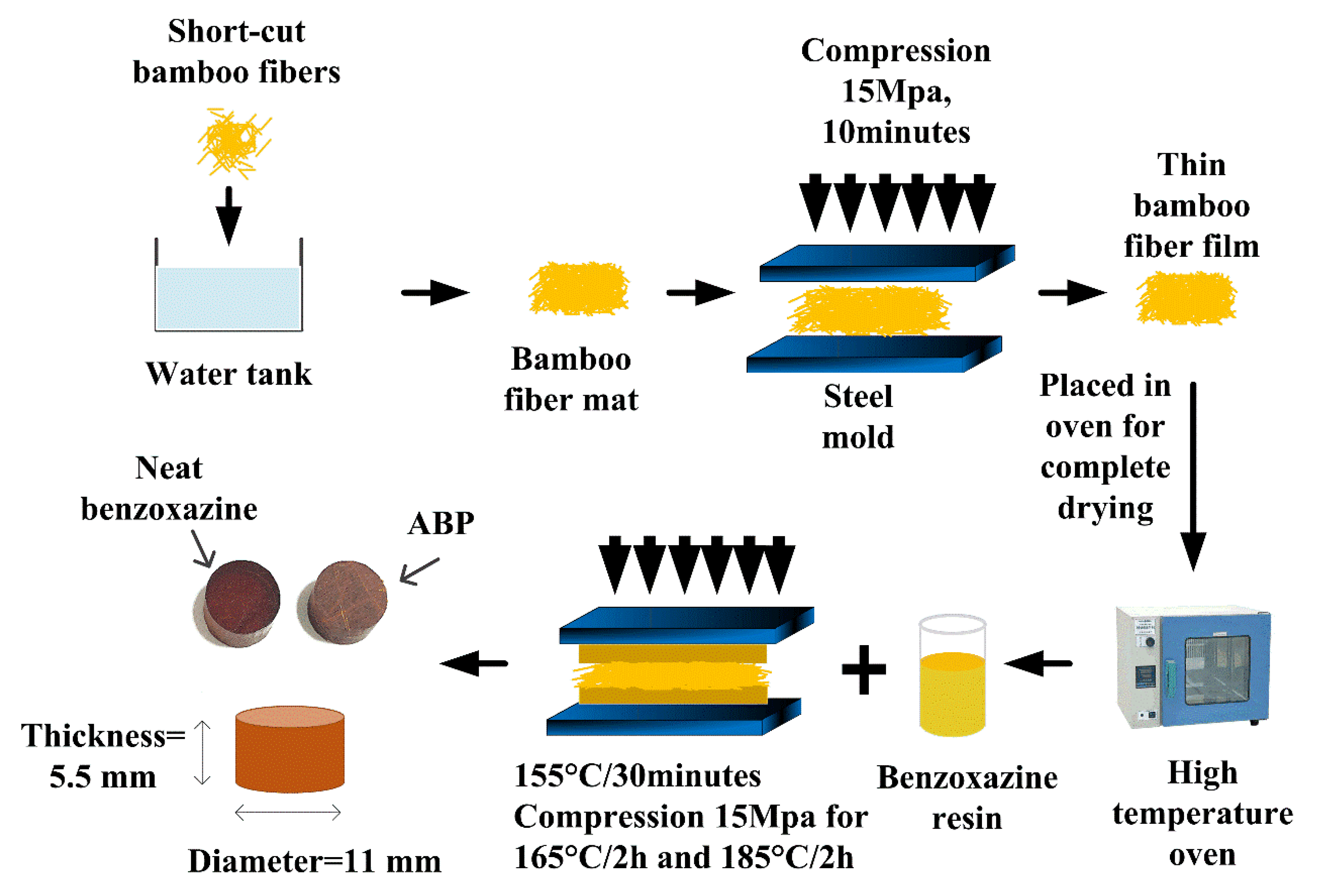

2.3. Composite Preparation

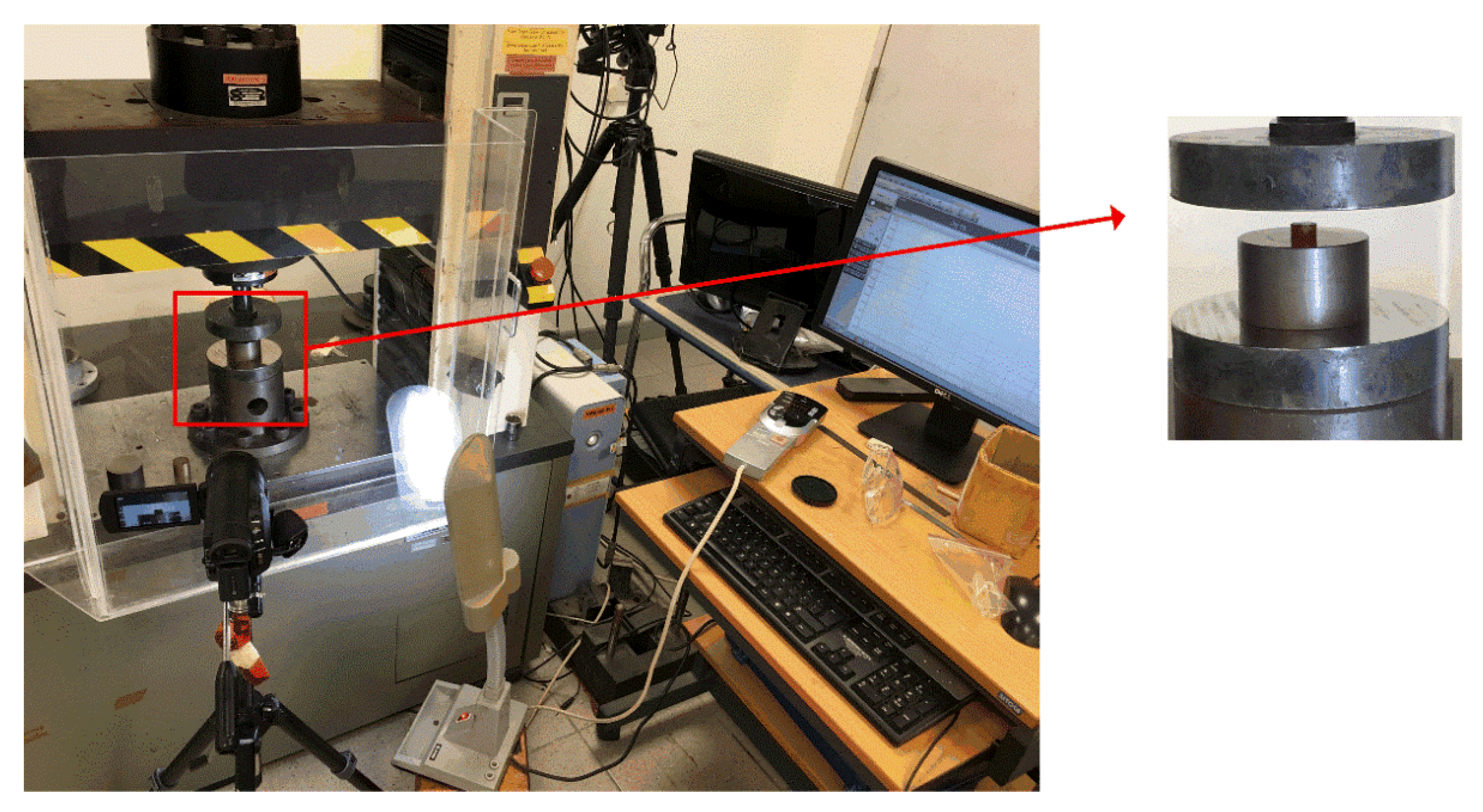

2.4. Quasistatic Compression Test

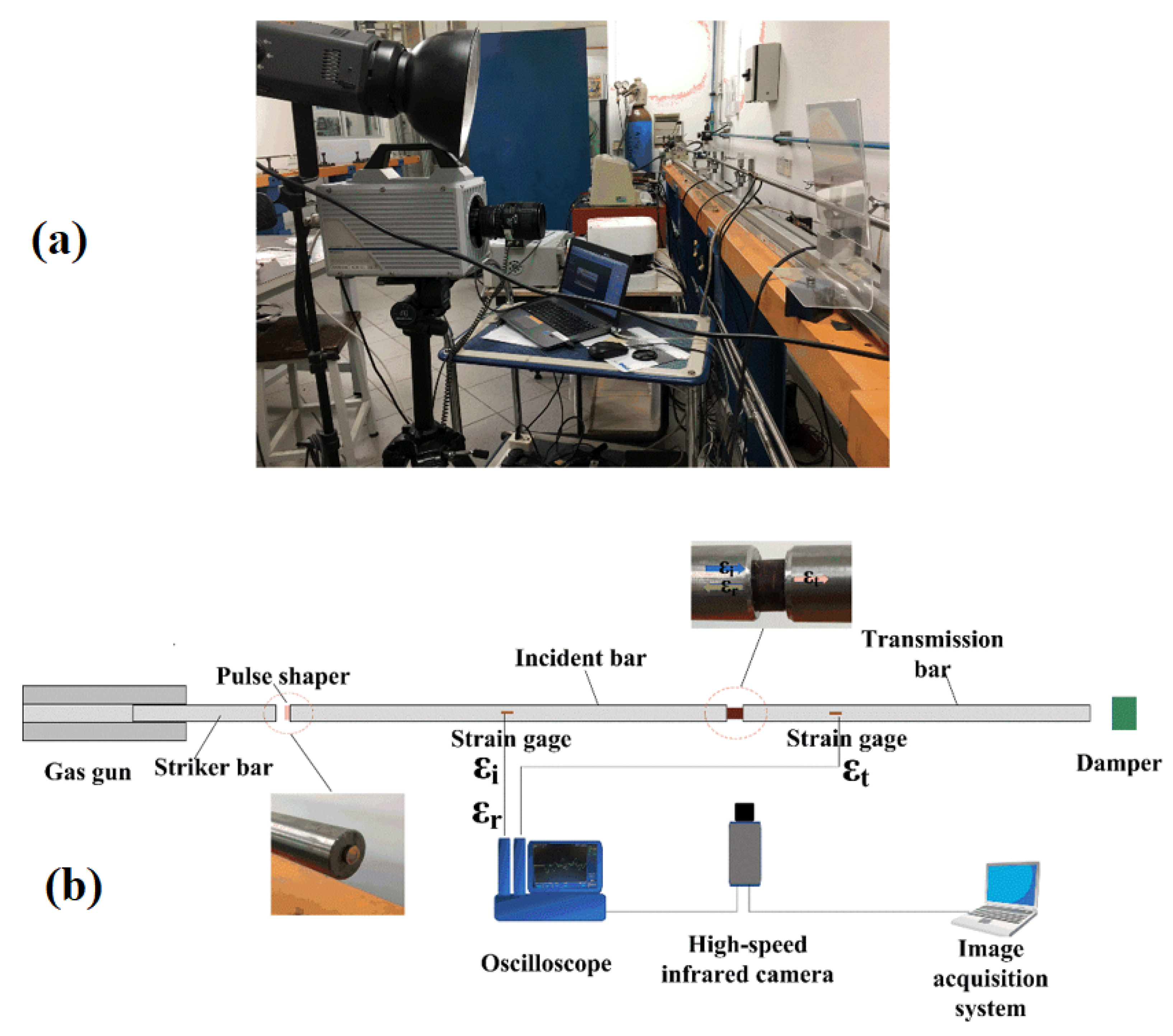

2.5. Impact Tests

3. Results and Discussion

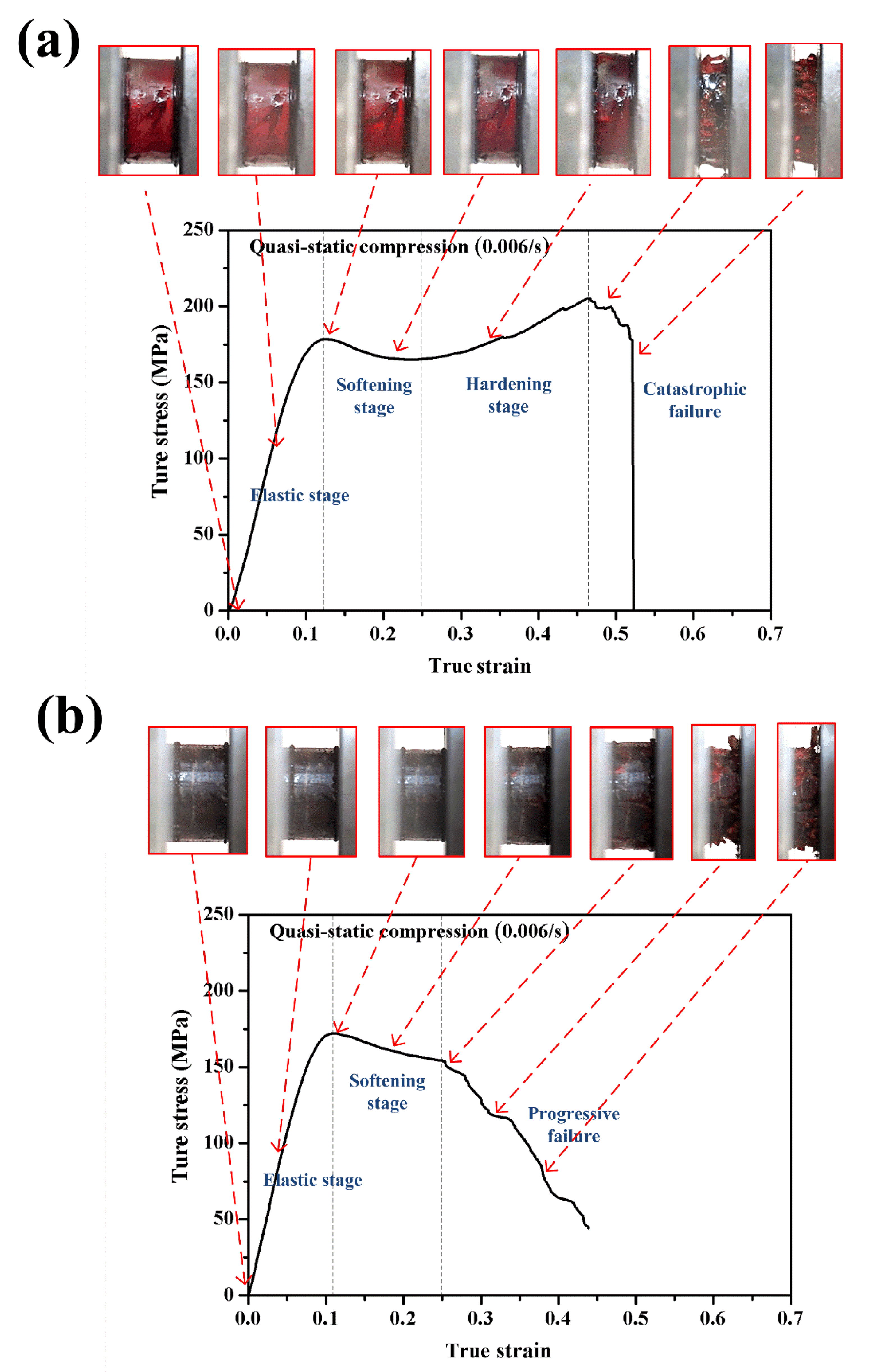

3.1. Quasistatic Compressive Behaviors of the Neat Benzoxazine and ABP

3.2. Dynamic Compressive Tests

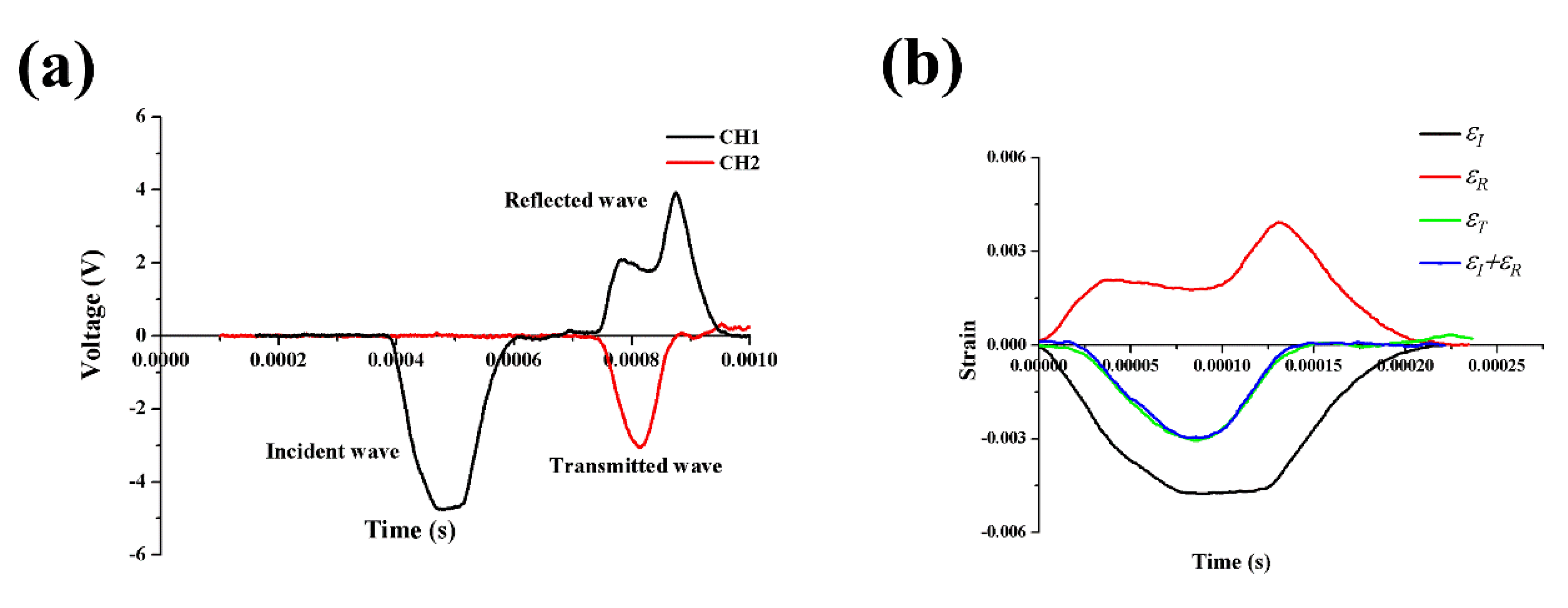

3.2.1. Validation

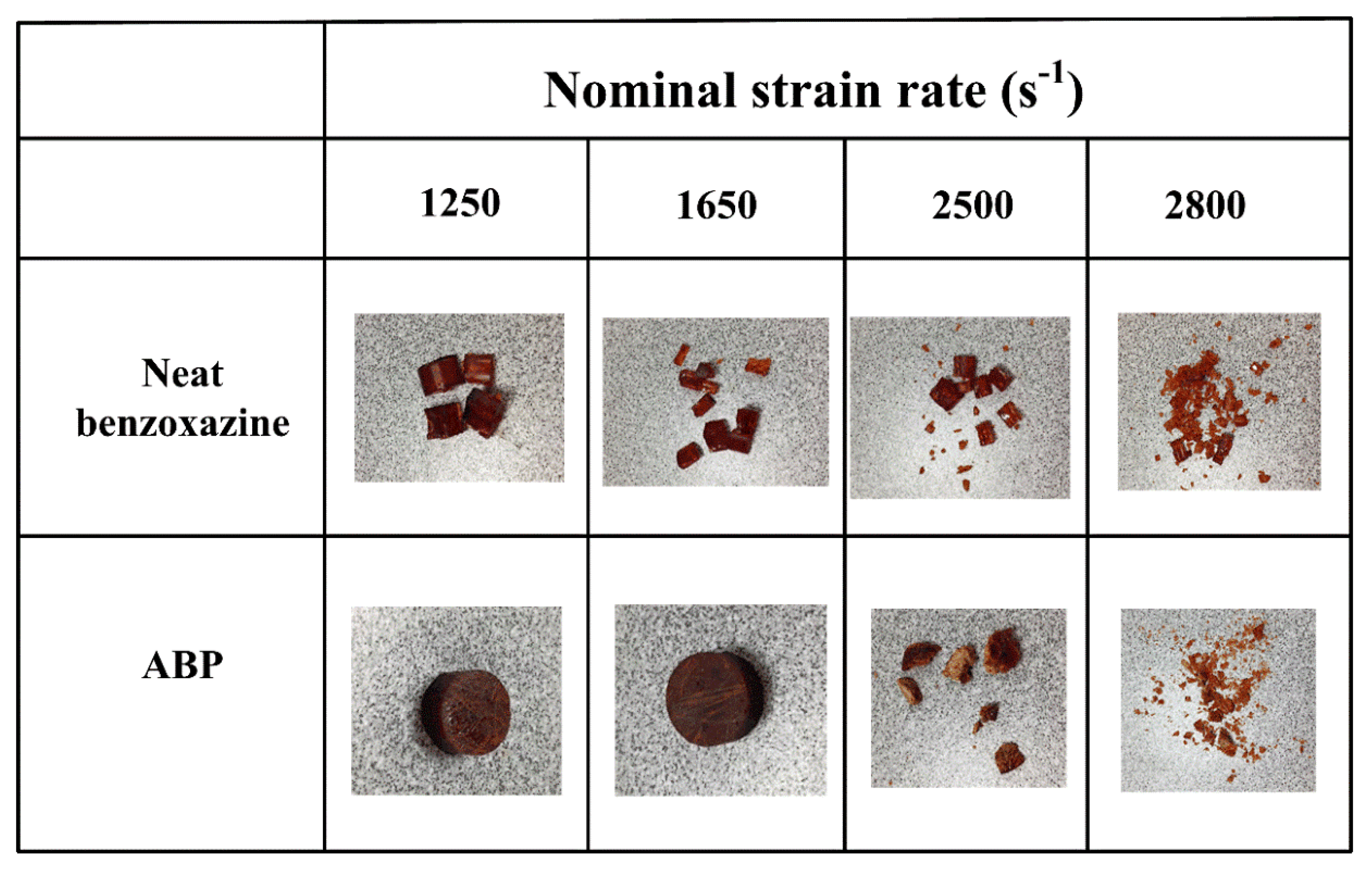

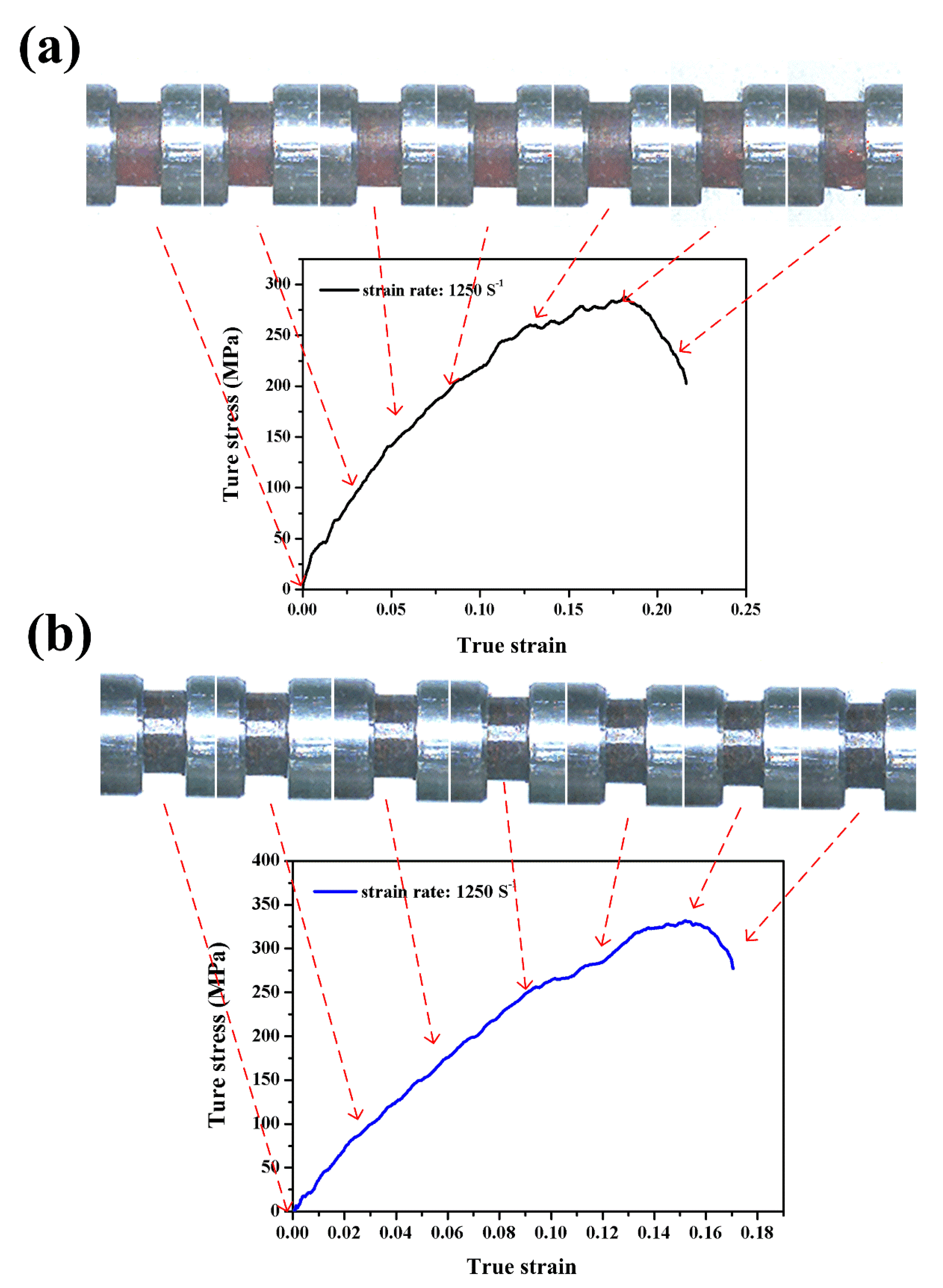

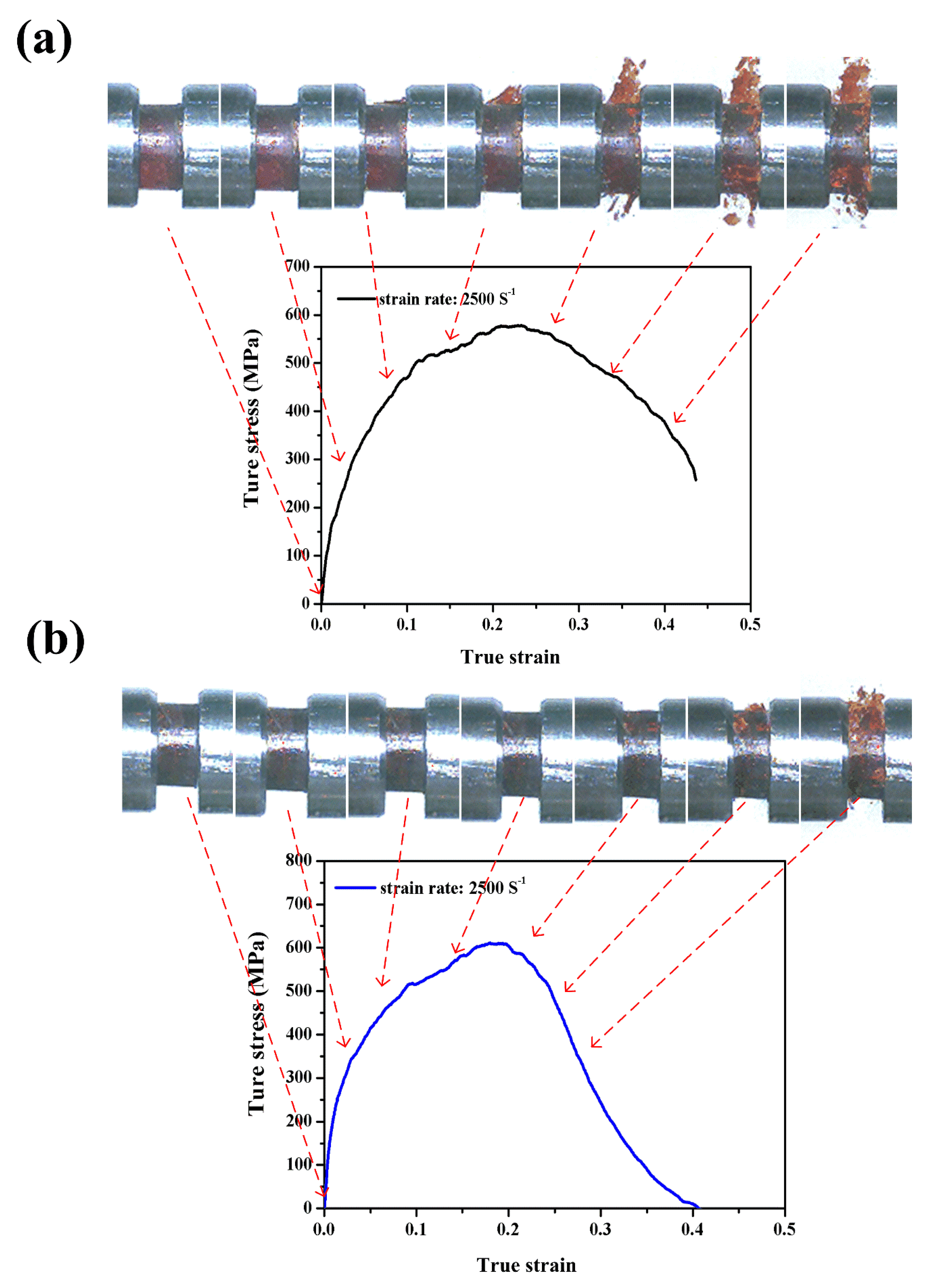

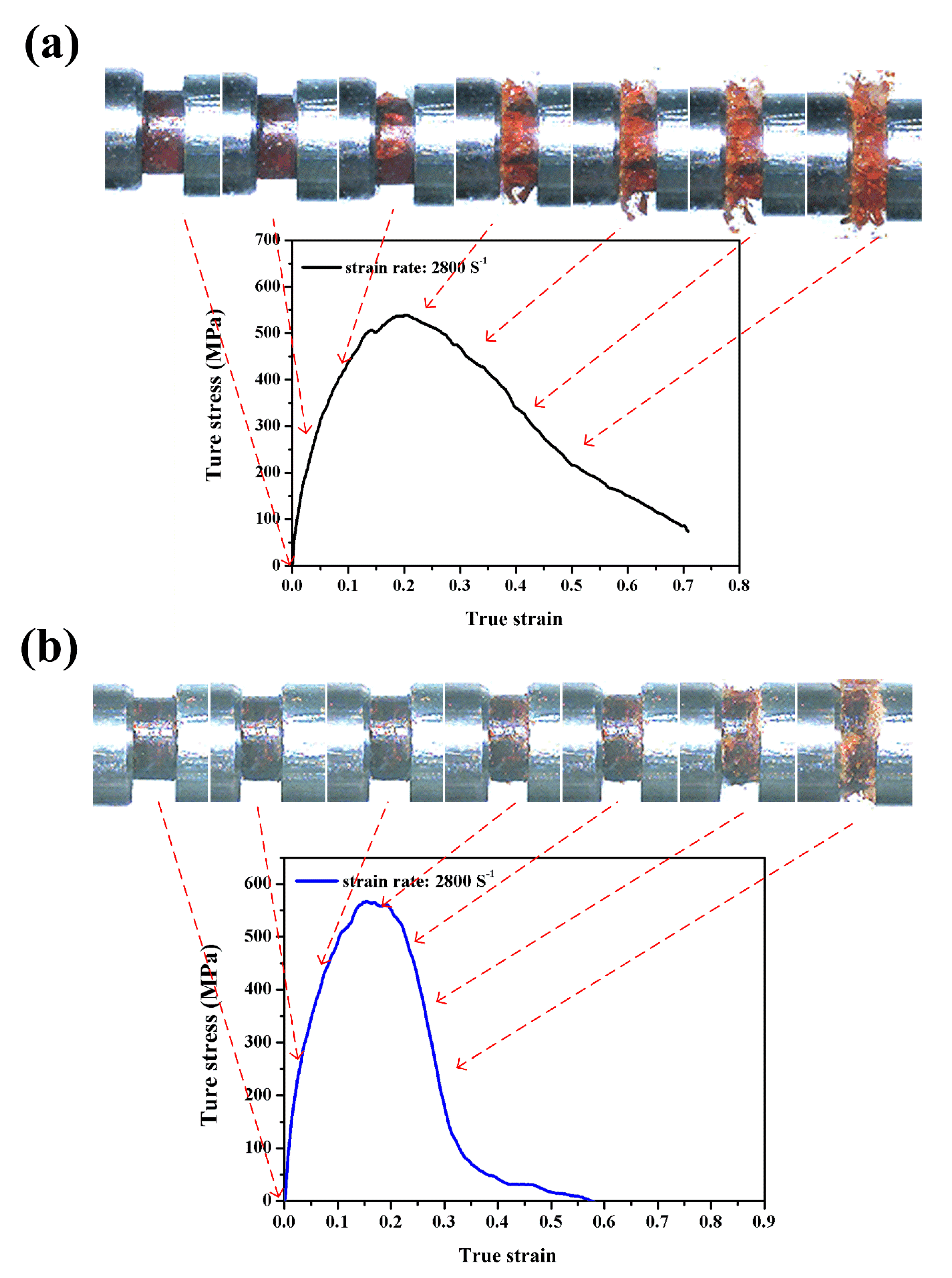

3.2.2. Compressive Behaviors of the Neat Benzoxazine and ABP

3.3. Strain Rate Effect

3.4. Energy Absorption

4. Conclusions

- The hardening stage of the composite under quasistatic compression disappeared due to the incorporation of chopped bamboo fibers. There were no softening and hardening stages of the neat benzoxazine under dynamic loadings, and both the matrix and the composite became more brittle with the increase of the strain rates.

- The bamboo fibers exhibited positive effects on the impact toughness of the composite under dynamic loading conditions. However, the stiffness and strength of the composite were still controlled by the benzoxazine matrix. This was because the direction of the fiber distribution and the high tensile strength of the bamboo fibers could not be utilized effectively.

- The maximum compressive stresses of the benzoxazine resin were 204 MPa, 287 MPa, 504 MPa, and 578 MPa at nominal strain rates of 0.006/s, 1250/s, 1650/s, and 2500/s, respectively. The high strength of the benzoxazine resin demonstates huge potential in fields of impact engineering.

- The chopped bamboo fibers could prevent the rapid propagation of microcracks in the matrix to some extent, which greatly enhanced the energy absoption the composite under high-speed impact loadings.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Lau, K.T.; Hung, P.Y.; Zhu, M.H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Mahir, F.I.; Keya, K.N.; Sarker, B.; Nahiun, K.M.; Khan, R.A. A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater. Eng. Res. 2019, 1, 86–97. [Google Scholar] [CrossRef]

- Shahzad, A.; Choudhry, R.S. Design and Manufacturing of Natural Fiber/Synthetic Fiber Reinforced Polymer Hybrid Composites. Handb. Compos. Renew. Mater. 2017, 2, 411–447. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Muhammad, A.; Rahman, M.R.; Hamdan, S.; Sanaullah, K. Recent developments in bamboo fiber-based composites: A review. Polym. Bull. 2019, 76, 2655–2682. [Google Scholar] [CrossRef]

- Depuydt, D.E.; Soete, J.; Asfaw, Y.D.; Wevers, M.; Ivens, J.; Van Vuure, A.W. Sorption behaviour of bamboo fibre reinforced composites, why do they retain their properties? Compos. Part A 2019, 119, 48–60. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Water barrier properties of nanoclay filled sisal fibre reinforced epoxy composites. Compos. Part A 2011, 42, 385–393. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, F.; Pang, Y.; Liang, W.; Wang, Z. High residual mechanical properties at elevated temperatures of bamboo/glass reinforced-polybenzoxazine hybrid composite. Polym. Eng. Sci. 2019, 59, 1818–1829. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Yogesha, B. Studies on natural/glass fiber reinforced polymer hybrid composites: An evolution. Mater. Today Proc. 2017, 4, 2739–2747. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.Q.N.; Teo, W.S.; Tay, T.E.; Lee, H.P. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers–A review of potential eco-friendly applications to the construction industry. Sustainable Mater. Technol. 2020, 3, e00132. [Google Scholar] [CrossRef]

- Takagi, H.; Ichihara, Y. Effect of fiber length on mechanical properties of “green” composites using a starch-based resin and short bamboo fibers. JSME Int. J. Ser. A 2004, 47, 551–555. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K.T. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre–polyester composites. Compos. Part B Eng. 2015, 80, 73–83. [Google Scholar] [CrossRef]

- Mylsamy, K.; Rajendran, I. Influence of alkali treatment and fibre length on mechanical properties of short Agave fibre reinforced epoxy composites. Mater. Des. 2011, 32, 4629–4640. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Gao, B.C.; Wang, J.; Liu, W.B.; Derradji, M.; Shah, A.H.; Babar, A.A. Natural hemp fiber reinforced polybenzoxazine composites: Curing behavior, mechanical and thermal properties. Compos. Sci. Technol. 2017, 144, 114–124. [Google Scholar] [CrossRef]

- Zuccarello, B.; Marannano, G. Random short sisal fiber biocomposites: Optimal manufacturing process and reliable theoretical models. Mater. Des. 2018, 149, 87–100. [Google Scholar] [CrossRef]

- Khan, Z.; Yousif, B.F.; Islam, M. Fracture behaviour of bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2017, 116, 186–199. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of mean stress and stress concentration on fatigue behavior of short fiber reinforced polymer composites. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 149–166. [Google Scholar] [CrossRef]

- Jiang, N.; Yu, T.; Li, Y. Effect of hydrothermal aging on injection molded short jute fiber reinforced poly (lactic acid)(PLA) composites. J. Polym. Environ. 2018, 26, 3176–3186. [Google Scholar] [CrossRef]

- Kim, W.; Argento, A.; Lee, E.; Flanigan, C.; Houston, D.; Harris, A.; Mielewski, D.F. High strain-rate behavior of natural fiber-reinforced polymer composites. J. Compos. Mater. 2012, 46, 1051–1065. [Google Scholar] [CrossRef]

- Fahmi, I.; Majid, M.A.; Afendi, M.; Helmi, E.A.; Haameem, J.A.M. Low-velocity impact responses of Napier fibre/polyester composites. Int. J. Automot. Mech. Eng. 2016, 13, 3226. [Google Scholar] [CrossRef]

- Ridzuan, M.J.M.; Majid, M.A.; Khasri, A.; Basaruddin, K.S.; Gibson, A.G. Effect of moisture exposure and elevated temperatures on impact response of Pennisetum purpureum/glass-reinforced epoxy (PGRE) hybrid composites. Compos. Part B Eng. 2019, 160, 84–93. [Google Scholar] [CrossRef]

- Lyu, Y.; Ishida, H. Natural-sourced benzoxazine resins, homopolymers, blends and composites: A review of their synthesis, manufacturing and applications. Prog. Polym. Sci. 2019, 99, 101168. [Google Scholar] [CrossRef]

- Kasemsiri, P.; Hiziroglu, S.; Rimdusit, S. Properties of wood polymer composites from eastern redcedar particles reinforced with benzoxazine resin/cashew nut shell liquid copolymer. Compos. Part A 2011, 42, 1454–1462. [Google Scholar] [CrossRef]

- Hu, W.; Huang, J.; Zhang, X.; Zhao, S.; Pei, L.; Zhang, C.; Wang, Z. A mechanically robust and reversibly wettable benzoxazine/epoxy/mesoporous TiO2 coating for oil/water separation. Appl. Surf. Sci. 2020, 507, 145168. [Google Scholar] [CrossRef]

- Li, S.; Yan, S. Synthesis and characterization of novel biobased benzoxazines from cardbisphenol and the properties of their polymers. RSC Adv. 2015, 5, 61808–61814. [Google Scholar] [CrossRef]

- Ribeiro, F.W.M.; Kotzebue, L.R.V.; Oliveira, J.R.; Maia, F.J.N.; Mazzetto, S.E.; Lomonaco, D. Thermal and mechanical analyses of biocomposites from cardanol-based polybenzoxazine and bamboo fibers. J. Therm. Anal. Calorim. 2017, 129, 281–289. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, F.; Liang, W.; Wang, Z.; Duan, Z.; Yang, B. Thermal and mechanical properties of bamboo fiber reinforced epoxy composites. Polymers 2018, 10, 608. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G. On the use of SHPB techniques to determine the dynamic behavior of materials in the range of small strains. Int. J. Solids Struct. 1996, 33, 3363–3375. [Google Scholar] [CrossRef]

- Hu, J.; Yin, S.; Yu, T.X.; Xu, J. Dynamic compressive behavior of woven flax-epoxy-laminated composites. Int. J. Impact Eng. 2018, 117, 63–74. [Google Scholar] [CrossRef]

- Safri, S.N.; Sultan, M.T.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Pan, Z.; Xiong, J.; Liang, S.; Zou, M. Transient deformation and heat generation of solid polyurethane under impact compression. Polym. Test. 2017, 61, 269–279. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Compressive and flexural strength of fiber-reinforced foamed concrete: Effect of fiber content, curing conditions and dry density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Xu, L.; Cheng, C.; Du, C.; Jiang, Z.; Du, Z.; Gao, G. Semi-Crystalline Polymers Applied to Taylor Impact Test: Constitutive, Experimental and FEM Analysis. Polymers 2020, 12, 1615. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, M.; Liu, S.; Wang, L.; Gu, B.; Sun, B. High strain rate compressive behaviors and adiabatic shear band localization of 3-D carbon/epoxy angle-interlock woven composites at different loading directions. Compos. Struct. 2019, 211, 502–521. [Google Scholar] [CrossRef]

- Gama, B.A.; Lopatnikov, S.L.; Gillespie, J.W., Jr. Hopkinson bar experimental technique: A critical review. Appl. Mech. Rev. 2004, 57, 223–250. [Google Scholar] [CrossRef]

- Fan, J.; Wang, C. Dynamic compressive response of a developed polymer composite at different strain rates. Compos. Part B Eng. 2018, 152, 96–101. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M.; Nachtane, M.; Yahia, H.B. Strain rate effects on the dynamic compressive response and the failure behavior of polyester matrix. Compos. Part B Eng. 2019, 174, 107040. [Google Scholar] [CrossRef]

- Siviour, C.R.; Jordan, J.L. High strain rate mechanics of polymers: A review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef]

- Hou, X.; Cao, S.; Rong, Q.; Zheng, W.; Li, G. Effects of steel fiber and strain rate on the dynamic compressive stress-strain relationship in reactive powder concrete. Constr. Build. Mater. 2018, 170, 570–581. [Google Scholar] [CrossRef]

| Nominal Strain Rate (s−1) | Maximum Stress (MPa) | |

|---|---|---|

| Neat Benzoxazine | ABP | |

| Quasistatic | 204.3 ± 2.1 | 175 ± 1.6 |

| 1250 | 287 ± 5.2 | 331 ± 6.8 |

| 1650 | 504 ± 6.4 | 563 ± 5.5 |

| 2500 | 578 ± 6.7 | 615 ± 5.1 |

| 2800 | 539 ± 7.5 | 565 ± 7.2 |

| Nominal Strain Rate (s−1) | Absorbed Energy (J) | |

|---|---|---|

| Neat Benzoxazine | ABP | |

| 1250 | 4.1 ± 0.6 | 5.2 ± 0.7 |

| 1650 | 7.5 ± 1.2 | 14.3 ± 1.9 |

| 2500 | 8.7 ± 1.4 | 17.9 ± 2.1 |

| 2800 | 4.6 ± 0.5 | 13.1 ± 2.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Sun, Y.; Wang, F.; Liang, W.; Wang, Z. Progressive Failure and Energy Absorption of Chopped Bamboo Fiber Reinforced Polybenzoxazine Composite under Impact Loadings. Polymers 2020, 12, 1809. https://doi.org/10.3390/polym12081809

Zhang K, Sun Y, Wang F, Liang W, Wang Z. Progressive Failure and Energy Absorption of Chopped Bamboo Fiber Reinforced Polybenzoxazine Composite under Impact Loadings. Polymers. 2020; 12(8):1809. https://doi.org/10.3390/polym12081809

Chicago/Turabian StyleZhang, Kai, Yongyang Sun, Fangxin Wang, Wenyan Liang, and Zhenqing Wang. 2020. "Progressive Failure and Energy Absorption of Chopped Bamboo Fiber Reinforced Polybenzoxazine Composite under Impact Loadings" Polymers 12, no. 8: 1809. https://doi.org/10.3390/polym12081809

APA StyleZhang, K., Sun, Y., Wang, F., Liang, W., & Wang, Z. (2020). Progressive Failure and Energy Absorption of Chopped Bamboo Fiber Reinforced Polybenzoxazine Composite under Impact Loadings. Polymers, 12(8), 1809. https://doi.org/10.3390/polym12081809