Numerical Investigation of Fabricated MWCNTs/Polystyrene Nanofibrous Membrane for DCMD

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Fabrication

2.2. Membrane Characterization

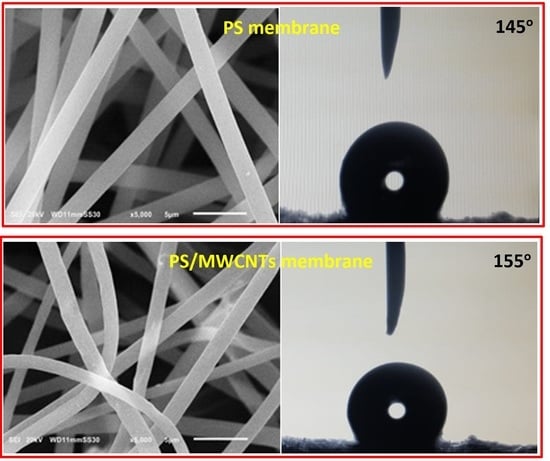

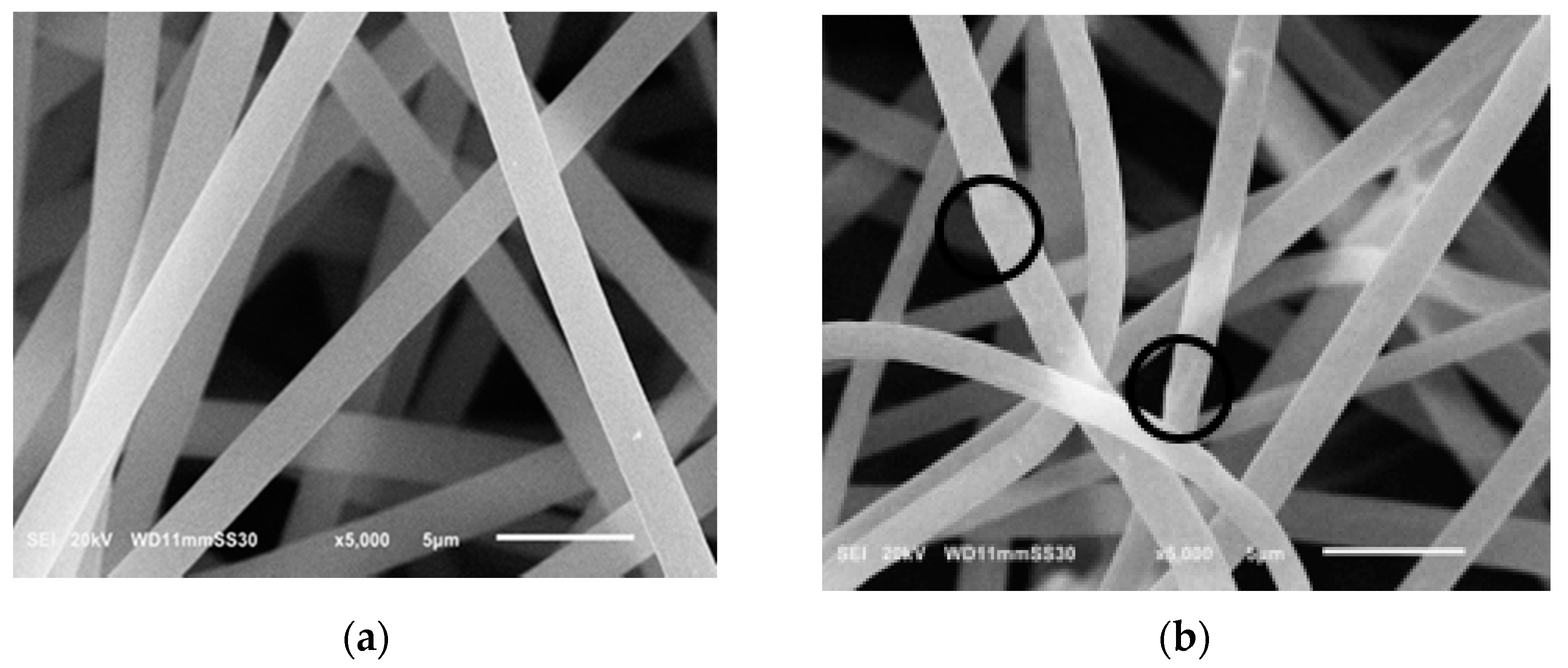

2.2.1. Scanning Electron Microscope (SEM)

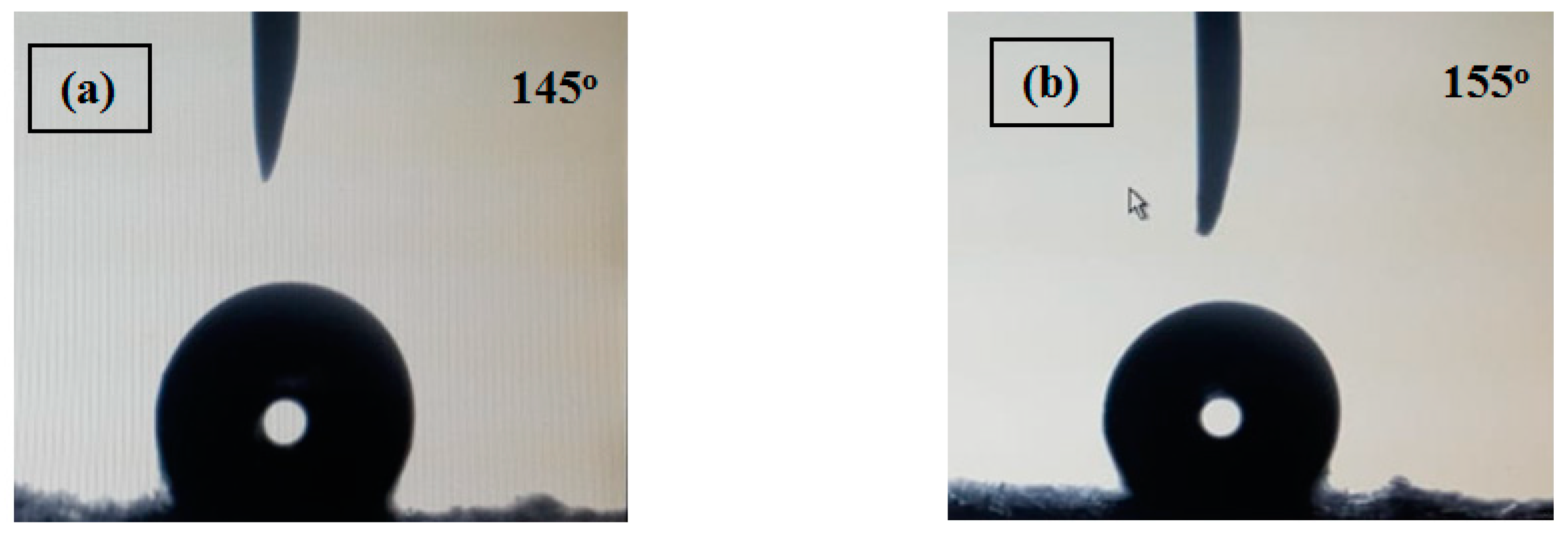

2.2.2. Single Drop Contact Angle

2.2.3. Thickness and Porosity

2.2.4. Pore Sizes and Fiber Diameter

2.2.5. Fourier-Transform Infra-Red (FTIR)

2.2.6. Numerical Analysis

- Steady and laminar flow and incompressible fluid.

- All properties (fluid and material) are constant within the operating range.

- No heat losses from the system to the surrounding.

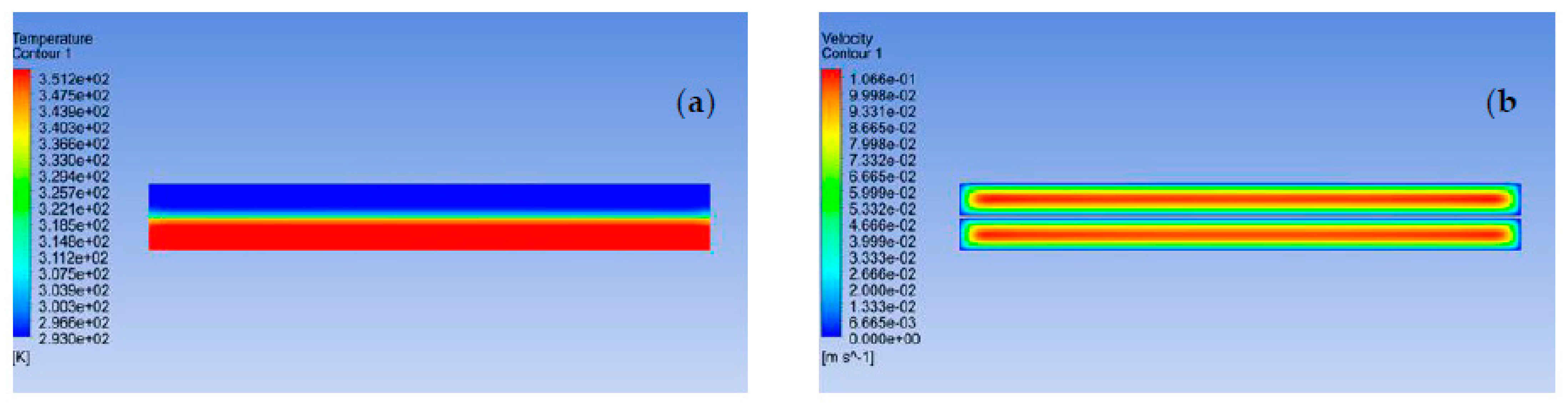

Model Discerption

Governing Equations

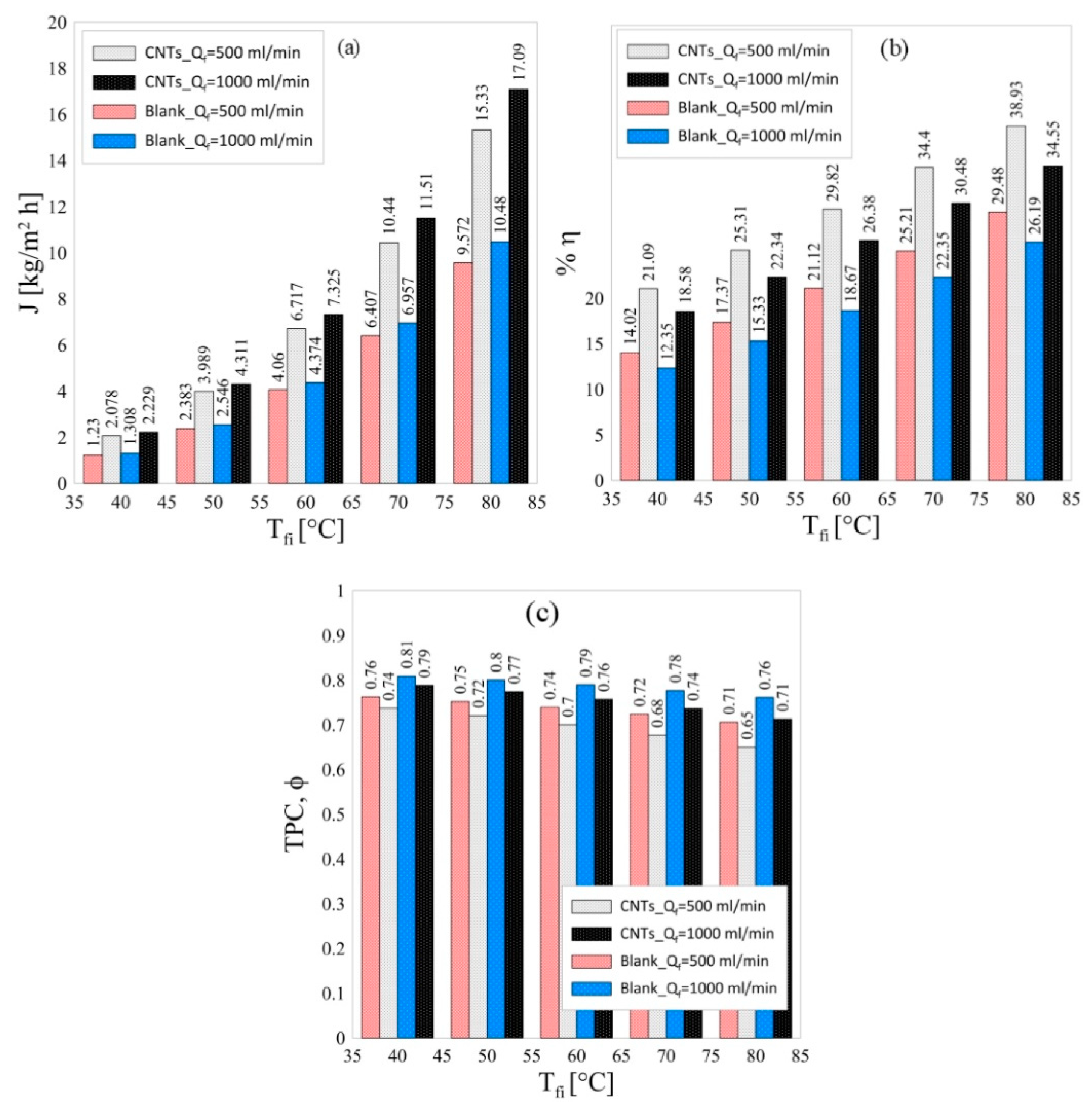

System Metrics

3. Results

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Takeuchi, K.; Takizawa, Y.; Kitazawa, H.; Fujii, M.; Hosaka, K.; Ortiz-Medina, J.; Morelos-Gomez, A.; Cruz-Silva, R.; Fujishige, M.; Akuzawa, N.; et al. Salt rejection behavior of carbon nanotube-polyamide nanocomposite reverse osmosis membranes in several salt solutions. Desalination 2018, 443, 165–171. [Google Scholar] [CrossRef]

- El-Mehalmey, W.A.; Safwat, Y.; Bassyouni, M.; Alkordi, M.H. Strong Interplay between Polymer Surface Charge and MOF Cage Chemistry in Mixed-Matrix Membrane for Water Treatment Applications. ACS Appl. Mater. Interfaces 2020, 12, 27625–27631. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, Y.; Wu, L.; Wei, G. Fabrication, Properties, Performances, and Separation Application of Polymeric Pervaporation Membranes: A Review. Polymers 2020, 12, 1466. [Google Scholar] [CrossRef] [PubMed]

- Bassyouni, M.; Mansi, A.E.; Elgabry, A.; Ibrahim, B.A.; Kassem, O.A.; Alhebeshy, R. Utilization of carbon nanotubes in removal of heavy metals from wastewater: A review of the CNTs’ potential and current challenges. Appl. Phys. A 2019, 126, 38. [Google Scholar] [CrossRef]

- Gutub, S.A.; Bassyouni, M.; Abdel-Hamid, S.M.S. Dissolved solids adsorption of freshwater using synthesized bio-foam composite. Life Sci. J. 2013, 10, 464–471. [Google Scholar]

- Zhang, Z.; Zhang, W.; Lichtfouse, E. (Eds.) Membranes for Environmental Applications; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Elrasheedy, A.; Nady, N.; Bassyouni, M.; El-Shazly, A.H. Metal Organic Framework Based Polymer Mixed Matrix Membranes: Review on Applications in Water Purification. Membranes 2019, 9, 88. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Chen, D.; Wang, Q.; Ying, Y.; Gao, W.; Xie, L. Recent Advances in Applications of Carbon Nanotubes for Desalination: A Review. Nanomaterials 2020, 10, 1203. [Google Scholar] [CrossRef]

- Ali, S.; Rehman, S.A.U.; Luan, H.-Y.; Farid, M.U.; Huang, H. Challenges and opportunities in functional carbon nanotubes for membrane-based water treatment and desalination. Sci. Total Environ. 2019, 646, 1126–1139. [Google Scholar] [CrossRef]

- Camacho, L.M.; Dumée, L.F.; Zhang, J.; Li, J.-D.; Duke, M.; Gomez, J.D.; Gray, S. Advances in Membrane Distillation for Water Desalination and Purification Applications. Water 2013, 5, 94–196. [Google Scholar] [CrossRef] [Green Version]

- Alanezi, A.A.; Elhenawy, Y.; Goodarzi, M.; Safaei, M.R. The Effect of Inclination Angle and Reynolds Number on the Performance of a Direct Contact Membrane Distillation (DCMD) Process. Energies 2020, 13, 2824. [Google Scholar] [CrossRef]

- Elminshawy, N.A.; Gadalla, M.A.; Bassyouni, M.; El-Nahhas, K.; Elminshawy, A.; Elhenawy, Y. A novel concentrated photovoltaic-driven membrane distillation hybrid system for the simultaneous production of electricity and potable water. Renew. Energy 2020, 162, 802–817. [Google Scholar] [CrossRef]

- Mabrouk, A.N.; Abdelkader, M.; Shatat, M. The impact of baffle orientation on the performance of the hollow fiber membrane. Desalin. Water Treat. 2017, 58, 35–45. [Google Scholar] [CrossRef]

- Bassyouni, M.; Abdel-Aziz, M.H.; Zoromba, M.S.; Abdel-Hamid, S.; Drioli, E. A review of polymeric nanocomposite membranes for water purification. J. Ind. Eng. Chem. 2019, 73, 19–46. [Google Scholar] [CrossRef]

- Woo, Y.C.; Tijing, L.D.; Shim, W.-G.; Choi, J.-S.; Kim, S.-H.; He, T.; Drioli, E.; Shon, H.K. Water desalination using graphene-enhanced electrospun nanofiber membrane via air gap membrane distillation. J. Membr. Sci. 2016, 520, 99–110. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.A.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Yang, F.; Efome, J.E.; Rana, D.; Matsuura, T.; Lan, C. Metal–Organic Frameworks Supported on Nanofiber for Desalination by Direct Contact Membrane Distillation. ACS Appl. Mater. Interfaces 2018, 10, 11251–11260. [Google Scholar] [CrossRef] [PubMed]

- Lawal, D.U.; Khalifa, A.E. Flux Prediction in Direct Contact Membrane Distillation. Int. J. Mater. Mech. Manuf. 2014, 2, 302–308. [Google Scholar] [CrossRef] [Green Version]

- Elhady, S.; Bassyouni, M.; Mansour, R.A.; Elzahar, M.H.; Abdel-Hamid, S.M.S.; Elhenawy, Y.; Saleh, M.Y. Oily Wastewater Treatment Using Polyamide Thin Film Composite Membrane Technology. Membranes 2020, 10, 84. [Google Scholar] [CrossRef]

- El-Marghany, M.R.; El-Shazly, A.H.; Salem, M.S.A.; Sabry, M.N.; Nady, N. Novel Membrane Suitable for Membrane Distillation: Effect of Mixed Nanofillers on the Membrane Performance. Key Eng. Mater. 2019, 801, 325–330. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Yang, Y.; Wang, X.; Zhu, M.; Hsiao, B.S. Dual-Biomimetic Superhydrophobic Electrospun Polystyrene Nanofibrous Membranes for Membrane Distillation. ACS Appl. Mater. Interfaces 2014, 6, 2423–2430. [Google Scholar] [CrossRef]

- Ihsanullah, I. Carbon nanotube membranes for water purification: Developments, challenges, and prospects for the future. Sep. Purif. Technol. 2019, 209, 307–337. [Google Scholar] [CrossRef]

- Baek, Y.; Kim, H.J.; Kim, S.-H.; Lee, J.-C.; Yoon, J. Evaluation of carbon nanotube-polyamide thin-film nanocomposite reverse osmosis membrane: Surface properties, performance characteristics and fouling behavior. J. Ind. Eng. Chem. 2017, 56, 327–334. [Google Scholar] [CrossRef]

- An, A.; Lee, E.-J.; Guo, J.; Jeong, S.; Lee, J.-G.; Ghaffour, N. Enhanced vapor transport in membrane distillation via functionalized carbon nanotubes anchored into electrospun nanofibres. Sci. Rep. 2017, 7, srep41562. [Google Scholar] [CrossRef] [Green Version]

- Silva, T.L.; Morales-Torres, S.; Figueiredo, J.L.; Silva, A.M. Multi-walled carbon nanotube/PVDF blended membranes with sponge- and finger-like pores for direct contact membrane distillation. Desalination 2015, 357, 233–245. [Google Scholar] [CrossRef]

- Dumée, L.F.; Sears, K.; Schütz, J.; Finn, N.; Huynh, C.; Hawkins, S.; Duke, M.; Gray, S.R. Characterization and evaluation of carbon nanotube Bucky-Paper membranes for direct contact membrane distillation. J. Membr. Sci. 2010, 351, 36–43. [Google Scholar] [CrossRef] [Green Version]

- Tijing, L.D.; Woo, Y.C.; Shim, W.-G.; He, T.; Choi, J.-S.; Kim, S.-H.; Shon, H.K. Superhydrophobic nanofiber membrane containing carbon nanotubes for high-performance direct contact membrane distillation. J. Membr. Sci. 2016, 502, 158–170. [Google Scholar] [CrossRef]

- Zhou, R.; Rana, D.; Matsuura, T.; Lan, C.Q. Effects of multi-walled carbon nanotubes (MWCNTs) and integrated MWCNTs/SiO2 nano-additives on PVDF polymeric membranes for vacuum membrane distillation. Sep. Purif. Technol. 2019, 217, 154–163. [Google Scholar] [CrossRef]

- Ke, H.; Feldman, E.; Guzman, P.; Cole, J.; Wei, Q.; Chu, B.; Alkhudhiri, A.; Alrasheed, R.; Hsiao, B.S. Electrospun polystyrene nanofibrous membranes for direct contact membrane distillation. J. Membr. Sci. 2016, 515, 86–97. [Google Scholar] [CrossRef]

- Kulkarni, A.; Bambole, V.A.; Mahanwar, P. Electrospinning of Polymers, Their Modeling and Applications. Polym. Technol. Eng. 2010, 49, 427–441. [Google Scholar] [CrossRef]

- Nuraje, N.; Khan, W.S.; Lei, Y.; Ceylan, M.; Asmatulu, R. Superhydrophobic electrospun nanofibers. J. Mater. Chem. A 2013, 1, 1929–1946. [Google Scholar] [CrossRef]

- Sadeghzadeh, A.; Bazgir, S.; Shirazi, M.M.A. Fabrication and characterization of a novel hydrophobic polystyrene membrane using electroblowing technique for desalination by direct contact membrane distillation. Sep. Purif. Technol. 2020, 239, 116498. [Google Scholar] [CrossRef]

- Khoshnevisan, S.; Bazgir, S. Treatment of dye wastewater by direct contact membrane distillation using superhydrophobic nanofibrous high-impact polystyrene membranes. Int. J. Environ. Sci. Technol. 2020, 1–16. [Google Scholar] [CrossRef]

- Parangusan, H.; Ponnamma, D.; Hassan, M.K.; Adham, S.; Al-Maadeed, M.A. Designing Carbon Nanotube-Based Oil Absorbing Membranes from Gamma Irradiated and Electrospun Polystyrene Nanocomposites. Materials 2019, 12, 709. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elmarghany, M.R.; El-Shazly, A.H.; Rajabzadeh, S.; Salem, M.S.A.; Shouman, M.A.; Sabry, M.N.; Matsuyama, H.; Nady, N. Triple-Layer Nanocomposite Membrane Prepared by Electrospinning Based on Modified PES with Carbon Nanotubes for Membrane Distillation Applications. Membranes 2020, 10, 15. [Google Scholar] [CrossRef] [Green Version]

- Manawi, Y.; Wang, K.; Kochkodan, V.; Johnson, D.J.; Atieh, M.A.; Khraisheh, M. Engineering the Surface and Mechanical Properties of Water Desalination Membranes Using Ultralong Carbon Nanotubes. Membranes 2018, 8, 106. [Google Scholar] [CrossRef] [Green Version]

- Sianipar, M.; Kim, S.H.; Khoiruddin, K.; Iskandar, F.; Wenten, I.G. Functionalized carbon nanotube (CNT) membrane: Progress and challenges. RSC Adv. 2017, 7, 51175–51198. [Google Scholar] [CrossRef] [Green Version]

- Esteves, R.J.A.; Gornick, V.; Alqurwani, D.S.; Koenig-Lovejoy, J.; Abdelrazeq, H.; Khraisheh, M.; Forzano, A.V.; Gad-El-Hak, M.; Tafreshi, H.V.; McLeskey, J.T. Activated carbon-doped polystyrene fibers for direct contact membrane desalination. Emergent Mater. 2020, 3, 807–814. [Google Scholar] [CrossRef]

- Amr, I.T.; Al-Amer, A.M.J.; Al-Harthi, M.A.; Girei, S.A.; Sougrat, R.; Atieh, M.A. Effect of acid treated carbon nanotubes on mechanical, rheological and thermal properties of polystyrene nanocomposites. Compos. Part B Eng. 2011, 42, 1554–1561. [Google Scholar] [CrossRef]

- Lehman, J.H.; Terrones, M.; Mansfield, E.; Hurst, K.E.; Meunier, V. Evaluating the characteristics of multiwall carbon nanotubes. Carbon 2011, 49, 2581–2602. [Google Scholar] [CrossRef]

- León-Bermúdez, Y.; Salazar, R. Synthesis and characterization of the polystyrene—Asphaltene graft copolymer by FT-IR spectroscopy. CT&F-Cienc. Tecnol. Futuro 2008, 3, 157–167. [Google Scholar]

- Ding, P.; Qu, B. Synthesis and characterization of polystyrene/layered double-hydroxide nanocomposites viain situ emulsion and suspension polymerization. J. Appl. Polym. Sci. 2006, 101, 3758–3766. [Google Scholar] [CrossRef]

- Chamakh, M.M.; Ponnamma, D.; Al-Maadeed, M.A.A. Vapor sensing performances of PVDF nanocomposites containing titanium dioxide nanotubes decorated multi-walled carbon nanotubes. J. Mater. Sci. Mater. Electron. 2018, 29, 4402–4412. [Google Scholar] [CrossRef]

- Rabie, M.; Salem, M.S.; Ali, A.Y.; El-Shazly, A.; Elkady, M.; Ookawara, S. Modeling of an integrated air gap membrane distillation unit utilizing a flat plate solar collector. Energy Rep. 2020, 6, 1591–1596. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Darvishi, M.M.; Azdast, T. Synergetic effect of MWCNT/nanoclays on microcellular polystyrene hybrid nanocomposite foams. Carbon Lett. 2019, 30, 367–371. [Google Scholar] [CrossRef]

- Patole, A.S.; Patole, S.P.; Yoo, J.B.; An, J.H.; Kim, T.H. Fabrication of Polystyrene/Multiwalled Carbon Nanotube Composite Films Synthesized by In Situ Microemulsion Polymerization. Polym. Eng. Sci. 2012, 6, 1327–1336. [Google Scholar] [CrossRef]

- Karanasiou, A.; Kostoglou, M.; Karabelas, A.J. An Experimental and Theoretical Study on Separations by Vacuum Membrane Distillation Employing Hollow-Fiber Modules. Water 2018, 10, 947. [Google Scholar] [CrossRef] [Green Version]

| Parameter | [19] | [22] | [31] | [37] |

|---|---|---|---|---|

| Feed flowrate (L/min) | 0.6 | 0.6 | 0.24–0.6 | 0.054 |

| Permeate flowrate (L/min) | 0.6 | 0.6 | 0.24–0.6 | 0.054 |

| Difference in operating temperature between the feed and the permeate (°C) | 50 | 63 | 25–60 | 40 |

| Contact angle | 150.2 ± 1.2° | 114 ± 1° | 154.52° | 119.6° |

| Membrane thickness (μm) | 60 | 147 ± 4 | 65 | – |

| Porosity (%) | 69 | 84 | 74.65 | – |

| Feed solution concentration (ppm) | 35,000 | 35,000 | 35,000 | 7000 |

| Membrane | Porosity | Contact Angle | Avg Fiber Diameter | Pore Size |

|---|---|---|---|---|

| PS | 0.56 | 145.4° | 1.783 µm | 0.423 µm |

| PS/MWCNTs | 0.72 | 155 | 1.545 µm | 0.357 µm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elrasheedy, A.; Rabie, M.; El-Shazly, A.; Bassyouni, M.; Abdel-Hamid, S.M.S.; El Kady, M.F. Numerical Investigation of Fabricated MWCNTs/Polystyrene Nanofibrous Membrane for DCMD. Polymers 2021, 13, 160. https://doi.org/10.3390/polym13010160

Elrasheedy A, Rabie M, El-Shazly A, Bassyouni M, Abdel-Hamid SMS, El Kady MF. Numerical Investigation of Fabricated MWCNTs/Polystyrene Nanofibrous Membrane for DCMD. Polymers. 2021; 13(1):160. https://doi.org/10.3390/polym13010160

Chicago/Turabian StyleElrasheedy, Asmaa, Mohammed Rabie, Ahmed El-Shazly, Mohamed Bassyouni, S.M.S. Abdel-Hamid, and Marwa F. El Kady. 2021. "Numerical Investigation of Fabricated MWCNTs/Polystyrene Nanofibrous Membrane for DCMD" Polymers 13, no. 1: 160. https://doi.org/10.3390/polym13010160

APA StyleElrasheedy, A., Rabie, M., El-Shazly, A., Bassyouni, M., Abdel-Hamid, S. M. S., & El Kady, M. F. (2021). Numerical Investigation of Fabricated MWCNTs/Polystyrene Nanofibrous Membrane for DCMD. Polymers, 13(1), 160. https://doi.org/10.3390/polym13010160