Thermal, Viscoelastic, Mechanical and Wear Behaviour of Nanoparticle Filled Polytetrafluoroethylene: A Comparison

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production Protocol and Properties of the Unfilled/Filled PTFE Samples

2.3. Material Characterisation

2.3.1. Spectroscopy and Micro-Analyses

2.3.2. Density Measurement

2.3.3. Thermal Conductivity

2.3.4. Mechanical Analyses

2.3.5. Wear Tests

3. Results and Discussion

3.1. Micro-analysis of the Samples and the Applied Mechanical Stirring

3.1.1. Dispersion of Graphene

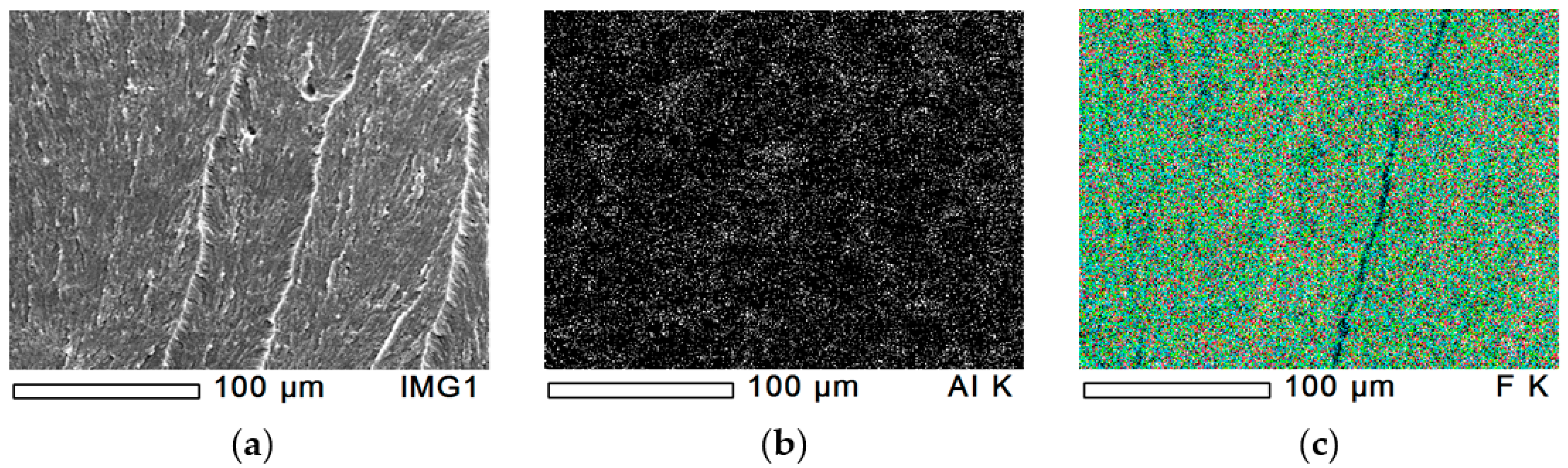

3.1.2. Dispersion of Alumina (Al2O3)

3.1.3. Dispersion of Boehmite Alumina (BA80, AlO(OH))

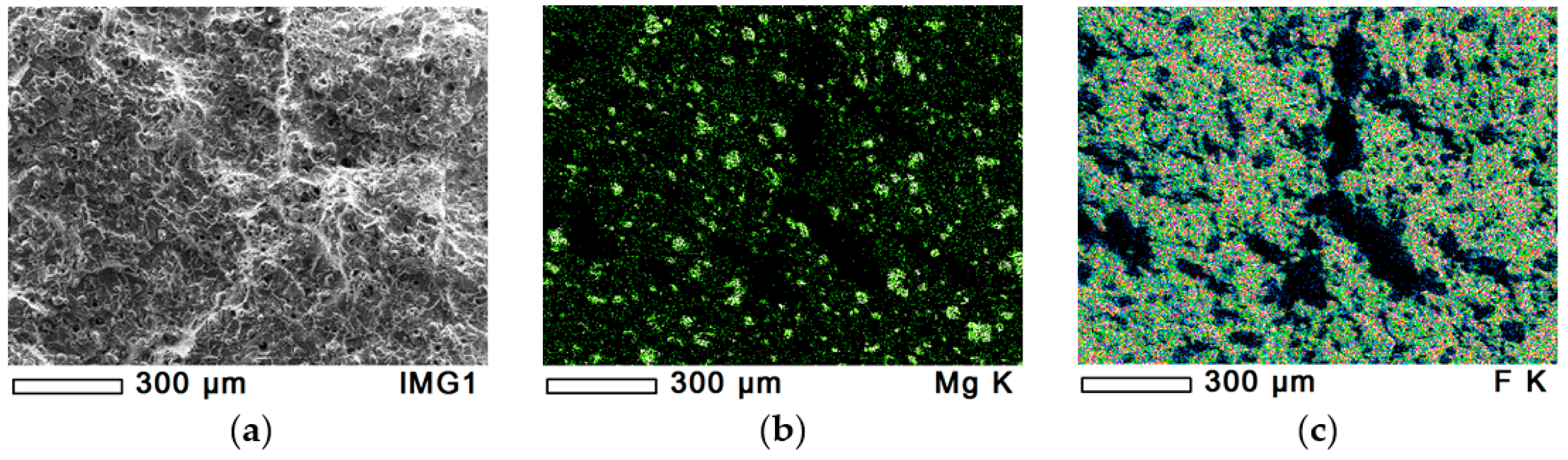

3.1.4. Dispersion of Hydrotalcite (MG70)

3.2. Density of the Unfilled/Filled PTFE Materials

3.3. Thermal Conductivity of the Unfilled/Filled PTFE Materials

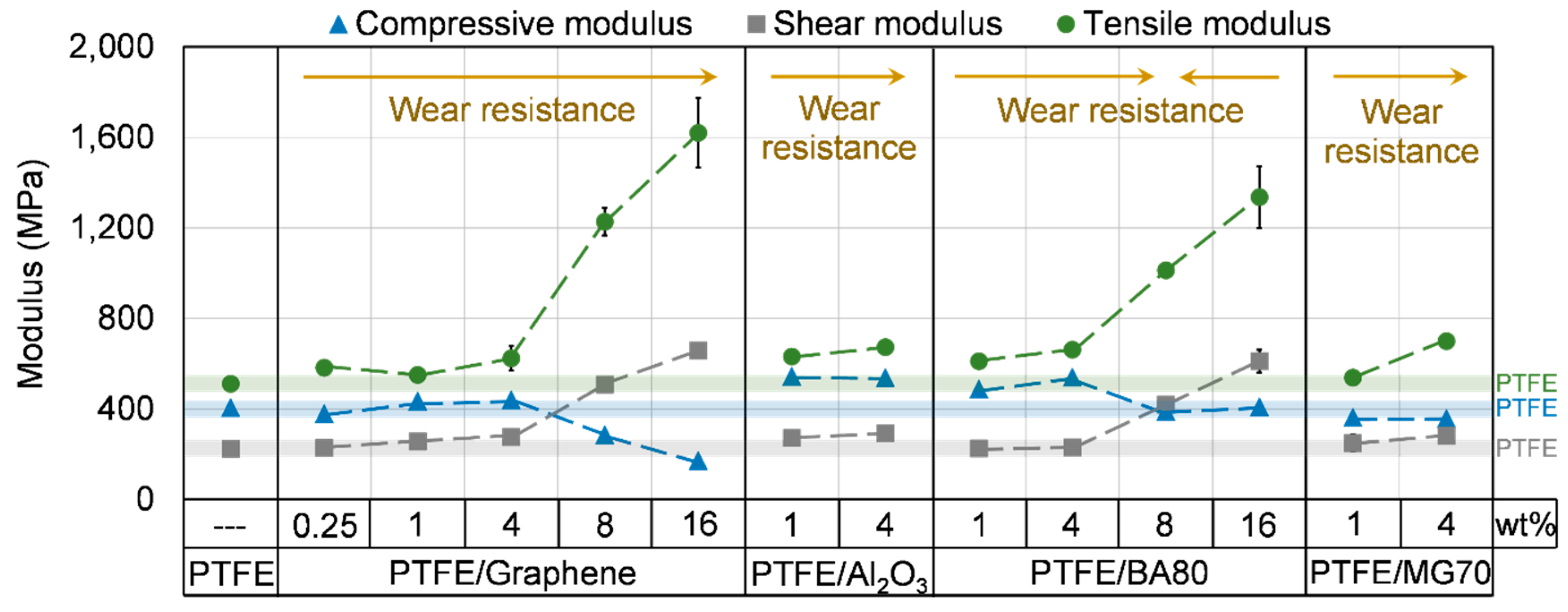

3.4. Mechanical Analyses of the Unfilled/Filled PTFE Materials

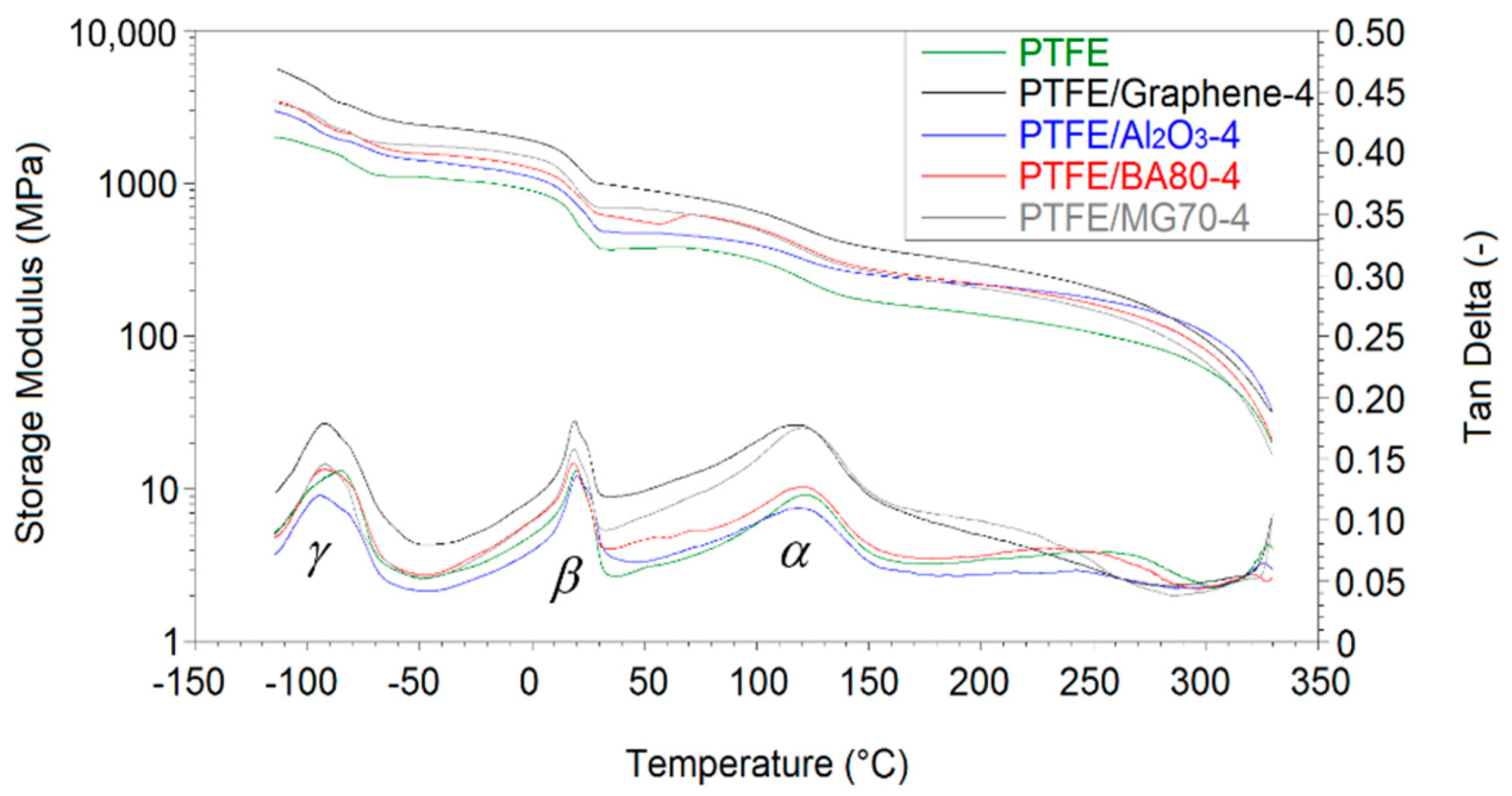

3.4.1. DMA Analysis

3.4.2. Hardness

3.4.3. Compressive Properties

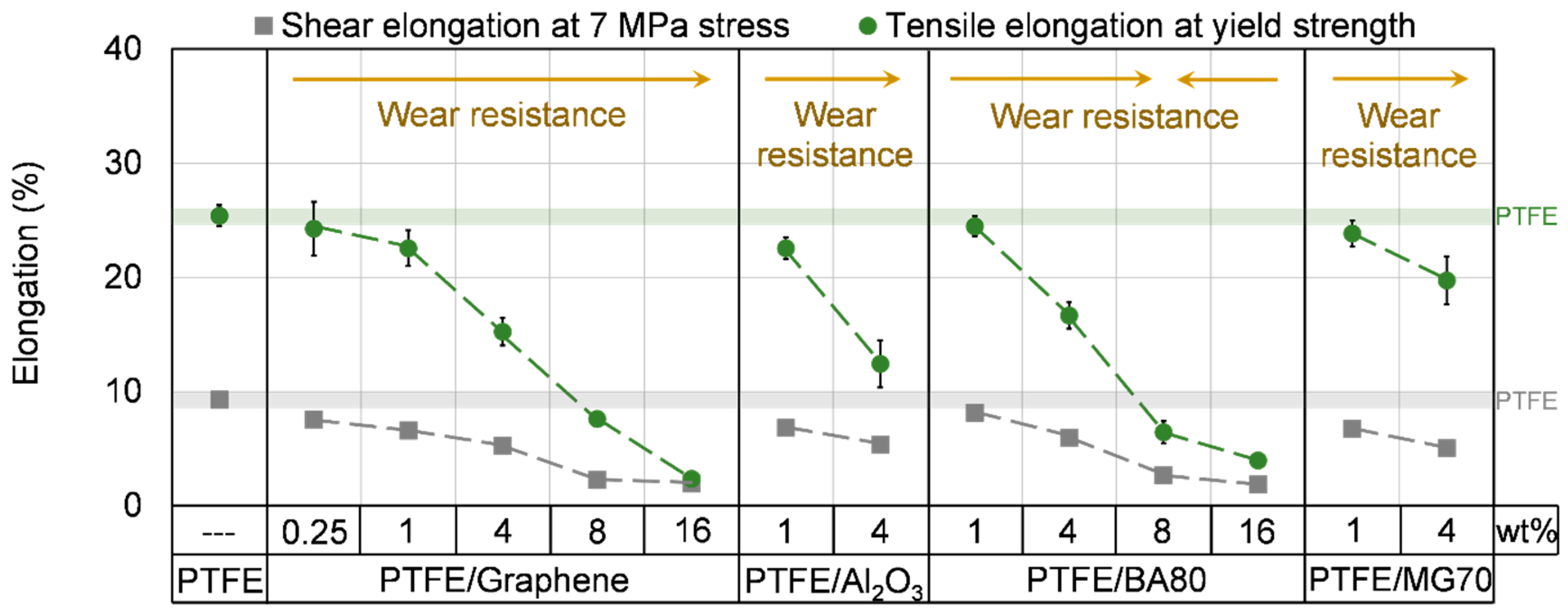

3.4.4. Shear Properties

3.4.5. Tensile Properties

3.5. Wear Behaviour of the Developed Unfilled/Filled PTFE Materials

4. Conclusions

- The applied blending method was an intensive dry mechanical stirring, which is suitable to make homogeneous blends. The homogeneity of the powder blends was investigated by EDS/Raman spectrometry.

- Graphene filler due to its excellent thermal properties remarkably increased the thermal conductivity of PTFE-based samples. Compared to neat PTFE, graphene in 4/8/16 wt % improved the thermal conductivity with ~29%/~84%/~157%, respectively.

- Compared to neat PTFE, the shear and tensile modulus of the developed mono-filled samples were increased together with the increase of the filler content. It is in line with the changes in storage modulus measured by DMA tests. All the applied fillers increased the storage modulus of PTFE. In agreement with the changes observed for the shear, tensile and storage modulus, the elongation at yield strength and the measured elongation during shear tests were significantly reduced with decreasing filler content. This reduced ductility, and the increase of the modulus values can be explained based on the restricted molecular chain motion caused by the applied fillers.

- Focusing on the compressive properties, with higher filler content (8 and 16 wt %), boehmite alumina is observed as a superior additive compared to graphene filler. Graphene significantly decreased the compressive stress and modulus compared to neat PTFE. Samples with lower alumina or boehmite content remarkably increased the compressive modulus.

- As the peak temperature of β-transition of PTFE is close to room temperature (19–20 °C), compressive tests at 50 °C were carried out as a confirmation of the measurements run at room temperature. The tendencies of the registered compressive stress and modulus values between room temperature (23 °C) and 50 °C are close to each other. It means that at the temperature range of the β-transition of PTFE, the ratio of the mechanical performance of the measured specimens does not change remarkably. It is in agreement with the measured storage modulus of the samples.

- PTFE/Al2O3-4 polymer samples had the lowest wear rate, reaching more than two orders of magnitude improvement compared to the neat PTFE. This ultra-low wear rate is not induced by the modified thermal conductivity, hardness or compressive/shear/tensile modulus as these values only slightly changed compared to the neat PTFE. It is supposed that this improvement comes from the modified transfer layer formation.

- The type of filler has a dominating (primary) role in wear mechanism. The increased shear/tensile properties and thermal conductivity have a lower influence on the wear mechanism (secondary role) in case of the investigated PTFE-based materials.

- The developed alumina and graphene-filled PTFE materials can be used in a wide field of tribological applications, e.g., as sliding bearings or seals. Focusing on the wear results, the suggested compositions are 4 wt % alumina or 4–16 wt % graphene, as these materials reached more than one order of magnitude enhancement in wear resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Song, P.; Wang, C.; Chen, L.; Zheng, Y.; Liu, L.; Wu, Q.; Huang, G.; Yu, Y.; Wang, H. Thermally stable, conductive and flame-retardant nylon 612 composites created by adding two-dimensional alumina platelets. Compos. Part A 2017, 97, 100–110. [Google Scholar] [CrossRef]

- Liang, J.Z. Effects of tension rates and filler size on tensile properties of polypropylene/graphene nano-platelets composites. Compos. Part B 2019, 167, 241–249. [Google Scholar] [CrossRef]

- Liang, J.Z.; Du, Q.; Tsui, G.C.P.; Tang, C.Y. Tensile properties of graphene nano-platelets reinforced polypropylene composites. Compos. Part B 2016, 95, 166–171. [Google Scholar] [CrossRef]

- Rodriguez, V.; Sukumaran, J.; Schlarb, A.K.; De Baets, P. Reciprocating sliding wear behaviour of PEEK-based hybrid composites. Wear 2016, 362–363, 161–169. [Google Scholar] [CrossRef]

- Khumalo, V.M.; Karger-Kocsis, J.; Thomann, R. Polyethylene/synthetic boehmite alumina nanocomposites: Structure, thermal and rheological properties. Express Polym. Lett. 2010, 4, 264–274. [Google Scholar] [CrossRef] [Green Version]

- Makowiec, M.E.; Blanchet, T.A. Improved wear resistance of nanotube- and other carbon- filled PTFE composites. Wear 2017, 374–375, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Khedkar, J.; Negulescu, I.; Meletis, E.I. Sliding wear behavior of PTFE composites. Wear 2002, 252, 361–369. [Google Scholar] [CrossRef]

- Kalácska, G. An engineering approach to dry friction behaviour of numerous engineering plastics with respect to the mechanical properties. Express Polym. Lett. 2013, 7, 199–210. [Google Scholar] [CrossRef]

- Krick, B.A.; Ewin, J.J.; Blackman, G.S.; Junk, C.P.; Sawyer, W.G. Environmental dependence of ultra-low wear behavior of polytetrafluoroethylene (PTFE) and alumina composites suggests tribochemical mechanisms. Tribol. Int. 2012, 51, 42–46. [Google Scholar] [CrossRef]

- Padenko, E.; van Rooyen, L.J.; Wetzel, B.; Karger-Kocsis, J. “Ultralow” sliding wear polytetrafluoro ethylene nanocomposites with functionalized graphene. J. Reinf. Plast. Compos. 2016, 35, 892–901. [Google Scholar] [CrossRef] [Green Version]

- Kandanur, S.S.; Rafiee, M.A.; Yavari, F.; Schrameyer, M.; Yu, Z.Z.; Blanchet, T.A.; Koratkar, N. Suppression of wear in graphene polymer composites. Carbon 2012, 50, 3178–3183. [Google Scholar] [CrossRef]

- Harris, K.L.; Pitenis, A.A.; Sawyer, W.G.; Krick, B.A.; Blackman, G.S.; Kasprzak, D.J.; Junk, C.P. PTFE tribology and the role of mechanochemistry in the development of protective surface films. Macromolecules 2015, 48, 3739–3745. [Google Scholar] [CrossRef]

- Padenko, E.; van Rooyen, L.J.; Karger-Kocsis, J. Transfer film formation in PTFE/oxyfluorinated graphene nanocomposites during dry sliding. Tribol. Lett. 2017, 65, 1–11. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Lendvai, L. Polymer/boehmite nanocomposites: A review. J. Appl. Polym. Sci. 2017, 45573, 1–31. [Google Scholar] [CrossRef] [Green Version]

- Pedrazzoli, D.; Khumalo, V.M.; Karger-Kocsis, J.; Pegoretti, A. Thermal, viscoelastic and mechanical behavior of polypropylene with synthetic boehmite alumina nanoparticles. Polym. Test. 2014, 35, 92–100. [Google Scholar] [CrossRef] [Green Version]

- Gumede, T.P.; Luyt, A.S.; Müller, A.J. Review on PCL, PBS, and PCL/PBS blends containing carbon nanotubes. Express Polym. Lett. 2018, 12, 505–529. [Google Scholar] [CrossRef]

- Suplicz, A.; Kovács, J.G. Development of thermally conductive polymer materials and their investigation. Mater. Sci. Forum 2013, 729, 80–84. [Google Scholar] [CrossRef] [Green Version]

- Kovacs, J.G.; Suplicz, A. Thermally conductive polymer compounds for injection moulding: The synergetic effect of hexagonal boron-nitride and talc. J. Reinf. Plast. Compos. 2013, 32, 1234–1240. [Google Scholar] [CrossRef] [Green Version]

- Zunlong, J.; Xiaotang, C.; Yongqing, W.; Dingbiao, W. Thermal conductivity of PTFE composites filled with graphite particles and carbon fibers. Comput. Mater. 2015, 102, 45–50. [Google Scholar]

- Calleja, G.; Jourdan, A.; Ameduri, B.; Habas, J.P. Where is the glass transition temperature of poly(tetrafluoroethylene)? A new approach by dynamic rheometry and mechanical tests. Eur. Polym. J. 2013, 49, 2214–2222. [Google Scholar] [CrossRef] [Green Version]

- Dorigato, A.; Dzenis, Y.; Pegoretti, A. Nanofiller aggregation as reinforcing mechanism in nanocomposites. Procedia Eng. 2011, 10, 894–899. [Google Scholar] [CrossRef] [Green Version]

- Jun, Y.S.; Um, J.G.; Jiang, G.; Yu, A. A study on the effects of graphene nano-platelets (GnPs) sheet sizes from a few to hundred microns on the thermal, mechanical, and electrical properties of polypropylene (PP)/GnPs composites. Express Polym. Lett. 2018, 12, 885–897. [Google Scholar] [CrossRef]

| Materials | Matrix | Filler | Filler Content (wt %) |

|---|---|---|---|

| PTFE | PTFE | --- | --- |

| PTFE/graphene-0.25 | PTFE | Graphene | 0.25 |

| PTFE/graphene-1 | PTFE | Graphene | 1 |

| PTFE/graphene-4 | PTFE | Graphene | 4 |

| PTFE/graphene-8 | PTFE | Graphene | 8 |

| PTFE/graphene-16 | PTFE | Graphene | 16 |

| PTFE/Al2O3-1 | PTFE | Alumina (Al2O3) | 1 |

| PTFE/Al2O3-4 | PTFE | Alumina (Al2O3) | 4 |

| PTFE/BA80-1 | PTFE | Boehmite alumina (BA80) | 1 |

| PTFE/BA80-4 | PTFE | Boehmite alumina (BA80) | 4 |

| PTFE/BA80-8 | PTFE | Boehmite alumina (BA80) | 8 |

| PTFE/BA80-16 | PTFE | Boehmite alumina (BA80) | 16 |

| PTFE/MG70-1 | PTFE | Hydrotalcite (MG70) | 1 |

| PTFE/MG70-4 | PTFE | Hydrotalcite (MG70) | 4 |

| Samples | Density (g/cm3) | Thermal Conductivity (W/mK) |

|---|---|---|

| PTFE | 2.17 | 0.24 ± 0.01 |

| PTFE/graphene-0.25 | 2.17 | 0.25 ± 0.01 |

| PTFE/graphene-1 | 2.17 | 0.25 ± 0.02 |

| PTFE/graphene-4 | 2.14 | 0.31 ± 0.01 |

| PTFE/graphene-8 | 2.07 | 0.45 ± 0.02 |

| PTFE/graphene-16 | 1.95 | 0.62 ± 0.03 |

| PTFE/Al2O3-1 | 2.18 | 0.25 ± 0.02 |

| PTFE/Al2O3-4 | 2.20 | 0.27 ± 0.02 |

| PTFE/BA80-1 | 2.17 | 0.25 ± 0.02 |

| PTFE/BA80-4 | 2.19 | 0.27 ± 0.02 |

| PTFE/BA80-8 | 2.19 | 0.31 ± 0.01 |

| PTFE/BA80-16 | 2.20 | 0.33 ± 0.00 |

| PTFE/MG70-1 | 2.14 | 0.26 ± 0.01 |

| PTFE/MG70-4 | 2.13 | 0.28 ± 0.01 |

| Storage Modulus, | Storage Modulus, | Storage Modulus, | |

| MPa (−50 °C) | MPa (20 °C) | MPa (150 °C) | |

| PTFE | 1102 | 545 | 170 |

| PTFE/graphene-4 | 2412 | 1297 | 381 |

| PTFE/Al2O3-4 | 1413 | 723 | 254 |

| PTFE/BA80-4 | 1567 | 842 | 277 |

| PTFE/MG70-4 | 1773 | 908 | 266 |

| Peak Temperature (γ) | Peak Temperature (β) | Peak Temperature (α) | |

| (°C) | (°C) | (°C) | |

| PTFE | −85.4 | 19.7 | 121.3 |

| PTFE/graphene-4 | −92.9 | 18.9 | 117.0 |

| PTFE/Al2O3-4 | −94.9 | 20.1 | 117.9 |

| PTFE/BA80-4 | −92.5 | 18.5 | 120.7 |

| PTFE/MG70-4 | −92.3 | 18.6 | 119.9 |

| Samples | Hardness (Shore-D) | Compressive Stress at 5% Strain, MPa | Compressive Stress at 10% Strain, MPa | Compressive Modulus, MPa |

|---|---|---|---|---|

| PTFE | 54.3 ± 0.9 | 13.92 ± 0.73 | 18.91 ± 0.57 | 405.9 ± 11.8 |

| PTFE/graphene-0.25 | 55.0 ± 0.2 | 14.14 ± 0.19 | 19.51 ± 0.15 | 378.6 ± 9.1 |

| PTFE/graphene-1 | 55.7 ± 0.9 | 14.33 ± 0.21 | 19.36 ± 0.25 | 435.2 ± 14.8 |

| PTFE/graphene-4 | 55.6 ± 1.2 | 14.15 ± 0.48 | 19.56 ± 0.24 | 440.2 ± 17.8 |

| PTFE/graphene-8 | 55.3 ± 0.7 | 12.27 ± 0.45 | 18.37 ± 0.13 | 286.0 ± 10.9 |

| PTFE/graphene-16 | 53.9 ± 0.9 | 7.57 ± 0.77 | 14.35 ± 0.35 | 172.2 ± 9.9 |

| PTFE/Al2O3-1 | 57.7 ± 1.0 | 14.52 ± 0.53 | 19.03 ± 0.64 | 544.7 ± 11.0 |

| PTFE/Al2O3-4 | 58.8 ± 0.4 | 14.70 ± 0.26 | 19.11 ± 0.29 | 538.2 ± 10.4 |

| PTFE/BA80-1 | 56.3 ± 0.7 | 14.44 ± 0.27 | 18.98 ± 0.32 | 488.3 ± 10.9 |

| PTFE/BA80-4 | 58.4 ± 0.5 | 15.12 ± 0.41 | 19.55 ± 0.44 | 540.4 ± 16.1 |

| PTFE/BA80-8 | 59.1 ± 0.9 | 13.72 ± 0.93 | 20.10 ± 0.34 | 388.9 ± 9.2 |

| PTFE/BA80-16 | 60.0 ± 1.1 | 14.27 ± 1.19 | 21.79 ± 0.26 | 409.2 ± 9.8 |

| PTFE/MG70-1 | 53.7 ± 0.9 | 10.94 ± 1.01 | 17.16 ± 0.12 | 362.5 ± 9.3 |

| PTFE/MG70-4 | 54.5 ± 0.7 | 10.73 ± 0.48 | 16.69 ± 0.24 | 357.4 ± 13.9 |

| Samples | Compressive Stress at 5% Strain, MPa (50 °C) | Compressive Stress at 10% Strain, MPa (50 °C) | Compressive Modulus, MPa (50 °C) |

|---|---|---|---|

| PTFE | 11.13 ± 0.27 | 16.00 ± 1.34 | 318.4 ± 12.7 |

| PTFE/graphene-4 | 11.00 ± 0.27 | 16.39 ± 0.17 | 351.0 ± 7.7 |

| PTFE/Al2O3-4 | 12.47 ± 0.12 | 17.06 ± 0.19 | 422.5 ± 17.3 |

| PTFE/BA80-4 | 12.02 ± 0.55 | 16.53 ± 0.19 | 422.0 ± 13.0 |

| PTFE/MG70-4 | 11.21 ± 0.62 | 15.99 ± 0.09 | 325.9 ± 10.0 |

| Samples | Shear Stress at 2% Strain, MPa | Shear Stress at 5% Strain, MPa | Elongation at 7 MPa stress, % | Shear Modulus, MPa |

|---|---|---|---|---|

| PTFE | 3.84 ± 0.08 | 5.93 ± 0.09 | 9.28 ± 0.55 | 223.2 ± 15.1 |

| PTFE/graphene-0.25 | 3.85 ± 0.64 | 5.79 ± 0.76 | 7.55 ± 0.31 | 226.8 ± 5.3 |

| PTFE/graphene-1 | 3.94 ± 0.20 | 6.35 ± 0.31 | 6.59 ± 0.41 | 256.6 ± 21.0 |

| PTFE/graphene-4 | 4.44 ± 0.26 | 6.89 ± 0.28 | 5.26 ± 0.60 | 275.8 ± 25.8 |

| PTFE/graphene-8 | 6.58 ± 0.22 | 9.23 ± 0.22 | 2.29 ± 0.16 | 507.8 ± 19.6 |

| PTFE/graphene-16 | 7.11 ± 0.33 | 9.63 ± 0.47 | 1.95 ± 0.22 | 657.4 ± 8.2 |

| PTFE/Al2O3-1 | 4.22 ± 0.02 | 6.12 ± 0.47 | 6.82 ± 0.24 | 272.1 ± 25.9 |

| PTFE/Al2O3-4 | 4.42 ± 0.31 | 6.83 ± 0.17 | 5.36 ± 0.39 | 293.7 ± 11.2 |

| PTFE/BA80-1 | 3.75 ± 0.38 | 6.08 ± 0.01 | 8.16 ± 0.54 | 225.5 ± 16.0 |

| PTFE/BA80-4 | 4.19 ± 0.35 | 6.40 ± 0.42 | 5.95 ± 0.07 | 229.6 ± 2.7 |

| PTFE/BA80-8 | 6.07 ± 0.30 | 8.63 ± 0.35 | 2.67 ± 0.32 | 418.9 ± 28.1 |

| PTFE/BA80-16 | 7.26 ± 0.34 | 9.68 ± 0.33 | 1.86 ± 0.21 | 611.4 ± 50.3 |

| PTFE/MG70-1 | 4.35 ± 0.43 | 6.49 ± 0.22 | 6.73 ± 0.59 | 249.9 ± 38.2 |

| PTFE/MG70-4 | 4.79 ± 0.32 | 6.99 ± 0.26 | 5.05 ± 0.68 | 281.3 ± 30.0 |

| Samples | Tensile Stress at 2% Strain, MPa | Tensile Stress at 5% Strain, MPa | Tensile Modulus, MPa |

|---|---|---|---|

| PTFE | 10.16 ± 0.18 | 12.18 ± 0.14 | 511.6 ± 22.3 |

| PTFE/graphene-0.25 | 10.34 ± 0.13 | 12.60 ± 0.08 | 582.6 ± 10.0 |

| PTFE/graphene-1 | 10.29 ± 0.14 | 12.19 ± 0.21 | 551.0 ± 5.5 |

| PTFE/graphene-4 | 11.23 ± 0.15 | 13.21 ± 0.18 | 624.1 ± 53.8 |

| PTFE/graphene-8 | 12.22 ± 0.82 | 14.90 ± 0.75 | 1227.4 ± 60.3 |

| PTFE/graphene-16 | 13.31 ± 1.32 | --- | 1620.5 ± 153.4 |

| PTFE/Al2O3-1 | 10.33 ± 0.18 | 12.22 ± 0.24 | 632.0 ± 12.5 |

| PTFE/Al2O3-4 | 11.51 ± 0.06 | 12.58 ± 0.11 | 673.4 ± 23.5 |

| PTFE/BA80-1 | 10.52 ± 0.43 | 12.06 ± 0.27 | 611.2 ± 7.8 |

| PTFE/BA80-4 | 10.81 ± 0.45 | 11.95 ± 0.40 | 661.9 ± 11.2 |

| PTFE/BA80-8 | 11.87 ± 0.41 | 13.92 ± 0.55 | 1013.1 ± 29.2 |

| PTFE/BA80-16 | 13.27 ± 0.47 | 14.42 ± 0.63 | 1336.1 ± 136.1 |

| PTFE/MG70-1 | 9.58 ± 0.22 | 11.33 ± 0.26 | 538.8 ± 13.2 |

| PTFE/MG70-4 | 10.64 ± 0.32 | 11.86 ± 0.33 | 699.8 ± 12.5 |

| Samples | Yield Strength, MPa | Elongation at Yield Strength, % | Tensile Stress at Break, MPa | Elongation at Break, % |

|---|---|---|---|---|

| PTFE | 12.69 ± 0.12 | 25.39 ± 0.93 | 20.06 ± 1.26 | 288.0 ± 15.3 |

| PTFE/graphene-0.25 | 14.52 ± 0.19 | 24.26 ± 2.36 | 24.81 ± 2.99 | 348.8 ± 35.9 |

| PTFE/graphene-1 | 12.67 ± 0.28 | 22.55 ± 1.57 | 23.35 ± 1.34 | 356.9 ± 67.0 |

| PTFE/graphene-4 | 13.32 ± 0.21 | 15.24 ± 1.20 | 17.15 ± 0.74 | 226.0 ± 22.1 |

| PTFE/graphene-8 | 15.17 ± 0.74 | 7.60 ± 0.26 | 13.05 ± 1.35 | 15.4 ± 0.8 |

| PTFE/graphene-16 | 13.06 ± 0.95 | 2.36 ± 0.38 | 13.69 ± 1.51 | 2.5 ± 0.4 |

| PTFE/Al2O3-1 | 12.60 ± 0.20 | 22.55 ± 0.96 | 24.11 ± 2.22 | 369.9 ± 3.0 |

| PTFE/Al2O3-4 | 12.60 ± 0.13 | 12.43 ± 2.06 | 20.17 ± 1.72 | 306.5 ± 25.8 |

| PTFE/BA80-1 | 12.56 ± 0.22 | 24.46 ± 0.88 | 22.32 ± 1.31 | 378.2 ± 81.2 |

| PTFE/BA80-4 | 12.21 ± 0.29 | 16.66 ± 1.15 | 22.05 ± 1.68 | 344.7 ± 43.9 |

| PTFE/BA80-8 | 13.98 ± 0.56 | 6.44 ± 0.96 | 23.16 ± 0.53 | 368.2 ± 8.7 |

| PTFE/BA80-16 | 14.51 ± 0.62 | 3.96 ± 0.24 | 17.50 ± 0.95 | 320.0 ± 13.0 |

| PTFE/MG70-1 | 11.93 ± 0.27 | 23.84 ± 1.13 | 21.78 ± 1.58 | 319.6 ± 36.2 |

| PTFE/MG70-4 | 12.05 ± 0.38 | 19.73 ± 2.11 | 23.40 ± 2.36 | 438.9 ± 73.6 |

| Materials | Wear Rate (mm3/mN) | |

|---|---|---|

| Average | Deviation (%) | |

| PTFE | 5.16 × 10−4 | 8.8 |

| PTFE/graphene-0.25 | 5.47 × 10−4 | 6.0 |

| PTFE/graphene-1 | 5.07 × 10−4 | 20.6 |

| PTFE/graphene-4 | 4.72 × 10−5 | 17.2 |

| PTFE/graphene-8 | 3.17 × 10−5 | 25.6 |

| PTFE/graphene-16 | 8.51 × 10−6 | 39.6 |

| PTFE/Al2O3-1 | 9.26 × 10−5 | 12.5 |

| PTFE/Al2O3-4 | 2.91 × 10−6 | 68.4 |

| PTFE/BA80-1 | 2.40 × 10−4 | 10.9 |

| PTFE/BA80-4 | 2.01 × 10−4 | 6.7 |

| PTFE/BA80-8 | 7.27 × 10−5 | 10.3 |

| PTFE/BA80-16 | 1.12 × 10−4 | 10.9 |

| PTFE/MG70-1 | 5.39 × 10−4 | 2.2 |

| PTFE/MG70-4 | 4.49 × 10−4 | 12.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, L.F.; De Baets, P.; Szebényi, G. Thermal, Viscoelastic, Mechanical and Wear Behaviour of Nanoparticle Filled Polytetrafluoroethylene: A Comparison. Polymers 2020, 12, 1940. https://doi.org/10.3390/polym12091940

Tóth LF, De Baets P, Szebényi G. Thermal, Viscoelastic, Mechanical and Wear Behaviour of Nanoparticle Filled Polytetrafluoroethylene: A Comparison. Polymers. 2020; 12(9):1940. https://doi.org/10.3390/polym12091940

Chicago/Turabian StyleTóth, Levente Ferenc, Patrick De Baets, and Gábor Szebényi. 2020. "Thermal, Viscoelastic, Mechanical and Wear Behaviour of Nanoparticle Filled Polytetrafluoroethylene: A Comparison" Polymers 12, no. 9: 1940. https://doi.org/10.3390/polym12091940

APA StyleTóth, L. F., De Baets, P., & Szebényi, G. (2020). Thermal, Viscoelastic, Mechanical and Wear Behaviour of Nanoparticle Filled Polytetrafluoroethylene: A Comparison. Polymers, 12(9), 1940. https://doi.org/10.3390/polym12091940