Investigation of Ultrasonic Treatment on Physicochemical, Structural and Morphological Properties of Sodium Alginate/AgNPs/Apple Polyphenol Films and Its Preservation Effect on Strawberry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Films

2.3. Film Thickness and Color

2.4. Mechanical Strength of the Film

2.5. Water Vapor Permeability of Films

2.6. Contact Angle of Water and Swelling Ratio

2.7. DPPH Free Radical Scavenging Activity and Antibacterial Property

2.8. Thermal Properties

2.9. Characterization of the Films

2.10. Strawberry Fresh-Keeping Performance Test

2.11. Weightlessness, Sensory, and Decay

2.12. Firmness, pH, Soluble Solids Test, and Titratable Acid

2.13. Vitamin C (VC)

2.14. Statistical Analysis

3. Results

3.1. Optical Properties of the Film

3.2. Mechanical Properties Analysis of Film

3.3. WVP Analysis of Film

3.4. Water Contact Angle and Swelling Ratio Analysis of Film

3.5. FTIR and XRD Analysis of Film

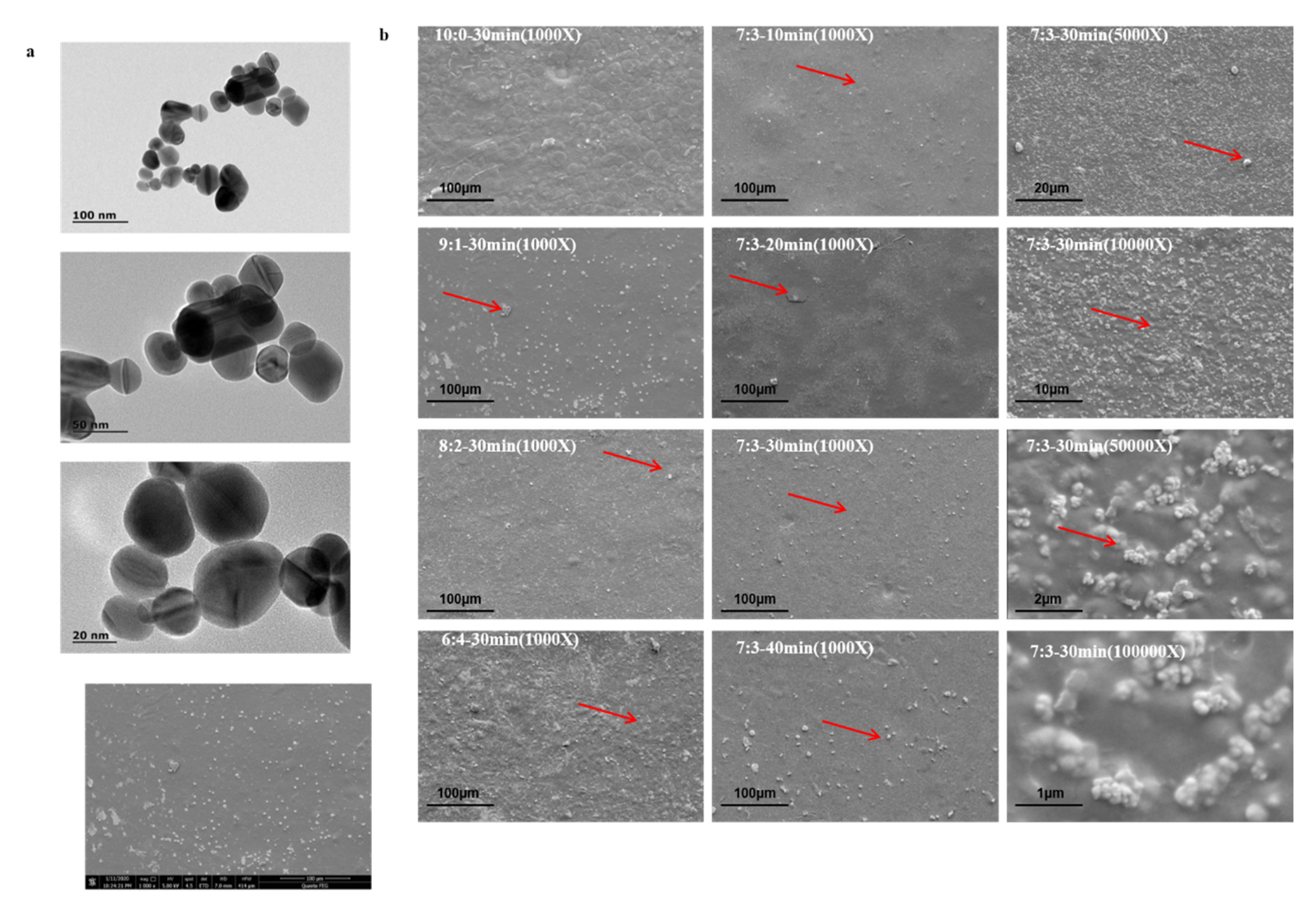

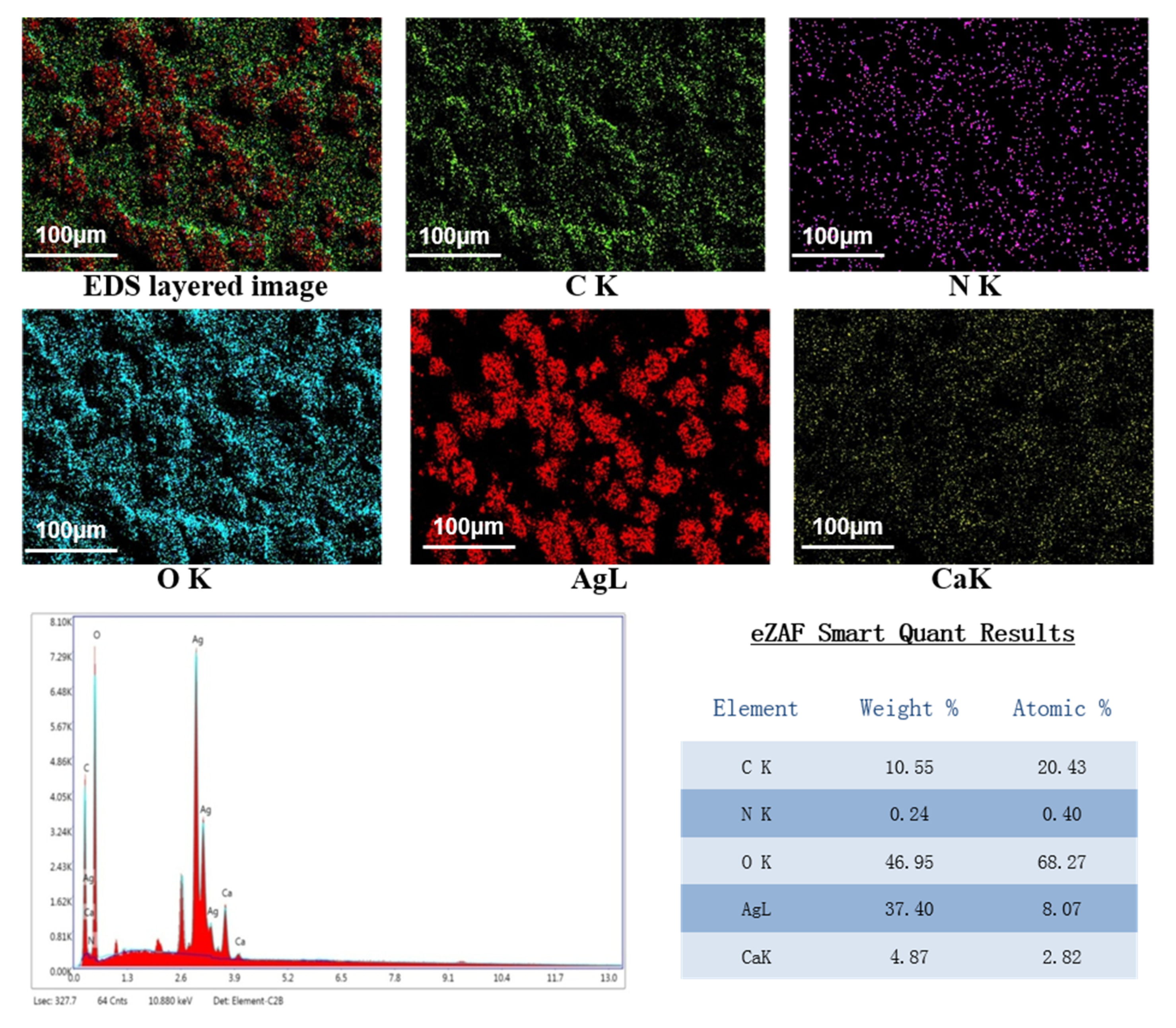

3.6. TEM and SEM Analysis of Film

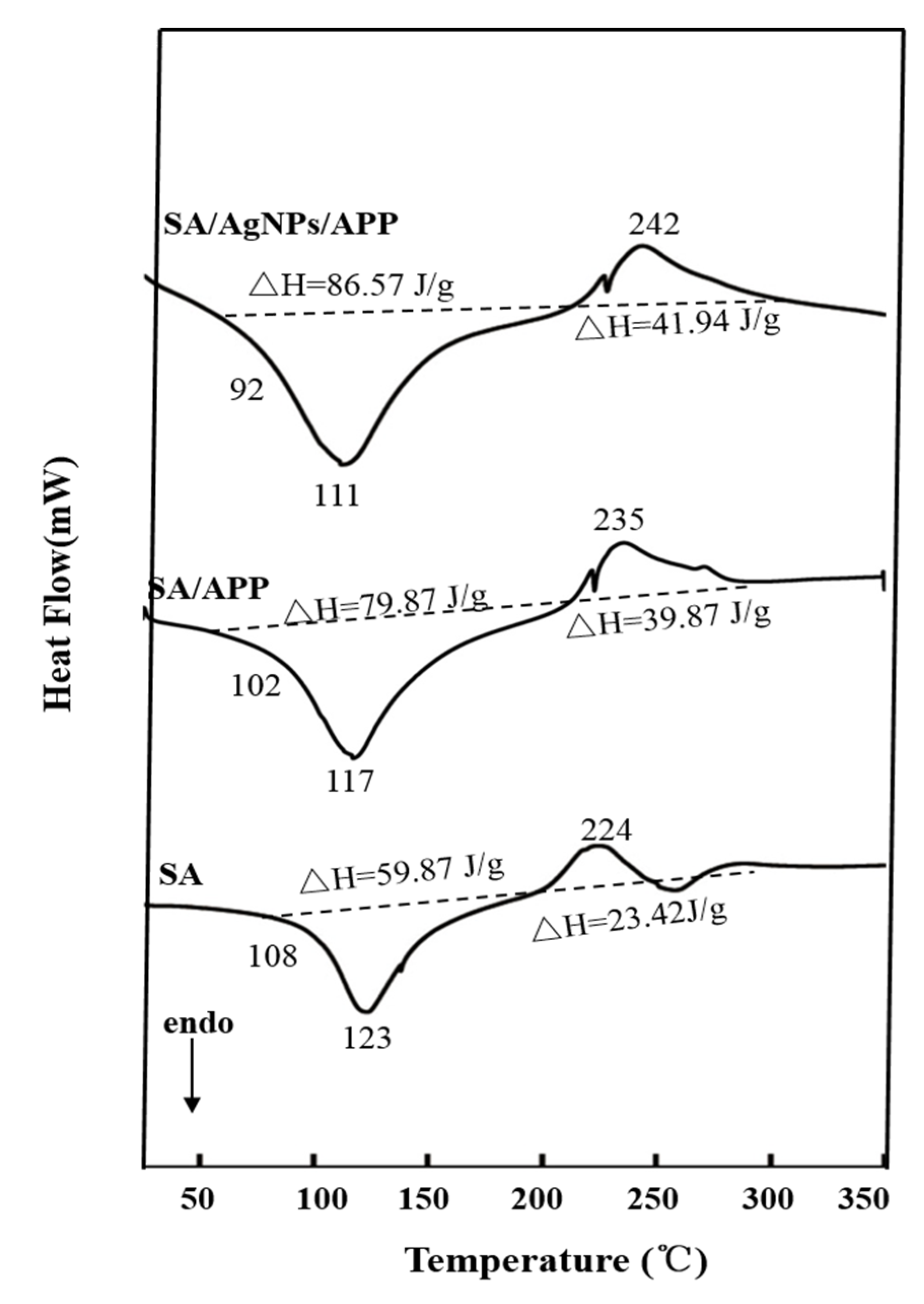

3.7. DSC Analysis of Film

3.8. Antimicrobial Activity and Antioxidant Activity Analysis of Film

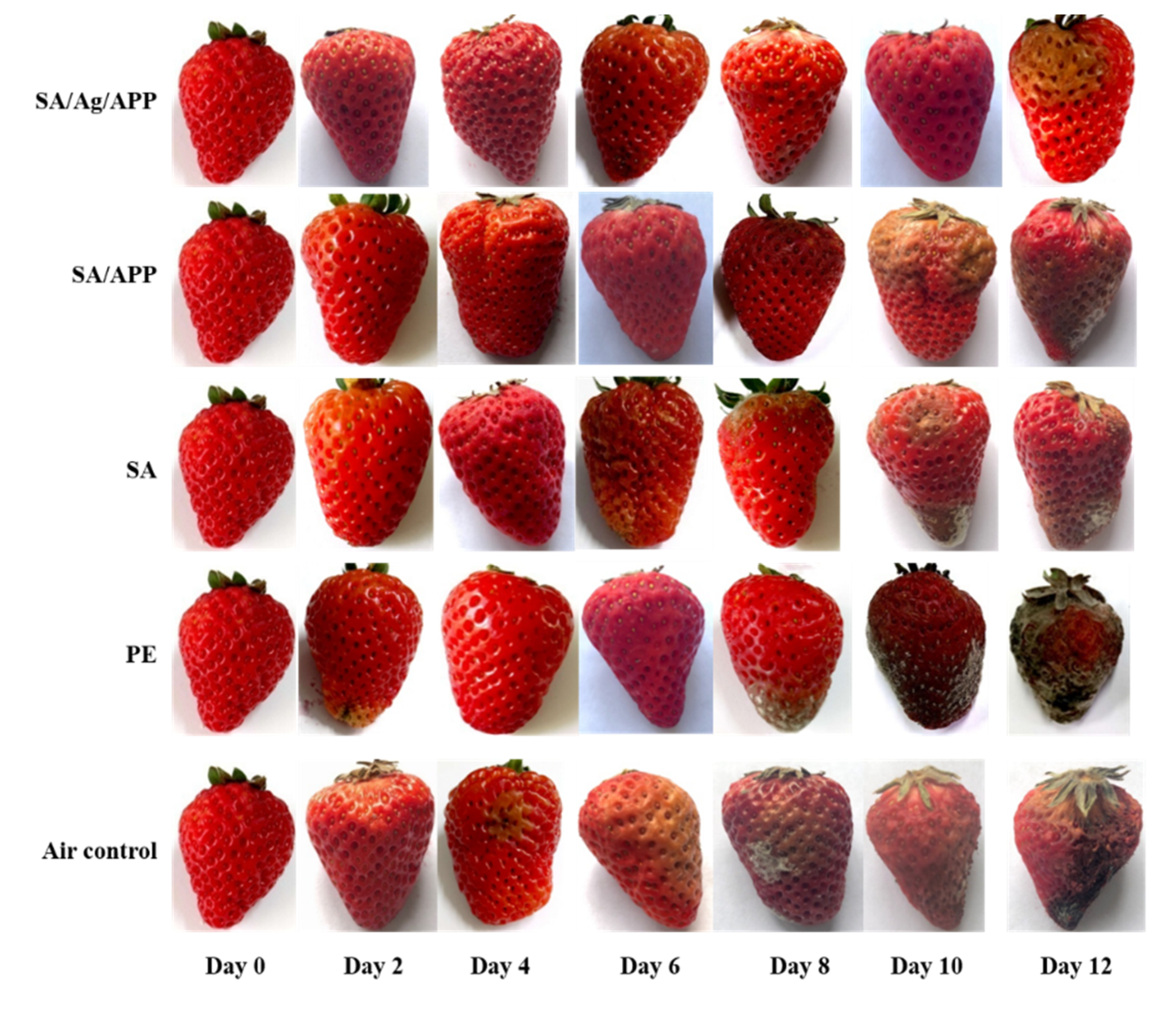

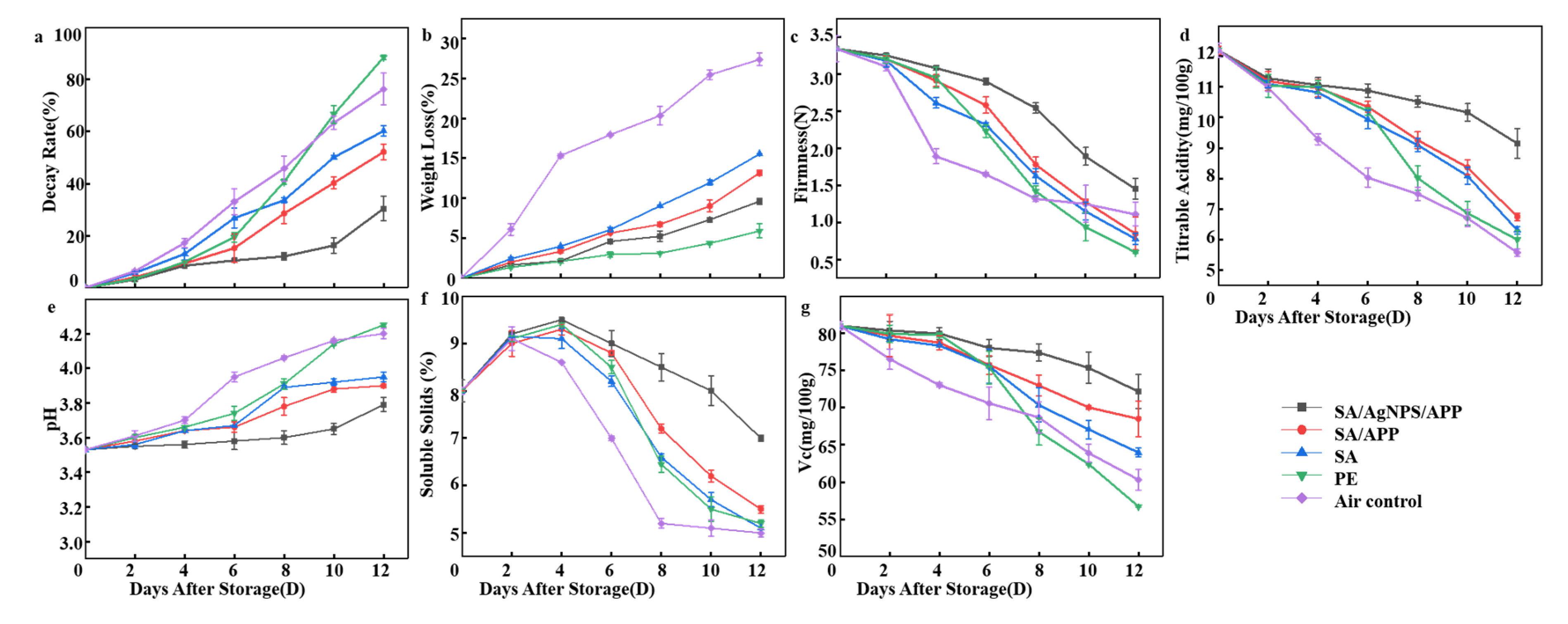

3.9. Strawberry Fresh-Keeping Performance

3.9.1. Sensory Evaluation and Sensory Evaluation Score

3.9.2. Decay Rate

3.9.3. Weight Loss

3.9.4. Firmness

3.9.5. Titratable Acidity

3.9.6. pH

3.9.7. Soluble Solids and Vitamin C

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Koc, B.; Akyuz, L.; Cakmak, Y.S.; Sargin, I.; Kaya, M. Production and characterization of chitosan-fungal extract films. Food Biosci. 2020, 35, 100545. [Google Scholar] [CrossRef]

- Mahcene, Z.; Khelil, A.; Hasni, S.; Akman, P.K.; Bozkurt, F.; Birech, K.; Goudjil, M.B.; Tornuk, F. Development and characterization of sodium alginate based active edible films incorporated with essential oils of some medicinal plants. Int. J. Biol. Macromol. 2020, 145, 124–132. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, B.; Hosseini, H.; Khani, M.; Farhoodi, M.; Honarvar, Z.; Feizollahi, E.; Shokri, B.; Shojaee-Aliabadi, S. Development and characterisation of chitosan or alginate-coated low density polyethylene films containing Satureja hortensis extract. Int. J. Biol. Macromol. 2017, 105, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Gong, X.; Miao, Y.; Guo, X.; Liu, C.; Fan, Y.Y.; Zhang, J.; Niu, B.; Li, W. Preparation and characterization of multilayer films composed of chitosan, sodium alginate and carboxymethyl chitosan-ZnO nanoparticles. Food Chem. 2019, 283, 397–403. [Google Scholar] [CrossRef] [PubMed]

- Castro-Acosta, M.L.; Stone, S.G.; Mok, J.E.; Mhajan, R.K.; Fu, C.I.; Lenihan-Geels, G.N.; Crope, C.P.; Hall, W.L. Apple and blackcurrant polyphenol-rich drinks decrease postprandial glucose, insulin and incretin response to a high-carbohydrate meal in healthy men and women. J. Nutr. Biochem. 2017, 49, 53–62. [Google Scholar] [CrossRef] [Green Version]

- Sun, L.; Sun, J.; Chen, L.; Niu, P.; Yang, X.; Guo, Y. Preparation and characterization of chitosan film incorporated with thinned young apple polyphenols as an active packaging material. Carbohydr. Polym. 2017, 163, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Espitia, P.J.P.; Du, W.X.; Avena-Bustillos, R.D.J.; Espitia, P.J.P.; Du, W.X.; Avena-Bustillos, R.D.J.; Soares, N.D.F.F.; Mchugh, T.H. Edible films from pectin: Physical-mechanical and antimicrobial properties—A review. Food Hydrocoll. 2014, 35, 287–296. [Google Scholar] [CrossRef]

- Biao, Y.; Yuxuan, C.; Qi, T.; Ziqi, Y.; Chongjiang, C. David Julian McClementsb Cao Chongjianga. Enhanced performance and functionality of active edible films by incorporating tea polyphenols into thin calcium alginate hydrogels. Food Hydrocoll. 2019, 97, 105197. [Google Scholar] [CrossRef]

- Riaz, A.; Lei, S.; Akhtar, H.M.S.; Wan, P.; Chen, D.; Jabbar, S.; Abid, M.; Hashim, M.M.; Zeng, X. Preparation and characterization of chitosan-based antimicrobial active food packaging film incorporated with apple peel polyphenols. Int. J. Biol. Macromol. 2018, 114, 547–555. [Google Scholar] [CrossRef]

- Nakkala, J.R.; Mata, R.; Sadras, S.R. Green synthesized nano silver: Synthesis, physicochemical profiling, antibacterial, anticancer activities and biological in vivo toxicity. J. Colloid Interface Sci. 2017, 499, 33–45. [Google Scholar] [CrossRef]

- Lang, D.; Shan, X.D.; Zhao, X.L.; Zha, H.L.; Chen, X.Y.; Wang, J.J.; Cai, C.; Wang, X.J.; Li, G.Y.; Hao, J.J.; et al. Spongy bilayer dressing composed of chitosan–Ag nanoparticles and chitosan–Bletilla striata polysaccharide for wound healing applications. Carbohydr. Polym. 2017, 157, 1538–1547. [Google Scholar]

- Maryan, A.S.; Montazer, M.; Harifi, T. Synthesis of nano silver on cellulosic denim fabric producing yellow colored garment with antibacterial properties. Carbohydr. Polym. 2015, 115, 568–574. [Google Scholar] [CrossRef] [PubMed]

- Sathishkumar, M.; Sneha, K.; Won, S.W.; Cho, C.W.; Kim, S.; Yun, Y.S. Cinnamon zeylanicum bark extract and powder mediated green synthesis of nano-crystalline silver particles and its bactericidal activity. Colloids Surf. B Biointerfaces 2019, 73, 332–338. [Google Scholar] [CrossRef] [PubMed]

- Xiong, K.R.; Liang, Y.R.; Ou-yang, Y.; Wu, D.C.; Fu, R.W. Nanohybrids of silver nanoparticles grown in-situ on a graphene oxide silver ion salt: Simple synthesis and their enhanced antibacterial activity. New Carbon Mater. 2019, 34, 426–433. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Q.; Ma, X.; Quan, F.; Wang, J.; Xia, Y. The preparation of alginate–AgNPs composite fiber with green approach and its antibacterial activity. J. Ind. Eng. Chem. 2015, 24, 188–195. [Google Scholar] [CrossRef]

- Abou-Okeil, H.M.; Fahmy, M.K. Hyaluronic acid/na-alginate films as topical bioactive wound dressings. Eur. Polym. J. 2018, 109, 101–109. [Google Scholar] [CrossRef]

- Narayanan, K.B.; Han, S.S. Dual-crosslinked poly (vinyl alcohol)/sodium alginate/silver nanocomposite beads-A promising antimicrobial material. Food Chem. 2017, 234, 103–110. [Google Scholar] [CrossRef]

- Buia, V.D.; Mwangia, J.W.; Meinshausenb, A.K.; Muellercd, A.J.; Bertrandb, J.; Schubertae, A. Antibacterial coating of Ti-6Al-4V surfaces using silver nano-powder mixed electrical discharge machining. Surf. Coat. Technol. 2020, 383, 125254. [Google Scholar] [CrossRef]

- Gedanken, A. Doping nanoparticles into polymers and ceramics using ultrasound radiation. Ultrason. Sonochem. 2007, 14, 418–430. [Google Scholar] [CrossRef]

- Estrada-Monje, A.; Zitzumbo-Guzmán, R.; Bañuelos-Díaz, J.A.; Zaragoza-Contreras, E.A. Ultrasonic dispersion and activation of TiO2 nanoparticles and its effect on bacterial inhibition in EVA films. Mater. Chem. Phys. 2019, 235, 121760. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, Y.; Ma, D.; Ahmed, S.; Qin, W.; Liu, Y. Effects of ultrasonication duration and graphene oxide and nano-zinc oxide contents on the properties of polyvinyl alcohol nanocomposites. Ultrason. Sonochem. 2019, 59, 104731. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, S.; Lan, W.; Qin, W. Development of ultrasound treated polyvinyl alcohol/tea polyphenol composite films and their physicochemical properties. Ultrason. Sonochem. 2019, 51, 386–394. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, S.; Lan, W.; Qin, W. Fabrication of polylactic acid/carbon nanotubes/chitosan composite fibers by electrospinning for strawberry preservation. Int. J. Biol. Macromol. 2019, 121, 1329–1336. [Google Scholar] [CrossRef]

- ASTM Standard. Standard test methods for vulcanized rubber and thermoplastic elastomers-tension. In Annual Book of ASTM Standards; Designation, D412-98a ASTM: Philadelphia, PA, USA, 1998; pp. 43–55. [Google Scholar]

- ASTM Standard. Standard test methods for water vapor transmission of materials. In Annual Book of ASTM Standards; Designation E96-E80 ASTM: Philadelphia, PA, USA, 1989; pp. 730–739. [Google Scholar]

- Shaari, N.; Kamarudin, S.K. Sodium alginate/alumina composite biomembrane preparation and performance in DMFC application. Polym. Test. 2020, 81, 106183. [Google Scholar] [CrossRef]

- Lan, W.; Zhang, R.; Ahmed, S.; Qin, W.; Liu, Y. Effects of various antimicrobial polyvinyl alcohol/tea polyphenol composite films on the shelf life of packaged strawberries. LWT-Food Sci. Technol. 2019, 113, 108297. [Google Scholar] [CrossRef]

- Jesus-Filho, M.D.; Scolforo, C.Z.; Saraiva, S.H.; Pinheiro, C.J.G.; Silva, P.I.; Della Lucia, S.M. Physicochemical, microbiological and sensory acceptance alterations of strawberries caused by gamma radiation and storage time. Sci. Hortic. 2018, 238, 187–194. [Google Scholar] [CrossRef]

- Saedi, S.; Rhim, J.W. Synthesis of Fe3O4@SiO2@PAMAM dendrimer@AgNP hybrid nanoparticles for the preparation of carrageenan-based functional nanocomposite film. Food Packag. Shelf Life 2020, 24, 100473. [Google Scholar] [CrossRef]

- Dou, L.; Li, B.; Zhang, K.; Chu, X.; Hou, H. Physical properties and antioxidant activity of gelatin-sodium alginate edible films with tea polyphenols. Int. J. Biol. Macromol. 2018, 118, 1377–1383. [Google Scholar] [CrossRef]

- Bibi, S.; Jamil, A.; Yasin, T.; Rafiq, M.A.; Nawaz, M.; Price, G.J. Ultrasound promoted synthesis and properties of chitosan nanocomposites containing carbon nanotubes and silver nanoparticles. Eur. Polym. J. 2018, 105, 297–303. [Google Scholar] [CrossRef]

- Borah, P.P.; Das, P.; Badwaik, L.S. Ultrasound treated potato peel and sweet lime pomace based biopolymer film development. Ultrason. Sonochem. 2017, 36, 11–19. [Google Scholar] [CrossRef]

- Bahrami, A.; Rezaei Mokarram, R.; Sowti Khiabani, M.; Ghanbarzadeh, B.; Salehi, R. Physico-mechanical and antimicrobial properties of tragacanth/hydroxypropyl methylcellulose/beeswax edible films reinforced with silver nanoparticles. Int. J. Biol. Macromol. 2019, 129, 1103–1112. [Google Scholar] [CrossRef] [PubMed]

- Bourakadi, K.E.; Merghoub, N.; Fardioui, M.; Mekhzoum, M.E.M.; Kadmiri, I.M.; Essassi, E.M.; Qiass, A.K.; Bouhfid, R. Chitosan/polyvinyl alcohol/thiabendazoluim-montmorillonite bio-nanocomposite films: Mechanical, morphological and antimicrobial properties. Compos. Part B Eng. 2019, 172, 103–110. [Google Scholar] [CrossRef]

- Kim, S.; Baek, S.-K.; Song, K.B. Physical and antioxidant properties of alginate films prepared from Sargassum fulvellum with black chokeberry extract. Food Packag. Shelf Life 2018, 18, 157–163. [Google Scholar] [CrossRef]

- Sharma, S.; Sanpui, P.; Chattopadhyay, A.; Ghosh, S.S. Fabrication of antibacterial silver nanoparticle—sodium alginate–chitosan composite films. RSC Adv. 2012, 2, 5837–5843. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, H.; Yang, S.; Zeng, J.; Wu, Z. Sodium alginate-based green packaging films functionalized by guava leaf extracts and their bioactivities. Materials 2019, 12, 2923. [Google Scholar] [CrossRef] [Green Version]

- Jafari, H.; Pirouzifard, M.; Khaledabad, M.A.; Almasi, H. Effect of chitin nanofiber on the morphological and physical properties of chitosan/silver nanoparticle bionanocomposite films. Int. J. Biol. Macromol. 2016, 92, 461–466. [Google Scholar] [CrossRef]

- Bang, Y.J.; Shankar, S.; Rhim, J.W. In situ synthesis of multi-functional gelatin/resorcinol/silver nanoparticles composite films. Food Packag. Shelf Life 2019, 22, 100399. [Google Scholar] [CrossRef]

- Cruz-Diaz, K.; Cobos, Á.; Fernández-Valle, M.E.; Díaz, O.; Cambero, M.I. Characterization of edible films from whey proteins treated with heat, ultrasounds and/or transglutaminase. Application in cheese slices packaging. Food Packag. Shelf Life 2019, 22, 100397. [Google Scholar] [CrossRef]

- Shankar, S.; Wang, L.F.; Rhim, J.W. Preparations and characterization of alginate/silver composite films: Effect of types of silver particles. Carbohydr. Polym. 2016, 146, 208–216. [Google Scholar] [CrossRef]

- Wang, W.; Sabo, R.C.; Mozuch, M.D.; Kersten, P.; Zhu, J.Y.; Jin, Y. Physical and mechanical properties of cellulose nanofibril films from bleached eucalyptus pulp by endoglucanase treatment and microfluidization. J. Polym. Environ. 2015, 23, 551–558. [Google Scholar] [CrossRef]

- Wu, H.; Lei, Y.; Zhu, R.; Zhao, M.; Lu, J.; Xiao, D.; Li, S. Preparation and characterization of bioactive edible packaging films based on pomelo peel flours incorporating tea polyphenol. Food Hydrocoll. 2019, 90, 41–49. [Google Scholar] [CrossRef]

- Lopes, L.A.; Paixão, L.C.; Silva, L.J.S.D.; Rocha, A.A.; Kardec, A.; Filho, B.; Santana, A.A. Elaboration and characterization of biopolymer films with alginate and babassu coconut mesocarp. Carbohydr. Polym. 2020, 235, 115747. [Google Scholar] [CrossRef] [PubMed]

- Giz, A.S.; Berberoglu, M.; Bener, S.; Aydelik-Ayazoglu, S.; Bayraktar, H.; Alaca, B.E.; Catalgil-Giz, H. A detailed investigation of the effect of calcium crosslinking and glycerol plasticizing on the physical properties of alginate films. Int. J. Biol. Macromol. 2020, 148, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Fortunati, E.; Peltzer, M.; Armentano, I.; Jiménez, A.; Kenny, J.M. Combined effects of cellulose nanocrystals and silver nanoparticles on the barrier and migration properties of PLA nano-biocomposites. J. Food Eng. 2013, 118, 117–124. [Google Scholar] [CrossRef]

- Hou, Y.; Gong, T.; Zhang, J.; Yang, X.; Guo, Y. Structural characterization and emulsifying properties of thinned-young apples polysaccharides. Biochem. Biophys. Res. Commun. 2019, 516, 1175–1182. [Google Scholar] [CrossRef]

- Gao, Z.; Cao, J.; Muzammal, H.M.; Wang, C.; Sun, H.; Dong, C.; Ma, H.T.; Wang, Y. Ultrasound assisted large scale fabrication of superhydrophilic anodized SnOx films with highly uniformed nanoporous arrays. Mater. Chem. Phys. 2020, 242, 122540. [Google Scholar] [CrossRef]

- Ananda, A.P.; Manukumar, H.M.; Krishnamurthy, N.B.; Nagendra, B.S.; Savitha, K.R. Assessment of antibacterial efficacy of a biocompatible nanoparticle PC@AgNPs against Staphylococcus aureus. Microb. Pathog. 2019, 126, 27–39. [Google Scholar] [CrossRef]

- Nieto, J.M.; Peniche-Covas, C.; Padro′n, G. Characterization of chitosan by pyrolysis-mass spectrometry, thermal analysis and differential scanning calorimetry. Thermochim. Acta 1991, 176, 63–68. [Google Scholar] [CrossRef]

- Donato, P.D.; Taurisano, V.; Poli, A.; Ayala, G.G.; Nicolaus, B.; Malinconinco, M.; Santagata, G. Vegetable wastes derived polysaccharides as natural eco-friendly plasticizers of sodium alginate. Carbohydr. Polym. 2020, 229, 115427. [Google Scholar] [CrossRef]

- Nigiz, F.U. Graphene oxidesodium alginate membrane for seawater desalination through pervaporation. Desalination 2020, 485, 114465. [Google Scholar] [CrossRef]

- Denev, P.; Ciz, M.; Kratchanova, M.; Blazheva, D. Black chokeberry (aronia melanocarpa) polyphenols reveal different antioxidant, antimicrobial and neutrophil-modulating activities. Food Chem. 2019, 284, 108–117. [Google Scholar] [CrossRef] [PubMed]

- Feng, M.; Yu, L.; Zhu, P.; Zhou, X.; Liu, H.; Yang, Y.; Zhou, J.; Gao, C.; Bao, X.; Chen, P. Development and preparation of active starch films carrying tea polyphenol. Carbohydr. Polym. 2018, 196, 162–167. [Google Scholar] [CrossRef] [PubMed]

- Olszewska, M.A.; Astrid, G.; Manuel, S. Antimicrobial polyphenol-rich extracts: Applications and limitations in the food industry. Food Res. Int. 2020, 134, 109214. [Google Scholar] [CrossRef] [PubMed]

- Shahriary, M.; Veisi, H.; Hekmati, M.; Hemmati, S. In situ green synthesis of Ag nanoparticles on herbal tea extract (Stachys lavandulifolia)-modified magnetic iron oxide nanoparticles as antibacterial agent and their 4-nitrophenol catalytic reduction activity. Mater. Sci. Eng. C Mater. Biogical Appl. 2018, 90, 57–66. [Google Scholar] [CrossRef]

- Agnihotri, S.; Mukherji, S.; Mukherji, S. Size-controlled silver nanoparticles synthesized over the range 5–100 nm using the same protocol and their antibacterial efficacy. RSC Adv. 2014, 4, 3974–3983. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Meckling, K.A.; Marcone, M.F.; Kakuda, Y.; Proulx, A.; Tsao, R. In vitro antioxidant synergism and antagonism between food extracts can lead to similar activities in H2O2-induced cell death, caspase-3 and MMP-2 activities in H9c2 cells. J. Sci. Food Agric. 2012, 92, 2983–2993. [Google Scholar] [CrossRef]

- Jiang, T.L.; Yu, L.; Hu, Y.W.; Zhu, Z.C.; Zhuang, C.J.; Zhao, Y.Y.; Zhong, Y. The preservation performance of chitosan coating with different molecular weight on strawberry using electrostatic spraying technique. Int. J. Biol. Macromol. 2020, 151, 278–285. [Google Scholar] [CrossRef]

- Kanikireddy, V.; Varaprasad, K.; SandhyaRani, M.; Venkataswamy, P.; JaganMohan Reddy, B.; Vithal, M. Biosynthesis of CMC-Guar gum-Ag nanocomposites for inactivation of food pathogenic microbes and its effect on the shelf life of strawberries. Carbohydr. Polym. 2020, 236, 116053. [Google Scholar] [CrossRef]

- Briassoulis, D.; Tserotas, P.; Hiskakis, M. Mechanical and degradation behaviour of multilayer barrier films. Polym. Degrad. Stab. 2017, 143, 214–230. [Google Scholar] [CrossRef]

- Yansu, Y.; Songqi, D.; Huilan, Z.; Yuntao, L.; Wenjuan, W. Preparation and characterization of konjac glucomannan and pullulan composite films for strawberry preservation. Carbohydr. Polym. 2020, 243, 116446. [Google Scholar]

- Fan, Y.; Xu, Y.; Wang, D.; Zhang, L.; Sun, J.; Sun, L.; Zhang, B. Effect of alginate coating combined with yeast antagonist on strawberry (Fragaria×ananassa) preservation quality. Postharvest Biol. Technol. 2009, 53, 84–90. [Google Scholar] [CrossRef]

- Kou, X.; He, Y.; Li, Y.; Chen, X.; Feng, Y.; Xue, Z. Effect of abscisic acid (aba) and chitosan/nano-silica/sodium alginate composite film on the color development and quality of postharvest chinese winter jujube (zizyphus jujuba mill. cv. dongzao). Food Chem. 2019, 270, 385–394. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Yu, L.; Hu, Y.; Zhu, Z.; Zhuang, C.; Zhao, Y.; Zhong, Y. Electrostatic spraying of chitosan coating with different deacetylation degree for strawberry preservation. Int. J. Biol. Macromol. 2019, 139, 1232–1238. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Shukla, A.; Baul, P.P.; Mitra, A.; Halder, D. Biodegradable hybrid nanocomposites of chitosan/gelatin and silver nanoparticles for active food packaging applications. Food Packag. Shelf Life 2018, 16, 178–184. [Google Scholar] [CrossRef]

- Moggia, C.; Beaudry, R.M.; Retamales, J.B.; Lobos, G.A. Variation in the impact of stem scar and cuticle on water loss in highbush blueberry fruit argue for the use of water permeance as a selection criterion in breeding. Postharvest Biol. Technol. 2017, 132, 88–96. [Google Scholar] [CrossRef] [Green Version]

- Jamróz, E.; Kopel, P.; Juszczak, L.; Kawecka, A.; Bytesnikova, Z.; Milosavljevic, V.; Makarewicz, M. Development of furcellaran-gelatin films with Se-AgNPs as an active packaging system for extension of mini kiwi shelf life. Food Packag. Shelf Life 2019, 21, 100339. [Google Scholar] [CrossRef]

- Stanley, J.; Prakash, R.; Marshall, R.; Schröder, R. Effect of harvest maturity and cold storage on correlations between fruit properties during ripening of apricot (Prunus armeniaca). Postharvest Biol. Technol. 2013, 82, 39–50. [Google Scholar] [CrossRef]

- Niu, X.; Zhu, L.; Xi, L.; Guo, L.; Wang, H. An antimicrobial agent prepared by N-succinyl chitosan immobilized lysozyme and its application in strawberry preservation. Food Control 2020, 108, 106829. [Google Scholar] [CrossRef]

- Ella Missang, C.; Maingonnat, J.F.; Renard, C.M.G.C.; Audergon, J.M. Apricot cell wall composition: Relation with the intra-fruit texture heterogeneity and impact of cooking. Food Chem. 2012, 133, 45–54. [Google Scholar] [CrossRef]

- Zhang, L.; Li, S.; Dong, Y.; Zhi, H.; Zong, W. Tea polyphenols incorporated into alginate-based edible coating for quality maintenance of Chinese winter jujube under ambient temperature. LWT 2016, 70, 155–161. [Google Scholar] [CrossRef]

- Hajji, S.; Younes, I.; Affes, S.; Boufi, S.; Nasri, M. Optimization of the formulation of chitosan edible coatings supplemented with carotenoproteins and their use for extending strawberries postharvest life. Food Hydrocoll. 2018, 83, 375–392. [Google Scholar] [CrossRef]

- Han, C.; Zhao, Y.; Leonard, S.W.; Traber, M.G. Edible coatings to improve storability and enhance nutritional value of fresh and frozen strawberries (Fragaria × ananassa) and raspberries (Rubus ideaus). Postharvest Biol. Technol. 2004, 33, 67–78. [Google Scholar] [CrossRef]

- Martínez-errer, M.; Harper, C.; Pérezcmuntoz, F.; Chaparro, M. Modified atmosphere packaging of minimally processed mango and pineapple fruits. J. Food Sci. 2010, 67, 3365–3371. [Google Scholar] [CrossRef]

- Dhital, R.; Mora, N.B.; Watson, D.G.; Kohli, P.; Choudhary, R. Efficacy of limonene nano coatings on post-harvest shelf life of strawberries. LWT—Food Sci. Technol. 2018, 97, 124–134. [Google Scholar] [CrossRef]

- Cao, F.; Guan, C.; Dai, H.; Li, X.; Zhang, Z. Soluble solids content is positively correlated with phosphorus content in ripening strawberry fruits. Sci. Hortic. 2015, 195, 183–187. [Google Scholar] [CrossRef]

- Khodaei, D. Influence of bioactive edible coatings loaded with Lactobacillus plantarum on physicochemical properties of fresh strawberries. Postharvest Biol. Technol. 2019, 156, 110944. [Google Scholar] [CrossRef]

| Decay Level | Evaluation Criterion |

|---|---|

| 1 | 1–20% of surface was infected |

| 2 | 21–40% of surface was infected |

| 3 | 41–60% of surface was infected |

| 4 | 61–80% of surface was infected |

| 5 | ≥81% of surface was infected |

| SA:AgNPs | 0 min | 10 min | 20 min | 30 min | 40 min | |

|---|---|---|---|---|---|---|

| TS (MPa) | 10:0 | 23.16 ± 1.64 a | 25.72 ± 1.53 a | 27.96 ± 1.41 a | 28.06 ± 1.55 a | 24.07 ± 1.28 a |

| 9:1 | 21.46 ± 1.38 b | 23.23 ± 1.15 b | 24.31 ± 1.21 b | 26.98 ± 1.32 b | 23.43 ± 1.19 a | |

| 8:2 | 20.04 ± 1.12 b | 22.49 ± 1.13 b | 23.96 ± 1.13 b | 24.07 ± 1.18 b | 21.52 ± 1.10 b | |

| 7:3 | 18.11 ± 0.99 c | 20.54 ± 1.07 b | 22.57 ± 1.10 b | 23.94 ± 1.13 b | 20.80 ± 1.02 b | |

| 6:4 | 16.34 ± 0.89 d | 17.45 ± 0.92 c | 20.24 ± 0.96 c | 21.50 ± 1.01 c | 16.67 ± 0.90 c | |

| E (%) | 10:0 | 18.10 ± 1.12 a | 21.60 ± 1.19 a | 24.31 ± 1.23 a | 26.10 ± 1.39 a | 23.30 ± 1.11 a |

| 9:1 | 13.99 ± 2.19 b | 22.83 ± 1.14 a | 25.95 ± 1.26 a | 27.49 ± 1.42 a | 26.51 ± 1.32 b | |

| 8:2 | 14.79 ± 1.16 b | 23.25 ± 1.18 a | 26.83 ± 1.37 a | 28.90 ± 1.54 a | 27.95 ± 1.40 b | |

| 7:3 | 16.40 ± 1.18 a | 25.15 ± 1.21 b | 27.44 ± 1.40 a | 29.18 ± 1.59 a | 28.29 ± 1.46 b | |

| 6:4 | 21.08 ± 1.31 c | 23.15 ± 1.18 a | 25.07 ± 1.34 a | 27.09 ± 1.41 a | 26.04 ± 1.33 b |

| Samples | Antibacterial Property (%) | DPPH (%) | |

|---|---|---|---|

| S. aureus | E. coli | ||

| SA | - | - | 1.01 ± 0.53 |

| SA/AgNPs/APP-10:0 | 27.61 ± 0.53 d | 27.84 ± 0.49 d | 99.89 ± 0.07 a |

| SA/AgNPs/APP-9:1 | 58.98 ± 0.28 c | 54.90 ± 0.22 c | 95.57 ± 0.32 a |

| SA/AgNPs/APP-8:2 | 83.17 ± 0.73 b | 84.54 ± 0.53 b | 97.23 ± 0.21 a |

| SA/AgNPs/APP-7:3 | 91.26 ± 0.49 a | 92.01 ± 0.55 a | 98.39 ± 0.11 a |

| SA/AgNPs/APP-6:4 | 92.48 ± 0.88 a | 92.78 ± 0.37 a | 95.92 ± 0.35 a |

| Days (d) | 0 | 2 | 4 | 6 | 8 | 10 | 12 |

|---|---|---|---|---|---|---|---|

| SA/AgNPs/APP | 9.0 ± 0.1 a | 8.5 ± 0.3 a | 8.2 ± 0.1 a | 7.9 ± 0.1 a | 7.3 ± 0.2 a | 7.0 ± 0.5 a | 6.5 ± 0.2 a |

| SA/APP | 9.0 ± 0.1 a | 8.2 ± 0.2 a | 7.8 ± 0.4 b | 7.3 ± 0.3 a | 5.5 ± 0.1 b | 4.5 ± 0.6 b | 2.5 ± 0.5 b |

| SA | 9.0 ± 0.1 a | 8.0 ± 0.1 a | 7.6 ± 0.7 b | 6.8 ± 0.2 b | 4.2 ± 0.2 c | 2.5 ± 0.4 c | 1.0 ± 0.2 c |

| PE | 9.0 ± 0.1 a | 8.4 ± 0.3 a | 7.5 ± 0.2 b | 6.3 ± 0.4 b | 4.0 ± 0.4 c | 1.0 ± 0.2 d | 1.0 ± 0.3 c |

| Air control | 9.0 ± 0.1 a | 7.8 ± 0.1 b | 6.0 ± 0.1 c | 4.2 ± 0.3 c | 3.1 ± 0.2 d | 1.3 ± 0.3 d | 1.1 ± 0.1 c |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, W.; Li, S.; Shama, S.; Zhao, Y.; Sameen, D.E.; He, L.; Liu, Y. Investigation of Ultrasonic Treatment on Physicochemical, Structural and Morphological Properties of Sodium Alginate/AgNPs/Apple Polyphenol Films and Its Preservation Effect on Strawberry. Polymers 2020, 12, 2096. https://doi.org/10.3390/polym12092096

Lan W, Li S, Shama S, Zhao Y, Sameen DE, He L, Liu Y. Investigation of Ultrasonic Treatment on Physicochemical, Structural and Morphological Properties of Sodium Alginate/AgNPs/Apple Polyphenol Films and Its Preservation Effect on Strawberry. Polymers. 2020; 12(9):2096. https://doi.org/10.3390/polym12092096

Chicago/Turabian StyleLan, Wenting, Siying Li, Shiti Shama, Yuqing Zhao, Dur E. Sameen, Li He, and Yaowen Liu. 2020. "Investigation of Ultrasonic Treatment on Physicochemical, Structural and Morphological Properties of Sodium Alginate/AgNPs/Apple Polyphenol Films and Its Preservation Effect on Strawberry" Polymers 12, no. 9: 2096. https://doi.org/10.3390/polym12092096