Tensile Strength and Moisture Absorption of Sugar Palm-Polyvinyl Butyral Laminated Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Sugar Palm Fiber

2.1.2. PVB Films

2.2. Fabrication

2.3. Characterization and Analysis

2.3.1. Tensile Test

2.3.2. Moisture Absorption Test

- wf = mass of the sample at Day 25 (g)

- and w0 = mass of the sample at Day 1 (g)

3. Results and Discussion

3.1. Tensile Properties

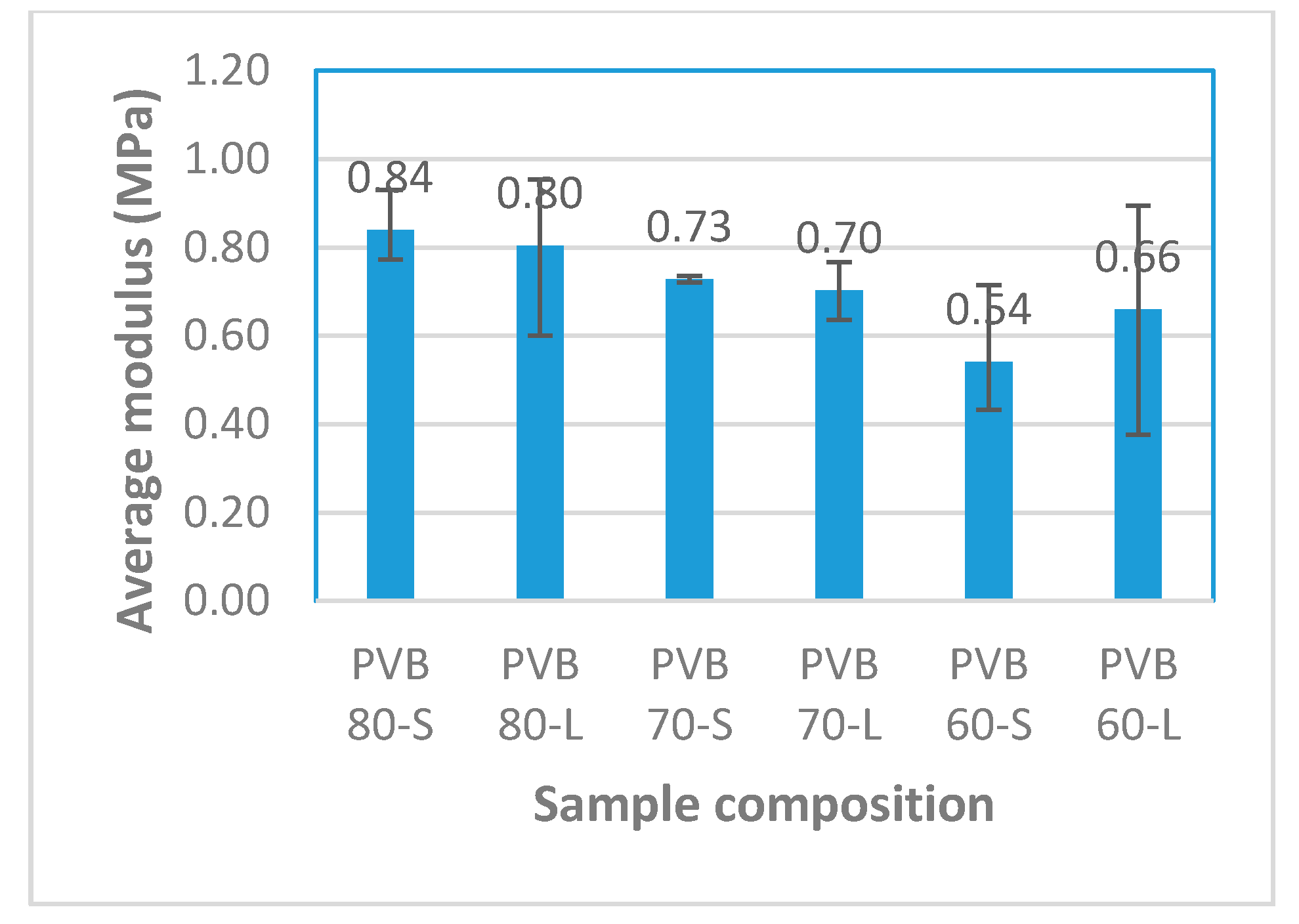

3.1.1. Modulus

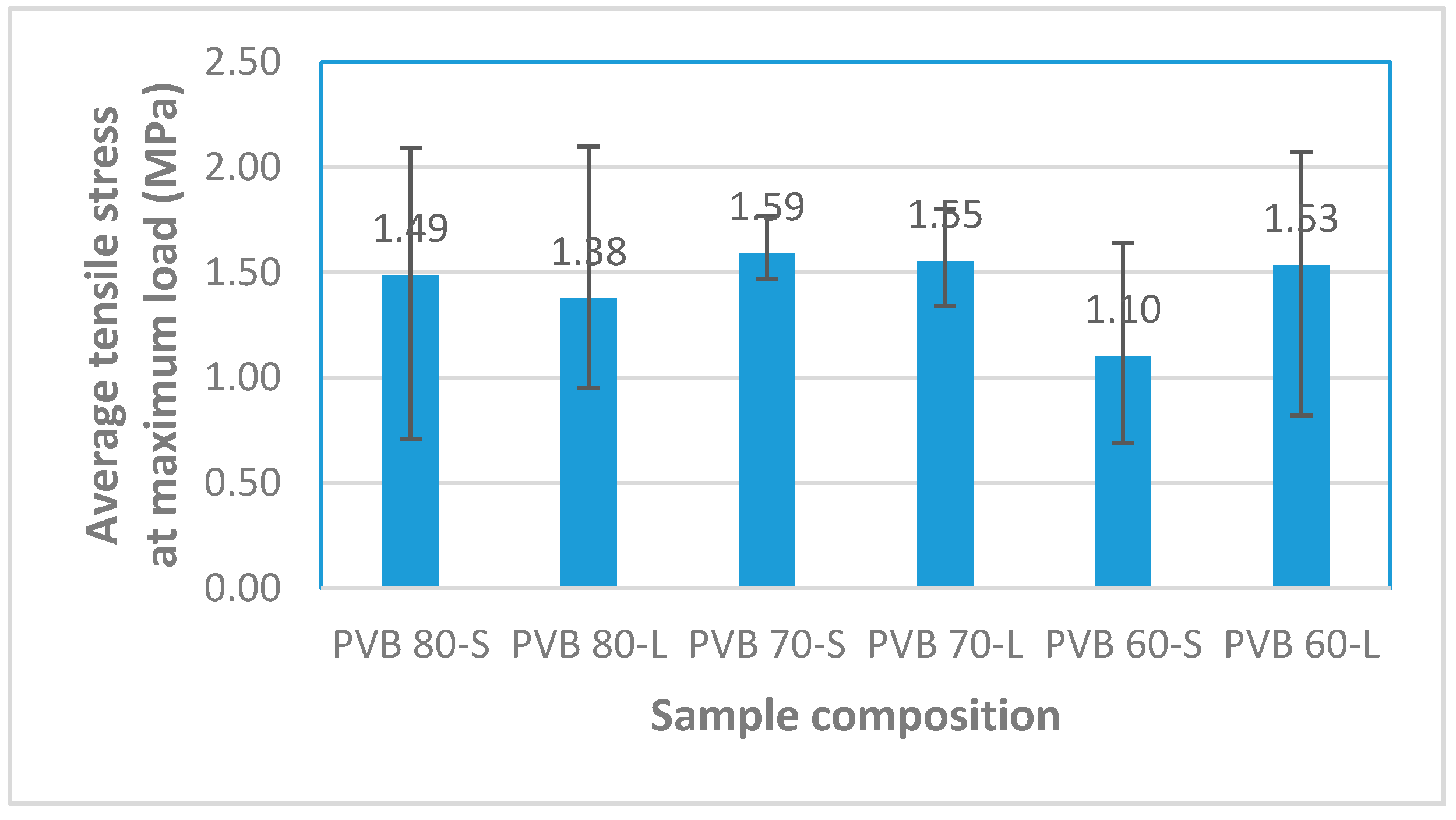

3.1.2. Tensile Stress

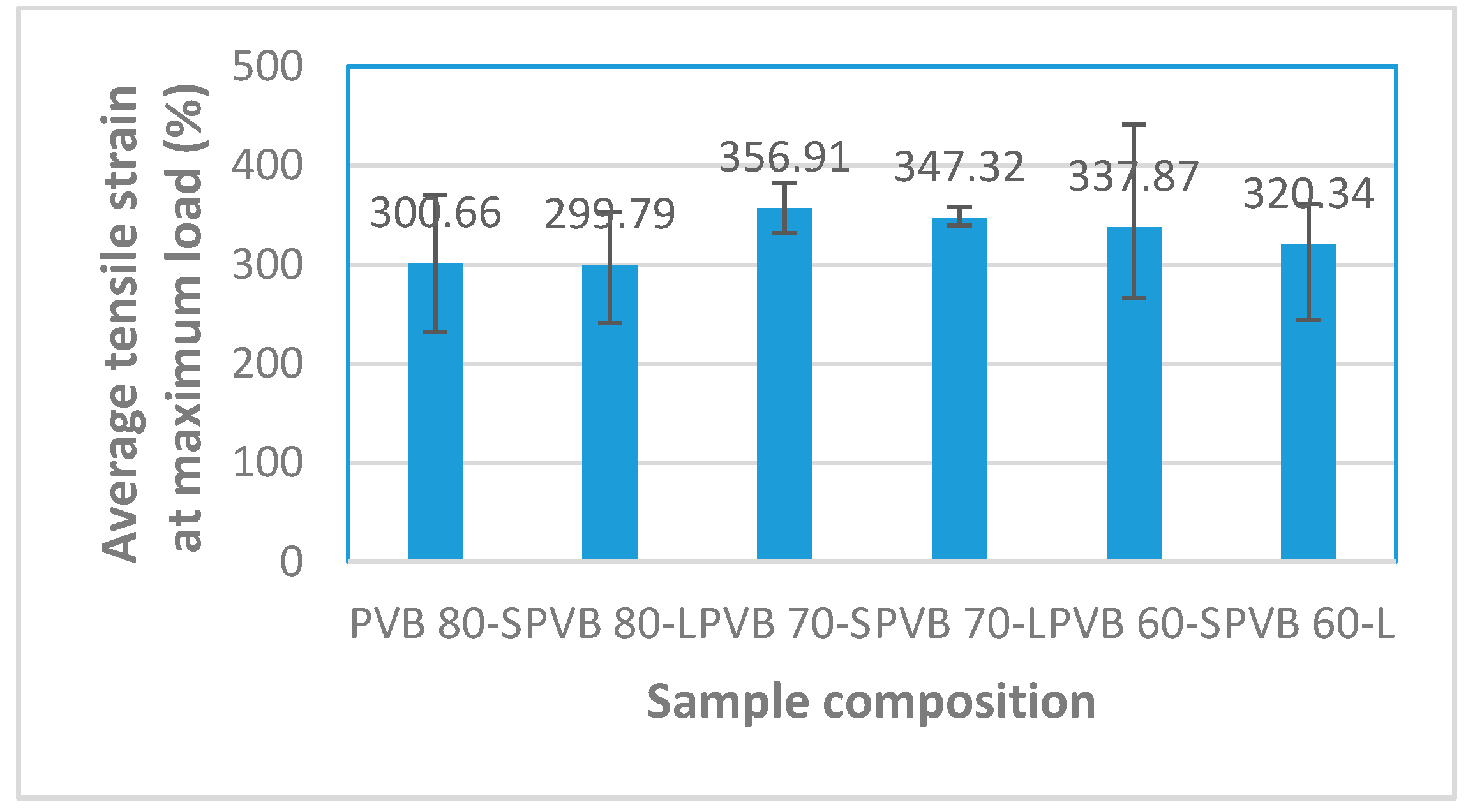

3.1.3. Tensile Strain

3.2. Moisture Absorption

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Hristozov, D.; Wroblewski, L.; Sadeghian, P. Long-term tensile properties of natural fibre-reinforced polymer composites: Comparison of flax and glass fibres. Compos. Part B Eng. 2016, 95, 82–95. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.; Ishak, M. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef]

- Alaaeddin, M.H.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Al-Oqla, F.M. Physical and mechanical properties of polyvinylidene fluoride-Short sugar palm fiber nanocomposites. J. Clean. Prod. 2019, 235, 473–482. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.; Ishak, M.; Alothman, O.Y. Thermal properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. Compos. Struct. 2018, 202, 954–958. [Google Scholar] [CrossRef]

- Safri, S.; Sultan, M.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Mogea, J.; Seibert, B.; Smits, W. Multipurpose palms: The sugar palm (Arenga pinnata (Wurmb) Merr.). Agrofor. Syst. 1991, 13, 111–129. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Ansari, M.N.M.; Ilyas, R.A. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3726–3732. [Google Scholar] [CrossRef]

- Bachtiar, D.; Sapuan, S.M.; Hamdan, M.M.; Sapuan, S. The Influence of Alkaline Surface Fibre Treatment on the Impact Properties of Sugar Palm Fibre-Reinforced Epoxy Composites. Polym. Technol. Eng. 2009, 48, 379–383. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. Thermal and electrical characterization of polymer/ceramic composites with polyvinyl butyral matrix. Mater. Chem. Phys. 2018, 205, 401–415. [Google Scholar] [CrossRef]

- Dhaliwal, A.; Hay, J. The characterization of polyvinyl butyral by thermal analysis. Thermochim. Acta 2002, 391, 245–255. [Google Scholar] [CrossRef]

- Roff, W.J.; Scott, J.R. Fibres, Films, Plastics and Rubbers: A Handbook of Common Polymers; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Zhang, X.; Hao, H.; Shi, Y.; Cui, J. The mechanical properties of Polyvinyl Butyral (PVB) at high strain rates. Constr. Build. Mater. 2015, 93, 404–415. [Google Scholar] [CrossRef]

- Iwasaki, R.; Sato, C.; Latailladeand, J.L.; Viot, P. Experimental study on the interface fracture toughness of PVB (polyvinyl butyral)/glass at high strain rates. Int. J. Crashworthiness 2007, 12, 293–298. [Google Scholar] [CrossRef]

- Fors, C. Mechanical Properties of Interlayers in Laminated Glass-Experimental and Numerical Evaluation; TVSM: Chennai, India, 2014. [Google Scholar]

- Vedrtnam, A.; Pawar, S. Experimental and simulation studies on fatigue behavior of laminated glass having polyvinyl butyral and ethyl vinyl acetate interlayers. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1437–1446. [Google Scholar] [CrossRef]

- Chen, S.; Zang, M.; Wang, D.; Zheng, Z.; Zhao, C. Finite element modelling of impact damage in polyvinyl butyral laminated glass. Compos. Struct. 2016, 138, 1–11. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Pawar, S.J. Experimental and simulation studies on fracture and adhesion test of laminated glass. Eng. Fract. Mech. 2018, 190, 461–470. [Google Scholar] [CrossRef]

- Huang, J.K.; Young, W.B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Hassan, M.M.; Mueller, M.; Wagners, M.H. Exploratory study on seaweed as novel filler in polypropylene composite. J. Appl. Polym. Sci. 2008, 109, 1242–1247. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Hwansanoet, W. Effect of silk protein fibers on properties of thermoplastic rice starch. Fibers Polym. 2012, 13, 606–612. [Google Scholar] [CrossRef]

- Rashid, B.; Leman, Z.; Jawaid, M.; Ghazali, M.J.; Ishak, M.R. The mechanical performance of sugar palm fibres (ijuk) reinforced phenolic composites. Int. J. Precis. Eng. Manuf. 2016, 17, 1001–1008. [Google Scholar] [CrossRef]

- Kasim, A.N.; Selamat, M.Z.; Aznan, N.; Sahadan, S.N.; Daud, M.A.M.; Jumaidin, R.; Salleh, S. Effect of pineapple leaf fiber loading on the properties of pineapple leaf fiber–polypropylene composite. Proc. Mech. Eng. Res. Day 2015, 77, 3–4. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Ibrahim, M.; Sapuan, S.; Zainudin, E.; Zuhri, M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Wang, W.; Sain, M.; Cooper, P. Study of moisture absorption in natural fiber plastic composites. Compos. Sci. Technol. 2006, 66, 379–386. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syaqira S, S.N.; Leman, Z.; Sapuan, S.M.; Dele-Afolabi, T.T.; Azmah Hanim, M.A.; S., B. Tensile Strength and Moisture Absorption of Sugar Palm-Polyvinyl Butyral Laminated Composites. Polymers 2020, 12, 1923. https://doi.org/10.3390/polym12091923

Syaqira S SN, Leman Z, Sapuan SM, Dele-Afolabi TT, Azmah Hanim MA, S. B. Tensile Strength and Moisture Absorption of Sugar Palm-Polyvinyl Butyral Laminated Composites. Polymers. 2020; 12(9):1923. https://doi.org/10.3390/polym12091923

Chicago/Turabian StyleSyaqira S, Shamsudin N., Z. Leman, S. M. Sapuan, T. T. Dele-Afolabi, M. A. Azmah Hanim, and Budati S. 2020. "Tensile Strength and Moisture Absorption of Sugar Palm-Polyvinyl Butyral Laminated Composites" Polymers 12, no. 9: 1923. https://doi.org/10.3390/polym12091923

APA StyleSyaqira S, S. N., Leman, Z., Sapuan, S. M., Dele-Afolabi, T. T., Azmah Hanim, M. A., & S., B. (2020). Tensile Strength and Moisture Absorption of Sugar Palm-Polyvinyl Butyral Laminated Composites. Polymers, 12(9), 1923. https://doi.org/10.3390/polym12091923