Copernicia Prunifera Leaf Fiber: A Promising New Reinforcement for Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

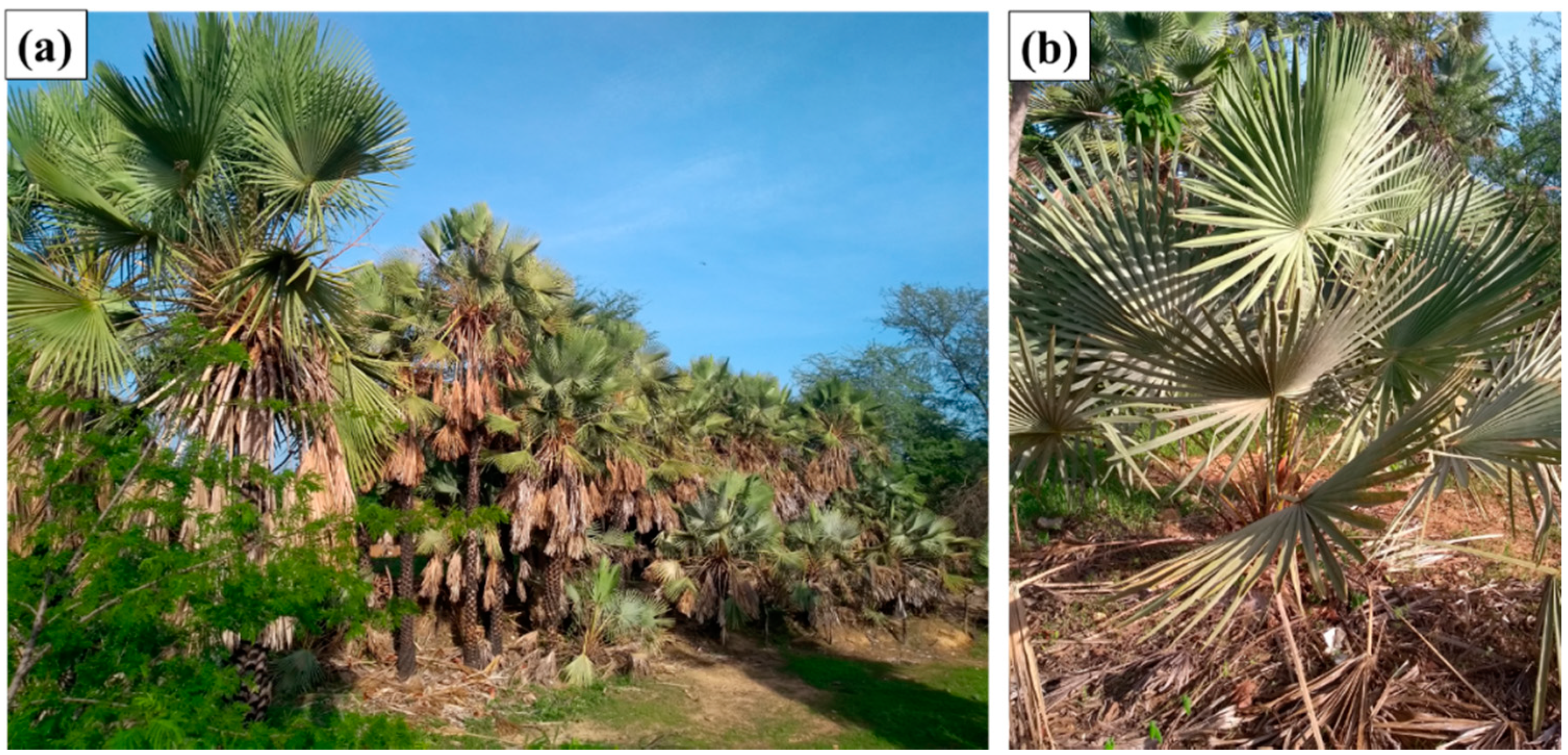

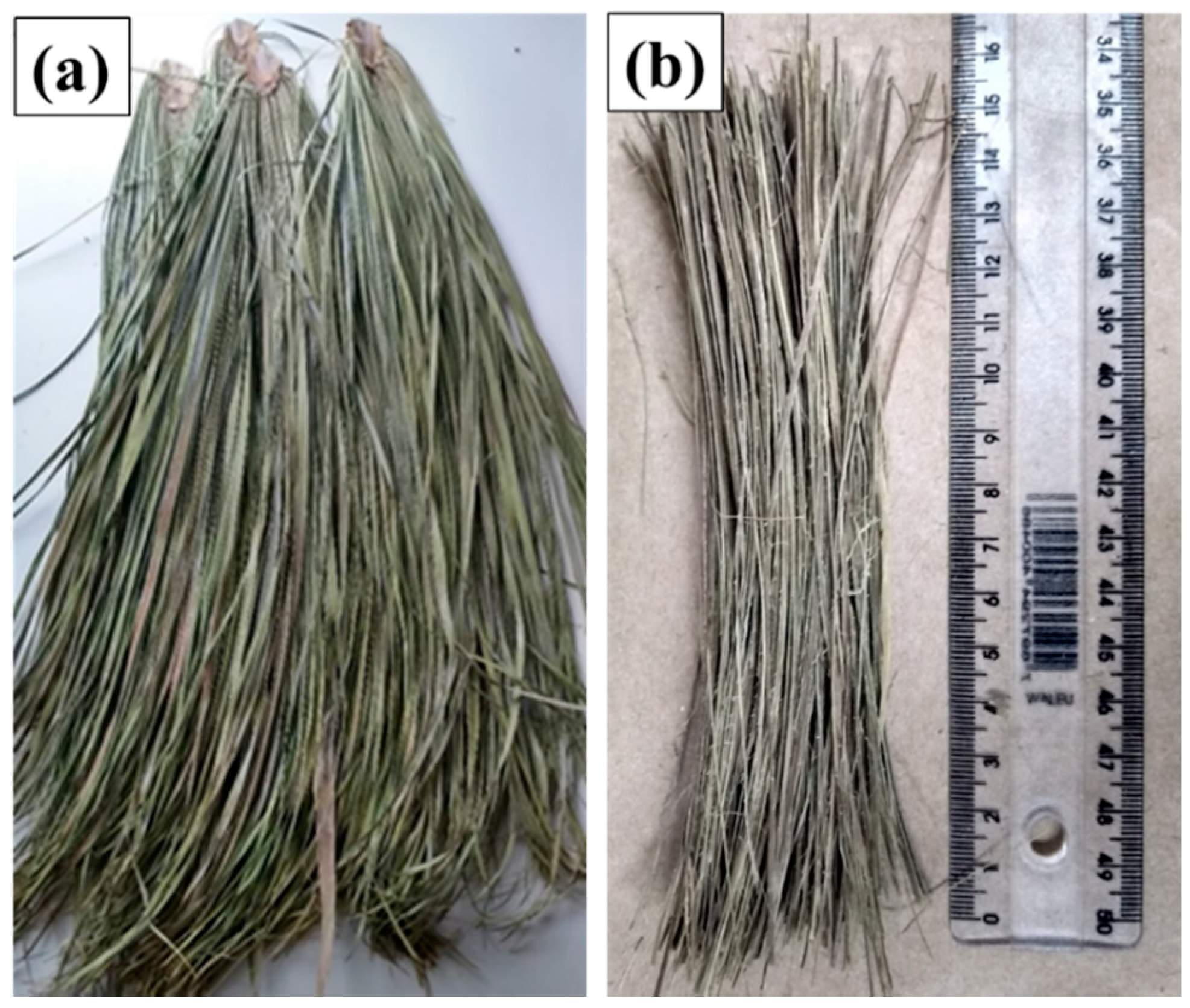

2.1. Materials

2.2. Composites Processing

2.3. Pullout Test

2.4. Tensile Test

2.5. Izod Impact Test

2.6. FTIR Analysis

2.7. Thermal Analysis (TG/DTG)

2.8. Differential Scanning Calorimetry (DSC)

2.9. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

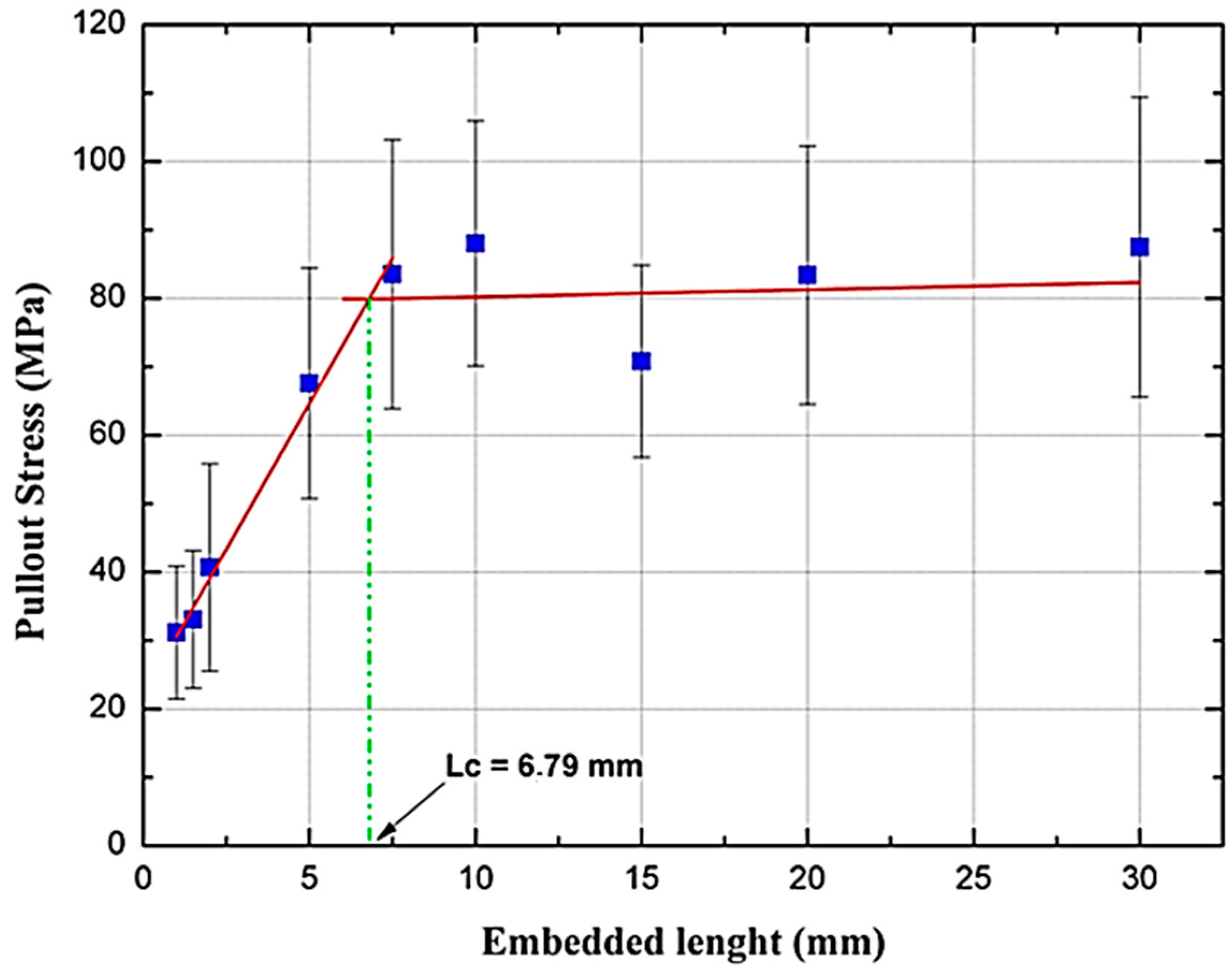

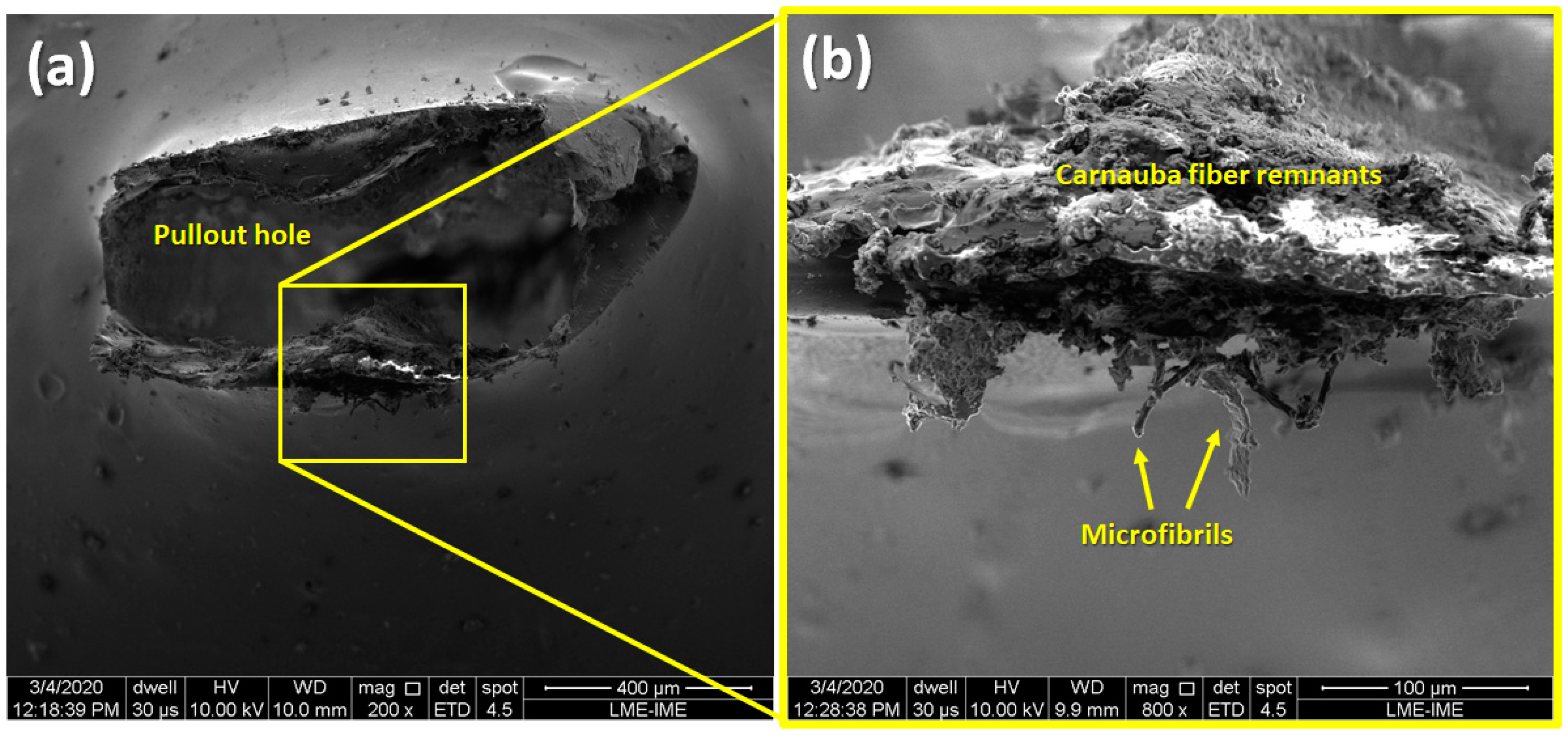

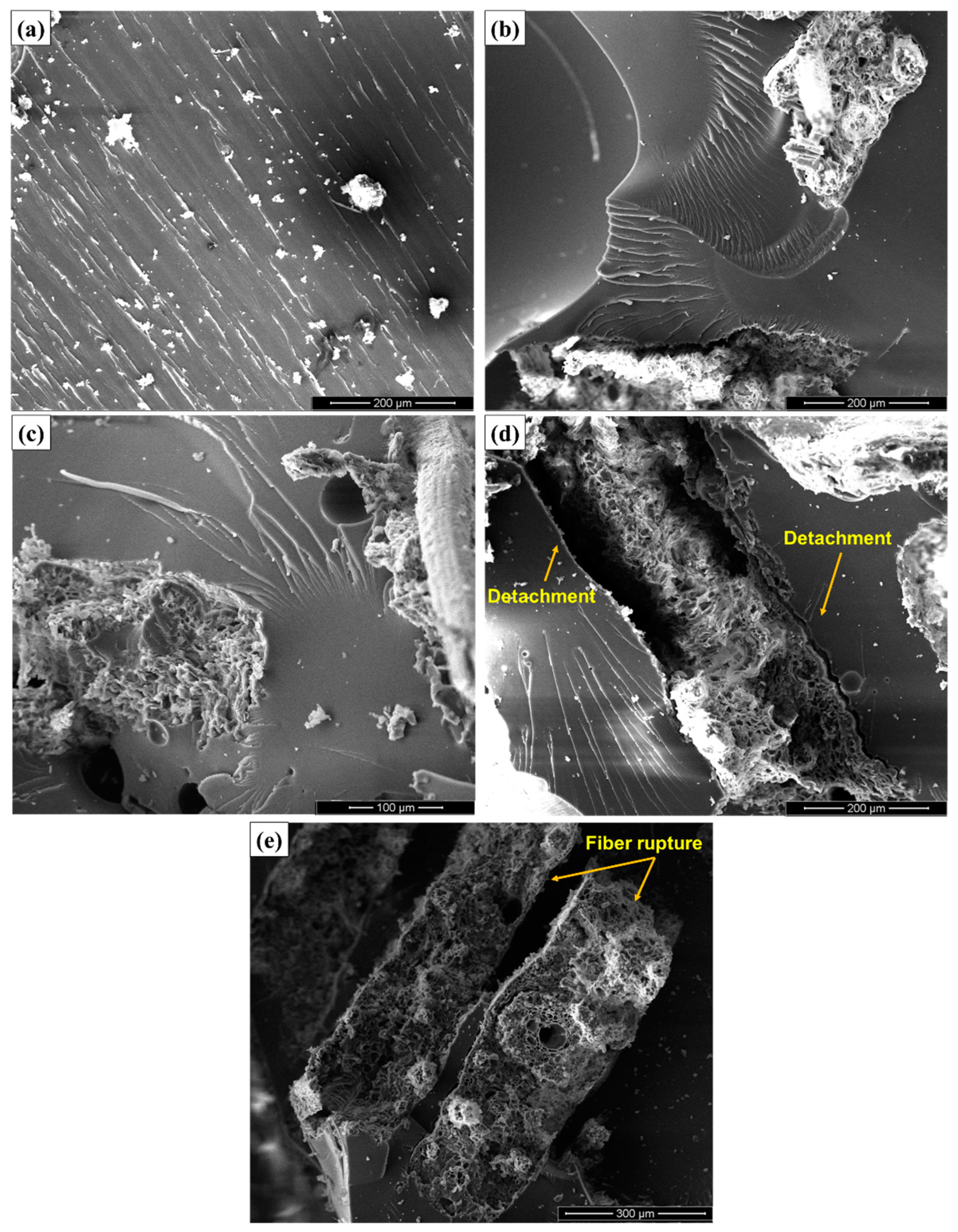

3.1. Pullout Test

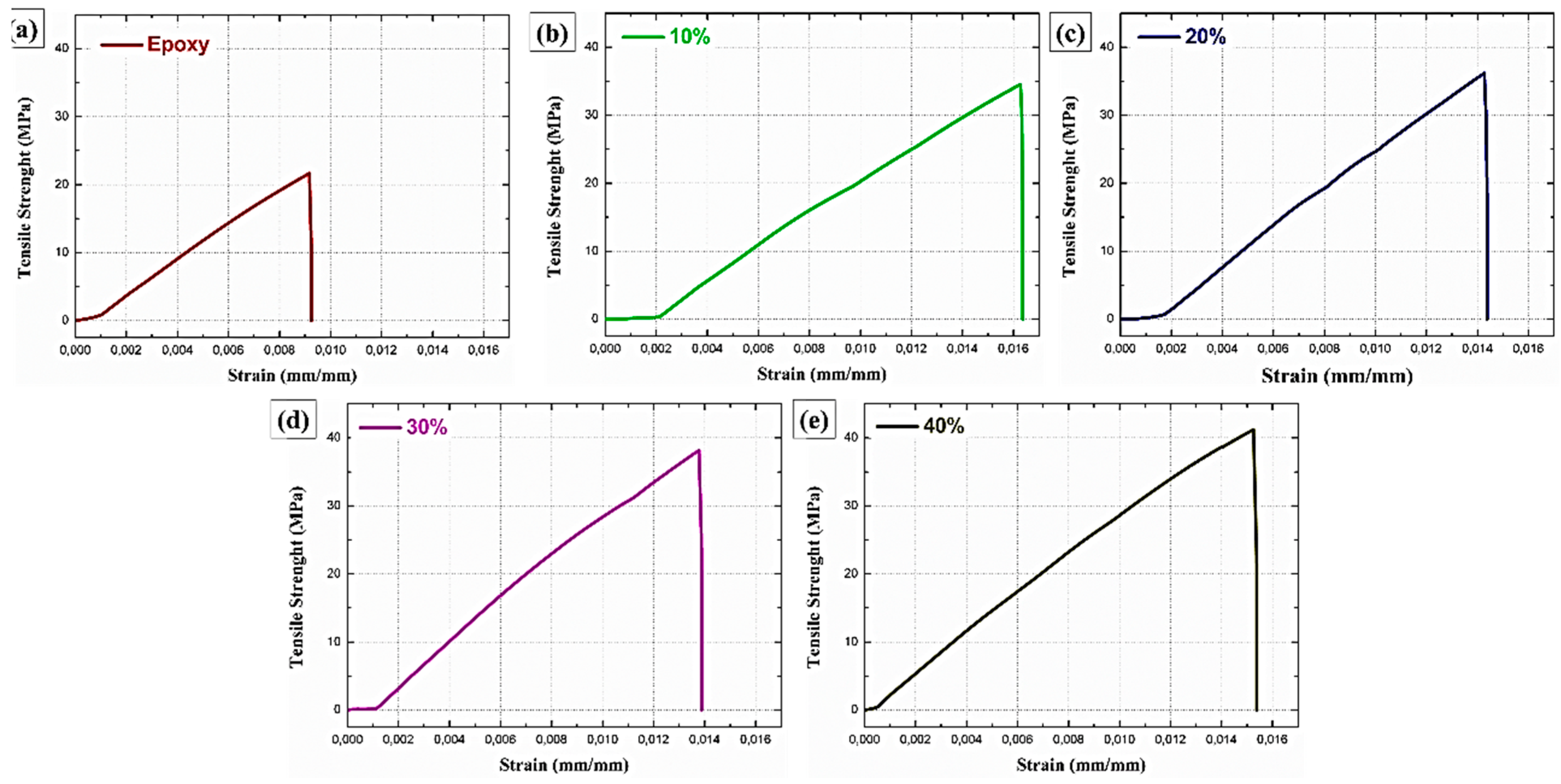

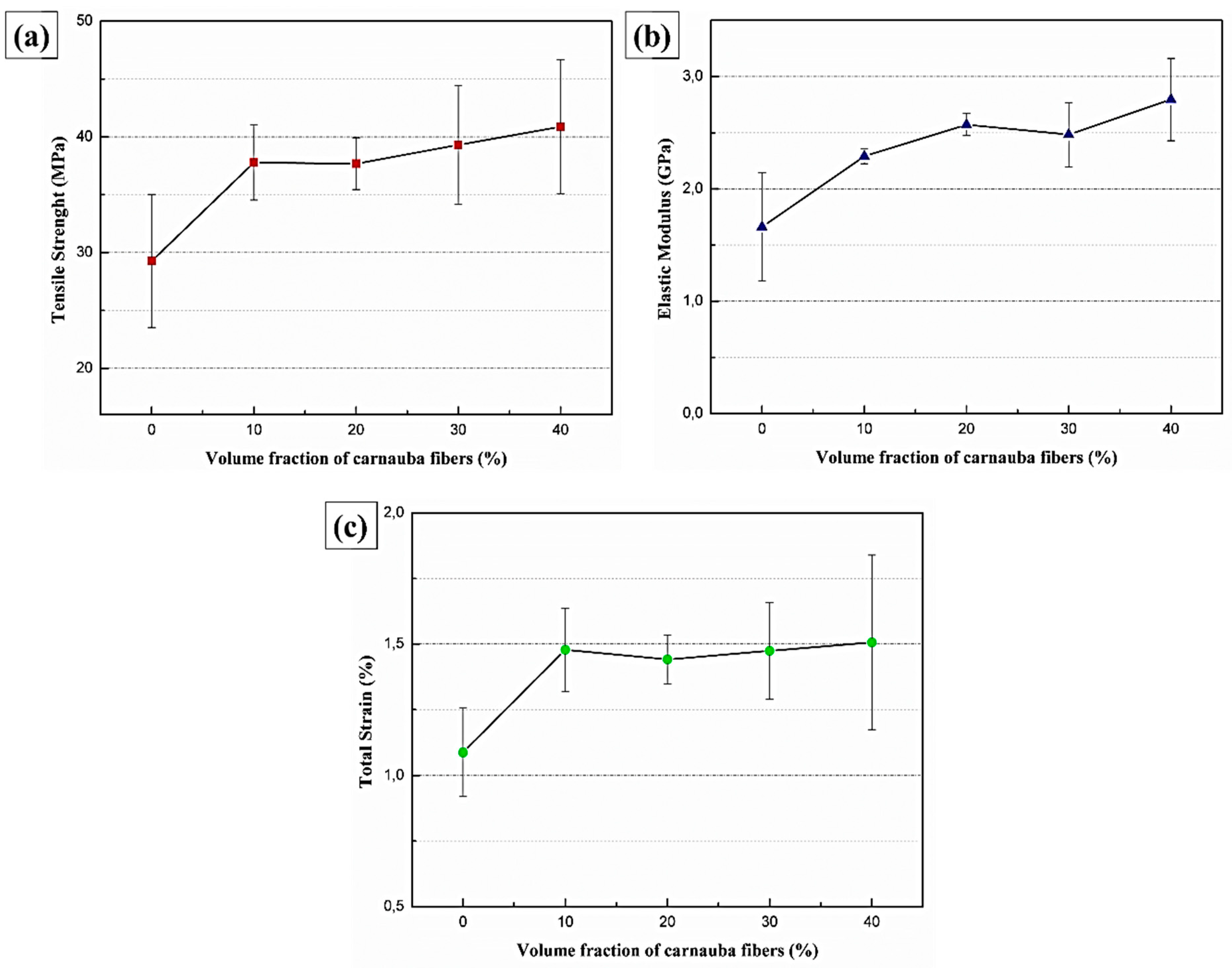

3.2. Tensile Test

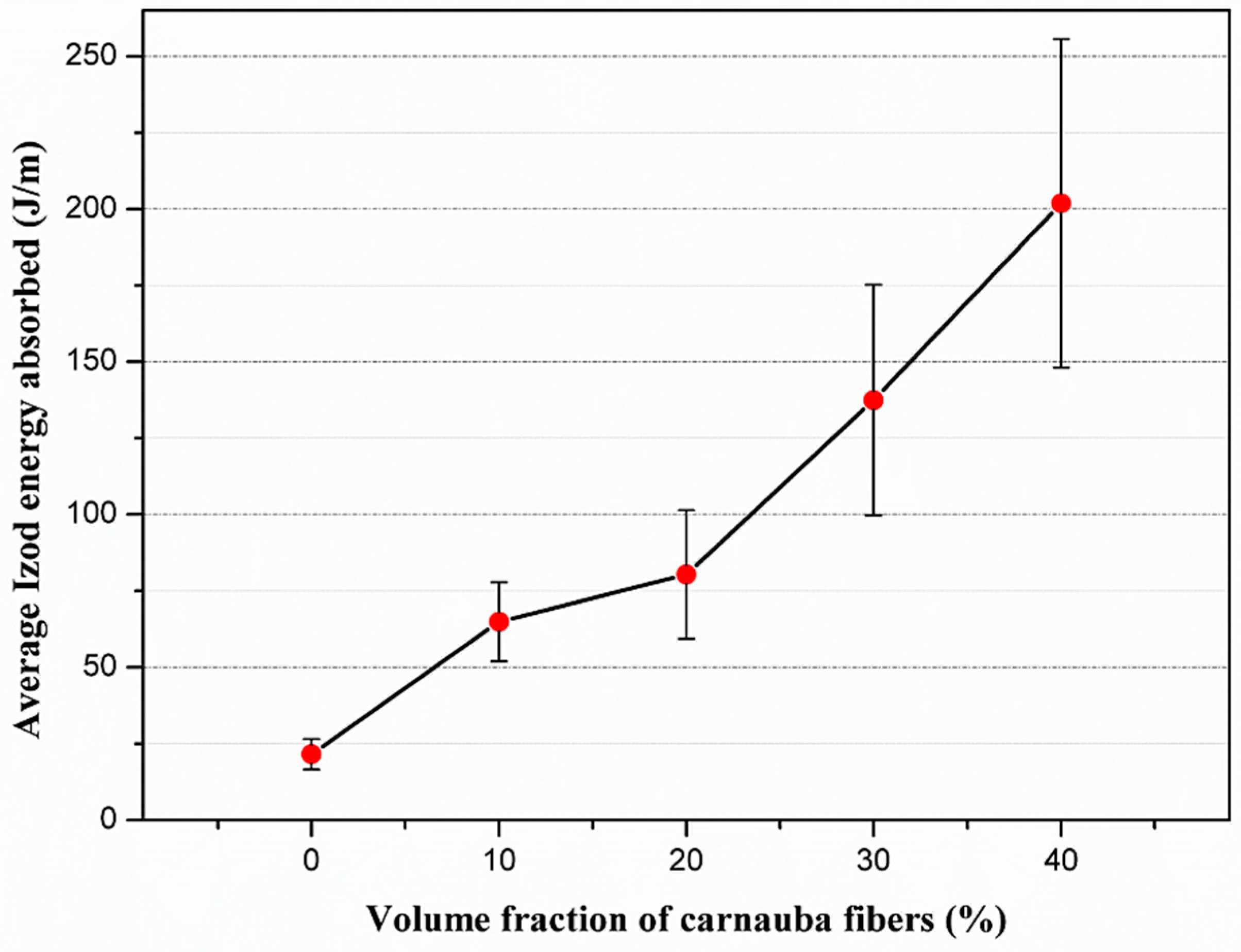

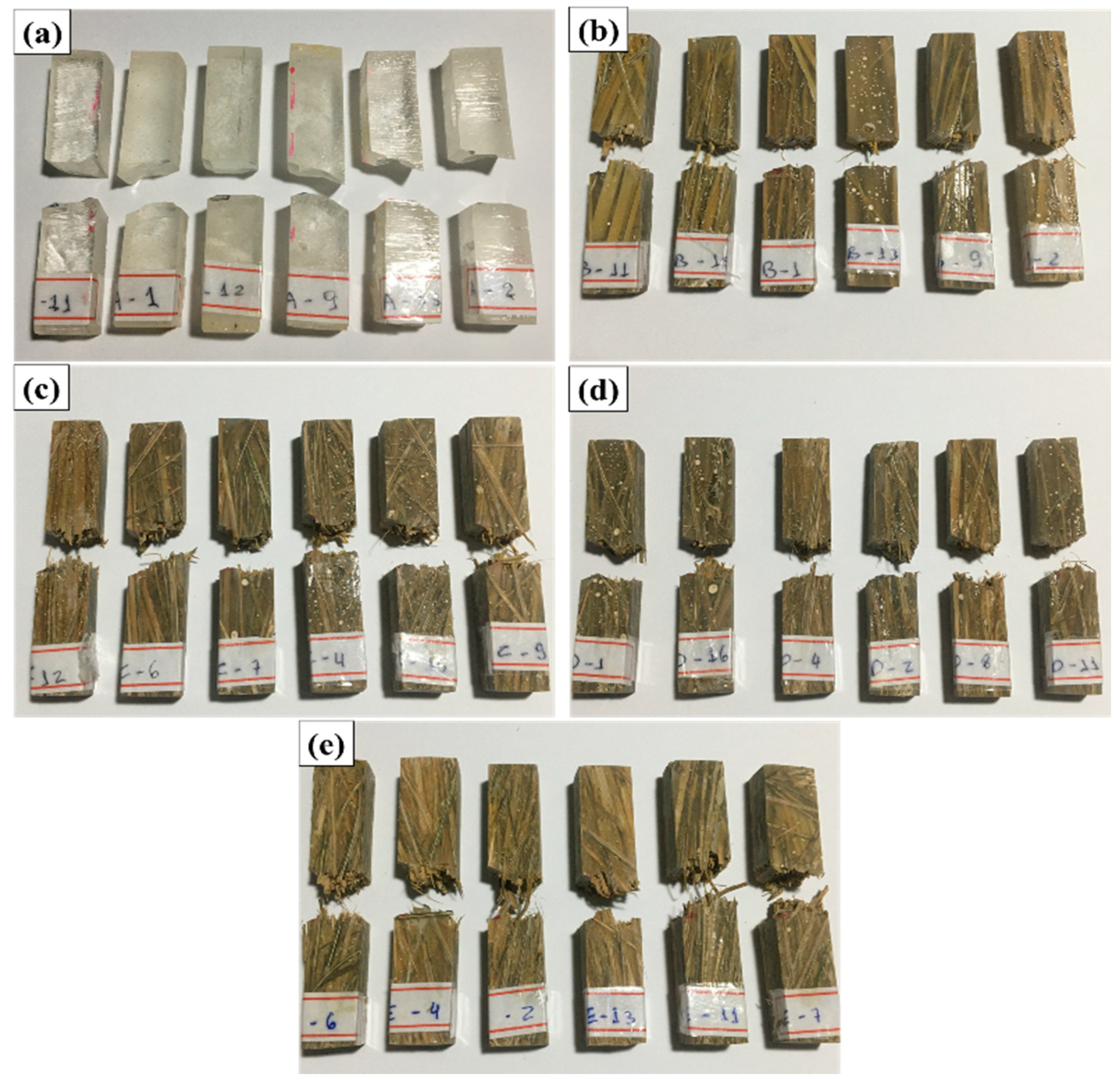

3.3. Izod Impact Test

3.4. Fourier Transform Infrared Spectroscopy (FTIR)

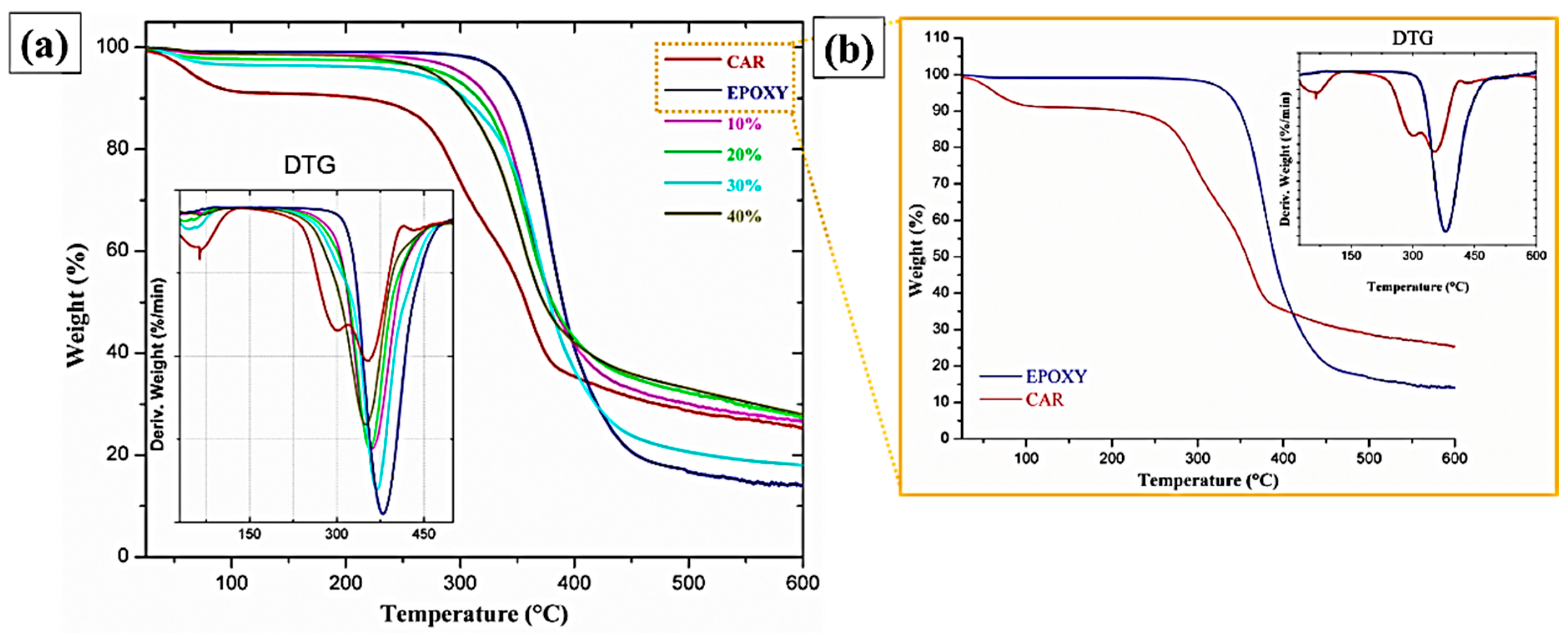

3.5. ThermoGravimetric Analysis (TG/DTG)

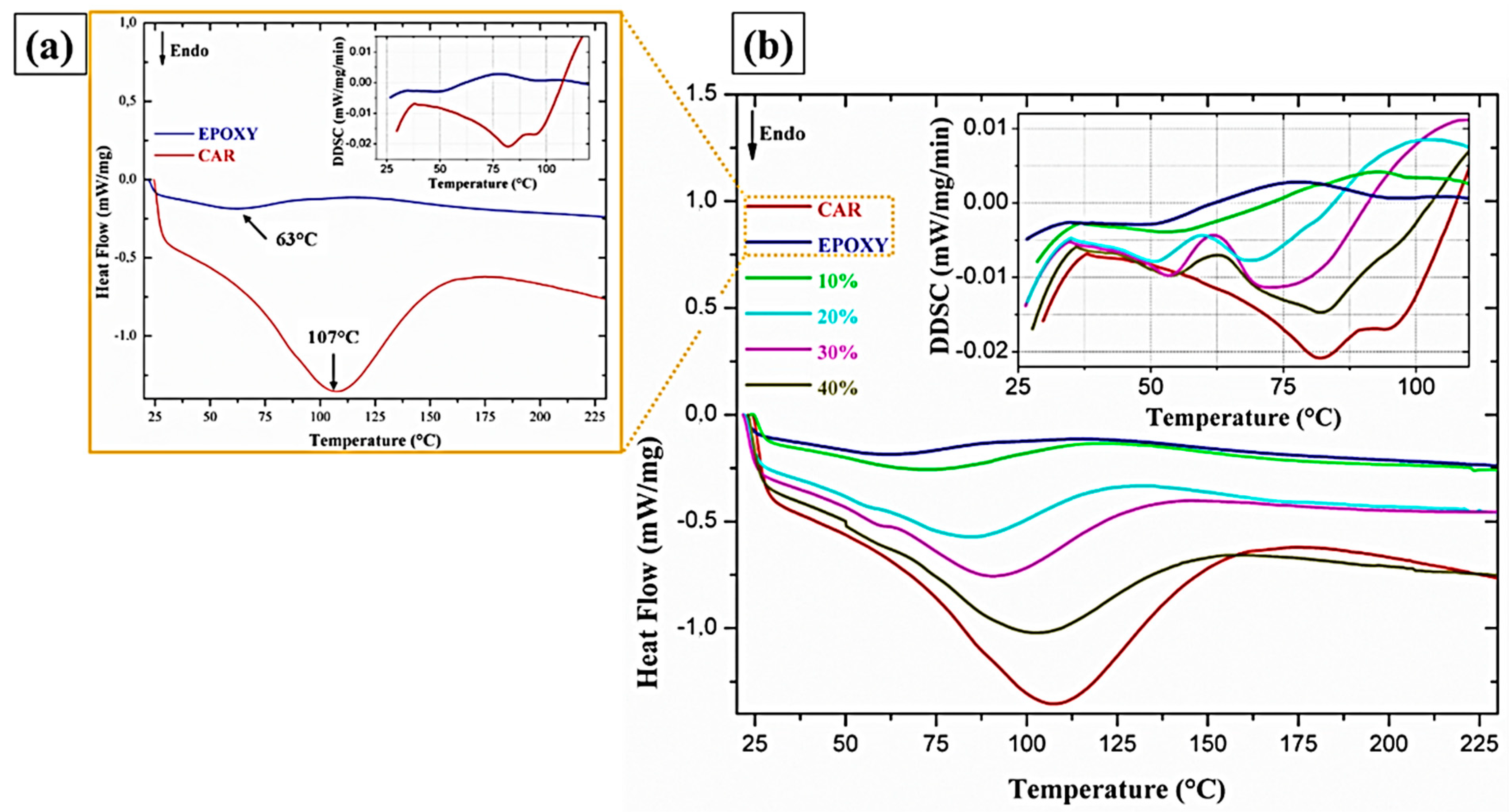

3.6. Differential Scanning Calorimetry (DSC)

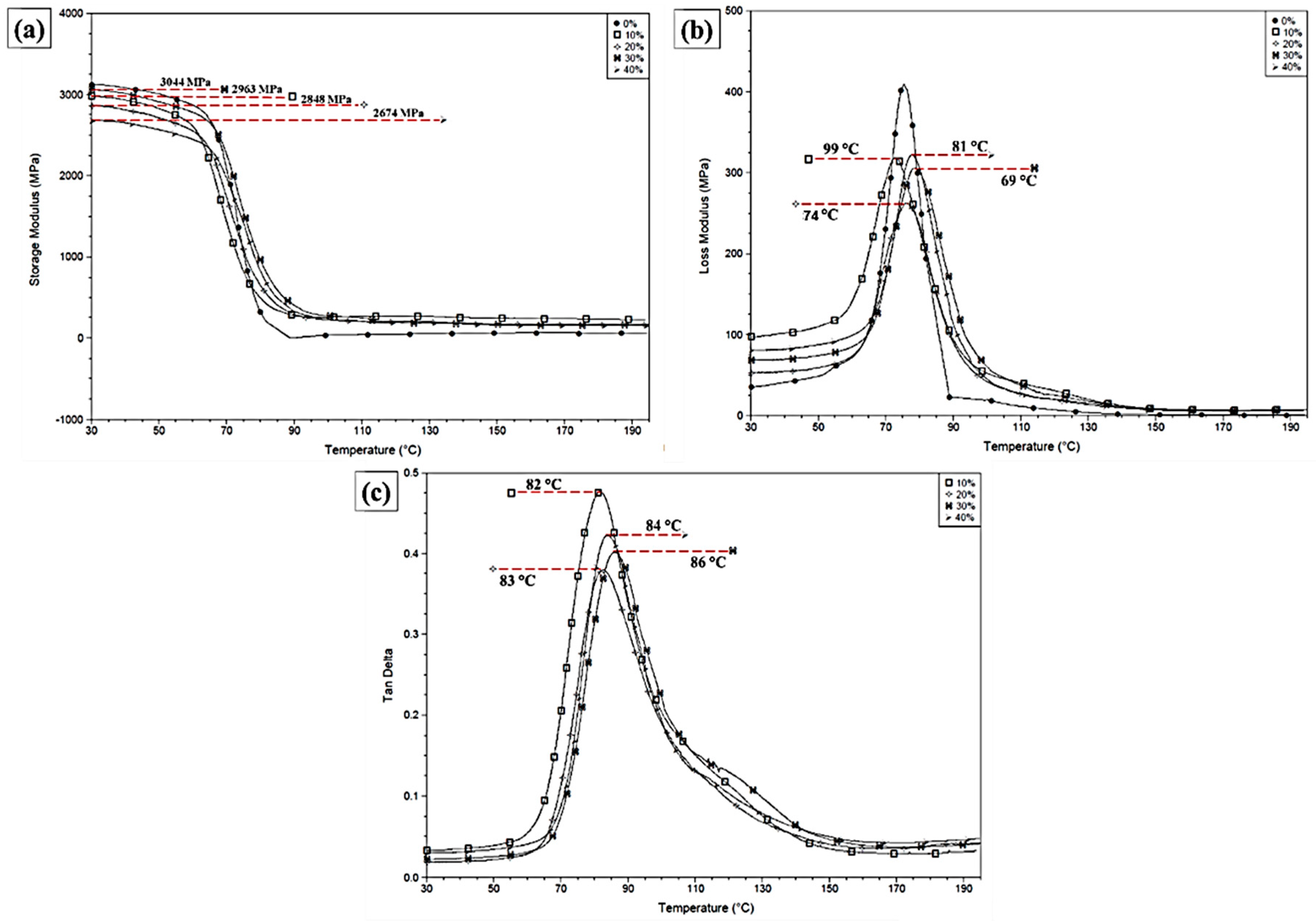

3.7. Dynamic Mechanical Analysis (DMA)

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Joshi, S.; Drzal, L.; Mohanty, A.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Maciel, N.O.R.; Ferreira, J.B.; Vieira, J.S.; Ribeiro, C.G.D.; Lopes, F.P.D.; Margem, F.M.; Monteiro, S.N.; Vieira, C.M.F.; Silva, L.C. Comparative tensile strength analysis between epoxy composites reinforced with curaua fiber and glass fiber. J. Mater. Res. Technol. 2018, 4, 561–565. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibers: Can they replace glass in fiber reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Da Silva, I.L.A.; Da Costa, L.L. Natural Lignocellulosic Fibers as Engineering Materials—An Overview. Metall. Mat. Trans. A 2011, 42, 2963. [Google Scholar] [CrossRef] [Green Version]

- Satyanarayana, K.G.; Guimaraes, J.L.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Hassan, K.M.F.; Horvath, P.G.; Alpár, T. Potential natural fiber polymeric nanobiocomposites: A review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced Composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fiber composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Güven, O.; Monteiro, S.N.; Moura, E.A.; Drelich, J.W. Re-emerging field of lignocellulosic fiber–polymer composites and ionizing radiation technology in their formulation. Polym. Rev. 2016, 56, 702–736. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 243947. [Google Scholar] [CrossRef] [Green Version]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Raw natural fiber–based polymer composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fiber composites for structural applications by optimizing composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Potluri, R.; Chaitanya Krishna, N. Potential and Applications of Green Composites in Industrial Space. Mater. Today Proc. 2020, 22, 2041–2048. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, S.M. Bionanocomposites materials for food packaging applications: Concepts and future outlook. Carbohy. Polym. 2018, 193, 19–27. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A Review of Recent Research on Materials used in Polymer–Matrix Composites for Body Armor Application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A App. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; Oliveira, M.S.; de Veiga, V.F.; Garcia Filho, F.D.C.; Pinheiro, M.A.; Monteiro, S.N. Guaruman fiber: Another possible reinforcement in composites. J. Mater. Res. Technol. 2019, 9, 622–628. [Google Scholar] [CrossRef]

- da Cruz Demosthenes, L.C.; Nascimento, L.F.C.; Monteiro, S.N.; Costa, U.O.; da Costa Garcia Filho, F.; da Luz, F.S.; Oliveira, M.S.; Ramos, F.J.H.T.V.; Pereira, A.C.; Braga, F.O. Thermal and structural characterization of buriti fibers and their relevance in fabric reinforced composites. J. Mater. Res. Technol. 2019, 9, 115–123. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Pereira, A.C.; Monteiro, S.N.; da Costa Garcia Filho, F.; da Cruz Demosthenes, L.C. Thermal Behavior of Epoxy Composites Reinforced with Fique Fabric by DSC. In Green Materials Engineering; Ikhmayies, S., Li, J., Vieira, C., Margem, J., Eds.; Springer: Cham, Switzerland, 2019; pp. 101–106. [Google Scholar] [CrossRef]

- Steinle, I.V. Carnauba wax: An expedition to its source. Ind. Eng. Chem. 1936, 28, 1004–1008. [Google Scholar] [CrossRef]

- The Danger of Carnauba Wax Explained: Stay Safe! Available online: https://www.mapleholistics.com/blog/dangers-carnauba-wax/ (accessed on 13 August 2020).

- Melo, J.D.D.; Carvalho, L.F.M.; Medeiros, A.M.; Souto, C.R.O.; Paskocimas, C.A. A biodegradable composite material based on polyhydrosybutyrate (PHB) and carnauba fibers. Compos. Part B 2012, 43, 2827–2835. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; Monteiro, S.N. Evaluation of Izod impact and bend properties of epoxy composites reinforced with mallow fibers. J. Mater. Res. Technol. 2019, 9, 373–382. [Google Scholar] [CrossRef]

- Kelly, A.; Tysson, W. Tensile properties of fiber-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–338. [Google Scholar] [CrossRef]

- Monteiro, S.N.; D’almeida, J.R.M. Pullout testing in lignocellulosic fibers—An analysis of methodology. Rev. Mater. 2006, 11, 189–196. [Google Scholar]

- Oushabi, O. The pull-out behavior of chemically treated lignocellulosic fibers/ polymeric matrix interface (LF/PM): A review. Compos. Part B 2019, 174, 107059. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Satyanarayana, K.G.; Margem, F.M.; Ferreira, A.S.; Nascimento, D.C.O.; Santafé, H.P.G., Jr.; Lopes, F.P.D. Interfacial shear strength in lignocellulosic fibers incorporated polymeric composites. Cellulose Fibers. In Cellulose Fibers: Bio and Nano Polymer Composites, 1st ed.; Kalia, S., Kaith, B.S., Kaur, I., Eds.; Springer: New York, NY, USA, 2011; Chapter 9; pp. 241–262. [Google Scholar]

- Monteiro, S.N.; Aquino, R.C.M.P.; Lopes, F.P.D. Performance of curauá fiber in pullout test. J. Mater. Sci. 2008, 43, 489–493. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. D3039-95: Standard Test Methods for Tensile Properties of Polymers Matrix Composite Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 1995. [Google Scholar]

- American Society for Testing and Materials. D256-10: Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics; American Society for Testing and Materials: West Conshohocken, PA, USA, 2000. [Google Scholar]

- American Society for Testing and Materials. E 1131. Standard Test Method for Compositional Analysis by Thermogravimetry; American Society for Testing and Materials: West Conshohocken, PA, USA, 2003. [Google Scholar]

- American Society for Testing and Materials D4065. Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Da Luz, F.S.; Monteiro, S.N.; Tommasini, F.J.H.V. Evaluation of dynamic mechanical properties of PALF and coir fiber reinforcing epoxy composites. Mater. Res. 2018, 21, e20171108. [Google Scholar] [CrossRef]

- Thomas, S.; Paul, S.A.; Pothan, L.A.; Deepa, B. Natural fibres: Structure, properties and applications. Cellulose Fibers: Bio and Nano-Polymer Composites, 1st ed.; Kalia, S., Kaith, B.S., Kaurs, I., Eds.; Springer: New York, NY, USA, 2011; pp. 3–42. [Google Scholar]

- Zini, E.; Scandola, M. Green composites—An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibers, Biodegradable Polymers and Bio-composites: An Overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Ferreira, A.S.; Nascimento, D.C.O. Natural Fiber Polymer matrix composites. Chapter, Tougher and environmentally friendly. JOM 2009, 61, 17–22. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering—An Introduction, 9th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2014; pp. 580–676. [Google Scholar]

- Nascimento, L.F.C.; Monteiro, S.N.; Louro, L.H.L.; Da Luz, F.S.; Santos, J.L.; Braga, F.O.; Marçal, R.L.S.B. Charpy impact test of epoxy composites reinforced with untreated and mercerized mallow fibers. J. Mater. Res. Technol. 2018, 7, 520–527. [Google Scholar] [CrossRef]

- Belouadah, Z.; Ati, A.; Rokbi, M. Characterization of new natural cellulosic fiber from Lygeumspartum L. Carbohy. Polym. 2015, 429–437. [Google Scholar] [CrossRef] [PubMed]

- Spinacé, M.A.S.; Lambert, C.S.; Fermoselli, K.K.G.; De Paoli, M.A. Characterization of lignocellulosic curaua fibers. Carbohy. Polym. 2009, 77, 47–53. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; Thomas, S. Extraction of nanocellulose fibrils from lignocellulosic fibers: A novel approach. Carbohy. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Cândido, V.S.; Nunes, L.F.; Monteiro, S.N. Chemical and morphological characterization of guaruman fiber. In Green Materials Engineering; Ikhmayies, S., Li, J., Vieira, C., Margem, J., de Oliveira Braga, F., Eds.; Springer: Cham, Switzerland, 2019; pp. 107–113. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.; Rodrigues, R.J.S.; Margem, F.M. Thermogravimetric stability of Polymer composites reinforced with less common lignocellulosic fiber—An overview. J. Mater. Res. Technol. 2012, 1, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Rafiee, M.; Nitzsche, F.; Laliberte, J.; Hind, S.; Robitaille, F.; Labrosse, M.R. Thermal properties of doubly reinforced fiberglass/epoxy composites with graphene nanoplatelets, graphene oxide and reduced-graphene oxide. Compos. Part B 2019, 164, 1–9. [Google Scholar] [CrossRef]

- Canevarolo, S.V., Jr. Polymer Science: A Basic Text for Technologists and Engineers (In Portuguese), 2nd ed.; Artliber: São Paulo, Brazil, 2002. [Google Scholar]

- Monteiro, S.N.; Calado, V.; Rodrigues, R.J.S.; Margem, F.M. Thermogravimetric behavior of natural fibers reinforced polymer composites—An overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar] [CrossRef]

- Silva, I.L.A.; Bevitare, A.B.; Oliveira, C.G.; Margem, F.M.; Monteiro, S.N. Dynamical-mechanical behavior of epoxy composites reinforced with jute fiber. In Characterization of Minerals, Metals and Materials; The Minerals, Metals and Materials Society; TMS-Willey: Hoboken, NJ, USA, 2014; pp. 483–490. [Google Scholar]

- Wang, H.; Memon, H.; Hassan, E.A.; Elagib, T.H.; Hassan, F.E.A.; Yu, M. Rheological and dynamic mechanical properties of abutilon natural staw and polyactic acid biocomposites. Int. J. Polym. Sci. 2019, 2019, 1–8. [Google Scholar]

- Souza, A.T.; Junio, R.F.P.; Neuba, L.M.; Candido, V.S.; Silva, A.C.R.; Azevedo, A.R.G.; Monteiro, S.N.; Nascimento, L.F.C. Caranan Fiber from Mauritiella armata palm tree as novel reinforcement for epoxy composites. Polymers 2020, 12, 2037. [Google Scholar] [CrossRef] [PubMed]

| Material | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|

| Neat PHB | 28–30 | 3.3–3.6 |

| Plain untreated carnauba fiber | 205–264 | 8.2–9.2 |

| 10 wt% untreated with carnauba fiber/PHB composite | 17–19 | 2.1–2.7 |

| Maximum values for a 10 wt% chemically modified carnauba fiber/PHB composite | 24–27 | 3.0–3.4 |

| Volume Fraction (%) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Total Strain (% of elongation) |

|---|---|---|---|

| 0 | 29.3 ± 5.7 | 1.66 ± 0.48 | 1.1 ± 0.2 |

| 10 | 37.8 ± 3.2 | 2.29 ± 0.07 | 1.5 ± 0.1 |

| 20 | 37.7 ± 2.2 | 2.57 ± 0.10 | 1.4 ± 0.1 |

| 30 | 39.3 ± 5.1 | 2.48 ± 0.29 | 1.5 ± 0.2 |

| 40 | 40.9 ± 5.8 | 2.80 ± 0.37 | 1.5 ± 0.3 |

| Fiber Fraction (vol%) | Average Izod Absorbed Energy (J/m) |

|---|---|

| 0% | 21.5 ± 4.9 |

| 10% | 65.0 ± 13.0 |

| 20% | 80.4 ± 21.0 |

| 30% | 137.4 ± 37.7 |

| 40% | 201.9 ± 53.8 |

| Variation Causes | DF | Sum of Squares | Mean Square | F(calc.) | F Critical (tab.) |

|---|---|---|---|---|---|

| Treatments | 4 | 312,767.02 | 78,191.75 | 74.06 | 2.496 |

| Residue | 75 | 79,185.15 | 1,055.80 | ||

| Total | 79 | 391,952.17 |

| Vol.% | 0 | 10 | 20 | 30 | 40 |

|---|---|---|---|---|---|

| 0 | 0 | 43.45 | 58.85 | 115.93 | 180.37 |

| 10 | 43.45 | 0 | 15.40 | 72.48 | 136.92 |

| 20 | 58.85 | 15.40 | 0 | 57.08 | 121.52 |

| 30 | 115.93 | 72.48 | 57.08 | 0 | 64.44 |

| 40 | 180.37 | 136.92 | 121.52 | 64.44 | 0 |

| Carnauba Fiber (vol %) | Mass Loss up to 200 °C (%) | Initial Degradation Temperature (°C) | Temperature of Maximum Degradation Rate (°C) | Mass Loss at the End of Second Stage (%) | Mass Loss at 600 °C (%) |

|---|---|---|---|---|---|

| Plain fiber | 9.63 | 267.3 | 353.1 | 63.1 | 74.7 |

| Neat epoxy | 1.05 | 341.6 | 380.7 | 81.9 | 86.1 |

| 10 | 1.49 | 326.4 | 360.1 | 66.5 | 73.4 |

| 20 | 2.50 | 320.5 | 355.6 | 63.3 | 72.8 |

| 30 | 3.75 | 325.9 | 368.5 | 75.6 | 81.9 |

| 40 | 1.75 | 305.3 | 350.7 | 63.2 | 71.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junio, R.F.P.; Nascimento, L.F.C.; Neuba, L.d.M.; Souza, A.T.; Moura, J.V.B.; Garcia Filho, F.d.C.; Monteiro, S.N. Copernicia Prunifera Leaf Fiber: A Promising New Reinforcement for Epoxy Composites. Polymers 2020, 12, 2090. https://doi.org/10.3390/polym12092090

Junio RFP, Nascimento LFC, Neuba LdM, Souza AT, Moura JVB, Garcia Filho FdC, Monteiro SN. Copernicia Prunifera Leaf Fiber: A Promising New Reinforcement for Epoxy Composites. Polymers. 2020; 12(9):2090. https://doi.org/10.3390/polym12092090

Chicago/Turabian StyleJunio, Raí Felipe Pereira, Lucio Fabio Cassiano Nascimento, Lucas de Mendonça Neuba, Andressa Teixeira Souza, João Victor Barbosa Moura, Fábio da Costa Garcia Filho, and Sergio Neves Monteiro. 2020. "Copernicia Prunifera Leaf Fiber: A Promising New Reinforcement for Epoxy Composites" Polymers 12, no. 9: 2090. https://doi.org/10.3390/polym12092090