Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research

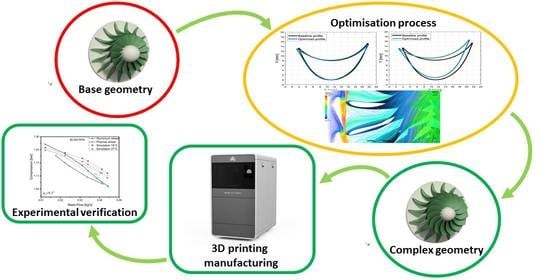

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manufacturing Technology

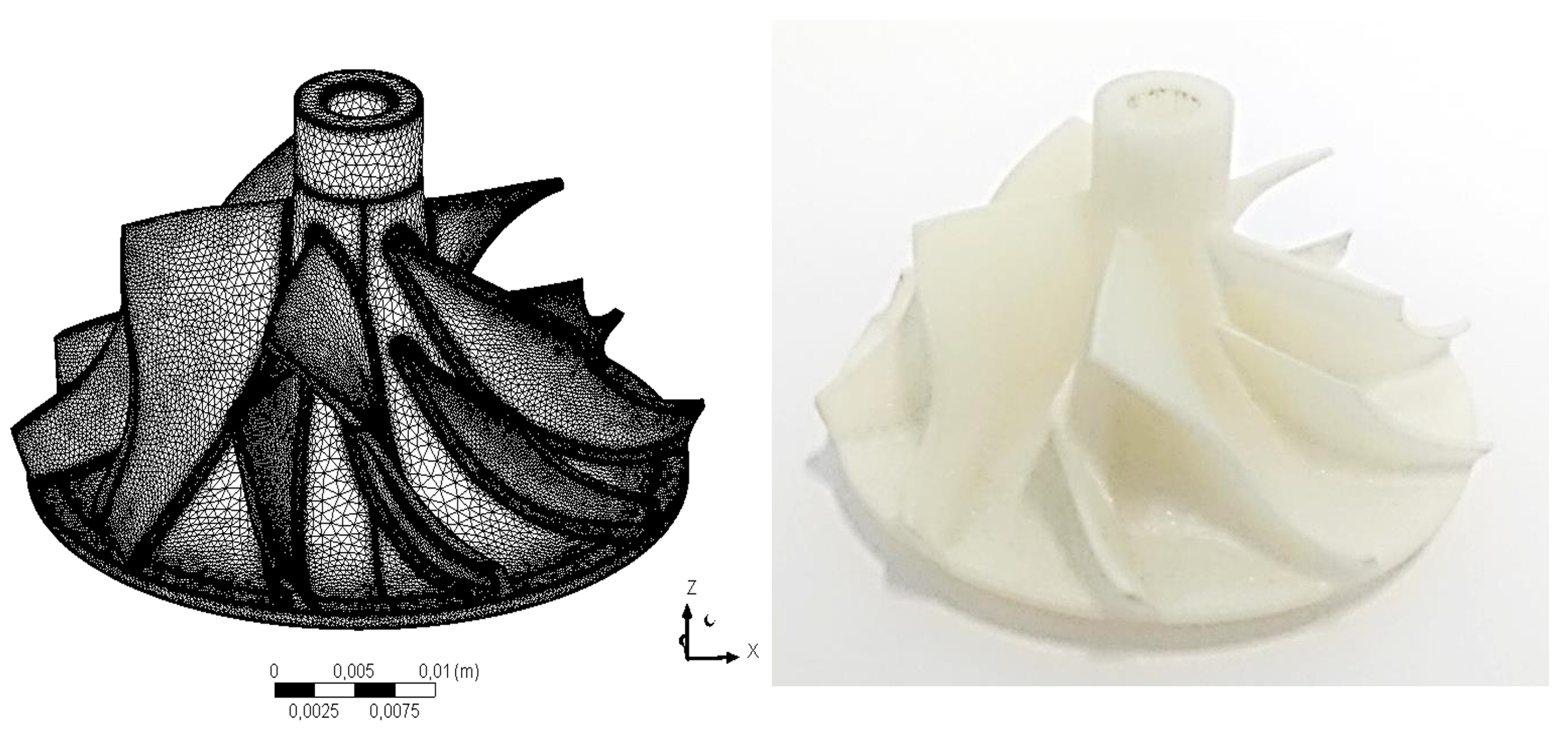

2.2. Numerical Analysis

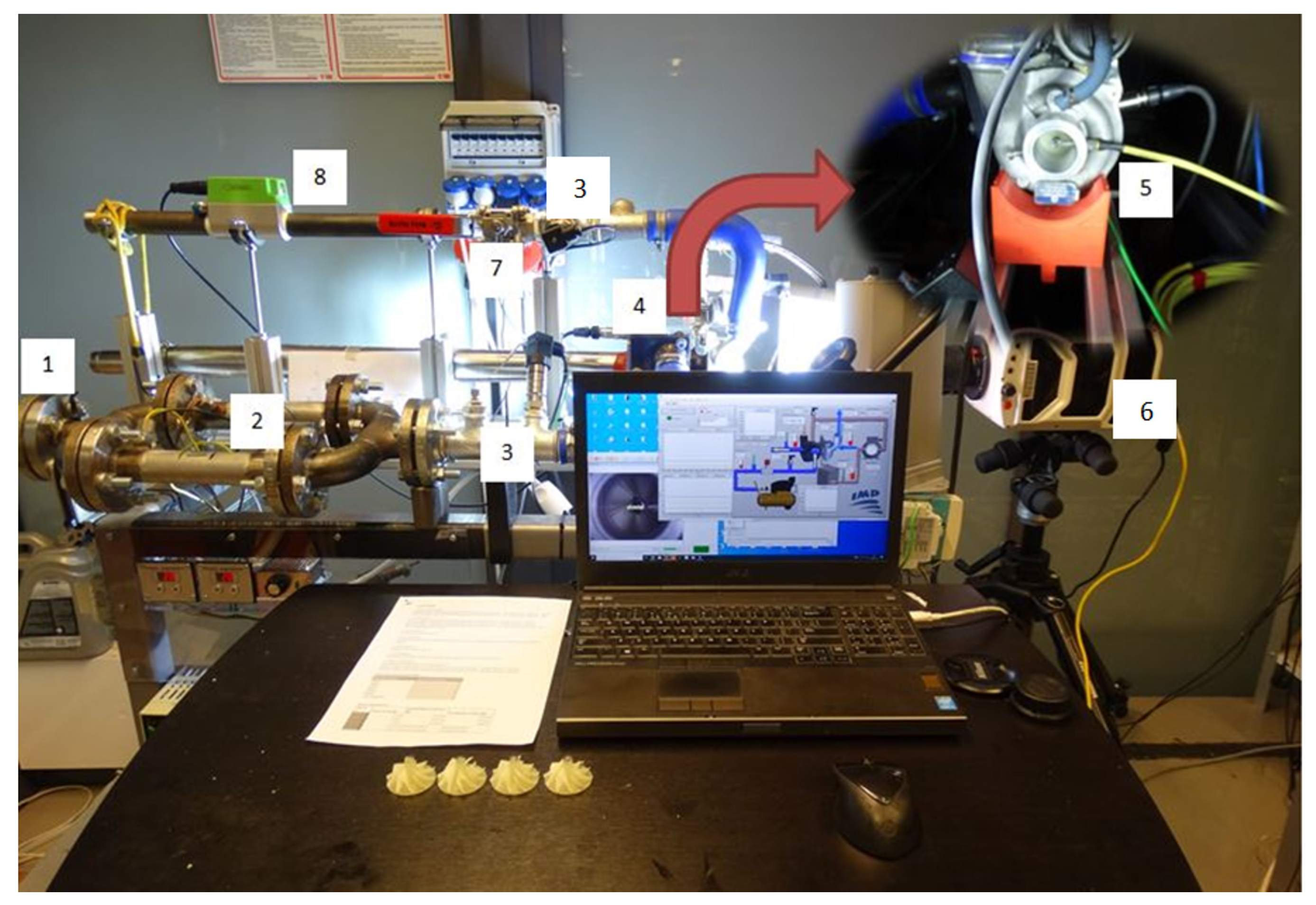

2.3. Experimental Setup

3. Results

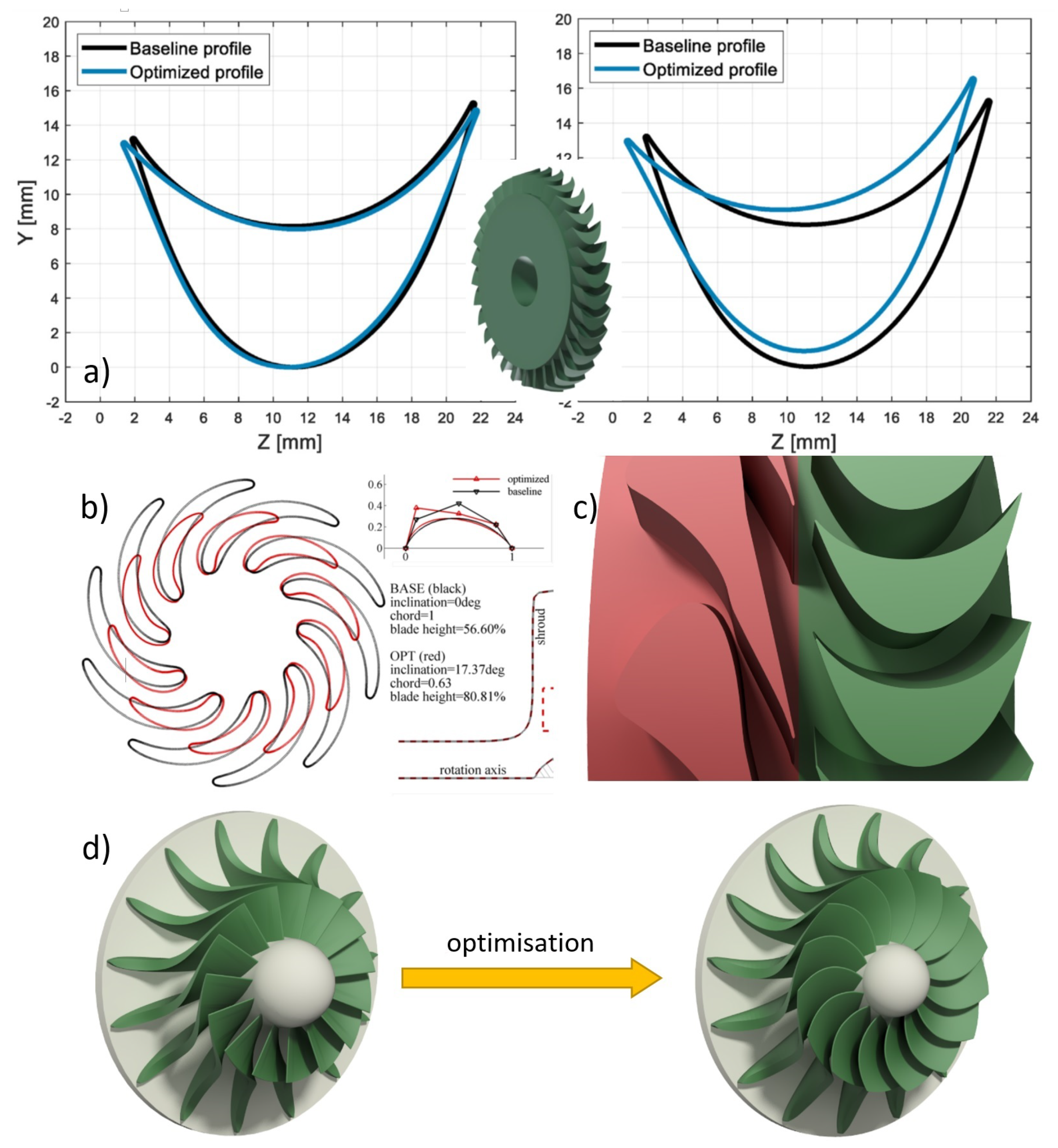

3.1. Numerical Results

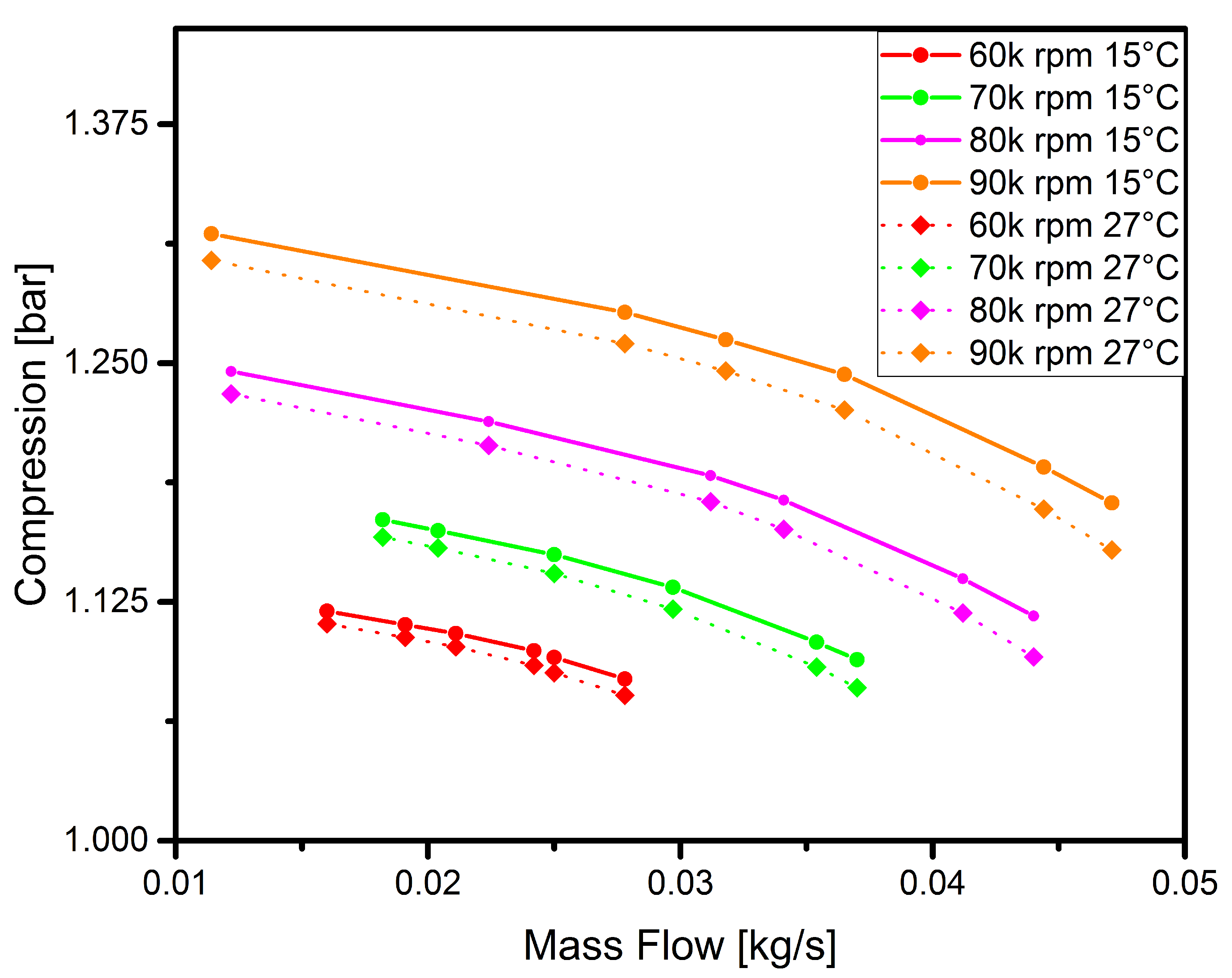

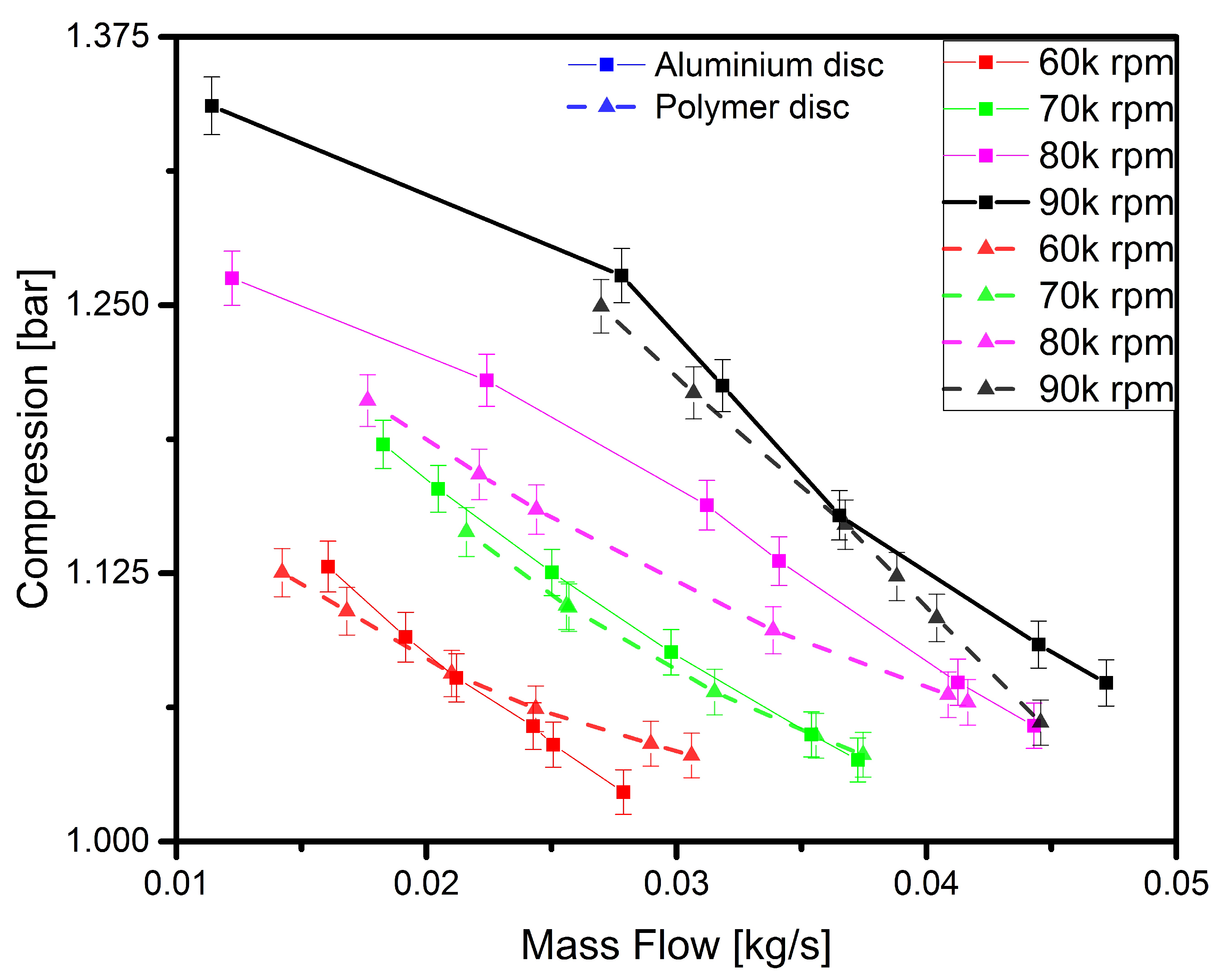

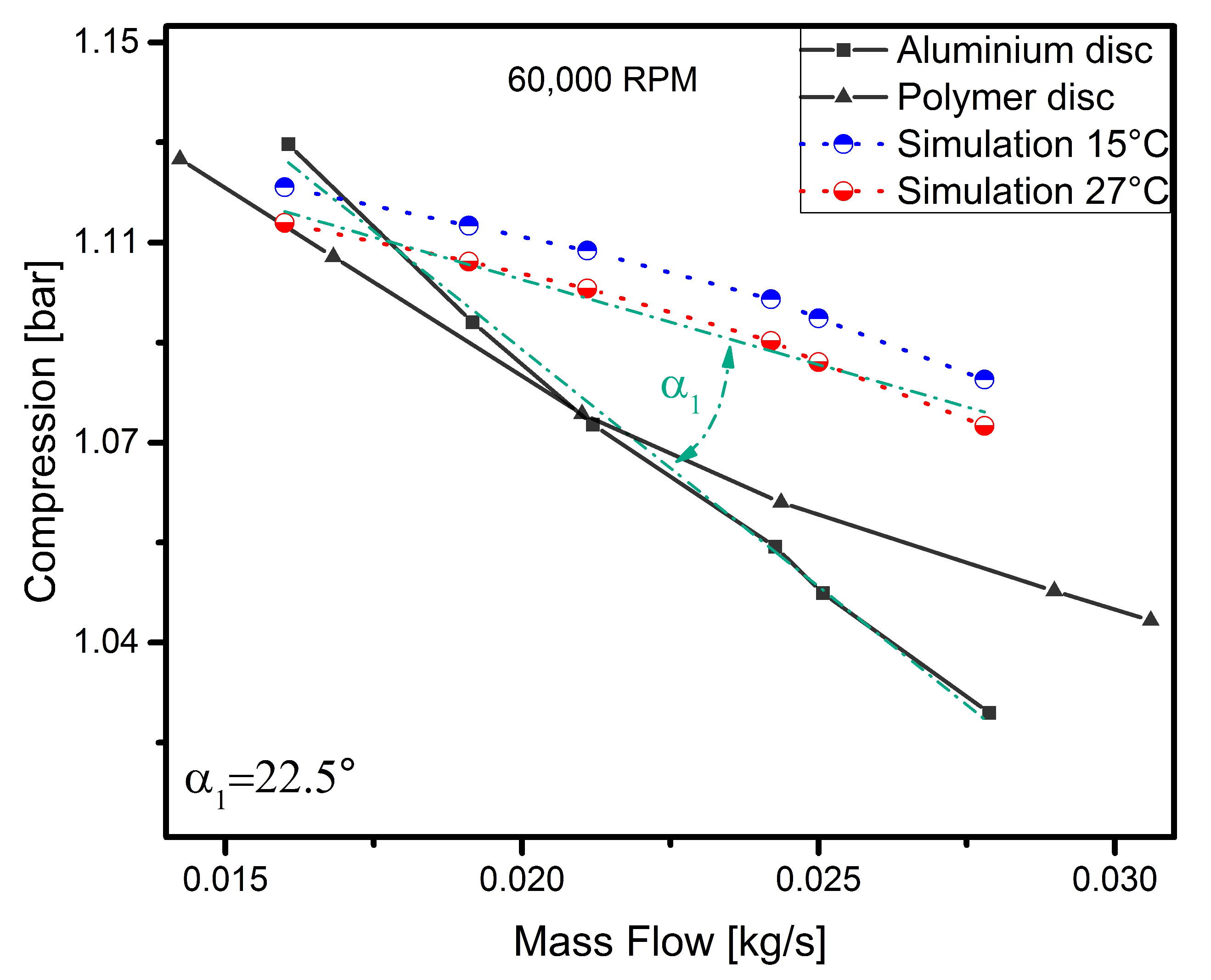

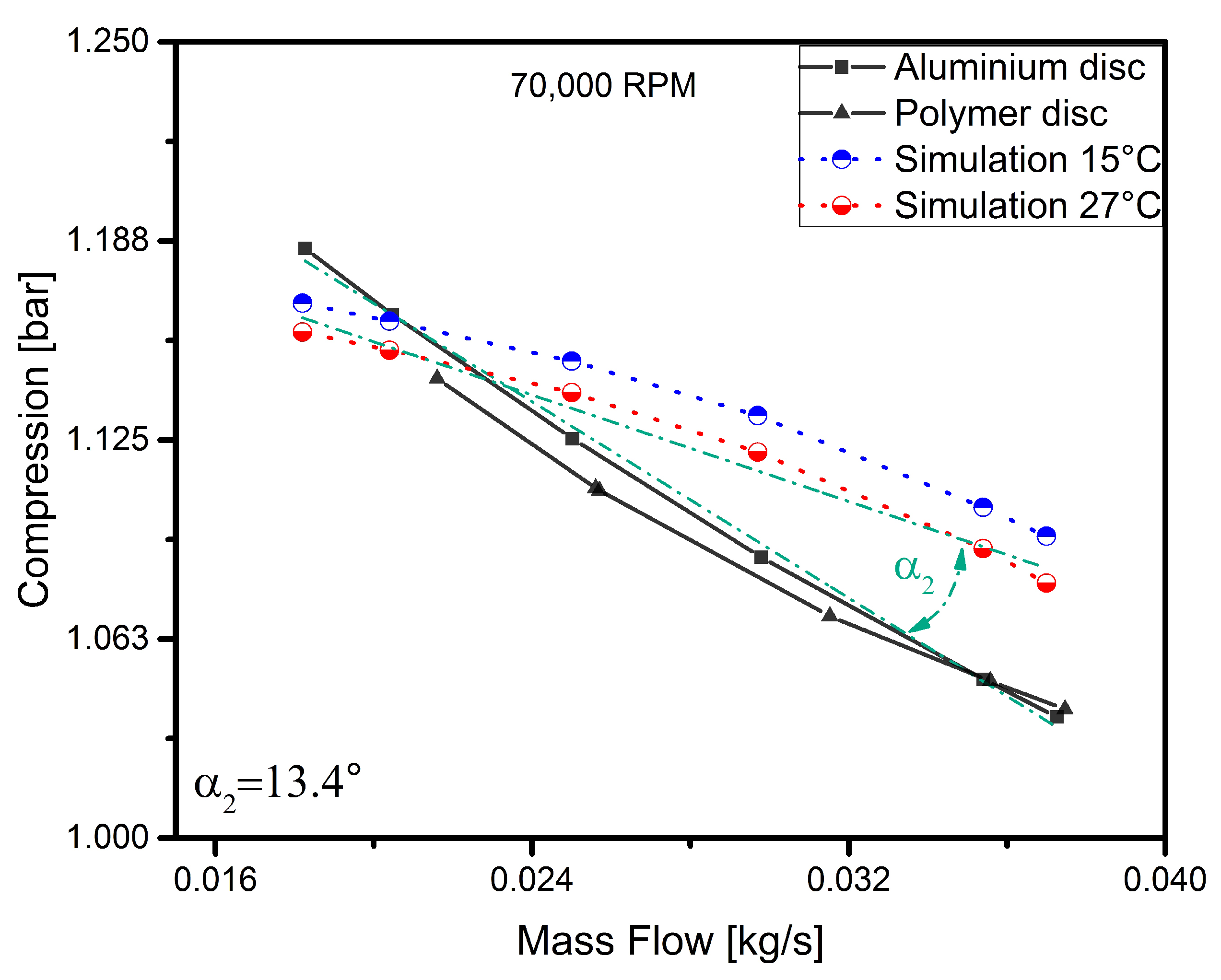

3.2. Flow Characteristics

3.3. Destructive Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gaharwar, A.K.; Cross, L.M.; Peak, C.W.; Gold, K.; Carrow, J.K.; Brokesh, A.; Singh, K.A. 2D nanoclay for biomedical applications: Regenerative medicine, therapeutic delivery, and additive manufacturing. Adv. Mater. 2019, 31, 1900332. [Google Scholar] [CrossRef] [PubMed]

- Guzzi, E.A.; Tibbitt, M.W. Additive manufacturing of precision biomaterials. Adv. Mater. 2020, 32, 1901994. [Google Scholar] [CrossRef] [PubMed]

- Tejo-Otero, A.; Buj-Corral, I.; Fenollosa-Artés, F. 3D printing in medicine for preoperative surgical planning: A review. Ann. Biomed. Eng. 2020, 48, 536–555. [Google Scholar] [CrossRef] [PubMed]

- Choong, Y.Y.C.; Tan, H.W.; Patel, D.C.; Choong, W.T.N.; Chen, C.H.; Low, H.Y.; Tan, M.J.; Patel, C.D.; Chua, C.K. The global rise of 3D printing during the COVID-19 pandemic. Nat. Rev. Mater. 2020, 5, 637–639. [Google Scholar] [CrossRef]

- Liu, D.; Koo, T.; Wong, J.; Wong, Y.; Fung, K.; Chan, Y.; Lim, H. Adapting re-usable elastomeric respirators to utilise anaesthesia circuit filters using a 3D-printed adaptor-a potential alternative to address N95 shortages during the COVID-19 pandemic. Anaesthesia 2020. [Google Scholar] [CrossRef]

- Wang, F. Research progress of 3D printing materials in stomatology. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Singapore, 21–23 June 2019; IOP Publishing: Bristol, UK, 2019; Volume 332, p. 032013. [Google Scholar]

- Bartkowiak, T.; Walkowiak-Śliziuk, A. 3D printing technology in orthodontics–review of current applications. J. Stomatol. 2018, 71, 356–364. [Google Scholar] [CrossRef]

- Muravyev, N.V.; Monogarov, K.A.; Schaller, U.; Fomenkov, I.V.; Pivkina, A.N. Progress in additive manufacturing of energetic materials: Creating the reactive microstructures with high potential of applications. Propellants Explos. Pyrotech. 2019, 44, 941–969. [Google Scholar] [CrossRef]

- Froes, F.H.; Boyer, R. Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Böckin, D.; Tillman, A.M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Andrearczyk, A.; Baginski, P.; Klonowicz, P. Numerical and experimental investigations of a turbocharger with a compressor wheel made of additively manufactured plastic. Int. J. Mech. Sci. 2020, 178, 105613. [Google Scholar] [CrossRef]

- Sasan, K.; Lange, A.; Yee, T.D.; Dudukovic, N.; Nguyen, D.T.; Johnson, M.A.; Herrera, O.D.; Yoo, J.H.; Sawvel, A.M.; Ellis, M.E.; et al. Additive Manufacturing of Optical Quality Germania–Silica Glasses. ACS Appl. Mater. Interfaces 2020, 12, 6736–6741. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2020, 116, 100736. [Google Scholar] [CrossRef]

- Wani, Z.; Abdullah, A. A Review on metal 3D printing; 3D welding. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Penang, Malaysia, 2–3 December 2019; IOP Publishing: Bristol, UK, 2020; Volume 920, p. 012015. [Google Scholar]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Chuang, K.C.; Grady, J.E.; Arnold, S.M.; Draper, R.D.; Shin, E.; Patterson, C.; Santelle, T.; Lao, C.; Rhein, M.; Mehl, J. A Fully Nonmetallic Gas Turbine Engine Enabled by Additive Manufacturing, Part II: Additive Manufacturing and Characterization of Polymer Composites. Available online: http://snari.arc.nasa.gov/sites/default/files/GradyTM-2015-218749.pdf (accessed on 10 December 2020).

- Murr, L.E. Frontiers of 3D printing/additive manufacturing: From human organs to aircraft fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Luo, C.; Wang, X.; Migler, K.B.; Seppala, J.E. Upper bound of feed rates in thermoplastic material extrusion additive manufacturing. Addit. Manuf. 2020, 32, 101019. [Google Scholar] [CrossRef]

- Shi, J.; Chen, H.; Jia, S.; Wang, W. Rapid and low-cost fabrication of thermoelectric composite using low-pressure cold pressing and thermocuring methods. Mater. Lett. 2018, 212, 299–302. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Oliveira, J.; Etxebarria, I.; Vilas-Vilela, J.L.; Lanceros-Mendez, S. State-of-the-art and future challenges of UV curable polymer-based smart materials for printing technologies. Adv. Mater. Technol. 2019, 4, 1800618. [Google Scholar] [CrossRef] [Green Version]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Mardis, N.J. Emerging technology and applications of 3D printing in the medical field. Mo. Med. 2018, 115, 368. [Google Scholar]

- Salentijn, G.I.; Oomen, P.E.; Grajewski, M.; Verpoorte, E. Fused deposition modeling 3D printing for (bio) analytical device fabrication: Procedures, materials, and applications. Anal. Chem. 2017, 89, 7053–7061. [Google Scholar] [CrossRef] [Green Version]

- Haryńska, A.; Kucinska-Lipka, J.; Sulowska, A.; Gubanska, I.; Kostrzewa, M.; Janik, H. Medical-grade PCL based polyurethane system for FDM 3D printing-Characterization and fabrication. Materials 2019, 12, 887. [Google Scholar] [CrossRef] [Green Version]

- Carneiro, V.; Rawson, S.; Puga, H.; Meireles, J.; Withers, P. Additive manufacturing assisted investment casting: A low-cost method to fabricate periodic metallic cellular lattices. Addit. Manuf. 2020, 33, 101085. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- Tunchel, S.; Blay, A.; Kolerman, R.; Mijiritsky, E.; Shibli, J.A. 3D printing/additive manufacturing single titanium dental implants: A prospective multicenter study with 3 years of follow-up. Int. J. Dent. 2016, 2016. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Z Kaczmarczyk, T.; Żywica, G.; Ihnatowicz, E. Vibroacoustic diagnostics of a radial microturbine and a scroll expander operating in the organic Rankine cycle installation. J. Vibroeng. 2016, 18, 4130–4147. [Google Scholar] [CrossRef]

- Baginski, P.; Zych, P.; Zywica, G. Stress analysis of the discs of axial-flow microturbines. J. Vibroeng. 2020, 22, 1519–1533. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Żywica, G.; Ihnatowicz, E. Experimental study of a low-temperature micro-scale organic Rankine cycle system with the multi-stage radial-flow turbine for domestic applications. Energy Convers. Manag. 2019, 199, 111941. [Google Scholar] [CrossRef]

- Zych, P.; Żywica, G. Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM. Open Eng. 2020, 10, 318–335. [Google Scholar] [CrossRef]

- Floudas, C.A. Deterministic Global Optimization: Theory, Methods and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 37. [Google Scholar]

- Reddi, S.J.; Sra, S.; Poczos, B.; Smola, A.J. Proximal stochastic methods for nonsmooth nonconvex finite-sum optimization. Adv. Neural Inf. Process. Syst. 2016, 29, 1145–1153. [Google Scholar]

- Friedlander, M.P.; Schmidt, M. Hybrid deterministic-stochastic methods for data fitting. SIAM J. Sci. Comput. 2012, 34, A1380–A1405. [Google Scholar] [CrossRef] [Green Version]

- Kondrashov, Y.N.; Ermakov, A. Optimization of planned solutions based on network models for large-scale problems. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Krasnoyarsk, Russia, 16–18 April 2020; IOP Publishing: Bristol, UK, 2020; Volume 862, p. 052074. [Google Scholar]

- Lampart, P.; Witanowski, Ł.; Klonowicz, P. Efficiency optimisation of blade shape in steam and ORC turbines. Mech. Mech. Eng. 2020, 22, 553–564. [Google Scholar] [CrossRef]

- Andrearczyk, A.; Bagiński, P. Vibration analysis of a turbocharger with an additively manufactured compressor wheel. Sci. J. Silesian Univ. Technol. Ser. Transp. 2020, 107, 5–17. [Google Scholar]

- Mieloszyk, M.; Andrearczyk, A.; Majewska, K.; Jurek, M.; Ostachowicz, W. Polymeric structure with embedded fiber Bragg grating sensor manufactured using multi-jet printing method. Measurement 2020, 166, 108229. [Google Scholar] [CrossRef]

- Andrearczyk, A.; Mieloszyk, M.; Bagiński, P. Destructive Tests of an Additively Manufactured Compressor Wheel Performed at High Rotational Speeds. In International Conference on Applied Human Factors and Ergonomics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 117–123. [Google Scholar]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Sharma, S.; Broatch, A.; García-Tíscar, J.; Nickson, A.K.; Allport, J.M. Acoustic and pressure characteristics of a ported shroud turbocompressor operating at near surge conditions. Appl. Acoust. 2019, 148, 434–447. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Broatch, A.; García-Tíscar, J.; Allport, J.M.; Nickson, A.K. Acoustic characteristics of a ported shroud turbocompressor operating at design conditions. Int. J. Engine Res. 2020, 21, 1454–1468. [Google Scholar] [CrossRef]

- Sivarupan, T.; Upadhyay, M.; Ali, Y.; El Mansori, M.; Dargusch, M.S. Reduced consumption of materials and hazardous chemicals for energy efficient production of metal parts through 3D printing of sand molds. J. Clean. Prod. 2019, 224, 411–420. [Google Scholar] [CrossRef]

- Klonowicz, P.; Lampart, P.; Suchocki, T.; Zaniewski, D.; Klimaszewski, P. Optimization of an axial turbine for a small scale ORC waste heat recovery system. Energy 2020, 205, 118059. [Google Scholar]

- Kavas, I.; Saracoglu, B.H.; Arts, T. Numerical optimization of air breathing radial outflow turbines. In Proceedings of the 13th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics, Lausanne, Switzerland, 8–12 April 2019. [Google Scholar]

- Klonowicz, P.; Witanowski, Ł.; Suchocki, T.; Ję.drzejewski, Ł.; Lampart, P. Selection of optimum degree of partial admission in a laboratory organic vapour microturbine. Energy Convers. Manag. 2019, 202, 112189. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrearczyk, A.; Konieczny, B.; Sokołowski, J. Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research. Polymers 2021, 13, 137. https://doi.org/10.3390/polym13010137

Andrearczyk A, Konieczny B, Sokołowski J. Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research. Polymers. 2021; 13(1):137. https://doi.org/10.3390/polym13010137

Chicago/Turabian StyleAndrearczyk, Artur, Bartlomiej Konieczny, and Jerzy Sokołowski. 2021. "Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research" Polymers 13, no. 1: 137. https://doi.org/10.3390/polym13010137

APA StyleAndrearczyk, A., Konieczny, B., & Sokołowski, J. (2021). Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research. Polymers, 13(1), 137. https://doi.org/10.3390/polym13010137