Preparation and Characterization of Composites Materials with Rubber Matrix and with Polyvinyl Chloride Addition (PVC)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Rubber Characterization

2.1.2. Characterization of PVC Particles

2.1.3. Characterization of the Textile Reinforcement

2.2. Methods of Obtaining and Testing Conveyor Belts

2.2.1. Obtaining Conveyor Belts

- -

- Samples I: R1—R2—R1—R2—R 1;

- -

- Samples II: R1—R2—PVC—R2—R1;

- -

- Samples III: R1—EP 100—R2—EP 100—R1;

- -

- Samples IV: R1—EP 100—R2—PVC—R2—EP 100—R1.

- -

- Samples I: the thickness of the foils R1, respectively, R2—3.6 mm;

- -

- Samples II: the thickness of the foils R1, respectively, R2—4 mm;

- -

- Samples III: the thickness of the foils R1, respectively, R2—5.6 mm;

- -

- Samples IV: the thickness of the foils R1, respectively, R2—3.7 mm.

2.2.2. Methods for Testing the Strips in Terms of Mechanical Properties

Experimental Testing of Samples to Tensile

Analysis of the Tensile Behavior of the Samples through FEM

2.2.3. Methods for Testing Conveyor Belts in Terms of Thermal Shock Behavior

- -

- A total of 2000 cycles of variation between −40 °C and 85 °C;

- -

- The times to accommodate varied, at the first 700 cycles it was 45 min, and for the rest, it was 15 min.

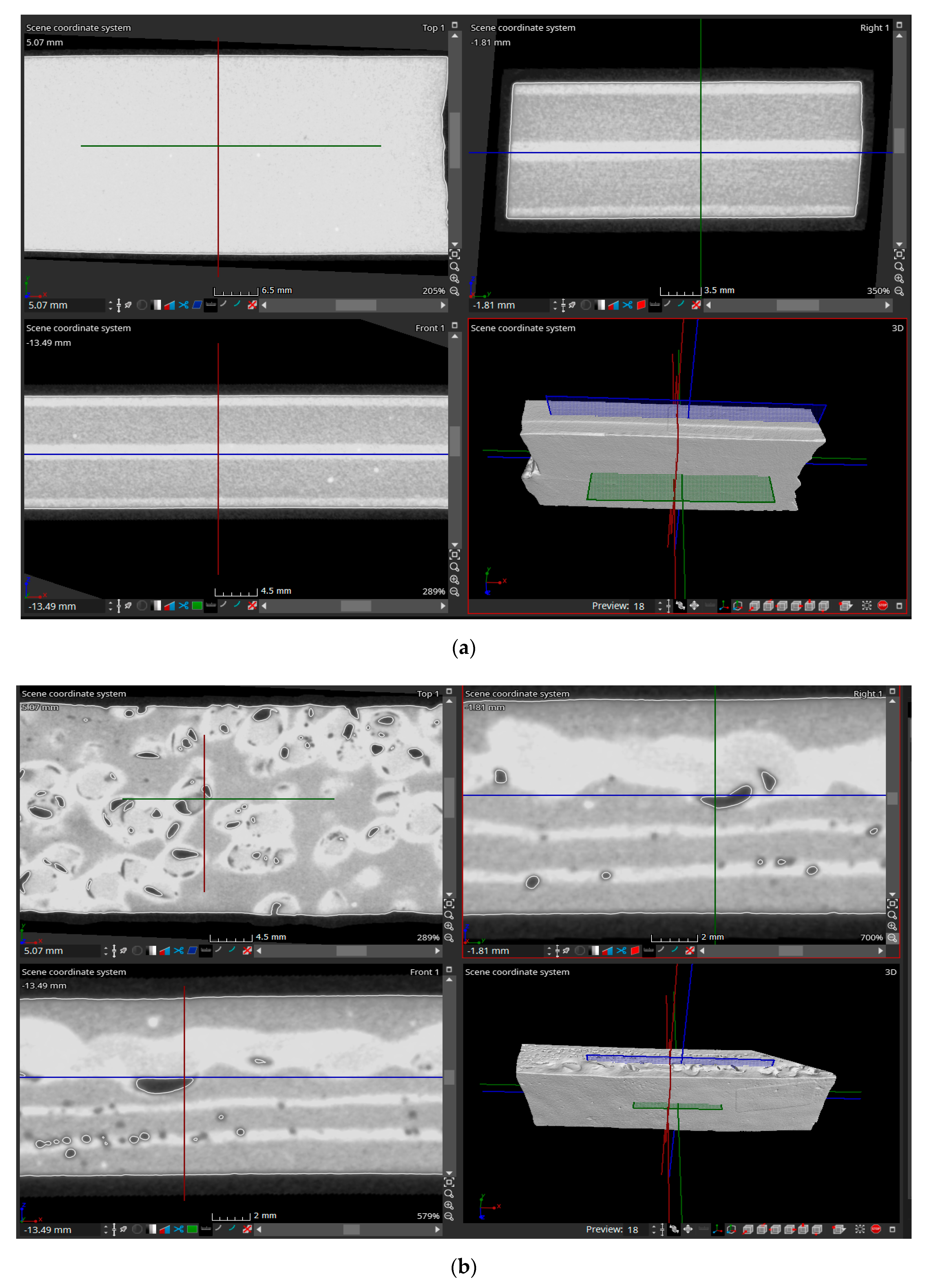

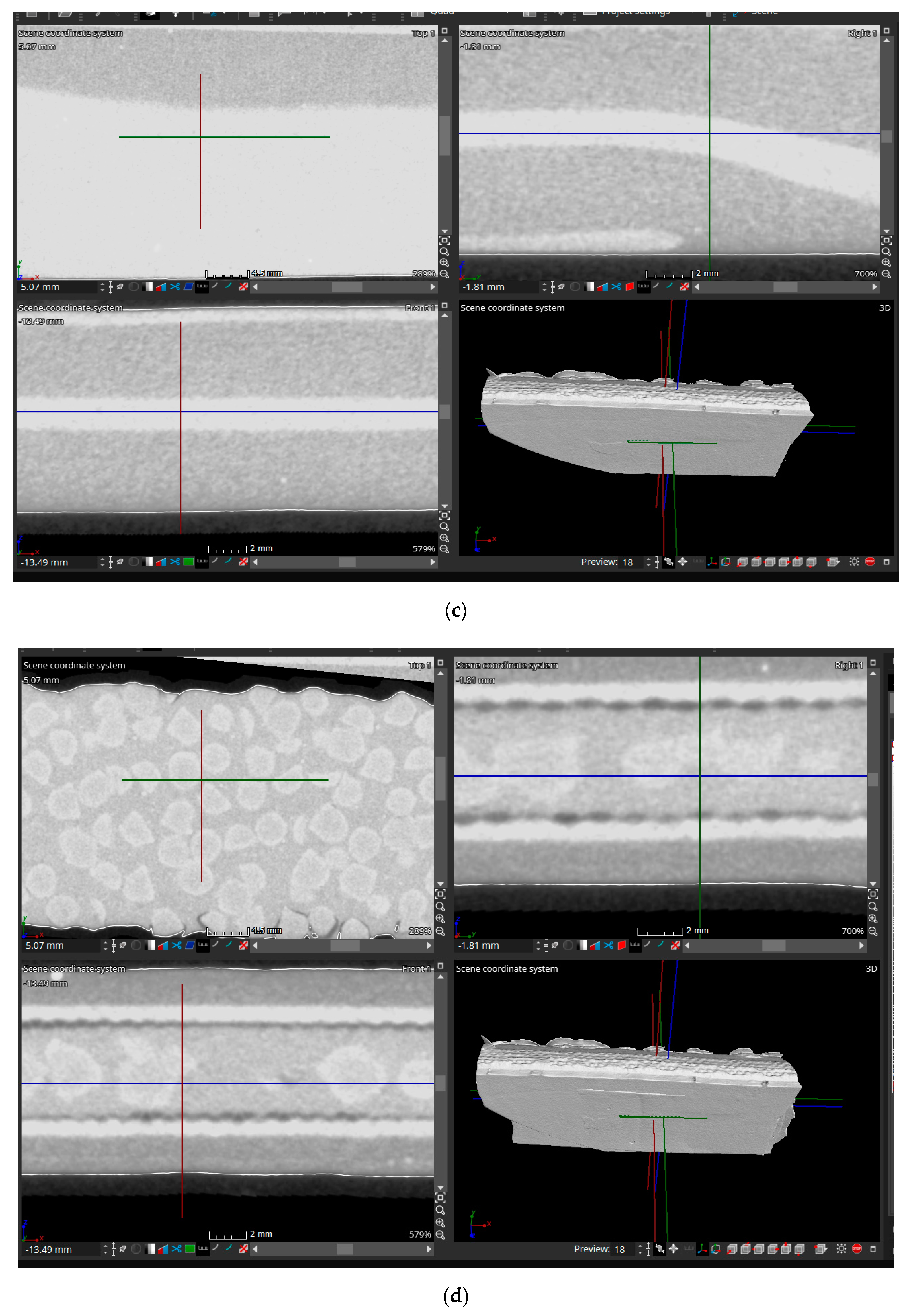

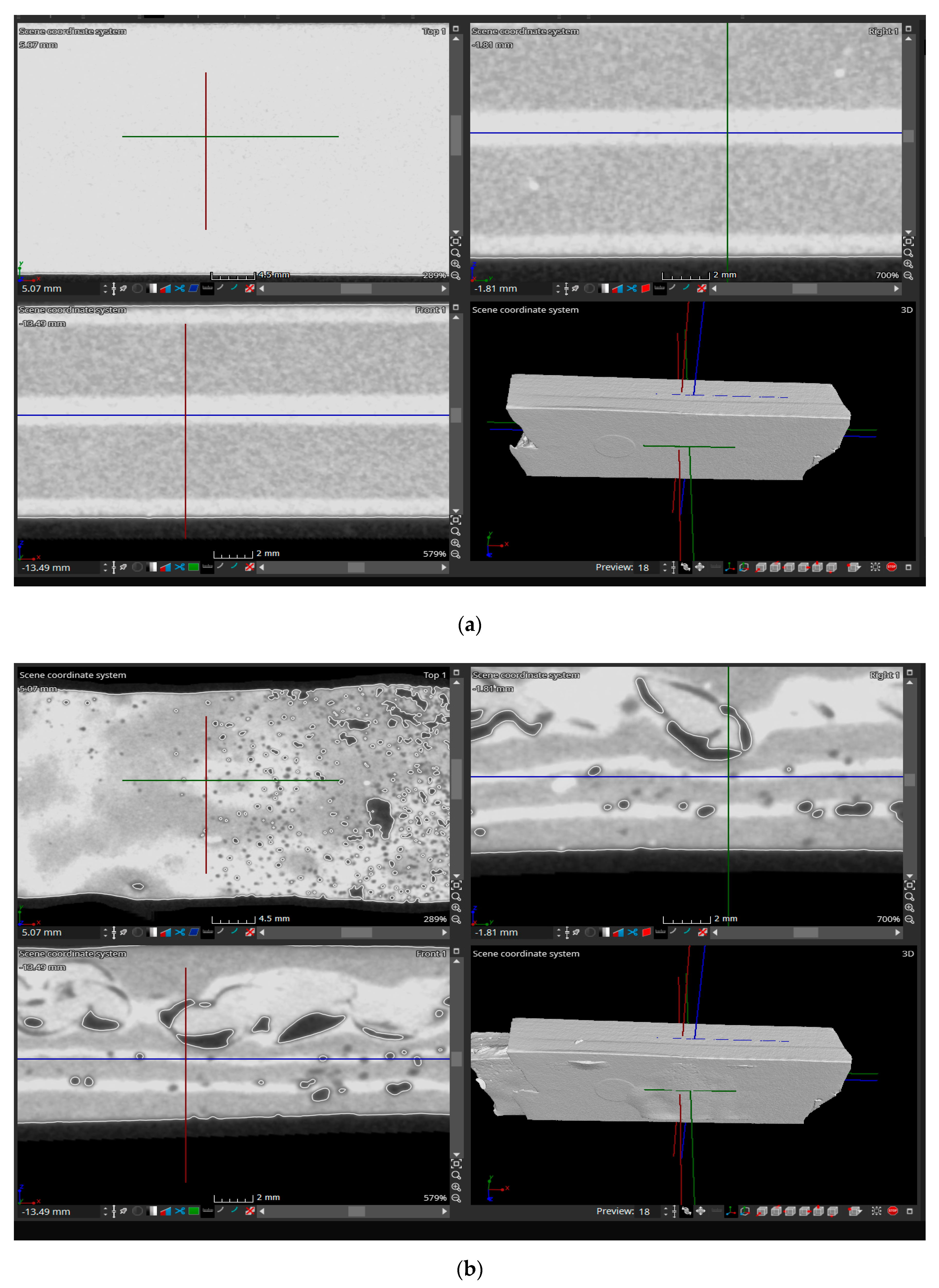

2.2.4. Analysis of the Materials Structure from Samples

3. Results and Discussions

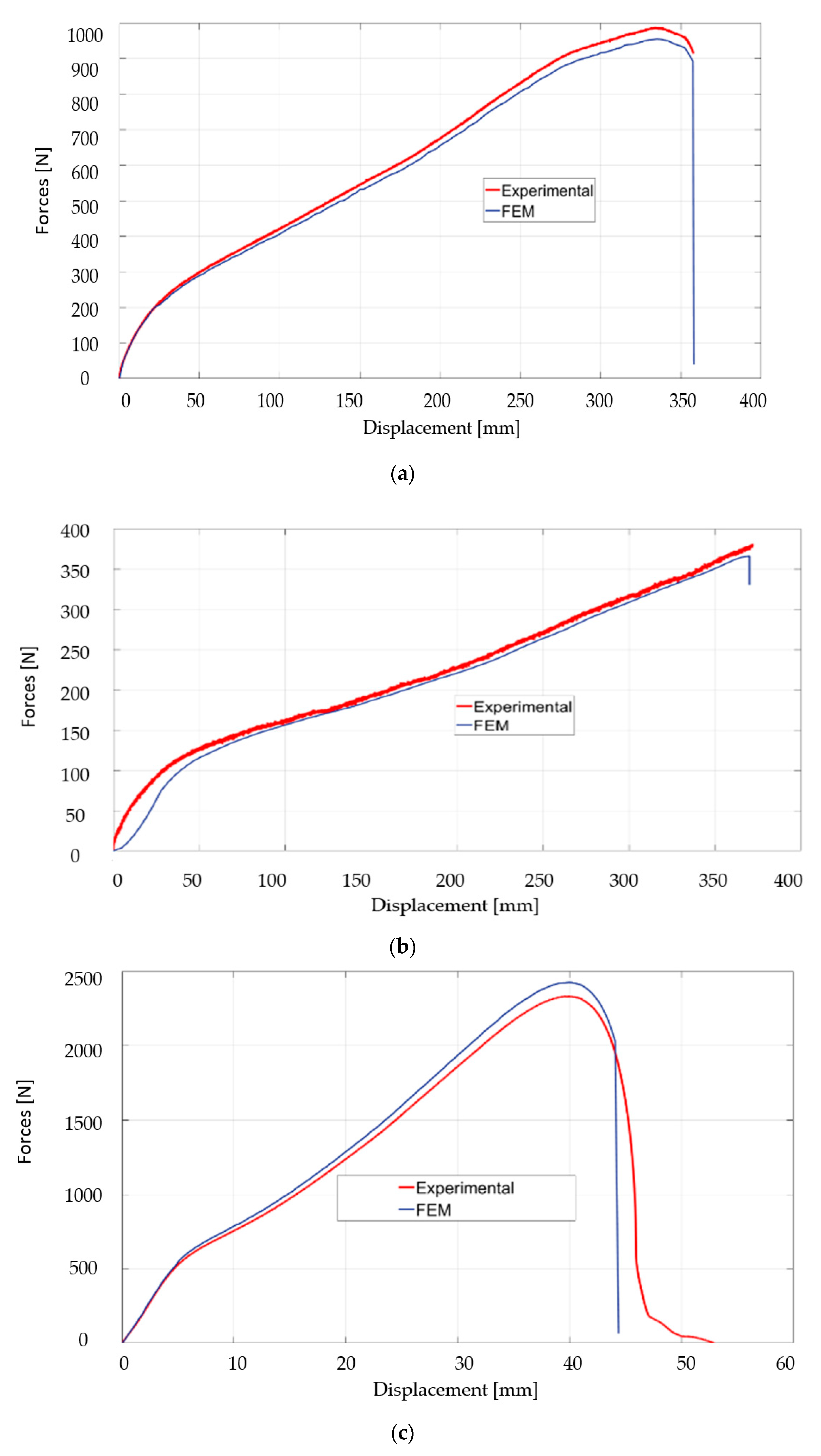

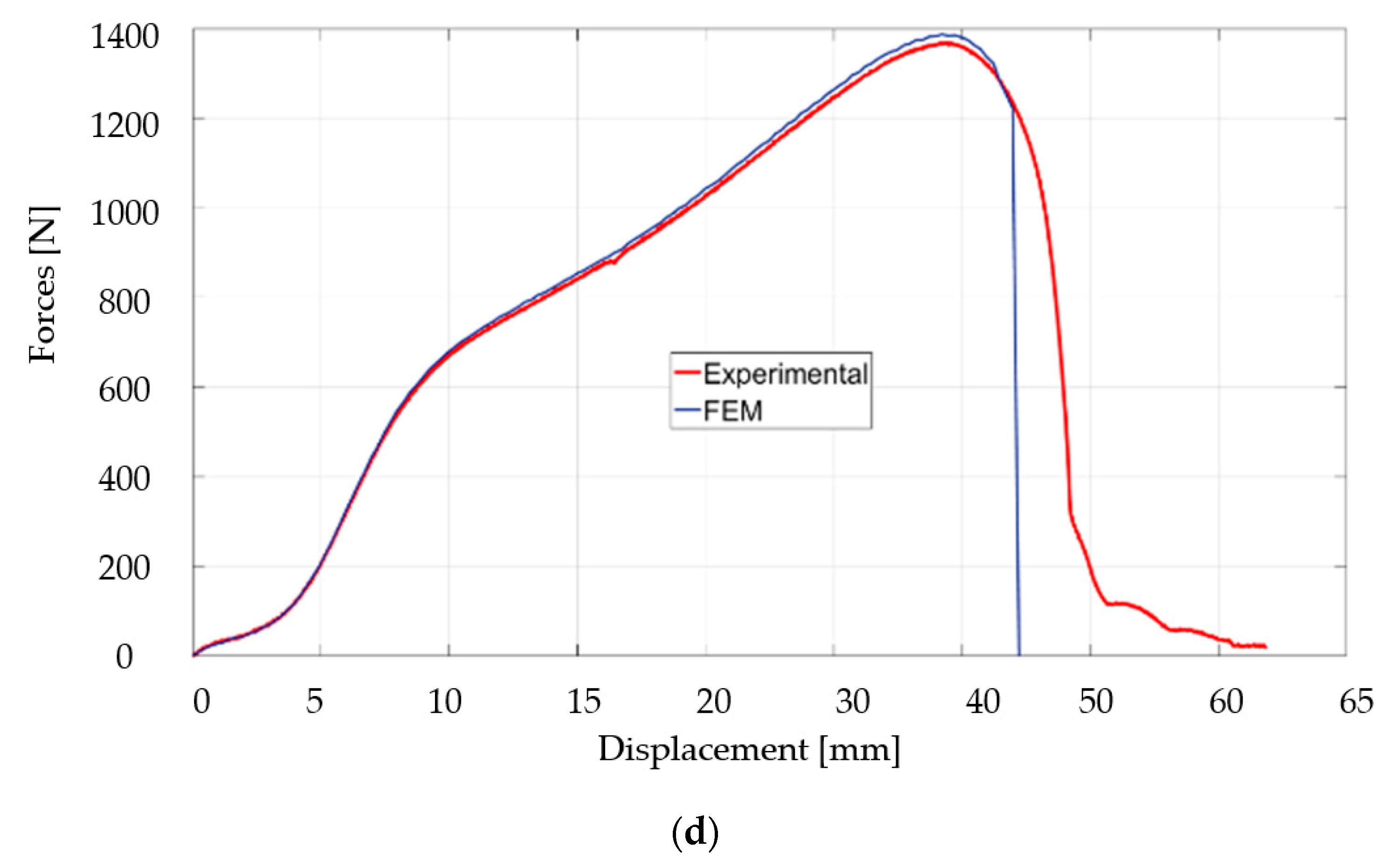

3.1. Determining the Behavior of Conveyor Belts to Traction

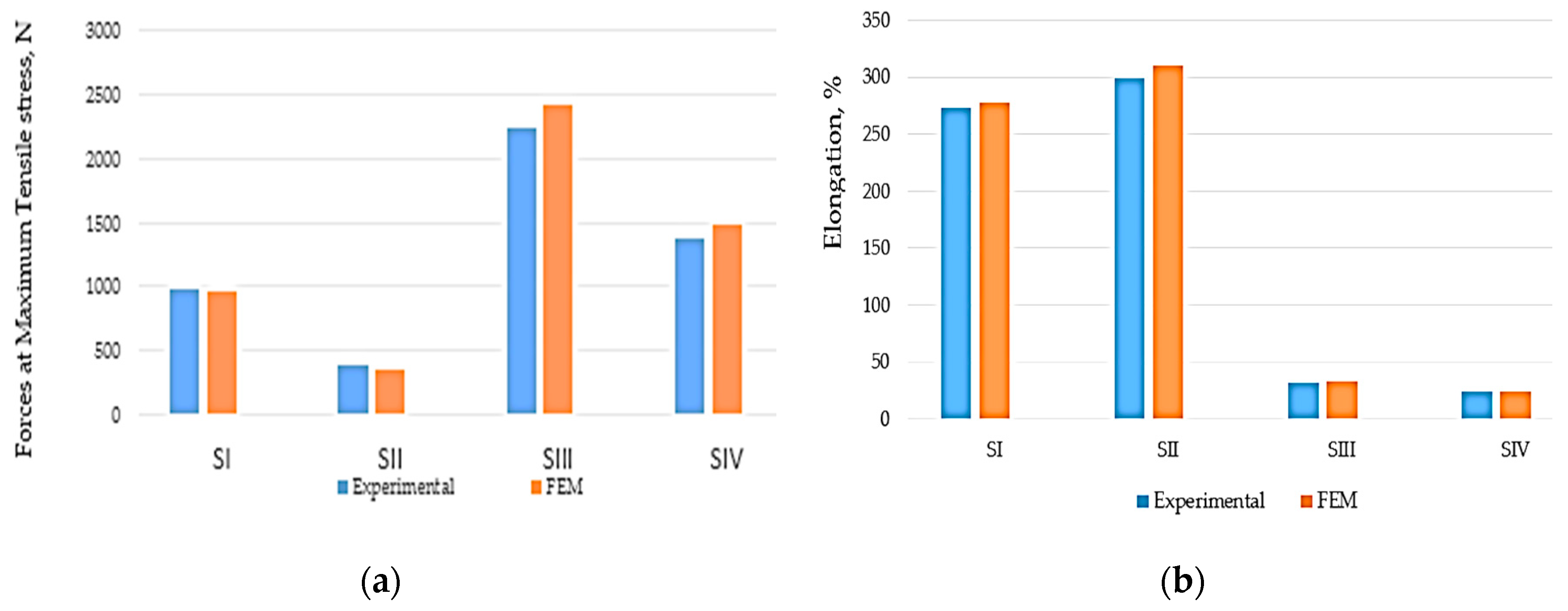

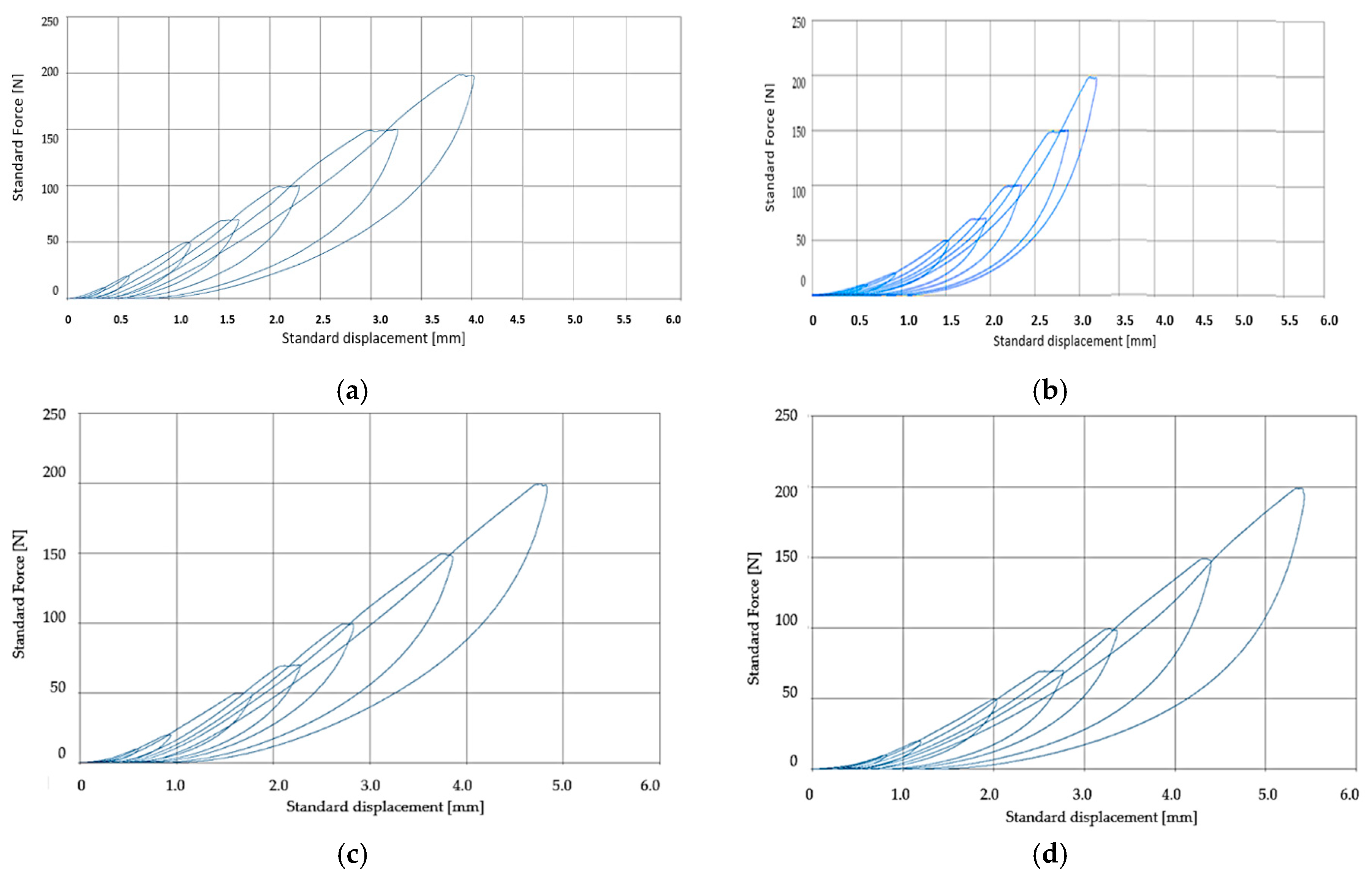

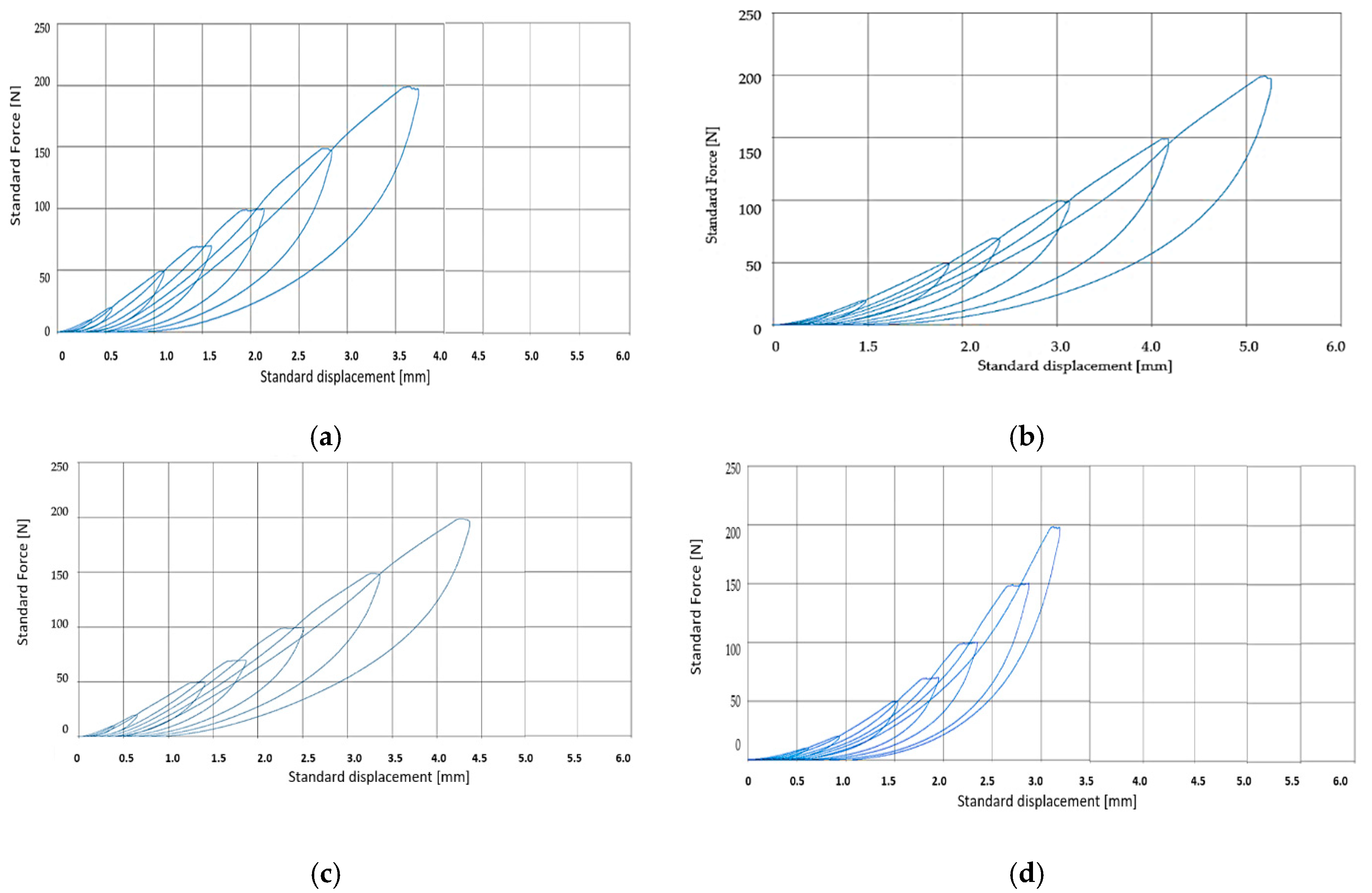

3.2. Determining the Elasticity of the Materials in the Conveyor Belts Subjected to the Accelerated Aging Process

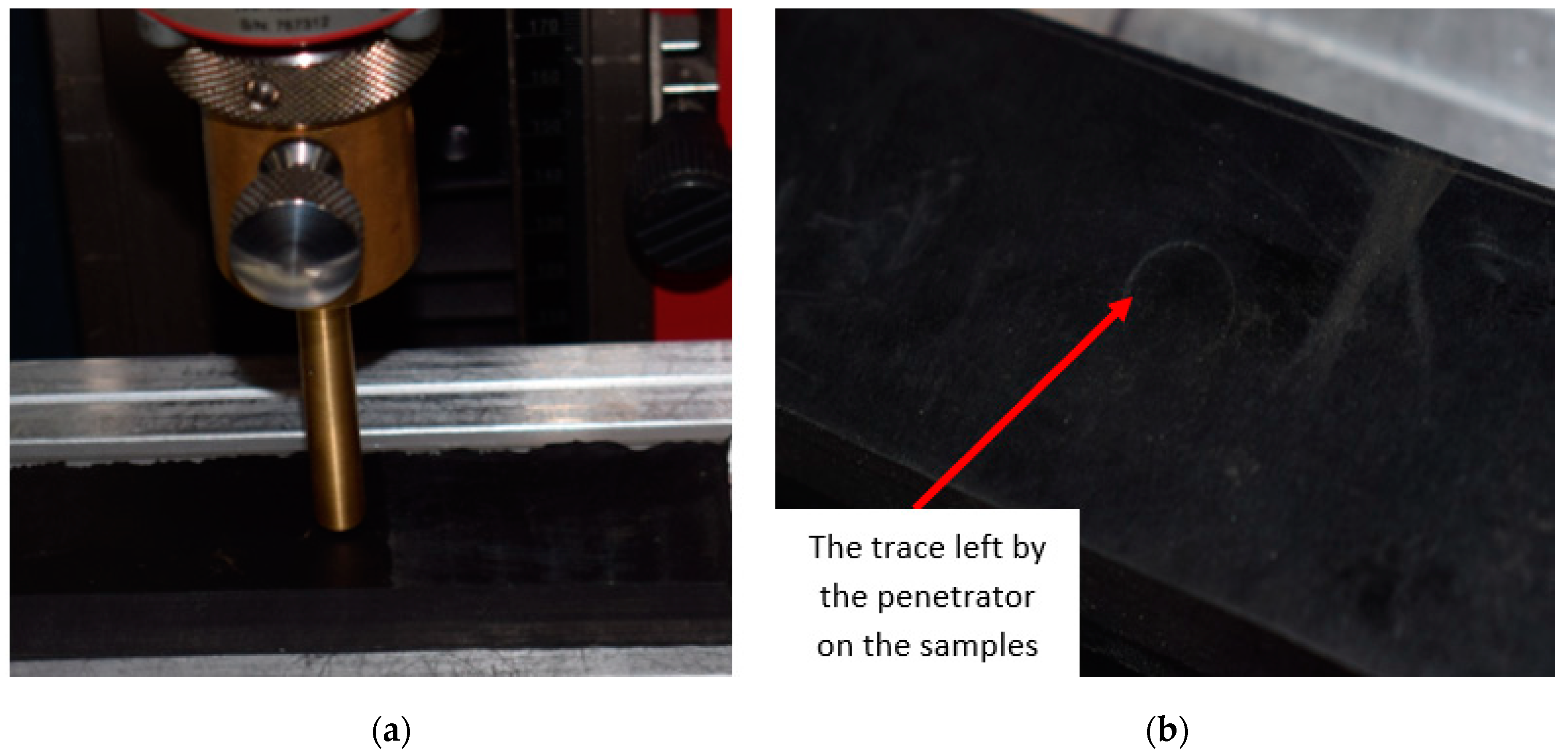

3.3. Determining the Structure of Samples Materials

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Blanco, I. The Rediscovery of POSS: A Molecule Rather than a Filler. Polymers 2018, 10, 904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cavallaro, G.; Lazzara, L.; Milioto, S. Sustainable nanocomposites based on halloysite nanotubes and pectin/polyethylene glycol blend. Polym. Degrad. Stab. 2013, 98, 2529–2536. [Google Scholar] [CrossRef] [Green Version]

- Cañavate, J.; Carrillo, F.; Casas, P. The use of waxes and wetting additives to improve compatibility between HDPE and ground tyre rubber. J. Compos. Mater. 2010, 44, 1233–1245. [Google Scholar] [CrossRef]

- Benkreira, H.; Khan, A.; Horoshenkov, K.V. Sustainable acoustic and thermal insulation materials from elastomeric waste residues. Chem. Eng. Sci. 2011, 66, 4157–4171. [Google Scholar] [CrossRef]

- Mujal-Rosas, R.; Marin-Genesca, M.; Orrit-Prat, J. Dielectric, mechanical and thermal characterization of HDPE composites with ground tire rubber. J. Thermoplast. Compos. Mater. 2011, 25, 537–559. [Google Scholar] [CrossRef]

- Da Silva, I.S.V.; Neto, W.P.F.; Silverio, H.A.; Pasquini, D.; Andrade, M.Z.; Otaguro, H. Mechanical, thermal and barrier properties of pectin/cellulose nanocrystal nanocomposite films and their effect on the storability of strawberries (Fragaria ananassa). Polym. Adv. Technol. 2017, 28, 1005–1012. [Google Scholar] [CrossRef]

- Phatcharasit, K.; Taweepreda, W.; Boonkerd, K.; Kim, J.K. Electrospun Epoxidized Natural Rubber with Poly(vinyl chloride) (ENR-PVC) Nanofibrous for PEMFC Applications. Adv. Mater. Res. 2013, 844, 507–510. [Google Scholar] [CrossRef]

- Biswal, M.; Mohanty, S.; Nayak, S.K.; Babu, S.A. Effect of reactive compatibilizers and impact modifier on the performance characteristics of polycarbonate/poly(acrylonitrile–butadiene–styrene) blends obtained from E-waste. Int. J. Plast. Technol. 2013, 17, 209–225. [Google Scholar] [CrossRef]

- Farzadfar, A.; Khorasani, S.N.; Khalili, S. Blends of recycled polycarbonate and acrylonitrile–butadiene–styrene: Comparing the effect of reactive compatibilizers on mechanical and morphological properties. Polym. Int. 2014, 63, 145–150. [Google Scholar] [CrossRef]

- Jahromi, A.E.; Jahromi, H.R.E.; Hemmati, F.; Saeb, M.R.; Goodarzi, V.; Formela, K. Morphology and mechanical properties of polyamide/clay nanocomposites toughened with NBR/NBR-g-GMA: A comparative study. Compos. Part B Eng. 2016, 90, 478–484. [Google Scholar] [CrossRef]

- Srivabut, C.; Ratanawilai, R.; Hiziroglu, S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubber wood fiber. Constr. Build. Mater. 2018, 162, 450–458. [Google Scholar] [CrossRef]

- Hajibaba, A.; Naderi, G.; Esmizadeh, E.; Ghoreishy, M.H.R. Morphology and dynamic-mechanical properties of PVC/NBR blends reinforced with two types of nanoparticles. J. Compos. Mater. 2012, 48, 131–141. [Google Scholar] [CrossRef]

- Abdul Majid, R.B.; Mat Taib, R. Effects of dynamic vulcanization on tensile, morphological, and swelling properties of poly(vinyl chloride) (PVC)/epoxidized natural rubber (ENR)/(Kenaf core powder) composites. J. Vinyl Addit. Technol. 2016, 22, 206–212. [Google Scholar] [CrossRef]

- Raksaksri, L.; Chuayjuljit, S.; Chaiwutthinan, P.; Boonmahitthisud, A. Use of TBzTD as Noncarcinogenic Accelerator for ENR/SiO2 Nanocomposites: Cured Characteristics, Mechanical Properties, Thermal Behaviors, and Oil Resistance. Int. J. Polym. Sci. 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Sidhharth, S.; Saiyam, D.; Manav, D.; Ratyakshi, N.; Krishna, D.; Balaram, P. Eco-friendly synthesis of PET-based polymeric plasticiser and its application in nitrile-PVC rubber blends. Indian Chem. Eng. 2019, 61, 206–217. [Google Scholar]

- Zhou, X.; Jiang, S.; Yan, X.; Ge, X.; Hong, J.; Sun, B. Processing and Characterization of Reclaimed Rubber Composite Materials. Iran. Polym. J. 2015, 24, 671–678. [Google Scholar] [CrossRef]

- Li, X.X.; Jeong, H.S.; Cho, U.R. A Study on Property Change with Mixing Ratio in NBR / PVC Composites. Elastomers Compos. 2018, 53, 48–51. [Google Scholar] [CrossRef]

- Li, X.X.; Cho, U.R. Modified silica with cellulose/starch by gel-adsorption method as reinforcing materials for SBR latex. Elastomers Compos. 2018, 6, 53. [Google Scholar]

- Bonda, S.; Mohanty, S.; Nayak, S.K. Property evaluation of nanostructured fly ash-reinforced acrylonitrile butadiene styrene nanocomposites. J. Thermoplast. Compos. Mater. 2016, 29, 1611–1626. [Google Scholar] [CrossRef]

- Anandhan, S.; Bhowmick, A.K. Thermoplastic vulcanizates from postconsumer computer plastics/nitrile rubber blends by dynamic vulcanization. J. Mater. Cycles Waste Manag. 2013, 15, 300–309. [Google Scholar] [CrossRef]

- Kunanusont, N.; Samthong, C.; Bowen, F.; Yamaguchi, M.; Somwangthanaroj, A. Effect of Mixing Method on Properties of Ethylene Vinyl Acetate Copolymer/Natural Rubber Thermoplastic Vulcanizates. Polymers 2020, 12, 1739. [Google Scholar] [CrossRef] [PubMed]

- Prioglio, G.; Agnelli, S.; Conzatti, L.; Balasooriya, W.; Schrittesser, B.; Galimberti, M. Graphene Layers Functionalized with A Janus Pyrrole-Based Compound in Natural Rubber Nanocomposites with Improved Ultimate and Fracture Properties. Polymers 2020, 12, 944. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, H.; Thakur, V.K.; Kessler, M.R. Novel low-cost hybrid composites from asphaltene/SBS tri-block copolymer with improved thermal and mechanical properties. J. Mater. Sci. 2016, 51, 2394–2403. [Google Scholar] [CrossRef]

- Thakur, V.K.; Grewell, D.; Thunga, M.; Kessler, M. Novel Composites from Eco-Friendly Soy Flour/SBS Triblock Copolymer. Macromol. Mater. Eng. 2014, 299, 953–958. [Google Scholar] [CrossRef]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, K.V. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020. [Google Scholar] [CrossRef]

- Al-Mosawi, A.; Al-Maamor, M.; Marossy, K.; Yasser, H.; Abdulsada, S. Mechanical Properties of Acrylonitrile-Butadiene Rubber (NBR)/Poly (Vinyl Chloride) Resin Binary Blend. Open Access Libr. J. 2019, 6, 1–7. [Google Scholar] [CrossRef]

- Guo, J.; Wang, X.; Jia, Z.; Wang, J.; Chen, C. Nonlinear Electrical Properties and Field Dependency of BST and Nano-ZnO-Doped Silicone Rubber Composites. Molecules 2018, 23, 3153. [Google Scholar] [CrossRef] [Green Version]

- Al-Maamori, M.H.; Al-Mosawi, A.I.; Yasser, H.A. Mechanical Behavior of NBR-PVC Mixture after Immersion in Different Media. Int. J. Adv. Res. Eng. Technol. 2014, 5, 34–39. [Google Scholar]

- Arayapranee, W.; Prasassarakich, P.; Rempel, G.L. Blends of Poly(Vinyl chloride) (PVC)/Natural Rubber-G-(Styrene-Co-Methyl Methacrylate) for Improved Impact Resistance of PVC. J. Appl. Polym. Sci. 2004, 93, 1666–1672. [Google Scholar] [CrossRef]

- Olsson, R. Analytical prediction of damage due to large mass impact on thin ply composites. Compos. Part A Appl. Sci. Manuf. 2015, 72, 184–192. [Google Scholar] [CrossRef]

- Ismail, N.F.H.; Chai, T.M.; Daik, R.; Othaman, R. Epoxidised natural rubber (ENR)/polyvinyl chloride (PVC)/silica (SiO2) membrane for treating palm oil mill effluents (POME). Plast. Rubber Compos. 2020, 49, 134–140. [Google Scholar] [CrossRef]

- Giannoukos, K.; Salonitis, K. Study of the mechanism of friction on functionally active tribological Polyvinyl Chloride (PVC)—Aggregate composite surfaces. Tribol. Int. 2020, 141. [Google Scholar] [CrossRef]

- Dobrota, D.; Dobrota, G. An innovative method in the regeneration of waste rubber and the sustainable development. J. Clean. Prod. 2018, 172, 3591–3599. [Google Scholar] [CrossRef]

- Faur, C.I.; Niculescu, B. Comparative biomechanical analysis of three implants used in bicondylar tibial fractures. Wien. Med. Wochenschr. 2018, 168, 254–260. [Google Scholar] [CrossRef]

- Dobrota, D. Vulcanization of Rubber Conveyor Belts with Metallic Reinforcemention Using Ultrasounds. Procedia Eng. 2015, 100, 1160–1166. [Google Scholar] [CrossRef] [Green Version]

- Amza, G.; Dobrotã, D.; Semenescu, A.; Iancului, I. Researches Concerning the Ultrasonic Energy’s Influence over the Resistance at Extraction of the Metallic Reinforcemention from the Rubber Matrix. Mater. Plast. 2008, 45, 377–380. [Google Scholar]

- Essawy, H.; El-Sabbagh, S.; Hussein, A.; Tawfik, M. Novel poly(vinyl chloride) based thermoplastic elastomers incorporating vinyl-functionalized silicone rubber. J. Macromol. Sci. Part A 2018, 55, 507–512. [Google Scholar] [CrossRef]

- Xu, H.; Gao, Y.; Li, J.; Wang, H.; Shi, H. Thermal performance and phase transformation of S-alkylated poly(vinyl chloride) comb-like polymers. Polymer 2018, 153, 362. [Google Scholar] [CrossRef]

- Herbert, C.G.; Goncalves, C.C.; Polkowski, R.D.; Nogueira Aguiar, A.N. Biodiesel Resistant PVC/NBR Rubber Composition. U.S. Patent No. 10166863B1, 1 January 2019. [Google Scholar]

- Barghamadi, M.; Ghoreishy, M.H.R.; Karrabi, M.; Mohammadian-Gezaz, S. Investigation on the kinetics of cure reaction of acrylonitrile–butadiene rubber (NBR)/polyvinyl chloride (PVC)/graphene nanocomposite using various models. J. Appl. Polym. Sci. 2020, 137, 48632. [Google Scholar] [CrossRef]

| Materials | The Rubber Compound, phr | |

|---|---|---|

| R1 | R2 | |

| Natural rubber (Standard Indonesia Rubber-20) | 30 | 11 |

| Styrene-butadiene synthetic rubber (SBR-1723 TDAE) | 10 | 29 |

| Poly-butadiene synthetic rubber SKD ND (Nizhnekamsk Russia) | 25 | 25 |

| Reclaimed rubber (ARTEGO Romania) | 20 | 20 |

| Rubber powder with size 100 µm (ARTEGO, Romania) | 15 | 15 |

| Naphtha | 7 | 6 |

| Carbon black HAF 330 | 8 | 8 |

| Antioxidant 4010NA/LG(IPPD) (HENAN, GO BIOTECH, China) | 3 | 3 |

| Stearin | 5 | 6 |

| Vulcanization accelerator DPG (standardQ/CNPC55-2001) | 4 | 4 |

| Sulfur | 3 | 3 |

| Total | 130 | 130 |

| Flexible PVC | Properties | ||||

| Density, g/cm3 | Thermal Conductivity W/(m·K) | Yield Strength MPa | Resistivity Ω·m | Surface Resistivity Ω | |

| 1.1–1.35 | 0.14–0.17 | 10–24.8 | 1012–1015 | 1011–1012 | |

| EP 100 | Material | Strength, N/mm | Elongation, % | Area Weight, g/m2 | Thickness, mm | Adhesion, N/mm | |||

| warp | weft | warp | weft | warp | weft | - | - | - | |

| PES | PA 66 | min. 120 | min. 60 | 23 ± 5 | 30 ± 5 | 350 ± 25 | 0.60 ± 0.15 | min. 10 | |

| Samples | Forces at Maximum Tensile Stress, N (FEM) | Equivalent von Mises Stress, MPa (FEM) | Elongation, % (FEM) | Forces at Maximum Tensile Stress, N (Experimental) | Equivalent von Mises Stress, MPa (Experimental) | Elongation, % (Experimental) |

|---|---|---|---|---|---|---|

| SI | 954.15 | 2.75 | 273.37 | 988.91 | 2.63 | 278.25 |

| SII | 351.01 | 2.82 | 299.93 | 381.57 | 2.85 | 309.89 |

| SIII | 2424.12 | 39.51 | 24.08 | 2232.13 | 39.57 | 24.51 |

| SIV | 1475.43 | 31.06 | 32.21 | 1369.56 | 30.97 | 33.01 |

| Standard Force, N | Standard Displacement, mm | |||||||

|---|---|---|---|---|---|---|---|---|

| SI | SII | SIII | SIV | |||||

| Initial | After Accelerated Aging | Initial | After Accelerated Aging | Initial | After Accelerated Aging | Initial | After Accelerated Aging | |

| 10 | 0.315 | 0.307 | 0.697 | 0.791 | 0.513 | 0.391 | 0.714 | 0.619 |

| 20 | 0.618 | 0.596 | 0.903 | 1.413 | 0.917 | 0.619 | 1.219 | 0.831 |

| 50 | 1.193 | 1.181 | 1.514 | 1.917 | 1.693 | 1.407 | 2.091 | 1.512 |

| 70 | 1.671 | 1.597 | 1.819 | 2.419 | 2.219 | 1.809 | 2.714 | 1.903 |

| 100 | 2.231 | 2.213 | 2.279 | 3.117 | 2.895 | 2.501 | 3.293 | 2.301 |

| 150 | 3.259 | 2.915 | 2.987 | 4.213 | 3.817 | 3.387 | 4.307 | 2.583 |

| 200 | 4.175 | 3.718 | 3.401 | 5.301 | 4.901 | 4.311 | 5.491 | 3.279 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrotă, D.; Petrescu, V.; Dimulescu, C.S.; Oleksik, M. Preparation and Characterization of Composites Materials with Rubber Matrix and with Polyvinyl Chloride Addition (PVC). Polymers 2020, 12, 1978. https://doi.org/10.3390/polym12091978

Dobrotă D, Petrescu V, Dimulescu CS, Oleksik M. Preparation and Characterization of Composites Materials with Rubber Matrix and with Polyvinyl Chloride Addition (PVC). Polymers. 2020; 12(9):1978. https://doi.org/10.3390/polym12091978

Chicago/Turabian StyleDobrotă, Dan, Valentin Petrescu, Cristinel Sabin Dimulescu, and Mihaela Oleksik. 2020. "Preparation and Characterization of Composites Materials with Rubber Matrix and with Polyvinyl Chloride Addition (PVC)" Polymers 12, no. 9: 1978. https://doi.org/10.3390/polym12091978

APA StyleDobrotă, D., Petrescu, V., Dimulescu, C. S., & Oleksik, M. (2020). Preparation and Characterization of Composites Materials with Rubber Matrix and with Polyvinyl Chloride Addition (PVC). Polymers, 12(9), 1978. https://doi.org/10.3390/polym12091978