Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.3. Characterization

2.3.1. Physical and Mechanical Properties

2.3.2. Thermal Analysis

Thermogravimetric Analysis (TGA)

Differential Scanning Calorimetry (DSC)

2.3.3. Thermal Conductivity

2.3.4. Electric Breakdown

2.4. Statistical Analysis

3. Results and Discussions

3.1. Physcial and Mechanical Properties

3.2. Thermal Properties (TGA and DSC)

3.3. Thermal Conductivity

3.4. Electrical Breakdown

3.5. Morphology Properties of PP and Its Composite

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Toriz, G.; Denes, F.; Young, R.A. Lignin-polypropylene composites. Part 1: Composites from unmodified lignin and polypropylene. Polym. Compos. 2002, 23, 806–813. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Urbaniak, M.; Stankowska-Walczak, D. Biocomposites in the past and in the future fibres. Fibres Text. East. Eur. 2012, 96, 15–22. [Google Scholar]

- Bledzki, A.K.; Franciszczak, P.; Osman, Z.; Elbadawib, M. Polypropylene biocomposites reinforced with softwood, abaca, jute, and kenaf fibers. Ind. Crops Prod. 2015, 70, 91–99. [Google Scholar] [CrossRef]

- Ahmad-Saffian, H.; Hyun-Joong, K.; Md Tahir, P.; Ibrahim, N.A.; Lee, S.H.; Lee, C.H. Effect of Lignin Modification on Properties of Kenaf Core Fiber Reinforced Poly (Butylene Succinate) biocomposites. Materials 2019, 12, 4043. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Juliana, A.H.; Lee, S.H.; Zaidon, A.; Paridah, M.T.; Lum, W.C. Effect of treatment on water absorption behavior of natural fibre reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 141–156. [Google Scholar]

- Summerscales, J.; Dissanayake, N.P.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part 1–Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.H.; Salit, M.S.; Hassan, M.R. A Review of the Flammability Factors of Kenaf and Allied Fiber Reinforced Polymer Composites. Adv. Mater. Sci. Eng. 2014, 2014, 514036. [Google Scholar] [CrossRef] [Green Version]

- Haniffah, W.H.; Sapuan, S.M.; Abdan, K.; Khalid, M.; Hasan, M.; Hoque, M.E. Kenaf fibre reinforced polypropylene composites: Effect of cyclic immersion on tensile properties. Int. J. Polym. Sci. 2015, 2015, 872387. [Google Scholar] [CrossRef] [Green Version]

- Loh, X.H.; Daud, M.M.; Selamat, M.Z. Mechanical properties of kenaf/polypropylene composite: An investigation. J. Mech. Eng. Sci. 2016, 10, 2098–2110. [Google Scholar]

- Lee, C.H.; Sapuan, S.M.; Hassan, M.R. Mechanical and thermal properties of kenaf fiber reinforced polypropylene/magnesium hydroxide composites. J. Eng. Fibers Fabr. 2017, 12, 50–58. [Google Scholar] [CrossRef] [Green Version]

- Zampaloni, M.; Pourboghrat, F.; Yankovich, S.A.; Rodgers, B.N.; Moore, J.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Kenaf natural fiber reinforced polypropylene composites: A discussion on manufacturing problems and solutions. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1569–1580. [Google Scholar] [CrossRef]

- Murali, G.; Fediuk, R.A. Taguchi approach for study on impact response of ultra-high-performance polypropylene fibrous cementitious composite. J. Build. Eng. 2020, 30, 101301. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Grząbka-Zasadzińska, A.; Borysiak, S.; Jesionowski, T. Preparation and characterization of polypropylene composites reinforced by functional ZnO/lignin hybrid materials. Polym. Test. 2019, 79, 106058. [Google Scholar] [CrossRef]

- Ahmed Dabbak, S.Z.; Illias, H.A.; Ang, B.C.; Abdul Latiff, N.A.; Makmud, M.Z.H. Electrical Properties of Polyethylene/Polypropylene Compounds for High-Voltage Insulation. Energies 2018, 11, 1448. [Google Scholar] [CrossRef] [Green Version]

- Hamzah, M.S.; Jaafar, M.; Jamil, M.K.M. Electrical insulation performance of flame retardant fillers filled with polypropylene/ethylene propylene diene monomer composites. Polym. Adv. Technol. 2014, 25, 784–790. [Google Scholar] [CrossRef]

- Netnapa, E.; Mariatti, M.; Hamid, Z.A.A.; Todo, M.; Banhan, L. Dielectric breakdown strength and flammability properties of flame retardant filler/PLLA-PLA microsphere/kenaf fiber composites. Procedia Chem. 2016, 19, 290–296. [Google Scholar] [CrossRef] [Green Version]

- Karkri, M. Thermal conductivity of biocomposite materials. In Biopolymer Composites in Electronics; Sadasivuni, K.K., Cabibihan, J., Ponnamma, D., AlMaadeed, M.A., Kim, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 129–153. [Google Scholar]

- Liu, D.T.; Xia, K.F.; Yang, R.D.; Li, J.; Chen, K.F.; Nazhad, M.M. Manufacturing of a biocomposite with both thermal and acoustic properties. J. Compos. Mater. 2012, 46, 1011–1020. [Google Scholar] [CrossRef]

- Gardner, L.; Munro, T.; Villarreal, E.; Harris, K.; Fronk, T.; Ban, H. Thermal characterization of alkali treated kenaf fibers and kenaf-epoxy composites. Fibers Polym. 2018, 19, 393–402. [Google Scholar] [CrossRef]

- Ang, A.F.; Ashaari, Z.; Lee, S.H.; Tahir, P.M.; Halis, R. Lignin-based copolymer adhesives for composite wood panels–A review. Int. J. Adhes. Adhes. 2019, 95, 102408. [Google Scholar] [CrossRef]

- Huang, J.; Fu, S.; Gan, L. Lignin-Modified Thermoplastic Materials. In Lignin Chemistry and Applications; Huang, J., Fu, S., Gan, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 135–161. [Google Scholar]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Effect of compatibilizer and fillers on the properties of injection molded lignin-based hybrid green composites. J. Appl. Polym. Sci. 2013, 127, 4110–4121. [Google Scholar] [CrossRef]

- Zhang, N.; Li, Z.; Xiao, Y.; Pan, Z.; Jia, P.; Feng, G.; Bao, C.; Zhou, Y.; Hua, L. Lignin-based phenolic resin modified with whisker silicon and its application. J. Bioresour. Bioprod. 2020, in press. [Google Scholar] [CrossRef]

- Kharade, A.Y.; Kale, D.D. Lignin-filled polyolefins. J. Appl. Polym. Sci. 1999, 72, 1321–1326. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Larrañeta, E.; Fong, M.L.; Martin, N.K.; Irwin, N.J.; Mutjé, P.; Tarrés, Q.; Delgado-Aguilar, M. Lignin/poly (butylene succinate) composites with antioxidant and antibacterial properties for potential biomedical applications. Int. J. Biol. Macromol. 2020, 145, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, M.; Bakar, A.; Md Radzi, M.K.F.; Ismail, N.; Raza, M.; Muhamad, N.; Khan, M. Influence of alkaline treatment and fiber loading on the physical and mechanical properties of kenaf/polypropylene composites for variety of applications. Prog. Nat. Sci. Mater. Int. 2016, 26, 657–664. [Google Scholar] [CrossRef]

- Layth, M.; Ansari, M.N.M.; Grace, P.; Mohammad, J.; Saiful-Islam, M. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 15. [Google Scholar]

- Nurshamila, S.; Ismail, H.; Othman, N. The effect of Rattan filler loading on properties of Rattan powder filled polypropylene composites. Bioresources 2012, 7, 5677–5690. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.H.; Sapuan, S.M.; Hassan, M.R. Thermal analysis of kenaf fiber reinforced floreon biocomposites with magnesium hydroxide flame retardant filler. Polym. Compos. 2018, 39, 869–875. [Google Scholar] [CrossRef]

- Mofokeng, J.; Luyt, A.; Tábi, T.; Kovacs, J. Comparison of injection moulded, natural fiber reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Mat-Shayuti, M.S.; Abdullah, M.; Megat-Yusoff, P. THERMAL properties and morphology of Polypropylene/Polycarbonate/Polypropylene-Graft-Maleic anhydride blends. MATEC Web Conf. 2016, 69, 03001. [Google Scholar] [CrossRef] [Green Version]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Mohd Nurrazi, N.; Isma, T.; Lee, C.H. Effect of Empty Fruit Brunch reinforcement in PolyButylene-Succinate/Modified Tapioca Starch blend for Agricultural Mulch Films. Sci. Rep. 2020, 10, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Tomczak, F.; Satyanarayana, K.G.; Sydenstricker, T.H.D. Studies on lignocellulosic fibers of Brazil: Part III – Morphology and properties of Brazilian curauá fibers. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2227–2236. [Google Scholar] [CrossRef]

- Hindle, C.; Polypropylene, P.P. British Plastics Federation. Available online: https://www.bpf.co.uk/plastipedia/polymers/pp.aspx (accessed on 7 July 2020).

- Han, S.O.; Karevan, M.; Sim, I.N.; Bhuiyan, M.A.; Jang, Y.H.; Ghaffar, J.; Kalaitzidou, K. Understanding the reinforcing mechanisms in kenaf fiber/PLA and kenaf fiber/PP composites: A comparative study. Int. J. Polym. Sci. 2012, 679252. [Google Scholar] [CrossRef]

- Sarifuddin, N.; Ismail, H.; Ahmad, Z. The effect of kenaf core fibre loading on properties of low density polyethylene/thermoplastic sago starch/kenaf core fiber composites. J. Phys. Sci. 2013, 24, 97–115. [Google Scholar]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Karwa, R. One-Dimensional Steady State Heat Conduction. In Heat and Mass Transfer; Karwa, R., Ed.; Springer: Singapore, 2017; pp. 7–116. [Google Scholar]

- Wei, W.; Chen, T.; Niu, M.; Xie, Y.; Wang, X. Optimized Pretreatment of kenaf (Hibiscus cannabinus) phloem insulation cotton. Bioresources 2016, 11, 2583–2596. [Google Scholar] [CrossRef] [Green Version]

- Munirah, A.; Ayop, S.; Kamaruddin, K. Evaluation on the Thermal Conductivity of Sand-Cement Blocks with Kenaf Fiber. Adv. Mater. Res. 2012, 626, 485–489. [Google Scholar]

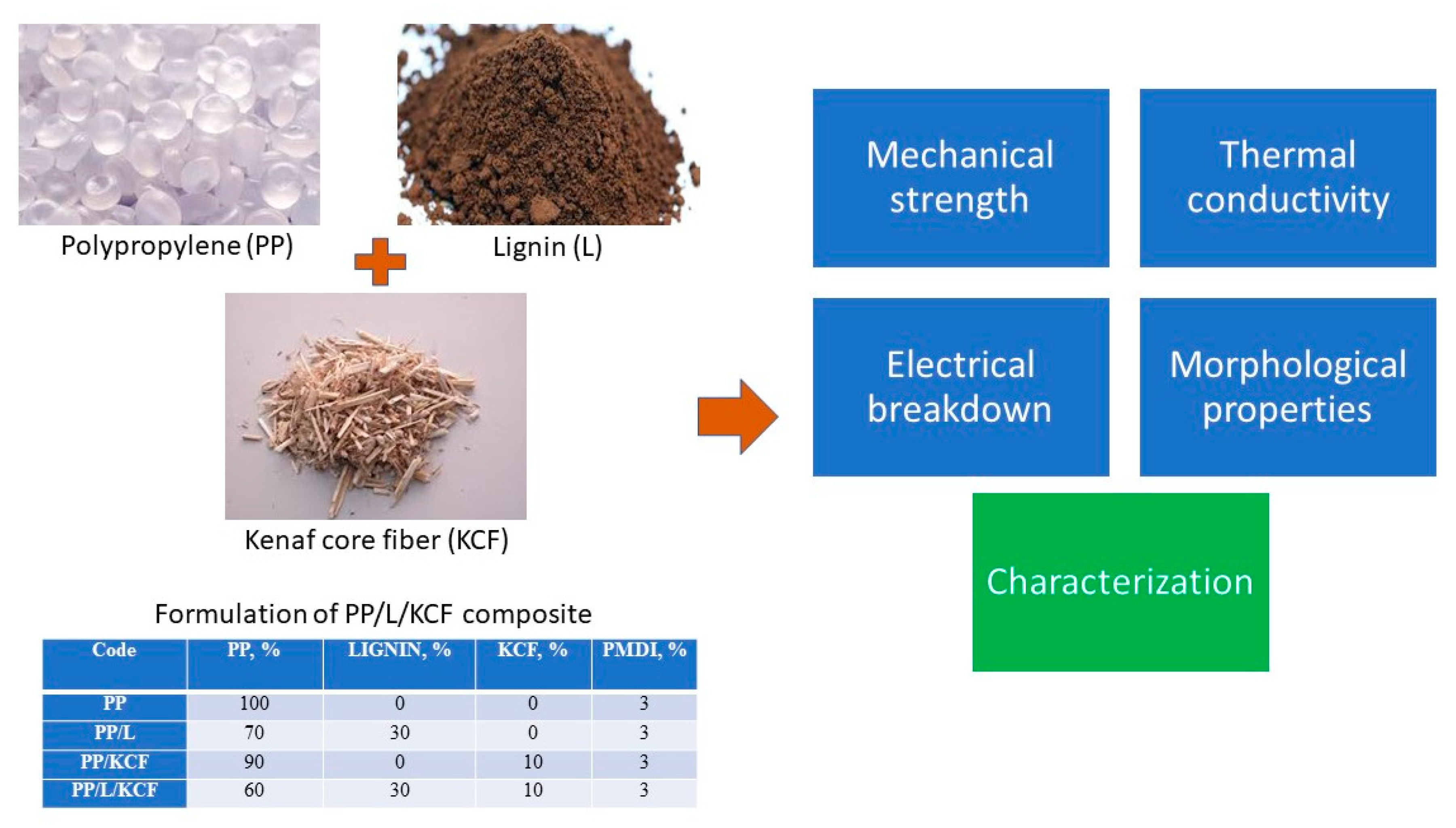

| Code | PP, % | LIGNIN, % | KCF, % | PMDI, % |

|---|---|---|---|---|

| PP | 100 | 0 | 0 | 3 |

| PP/L | 70 | 30 | 0 | 3 |

| PP/KCF | 90 | 0 | 10 | 3 |

| PP/L/KCF | 60 | 30 | 10 | 3 |

| Composites | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|---|

| PP | 45.79 ± 5.14 a | 1424.28 ± 142.10 a | 36.78 ± 4.20 b | 1975.43 ± 145.10 a |

| PP/L | 37.82 ± 4.30 b | 1241.28 ± 121.23 b | 42.51 ± 5.16 a | 1764.62 ± 132.15 ab |

| PP/KCF | 44.17 ± 5.10 a | 1409.35 ± 154.17 a | 43.16 ± 3.16 a | 1697.14 ± 132.16 b |

| PP/L/KCF | 44.60 ± 5.21 a | 1459.73 ± 156.10 a | 43.55 ± 4.12 a | 1801.66 ± 142.13 a |

| Composites | Onset Temperature (Ton), °C | Maximum Degradation Temperature (Tmax), °C | Residual, % |

|---|---|---|---|

| PP | 350.3 | 410.1 | 1.1 |

| Pure Kraft lignin | 255.2 | 300.0 | 54.9 |

| KCF | 139.3 | 275.1 | 21.5 |

| PP/L | 283.5 | 441.5 | 1.9 |

| PP/KCF | 226.9 | 442.0 | 6.6 |

| PP/L/KCF | 275.8 | 472.3 | 9.7 |

| Specimens | First Melting Temperature, Tm1 (°C) | Second Melting Temperautre, Tm2 (°C) |

|---|---|---|

| PP | - | 164.5 |

| PP/KCF | 150.0 | 166.2 |

| PP/L | 151.1 | 166.2 |

| PP/L/KCF | 110.4 | 163.7 |

| Composites | Thermal Conductivity (W/mK) | Volumetric Specific Heat (J/m3K) | Thermal Diffusivity (mm2/s) |

|---|---|---|---|

| PP | 0.0854 ± 0.0011 a | 1.57 ± 0.04 b | 0.055 ± 0.003 b |

| PP/L | 0.0858 ± 0.0015 a | 1.54 ± 0.03 b | 0.056 ± 0.004 b |

| PP/KCF | 0.0877 ± 0.0017 a | 1.56 ± 0.05 b | 0.056 ± 0.003 b |

| PP/L/KCF | 0.0879 ± 0.0012 a | 1.30 ± 0.03 a | 0.067 ± 0.005 a |

| Composites | Material in Air, kV | Current (A) | Material in Oil, kV | Current (A) |

|---|---|---|---|---|

| Standard IEC 60641-3 | 19 kV | 30 kV | ||

| PP | 35.70 | 0.581 | 42.10 | 0.678 |

| PP/L | 35.03 | 0.573 | 24.12 | 0.396 |

| PP/KCF | 30.70 | 0.511 | 35.20 | 0.578 |

| PP/L/KCF | 30 | 0.586 | 36.00 | 0.590 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad Saffian, H.; Talib, M.A.; Lee, S.H.; Md Tahir, P.; Lee, C.H.; Ariffin, H.; Asa’ari, A.Z.M. Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite. Polymers 2020, 12, 1833. https://doi.org/10.3390/polym12081833

Ahmad Saffian H, Talib MA, Lee SH, Md Tahir P, Lee CH, Ariffin H, Asa’ari AZM. Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite. Polymers. 2020; 12(8):1833. https://doi.org/10.3390/polym12081833

Chicago/Turabian StyleAhmad Saffian, Harmaen, Mohd Aizam Talib, Seng Hua Lee, Paridah Md Tahir, Ching Hao Lee, Hidayah Ariffin, and Ainun Zuriyati Mohamed Asa’ari. 2020. "Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite" Polymers 12, no. 8: 1833. https://doi.org/10.3390/polym12081833

APA StyleAhmad Saffian, H., Talib, M. A., Lee, S. H., Md Tahir, P., Lee, C. H., Ariffin, H., & Asa’ari, A. Z. M. (2020). Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite. Polymers, 12(8), 1833. https://doi.org/10.3390/polym12081833