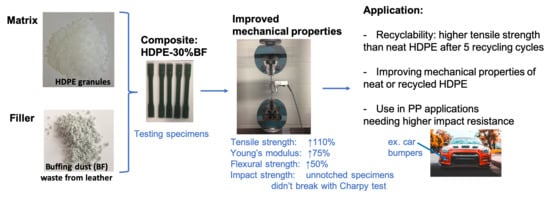

Leather Waste to Enhance Mechanical Performance of High-Density Polyethylene

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical and Morphological Characterization of Leather Buffing Dust

2.3. Composite Preparation and Characterization

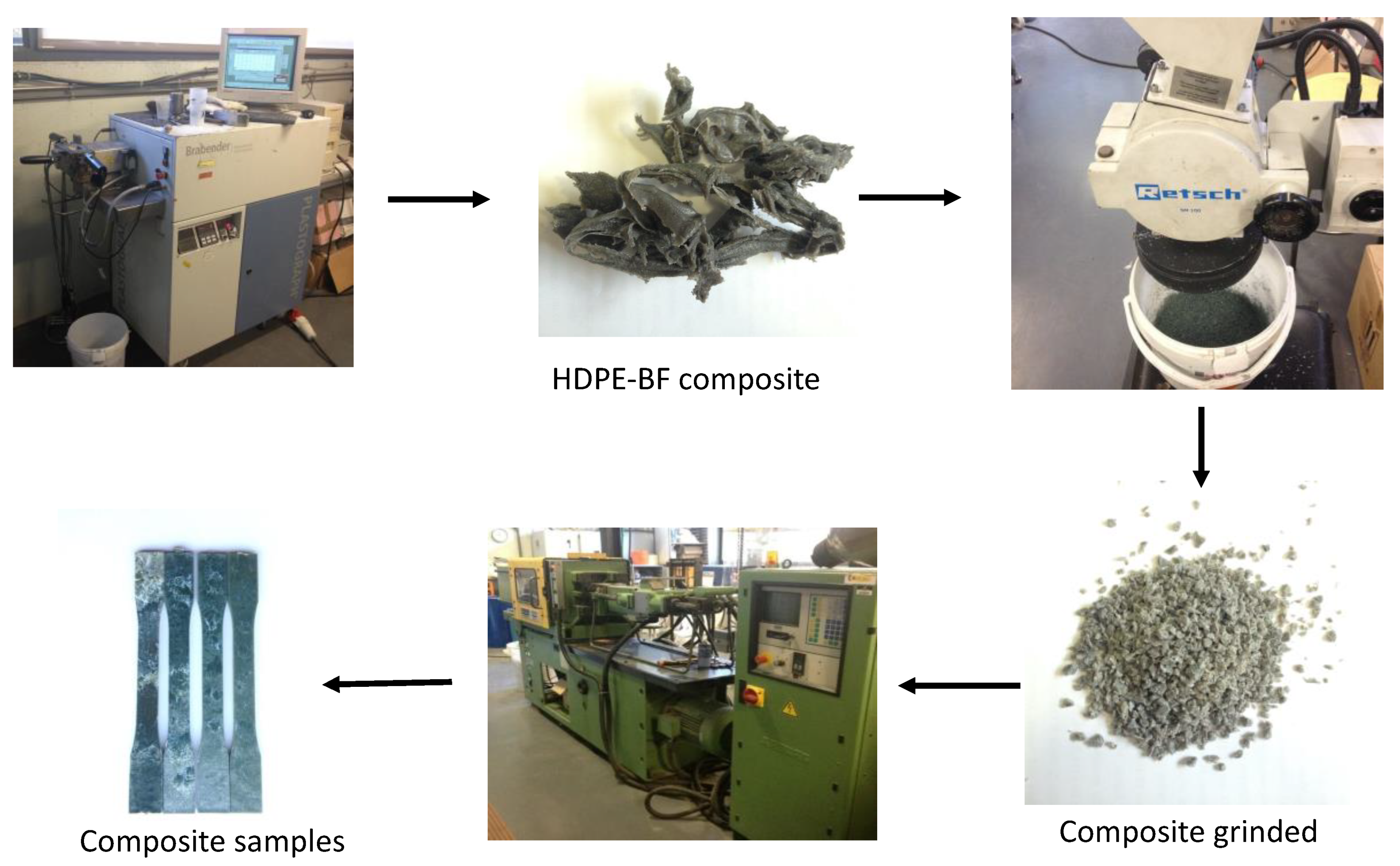

2.4. Recyclability Test of Composite Specimens

3. Results and Discussion

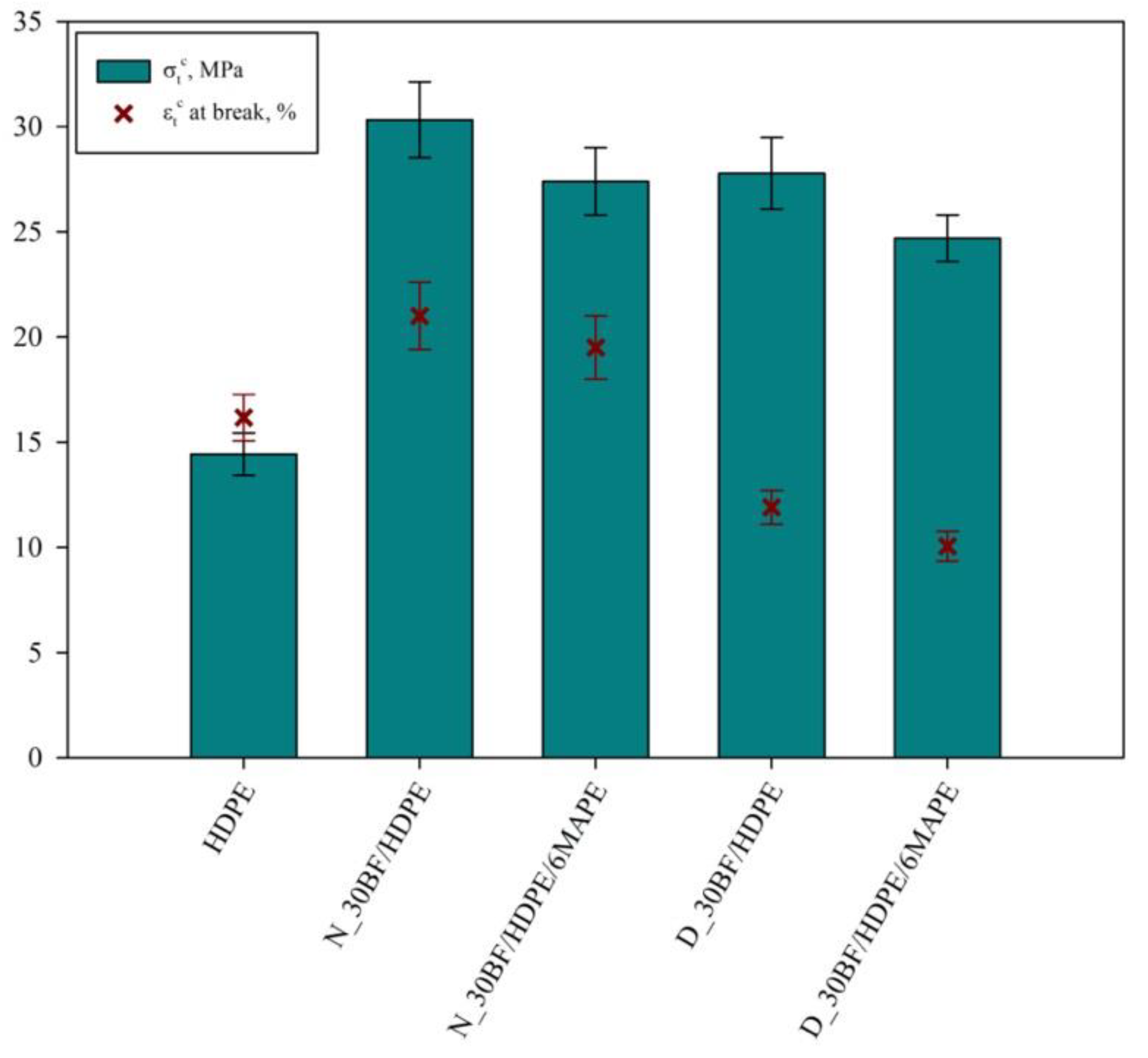

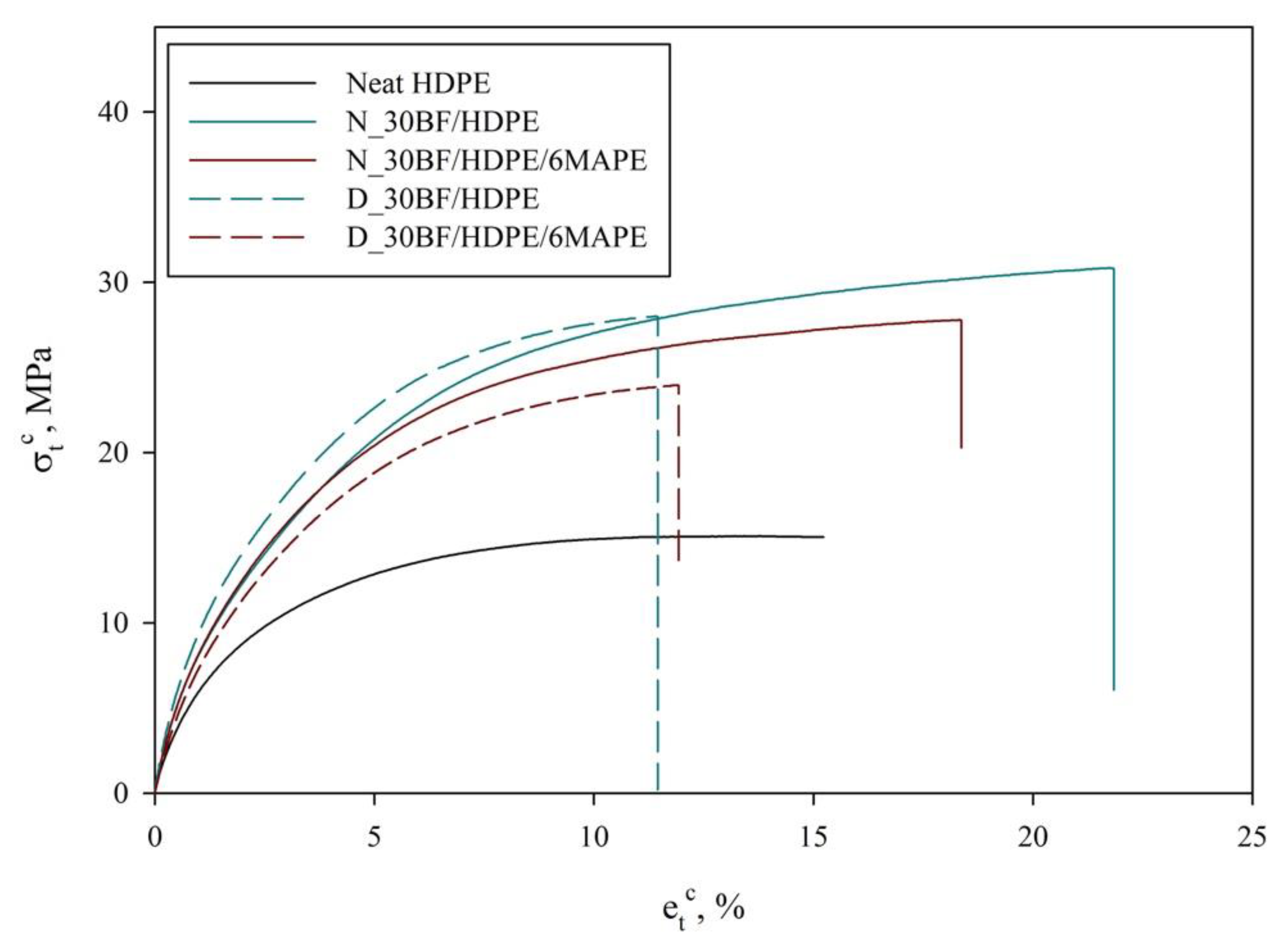

3.1. Effect of MAPE and Degreasing BF on the Mechanical Properties of the Composite

3.2. Mechanical Properties of HDPE Composite with Different Proportions of BF

3.2.1. Tensile Strength at Break and Young’s Modulus

3.2.2. Flexural Strength

3.2.3. Impact Strength

3.3. SEM Images of BF-Reinforced HDPE Composite

3.4. Recyclability Test of the Composite

3.5. Summary of the Main Results Obtained

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lakrafli, H.; Tahiri, S.; Albizane, A.; El Otmani, M.E. Effect of wet blue chrome shaving and buffing dust of leather industry on the thermal conductivity of cement and plaster based materials. Constr. Build. Mater. 2012, 30, 590–596. [Google Scholar] [CrossRef]

- Sekaran, G.; Shanmugasundaram, K.A.; Mariappan, M. Characterization and utilisation of buffing dust generated by the leather industry. J. Hazard. Mater. 1998, 63, 53–68. [Google Scholar] [CrossRef]

- Masilamani, D.; Srinivasan, V.; Ramachandran, R.K.; Gopinath, A.; Madhan, B.; Saravanan, P. Sustainable packaging materials from tannery trimming solid waste: A newparadigm in wealth from waste approaches. J. Clean. Prod. 2017, 164, 885–891. [Google Scholar] [CrossRef]

- Chandra, P.; Kulshreshtha, K. Chromium accumulation and toxicity in aquatic vascular plants. Bot. Rev. 2004, 70, 313–327. [Google Scholar] [CrossRef]

- Swamalatha, S.; Srinivasulu, T.; Srimurali, M.; Sekaran, G. Safe disposal of toxic chrome buffing dust generated from leather industries. J. Hazard. Mater. 2008, 150, 290–299. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular is the Global Economy?: An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q.; Li, L. Reuse of leather shavings as a reinforcing filler for poly (vinyl alcohol). J. Thermoplast. Compos. Mater. 2016, 29, 327–343. [Google Scholar] [CrossRef]

- Joseph, S.; Ambone, T.S.; Salvekar, A.V.; Jaisankar, S.N.; Saravanan, P.; Deenadayalan, E. Processing and characterization of waste leather based polycaprolactone biocomposites. Polym. Compos. 2017, 38, 2889–2897. [Google Scholar] [CrossRef]

- Hemalatha, D.; Kowsalya, S.; Fathima, N.N.; Sowmya, S.; Rao, J.R. Natural Fibers Reinforced Chrome Shaving Composites for Sound Absorption Applications. J. Am. Leather Chem. Assoc. 2018, 113, 352–357. [Google Scholar]

- Bufalo, G.; Florio, C.; Cinelli, G.; Lopez, F.; Cuomo, F.; Ambrosone, L. Principles of minimal wrecking and maximum separation of solid waste to innovate tanning industries and reduce their environmental impact: The case of paperboard manufacture. J. Clean. Prod. 2018, 174, 324–332. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thanikaivelan, P.; Krishnaraj, K.; Chandrasekaran, B. Transforming Chromium Containing Collagen Wastes into Flexible Composite Sheets Using Cellulose Derivatives: Structural, Thermal, and Mechanical Investigations. Polym. Compos. 2011, 32, 1009–1017. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thanikaivelan, P.; Murali, R.; Chandrasekaran, B. Preparation and Characterization of Composite Sheets from Collagenous and Chromium-Collagen Complex Wastes Using Polyvinylpyrrolidone: Two Problems, One Solution. Waste Biomass Valoriz. 2010, 1, 347–355. [Google Scholar] [CrossRef]

- Liu, B.; Li, Y.; Wang, Q.; Bai, S. Green fabrication of leather solid waste/thermoplastic polyurethanes composite: Physically de-bundling effect of solid-state shear milling on collagen bundles. Compos. Sci. Technol. 2019, 181, 107674. [Google Scholar] [CrossRef]

- Rajaram, J.; Rajnikanth, B.; Gnanamani, A. Preparation, Characterization and Application of Leather Particulate-Polymer Composites (LPPCs). J. Polym. Environ. 2009, 17, 181–186. [Google Scholar] [CrossRef]

- Cavalcante, D.G.S.M.; Gomes, A.S.; Santos, R.J.; Kerche-Silva, L.E.; Danna, C.S.; Yoshihara, E.; Job, A.E. Composites Produced from Natural Rubber and Chrome-Tanned Leather Wastes: Evaluation of their In Vitro Toxicological Effects for Application in Footwear and Textile Industries. J. Polym. Environ. 2018, 26, 980–988. [Google Scholar] [CrossRef]

- Benitez-Lozano, A.J.; Urrego-Yepes, W.; Velasquez-Restrepo, S.; Giraldo-Vasquez, D. Rheological behaviour of conventional mixtures of natural rubber and leather wastes. Dyna 2018, 93, 549–555. [Google Scholar] [CrossRef]

- Ambone, T.; Joseph, S.; Deenadayalan, E.; Mishra, S.; Jaisankar, S.; Saravanan, P. Polylactic Acid (PLA) Biocomposites Filled with Waste Leather Buff (WLB). J. Polym. Environ. 2017, 25, 1099–1109. [Google Scholar] [CrossRef]

- Hittini, W.; Mourad, A.-H.I.; Abu-Jdayil, B. Cleaner production of thermal insulation boards utilizing buffing dustwaste. J. Clean. Prod. 2019, 236, 117603. [Google Scholar] [CrossRef]

- Sivakumar, V.; Swathi, T.R.; Mohan, R.; Mandal, A.B. Preparation and characterization of nano-reinforced leather waste fiber-epoxy nano composite. J. Am. Leather Chem. Assoc. 2015, 110, 401–408. [Google Scholar]

- Singh, N.; Singh, R.; Ahuja, I.P.S. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Strangl, M.; Ortner, E.; Buettner, A. Evaluation of the efficiency of odor removal from recycled HDPE using a modified recycling process. Resour. Conserv. Recycl. 2019, 146, 89–97. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Ferrer, L.; Puig, R.; Fullana-i-Palmer, P. Are functional fillers improving environmental behavior of plastics? A review on LCA studies. Sci. Total Environ. 2018, 626, 927–940. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers 2018, 10, 286. [Google Scholar] [CrossRef] [PubMed]

- Zheng, B.; Guan, L.; Zhang, W.; Gu, J.; Tu, D.; Hu, C. Production and Characterization of Large-Scale Recycled Newspaper Enhanced HDPE Composite Laminates. Polymers 2020, 12, 851. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Ferrer, L.; Fullana-i-Palmer, P. Influence of end-of-life allocation, credits and other methodological issues in LCA of compounds: An in-company circular economy case study on packaging. J. Clean. Prod. 2019, 212, 925–940. [Google Scholar] [CrossRef]

- Wang, H.; Lin, F.; Qiu, P.; Liu, T. Effects of Extractives on Dimensional Stability, Dynamic Mechanical Properties, Creep, and Stress Relaxation of Rice Straw/High-Density Polyethylene Composites. Polymers 2018, 10, 1176. [Google Scholar] [CrossRef]

- Agayev, S.; Ozdemir, O. Fabrication of high density polyethylene composites reinforced with pine cone powder: Mechanical and low velocity impact performances. Mater. Res. Express 2019, 6, 045312. [Google Scholar] [CrossRef]

- Castiello, D.; Chiellini, E.; Cinelli, P.; D’Antone, S.; Puccini, M.; Salvadori, M.; Seggiani, M. Polyethylene-Collagen Hydrolizate Thermoplastic Blends: Thermal and Mechanical Properties. J. Appl. Polym. Sci. 2009, 114, 3827–3834. [Google Scholar] [CrossRef]

- Puccini, M.; Seggiani, M.; Castiello, D.; Calvanese, G.; Vitolo, S. Novel thermoplastic materials from wastes of the leather industry. Appl. Mech. Mater. 2014, 467, 41–48. [Google Scholar] [CrossRef]

- Puccini, M.; Seggiani, M.; Vitolo, S. Polyethylene and Hydrolyzed Collagen Blend Films Produced by Blown Extrusion. Chem. Eng. Trans. 2015, 43, 1705–1710. [Google Scholar] [CrossRef]

- Musa, E.T.; Hamza, A.; Ahmed, A.S.; Ishiuku, U.S. Investigation of the Mechanical and Morphological Properties of High-Density Polyethylene (HDPE)/Leather Waste Composites. J. Appl. Chem. 2017, 10, 48–58. [Google Scholar] [CrossRef]

- Reixach, R.; Franco-Marques, E.; El Mansouri, N.-E.; de Cartagena, F.; Arbat, G.; Espinach, F.X.; Mutje, P. Micromechanics of Mechanical, Thermomechanical, and Chemi-Thermomechanical Pulp from Orange Tree Pruning as Polypropylene Reinforcement: A Comparative Study. Bioresources 2013, 8, 3231–3246. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Mendez, J.A.; Vilaseca, F.; Delgado-Aguilar, M.; Mutje, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene composites: Flexural characterisation, impact behaviour and water uptake properties. Compos. Part B Eng. 2016, 97, 176–182. [Google Scholar] [CrossRef]

- Madera-Santana, T.J.; Torres, A.C.; Lucero, A.M. Extrusion and mechanical characterization of PVC-leather fiber composites. Polym. Compos. 1998, 19, 431–439. [Google Scholar] [CrossRef]

- Mohamed, O.A.; El Sayed, N.H.; Abdelhakim, A.A. Preparation and Characterization of Polyamide-Leather Wastes Polymer Composites. J. Appl. Polym. Sci. 2010, 118, 446–451. [Google Scholar] [CrossRef]

- Cardona, N.; Velasquez, S.; Giraldo, D. Characterization of Leather Wastes from Chrome Tanning and its Effect as Filler on the Rheometric Properties of Natural Rubber Compounds. J. Polym. Environ. 2017, 25, 1190–1197. [Google Scholar] [CrossRef]

- Salem, S.; Oliver-Ortega, H.; Espinach, F.; Ben Hamed, K.; Nasri, N.; Alcalà, M.; Mutjé, P. Study on the Tensile Strength and Micromechanical Analysis of Alfa Fibers Reinforced High Density Polyethylene Composites. Fibers Polym. 2019, 20, 602–610. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Tselios, C.; Bikiaris, D.; Savidis, P.; Panayiotou, C.; Larena, A. Glass-fiber reinforcement of in situ compatibilized polypropylene/polyethylene blends. J. Mater. Sci. 1999, 34, 385–394. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, J.; Tu, D.; Guan, L.; Hu, C. Efficient hydrophobic modification of old newspaper and its application in paper fiber reinforced composites. Polymers 2019, 11, 842. [Google Scholar] [CrossRef]

- Seggiani, M.; Altieri, R.; Puccini, M.; Stefanelli, E.; Esposito, A.; Castellani, F.; Stanzione, V.; Vitolo, S. Polycaprolactone-collagen hydrolysate thermoplastic blends: Processability and biodegradability/compostability. Polym. Degrad. Stab. 2018, 150, 13–24. [Google Scholar] [CrossRef]

- Karthiga, C.R.; Kamaraj, C.; Lakshmi, S.; Rose, C. Chrome –Tanned Leather Buffing Dust as Bitumen Modifier For The Design Of Dense Graded Bituminous Concrete. Int. J. Appl. Eng. Res. 2015, 10, 326–331. [Google Scholar]

- Ramaraj, B. Mechanical and thermal properties of ABS and leather waste composites. J. Appl. Polym. Sci. 2006, 101, 3062–3066. [Google Scholar] [CrossRef]

- Mutjé, P.; Vallejos, M.E.; Gironès, J.; Vilaseca, F.; López, A.; López, J.P.; Méndez, J.A. Effect of maleated polypropylene as coupling agent for polypropylene composites reinforced with hemp strands. J. Appl. Polym. Sci. 2006, 102, 833–840. [Google Scholar] [CrossRef]

- Guettler, B.E.; Moresoli, C.; Simon, L.C. Mechanical properties and crack propagation of soy-polypropylene composites. J. Appl. Polym. Sci. 2013, 130, 175–185. [Google Scholar] [CrossRef]

- Espinach, F.; Delgado-Aguilar, M.; Puig, J.; Julian, F.; Boufi, S.; Mutjé, P. Flexural properties of fully biodegradable alpha-grass fibers reinforced starch-based thermoplastics. Compos. Part B Eng. 2015, 81, 98–106. [Google Scholar] [CrossRef]

- Gironès, J.; Lopez, J.; Vilaseca, F.; Bayer, J.; Herrera-Franco, P.; Mutjé, P. Biocomposites from Musa textilis and polypropylene: Evaluation of flexural properties and impact strength. Compos. Sci. Technol. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Julian, F.; Alberto Mendez, J.; Espinach, F.X.; Verdaguer, N.; Mutje, P.; Vilaseca, F. Bio-based composites from stone groundwood applied to new product development. Bioresources 2012, 7, 5829–5842. [Google Scholar] [CrossRef]

- Civancik-uslu, D.; Puig, R.; Voigt, S.; Walter, D.; Fullana-i-palmer, P. Improving the production chain with LCA and eco-design: Application to cosmetic packaging. Resour. Conserv. Recycl. 2019, 151, 104475. [Google Scholar] [CrossRef]

- Villetti, M.; Crespo, J.; Soldi, M.; Pires, A.; Borsali, R.; Soldi, V. Thermal Degradation of Natural Polymers. J. Therm. Anal. Calorim. 2002, 67, 295–303. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.; Julian, F.; del Rey, R.; Mendez, J.; Mutje, P. Estimation of the interfacial shears strength, orientation factor and mean equivalent intrinsic tensile strength in old newspaper fiber/polypropylene composites. Compos. Part B Eng. 2013, 50, 232–238. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Pèlach, M.-A.; Mutjé, P.; Fullana-i-Palmer, P. Are Cellulose Nanofibers a solution for a more circular economy of paper products? Environ. Sci. Technol. 2015, 15, 629–637. [Google Scholar] [CrossRef] [PubMed]

- Kalaprasad, G.; Joseph, K.; Thomas, S.; Pavithran, C. Theoretical modelling of tensile properties of short sisal fibre-reinforced low-density polyethylene composites. J. Mater. Sci. 1997, 32, 4261–4267. [Google Scholar] [CrossRef]

- National Georaphic Recycling Polymer Plastics Guide. 2018. Available online: https://blog.nationalgeographic.org/2018/04/04/7-things-you-didnt-know-about-plastic-and-recycling/ (accessed on 13 July 2020).

- Polymer Search. 2020. Available online: http://www.polymer-search.com/recycling-polymer-plastics.html (accessed on 13 July 2020).

| Tests | Values | Reference Data | |

|---|---|---|---|

| Ash (wt%) | 12.1 | 12.3%, 12.86%, 12.86%, 12.86% | [8,17,34,35] |

| Chromium oxide (wt%) | 4.7 | 3.14%, 3.41%, 3.41% | [8,17,34] |

| Fatty substances (wt%) | 7.9 | 1.97% | [34] |

| Nitrogen (wt%) | 10.3 | 7.03%, 9.71%, 9.71% | [17,34,36] |

| Protein (wt%) | 57.5 | 54.58%, 54.58% | [17,34] |

| Moisture (wt%) | 50.9 | 14%, 7.9%, 7.92%, 7.92% | [8,17,34,35] |

| pH | 5.25 | 3.8, 4.15, 4.5 | [8,17,35] |

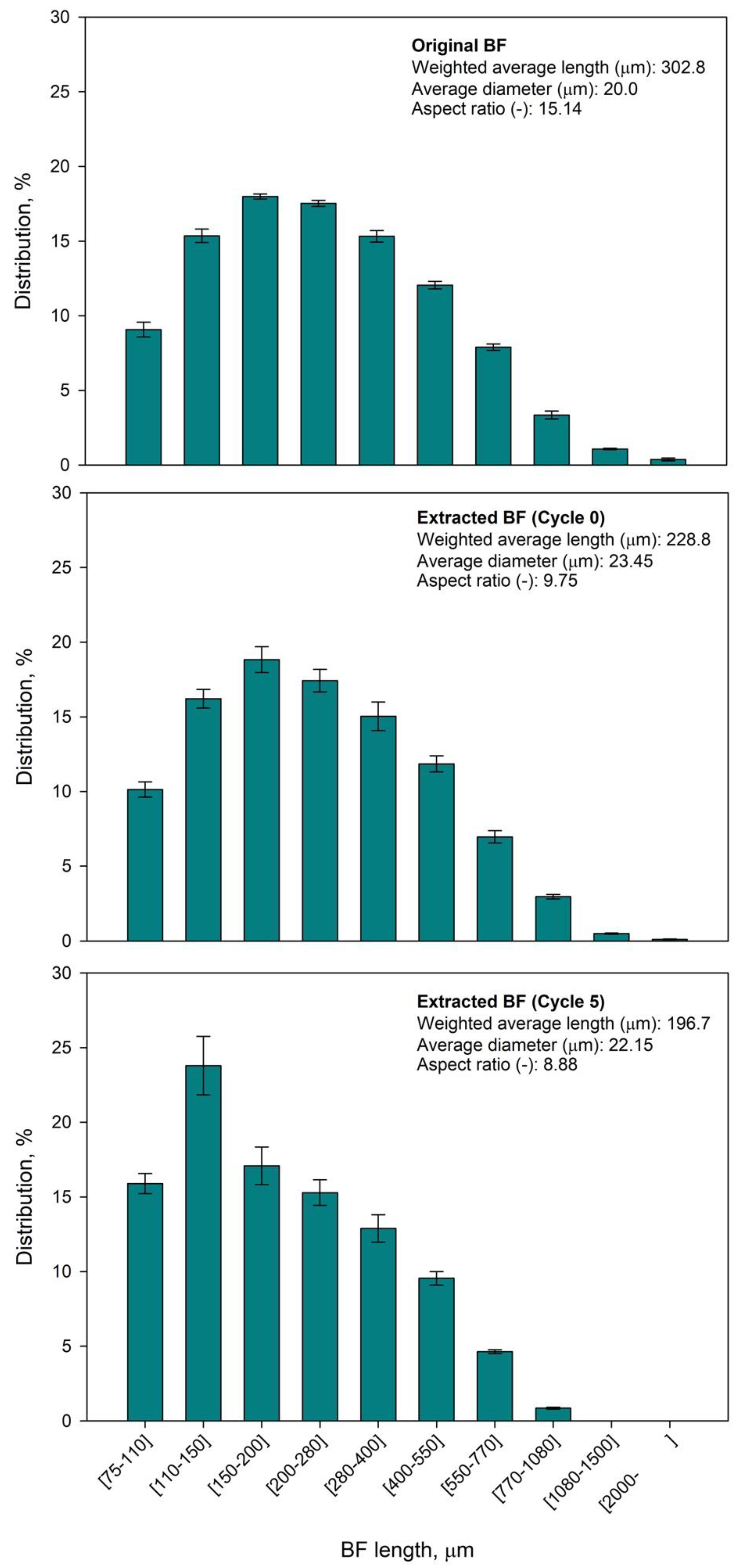

| Length Weighted in Length (µm) | Diameter (µm) | Fine Elements (%) | |

|---|---|---|---|

| Original BF | 302.8 ± 1.2 | 19.98 ± 0.13 | 50.7 ± 0.7 |

| Extracted BF | 228.8 ± 12.5 | 23.45 ± 0.40 | 66.8 ± 2.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiliç, E.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, X.; Fullana-i-Palmer, P.; Puig, R. Leather Waste to Enhance Mechanical Performance of High-Density Polyethylene. Polymers 2020, 12, 2016. https://doi.org/10.3390/polym12092016

Kiliç E, Tarrés Q, Delgado-Aguilar M, Espinach X, Fullana-i-Palmer P, Puig R. Leather Waste to Enhance Mechanical Performance of High-Density Polyethylene. Polymers. 2020; 12(9):2016. https://doi.org/10.3390/polym12092016

Chicago/Turabian StyleKiliç, Eylem, Quim Tarrés, Marc Delgado-Aguilar, Xavier Espinach, Pere Fullana-i-Palmer, and Rita Puig. 2020. "Leather Waste to Enhance Mechanical Performance of High-Density Polyethylene" Polymers 12, no. 9: 2016. https://doi.org/10.3390/polym12092016

APA StyleKiliç, E., Tarrés, Q., Delgado-Aguilar, M., Espinach, X., Fullana-i-Palmer, P., & Puig, R. (2020). Leather Waste to Enhance Mechanical Performance of High-Density Polyethylene. Polymers, 12(9), 2016. https://doi.org/10.3390/polym12092016