Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications

Abstract

1. Introduction

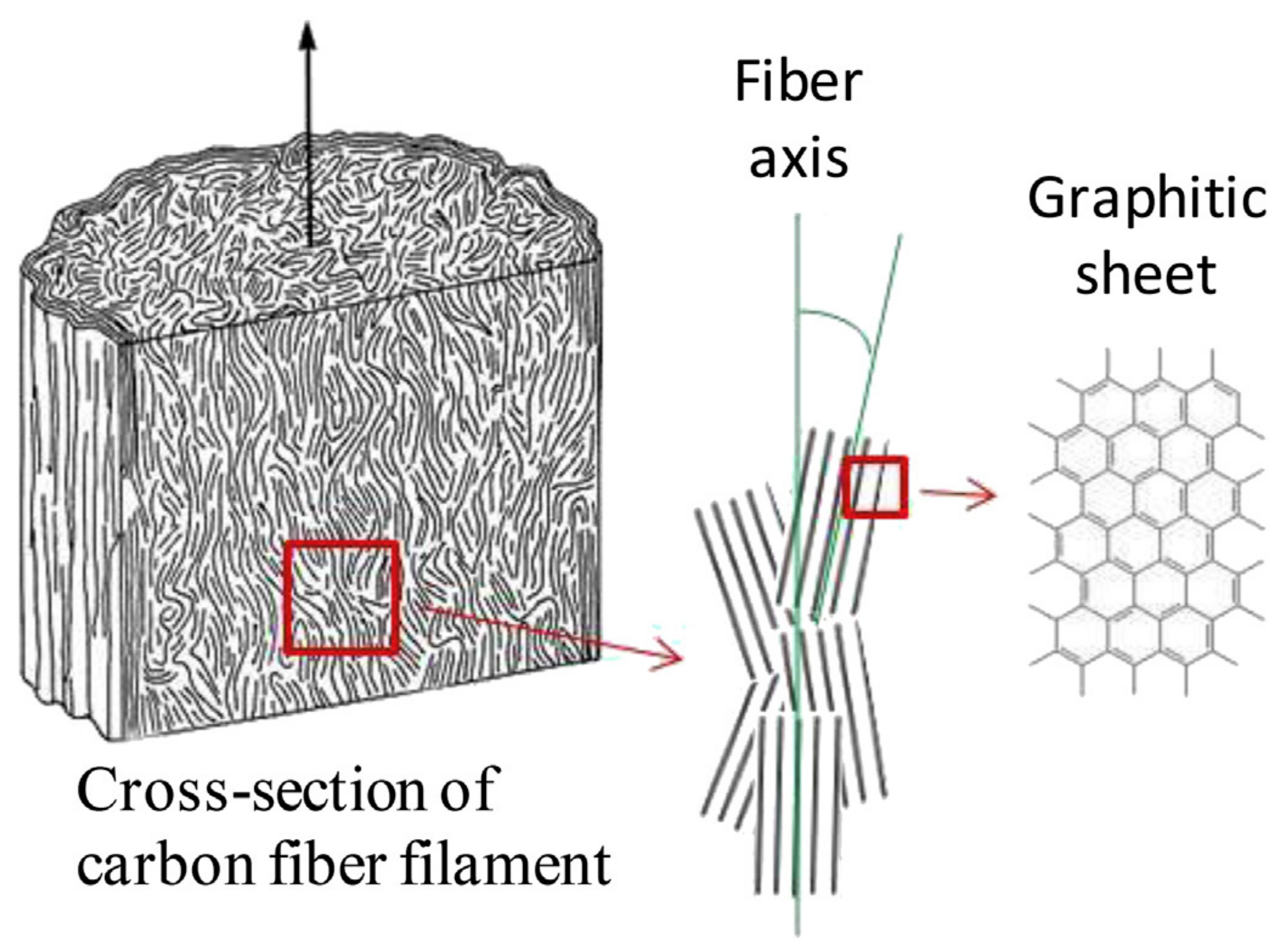

2. Thermal Transport Mechanisms

3. Preparation Methods

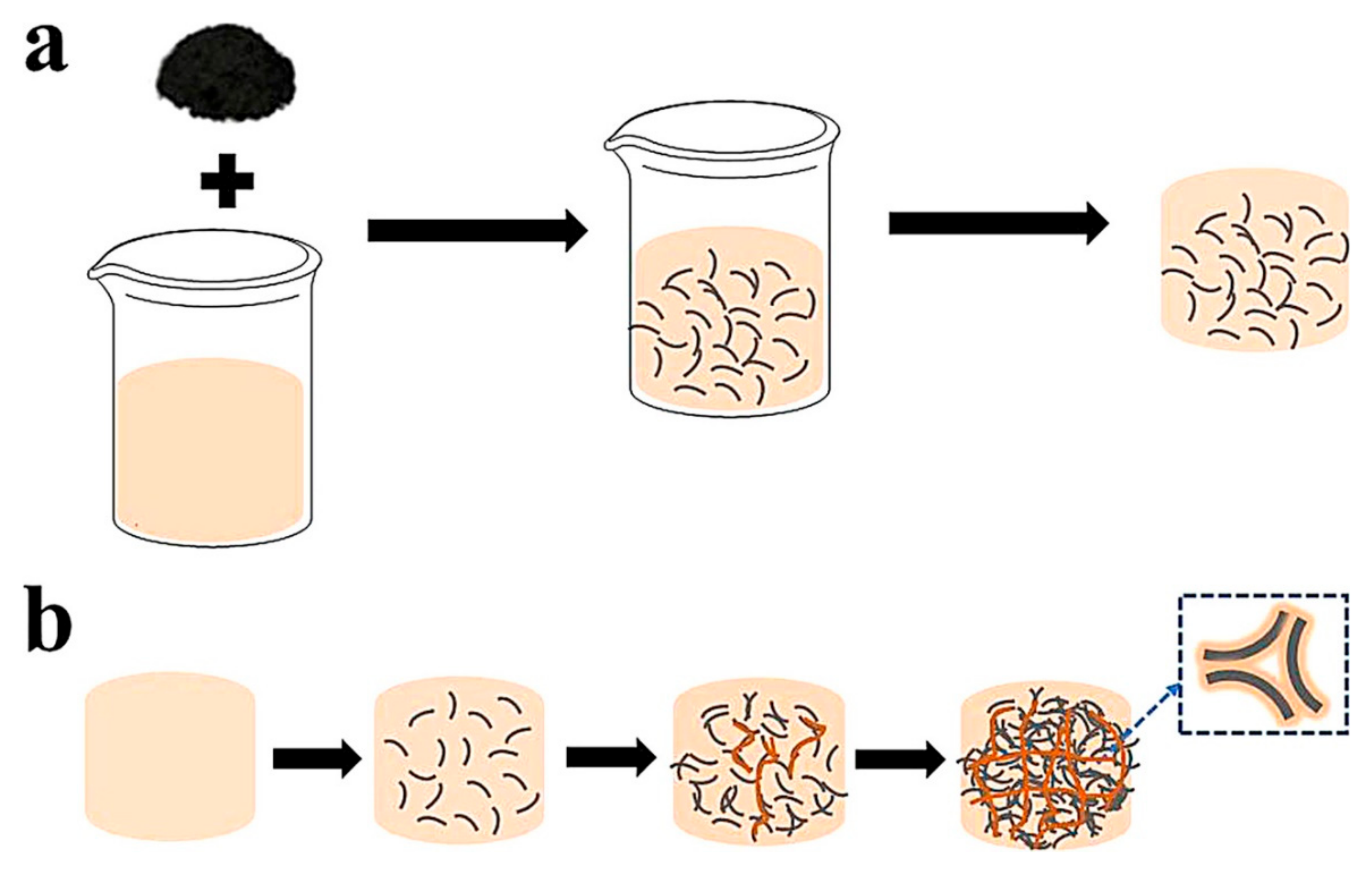

3.1. Blending Method

3.2. Freeze-Drying Method

3.3. Electrostatic Flocking Method

3.4. Vacuum Impregnation Method

3.5. Suction Filtration Method

3.6. Electrophoretic Deposition Method (EPD)

4. Influencing Factors of Thermal Conductivity

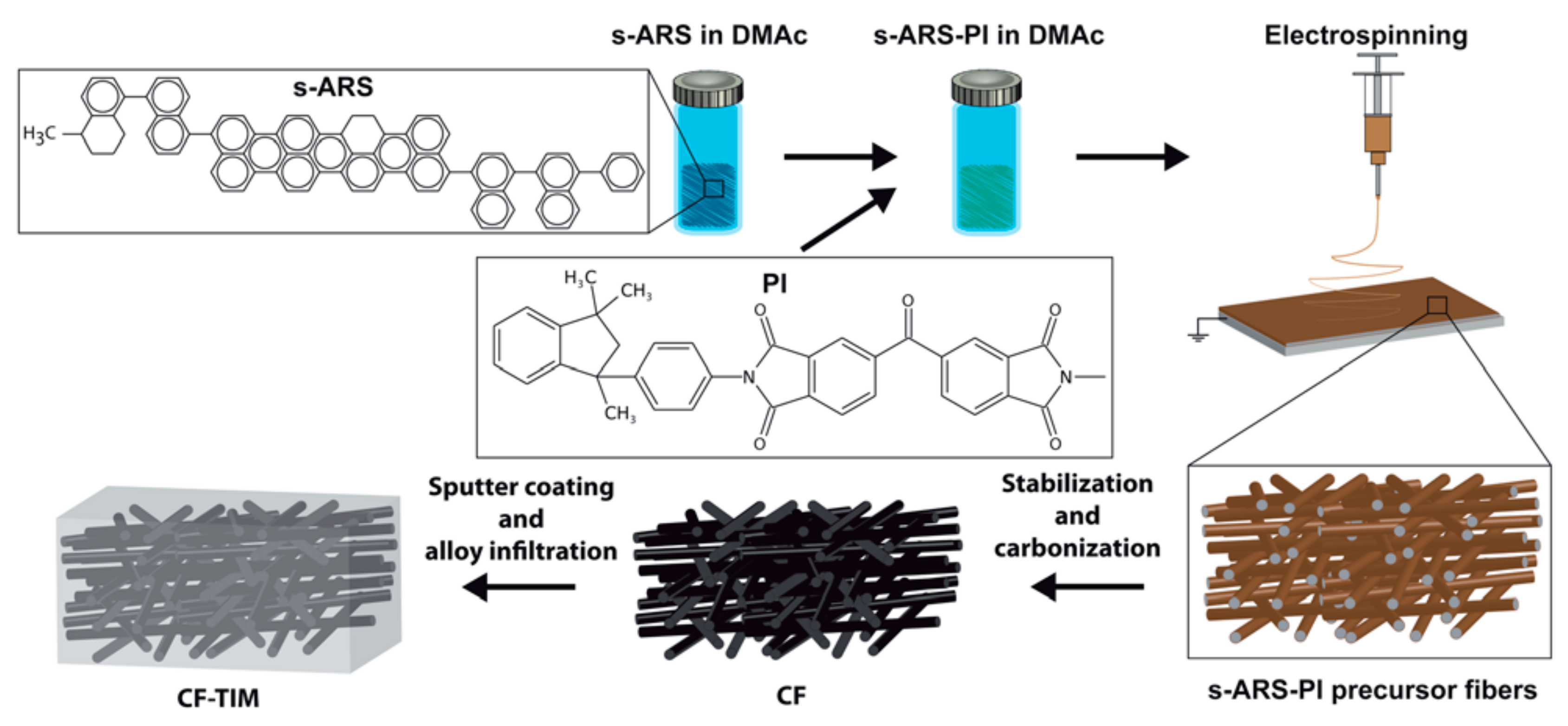

4.1. CF Types

4.2. CF Content

4.3. Synergistic Effects

4.4. Surface Modification of CF

4.5. Orientation of CF

4.6. D Structure of CF

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| (LED) | Light emitting diode |

| (CF) | Carbon fiber |

| (MPCFs) | Mesophase pitch-based carbon fibers |

| (PAN) | Polyacrylonitrile |

| (CFRP) | Carbon fiber reinforced polymer |

| (PDMS) | Polydimethylsiloxane |

| (SiC) | Silicon carbide |

| (PyC) | Pyrolytic carbon |

| (ZrC) | Zirconium carbide |

| (PCCs) | Phase change composites |

| (PC) | Polycarbonate |

| (PEGMEMA) | Polyethylene glycol methyl methacrylate |

| (BZMA) | Benzyl methacrylate |

| (DGEBA) | Diglycidyl ether of bisphenol-A |

| (FWCNTs) | Few walled carbon nanotubes |

| (EPD) | Electrophoretic deposition |

| (GO) | Graphene oxide |

| (VACNT) | Vertically aligned carbon nanotubes |

| (ZSC) | Zirconium silicate carbide |

| (PK) | Polyketone |

| (VE) | Vinyl ester |

References

- Li, M.; Wang, M.; Hou, X.; Zhan, Z.; Wang, H.; Fu, H.; Lin, C.-T.; Fu, L.; Jiang, N.; Yu, J. Highly thermal conductive and electrical insulating polymer composites with boron nitride. Compos. Part B Eng. 2020, 184, 107746. [Google Scholar] [CrossRef]

- Wang, Z.-G.; Liu, W.; Liu, Y.-H.; Ren, Y.; Li, Y.-P.; Zhou, L.; Xu, J.-Z.; Lei, J.; Li, Z.-M. Highly thermal conductive, anisotropically heat-transferred, mechanically flexible composite film by assembly of boron nitride nanosheets for thermal management. Compos. Part B Eng. 2020, 180, 107569. [Google Scholar] [CrossRef]

- Guan, C.; Qin, Y.; Li, L.; Wang, M.; Lin, C.-T.; He, X.; Nishimura, K.; Yu, J.; Yi, J.; Jiang, N. Highly thermally conductive polymer composites with barnacle-like nano-crystalline Diamond@ Silicon carbide hybrid architecture. Compos. Part B Eng. 2020, 198, 108167. [Google Scholar] [CrossRef]

- Leung, S.N. Thermally conductive polymer composites and nanocomposites: Processing-structure-property relationships. Compos. Part B Eng. 2018, 150, 78–92. [Google Scholar] [CrossRef]

- An, D.; Cheng, S.; Xi, S.; Zhang, Z.; Duan, X.; Ren, Y.; Li, J.; Sun, Z.; Liu, Y.; Wong, C.-P. Flexible thermal interfacial materials with covalent bond connections for improving high thermal conductivity. Chem. Eng. J. 2020, 383, 123151. [Google Scholar] [CrossRef]

- Jia, X.; Li, Q.; Ao, C.; Hu, R.; Xia, T.; Xue, Z.; Wang, Q.; Deng, X.; Zhang, W.; Lu, C. High thermal conductive shape-stabilized phase change materials of polyethylene glycol/boron nitride@ chitosan composites for thermal energy storage. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105710. [Google Scholar] [CrossRef]

- Ma, J.; Shang, T.; Ren, L.; Yao, Y.; Zhang, T.; Xie, J.; Zhang, B.; Zeng, X.; Sun, R.; Xu, J.-B. Through-plane assembly of carbon fibers into 3D skeleton achieving enhanced thermal conductivity of a thermal interface material. Chem. Eng. J. 2020, 380, 122550. [Google Scholar] [CrossRef]

- Hou, X.; Chen, Y.; Dai, W.; Wang, Z.; Li, H.; Lin, C.-T.; Nishimura, K.; Jiang, N.; Yu, J. Highly thermal conductive polymer composites via constructing micro-phragmites communis structured carbon fibers. Chem. Eng. J. 2019, 375, 121921. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, Z.; Li, M.; Kang, R.; Chen, Y.; Song, G.; Han, S.-T.; Lin, C.-T.; Jiang, N.; Yu, J. Extremely high thermal conductivity of carbon fiber/epoxy with synergistic effect of MXenes by freeze-drying. Compos. Commun. 2020, 19, 134–141. [Google Scholar] [CrossRef]

- Qiu, J.; Li, J.; Yuan, Z.; Zeng, H.; Chen, X. Surface modification of carbon fibres for interface improvement in textile composites. Appl. Compos. Mater. 2018, 25, 853–860. [Google Scholar] [CrossRef]

- Park, S.-J. History and Structure of Carbon Fibers. In Carbon Fibers; Springer: Cham, Switzerland, 2018; Volume 210, pp. 1–30. [Google Scholar]

- Deng, Y. Carbon Fiber Electronic Interconnects. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2007. [Google Scholar]

- Park, S.J.; Heo, G.Y. Precursors and manufacturing of carbon fibers. In Carbon Fibers; Springer: Dordrecht, The Netherlands, 2015; pp. 31–66. [Google Scholar]

- Landmarks, American Chemical Society, National Historic Chemical (A.C.S.N.H.C.) High Performance Carbon Fibers. Available online: https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/carbonfibers.html (accessed on 17 September 2003).

- DragonPlate. A Brief History of Carbon Fiber. Available online: https://dragonplate.com/a-brief-history-of-carbon-fiber (accessed on 1 September 2020).

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, J.M.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef] [PubMed]

- Ruland, W. Carbon fibers. Adv. Mater. 1990, 2, 528–536. [Google Scholar] [CrossRef]

- Talreja, R.; Varna, J. Modeling Damage, Fatigue and Failure of Composite Materials; Woodhead Publishing: Cambridge, UK; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Aleksendric, D.; Carlone, P. Soft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix Composites; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- İşmal, Ö.E.; Paul, R. Composite textiles in high-performance apparel. In High-Performance Apparel; Elsevier: Amsterdam, The Netherlands, 2018; pp. 377–420. [Google Scholar]

- Vasiliev, V.V.; Morozov, E.V. Advanced Mechanics of Composite Materials and Structural Elements; Newnes: Oxford, UK, 2013. [Google Scholar]

- Amir, S.M.M.; Sultan, M.; Jawaid, M.; Ariffin, A.H.; Mohd, S.; Salleh, K.A.M.; Ishak, M.R.; Shah, A.U.M. Nondestructive testing method for Kevlar and natural fiber and their hybrid composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 367–388. [Google Scholar]

- Yu, S.; Park, B.-I.; Park, C.; Hong, S.M.; Han, T.H.; Koo, C.M. RTA-treated carbon fiber/copper core/shell hybrid for thermally conductive composites. ACS Appl. Mater. Interfaces 2014, 6, 7498–7503. [Google Scholar] [CrossRef] [PubMed]

- Roy, A.K.; Farmer, B.L.; Varshney, V.; Sihn, S.; Lee, J.; Ganguli, S. Importance of interfaces in governing thermal transport in composite materials: Modeling and experimental perspectives. ACS Appl. Mater. Interfaces 2012, 4, 545–563. [Google Scholar] [CrossRef]

- Badrinarayanan, P.; Rogalski, M.K.; Kessler, M.R. Carbon fiber-reinforced cyanate ester/nano-ZrW2O8 composites with tailored thermal expansion. ACS Appl. Mater. Interfaces 2012, 4, 510–517. [Google Scholar] [CrossRef]

- Hu, Y.; Du, G.; Chen, N. A novel approach for Al2O3/epoxy composites with high strength and thermal conductivity. Compos. Sci. Technol. 2016, 124, 36–43. [Google Scholar] [CrossRef]

- Jeong, S.-H.; Song, J.-B.; Choi, Y.H.; Kim, S.-G.; Go, B.-S.; Park, M.; Lee, H. Effect of micro-ceramic fillers in epoxy composites on thermal and electrical stabilities of GdBCO coils. Compos. Part B Eng. 2016, 94, 190–196. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, X.; Zeng, X.; Sun, R.; Xu, J.-B.; Wong, C.-P. Vertically Aligned and Interconnected SiC Nanowire Networks Leading to Significantly Enhanced Thermal Conductivity of Polymer Composites. ACS Appl. Mater. Interfaces 2018, 10, 9669–9678. [Google Scholar] [CrossRef]

- Wei, J.M.; Liao, M.Z.; Ma, A.J.; Chen, Y.P.; Duan, Z.H.; Hou, X.; Li, M.H.; Jiang, N.; Yu, J.H. Enhanced thermal conductivity of polydimethylsiloxane composites with carbon fiber. Compos. Commun. 2020, 17, 141–146. [Google Scholar] [CrossRef]

- Chinkanjanarot, S.; Radue, M.S.; Gowtham, S.; Tomasi, J.M.; Klimek-McDonald, D.R.; King, J.A.; Odegard, G.M. Multiscale thermal modeling of cured cycloaliphatic epoxy/carbon fiber composites. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Li, M.; Fang, Z.N.; Wang, S.K.; Gu, Y.Z.; Li, Y.X.; Zhang, Z.G. Thermal conductivity enhancement and heat transport mechanism of carbon fiber z-pin graphite composite structures. Compos. Part B Eng. 2019, 172, 603–611. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.H.; Chen, Y.P.; Li, M.; Fu, H.; Xiao, H.; Wu, X.F.; Lin, C.T.; Jiang, N.; Yu, J.H. Efficient Thermal Transport Highway Construction Within Epoxy Matrix via Hybrid Carbon Fibers and Alumina Particles. ACS Omega 2020, 5, 1170–1177. [Google Scholar] [CrossRef] [PubMed]

- Alhashmy, H. Fabrication of Aluminium Matrix Composites (AMCs) by Squeeze Casting Technique Using Carbon Fiber as Reinforcement. Ph.D. Thesis, Université d’Ottawa/University of Ottawa, Ottawa, ON, Canada, 2012. [Google Scholar]

- Klemens, P. The thermal conductivity of dielectric solids at low temperatures (theoretical). Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1951, 208, 108–133. [Google Scholar] [CrossRef]

- Nolas, G.; Weakley, T.; Cohn, J.; Sharma, R. Structural properties and thermal conductivity of crystalline Ge clathrates. Phys. Rev. B 2000, 61, 3845. [Google Scholar] [CrossRef]

- Bouyrie, Y.; Candolfi, C.; Pailhes, S.; Koza, M.; Malaman, B.; Dauscher, A.; Tobola, J.; Boisron, O.; Saviot, L.; Lenoir, B. From crystal to glass-like thermal conductivity in crystalline minerals. Phys. Chem. Chem. Phys. 2015, 17, 19751–19758. [Google Scholar] [CrossRef]

- Šesták, J.; Mareš, J.J.; Hubík, P. Glassy, Amorphous and Nano-Crystalline Materials: Thermal Physics, Analysis, Structure and Properties; Springer Science & Business Media: Berlin, Germany, 2010; Volume 8. [Google Scholar]

- Zhang, T.; Luo, T. Role of chain morphology and stiffness in thermal conductivity of amorphous polymers. J. Phys. Chem. B 2016, 120, 803–812. [Google Scholar] [CrossRef]

- Thorpe, M.F.; Tichý, L. Properties and Applications of Amorphous Materials; Springer Science & Business Media: Berlin, Germany, 2012; Volume 9. [Google Scholar]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Crocker, A.G. Defects in crystalline materials and their relation to mechanical properties. Exp. Mech. 1966, 6, 266–272. [Google Scholar] [CrossRef]

- Crawford, J.H.; Slifkin, L.M. Point Defects in Solids: General and Ionic Crystals; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Liu, L.; Su, D.; Tang, Y.; Fang, G. Thermal conductivity enhancement of phase change materials for thermal energy storage: A review. Renew. Sustain. Energy Rev. 2016, 62, 305–317. [Google Scholar] [CrossRef]

- Wu, S.; Yan, T.; Kuai, Z.; Pan, W. Thermal conductivity enhancement on phase change materials for thermal energy storage: A review. Energy Storage Mater. 2020, 25, 251–295. [Google Scholar] [CrossRef]

- Tsekmes, I.; Kochetov, R.; Morshuis, P.; Smit, J. Thermal conductivity of polymeric composites: A review. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 678–681. [Google Scholar]

- Chen, S.; Feng, Y.; Qin, M.; Ji, T.; Feng, W. Improving thermal conductivity in the through-thickness direction of carbon fibre/SiC composites by growing vertically aligned carbon nanotubes. Carbon 2017, 116, 84–93. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.; Feng, W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Mater. Sci. Eng. R Rep. 2020, 142, 100580. [Google Scholar] [CrossRef]

- Xu, T.L.; Zhou, S.S.; Cui, S.Q.; Song, N.; Shi, L.Y.; Ding, P. Three-dimensional carbon fiber-graphene network for improved thermal conductive properties of polyamide-imide composites. Compos. Part B Eng. 2019, 178. [Google Scholar] [CrossRef]

- Hulicova, D.; Oya, A. The polymer blend technique as a method for designing fine carbon materials. Carbon 2003, 41, 1443–1450. [Google Scholar] [CrossRef]

- Kaur, G.; Adhikari, R.; Cass, P.; Bown, M.; Gunatillake, P. Electrically conductive polymers and composites for biomedical applications. RSC Adv. 2015, 5, 37553–37567. [Google Scholar] [CrossRef]

- Abdelwahed, W.; Degobert, G.; Stainmesse, S.; Fessi, H. Freeze-drying of nanoparticles: Formulation, process and storage considerations. Adv. Drug Deliv. Rev. 2006, 58, 1688–1713. [Google Scholar] [CrossRef]

- Wang, D.Z.; Lin, Y.; Hu, D.W.; Jiang, P.K.; Huang, X.Y. Multifunctional 3D-MXene/PDMS nanocomposites for electrical, thermal and triboelectric applications. Compos. Part A Appl. Sci. Manuf. 2020, 130. [Google Scholar] [CrossRef]

- Dong, L.B.; Li, Y.; Wang, L.; Hou, F.; Liu, J.C. Spatial dispersion state of carbon nanotubes in a freeze-drying method prepared carbon fiber based preform and its effect on electrical conductivity of carbon fiber/epoxy composite. Mater. Lett. 2014, 130, 292–295. [Google Scholar] [CrossRef]

- Liu, L.; Huang, H.; He, Z.; Li, S.; Li, J.; Chen, J.; Deng, L.; Osaka, Y.; Kobayashi, N. The heat and mass transfer performance of facile synthesized silica gel/carbon-fiber based consolidated composite adsorbents developed by freeze-drying method. Nanoscale Microscale Thermophys. Eng. 2018, 22, 255–269. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.Y.; Sun, B.; Wang, Y.X.; Zhu, Y.K.; Jiang, P.K. Vertically Aligned and Interconnected Boron Nitride Nanosheets for Advanced Flexible Nanocomposite Thermal Interface Materials. ACS Appl. Mater. Interfaces 2017, 9, 30909–30917. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, J.; Wang, K.; Yao, J.; Bian, H.; Song, K.; Komarneni, S.; Cai, Z. Three-dimensional stretchable fabric-based electrode for supercapacitors prepared by electrostatic flocking. Chem. Eng. J. 2020, 390. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S.; Li, M.; Gu, Y.; Zhang, Z. Improvement of out-of-plane thermal conductivity of composite laminate by electrostatic flocking. Mater. Des. 2018, 144, 263–270. [Google Scholar] [CrossRef]

- Uetani, K.; Ata, S.; Tomonoh, S.; Yamada, T.; Yumura, M.; Hata, K. Elastomeric Thermal Interface Materials with High Through-Plane Thermal Conductivity from Carbon Fiber Fillers Vertically Aligned by Electrostatic Flocking. Adv. Mater. 2014, 26, 5857–5862. [Google Scholar] [CrossRef] [PubMed]

- Sekii, Y.; Hayashi, T. Measurements of reflectance and thermal emissivity of a black surface created by electrostatic flocking with carbon-fiber piles. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 649–654. [Google Scholar] [CrossRef]

- Meng, S.; Wang, Y.; Zhang, B. Preparation and mechanical properties of MWCNTs modified glass fiber fabrics/epoxy composites disposed by electrostatic flocking method. Acta Mater. Compos. Sin. 2015, 32, 989–996. [Google Scholar]

- Kobayashi, S.; Tsukada, T.; Morimoto, T. Resin impregnation behavior in carbon fiber reinforced polyamide 6 composite: Effects of yarn thickness, fabric lamination and sizing agent. Compos. Part A Appl. Sci. Manuf. 2017, 101, 283–289. [Google Scholar] [CrossRef]

- Hu, P.; Cheng, Y.; Guo, X.; Ma, C.; Hu, P.; Qu, Q.; Zhao, H.; Du, S. Architectural engineering inspired method of preparing Cf/ZrC–SiC with graceful mechanical responses. J. Am. Ceram. Soc. 2019, 102, 70–78. [Google Scholar] [CrossRef]

- Sheng, N.; Zhu, R.; Dong, K.; Nomura, T.; Zhu, C.; Aoki, Y.; Habazaki, H.; Akiyama, T. Vertically aligned carbon fibers as supporting scaffolds for phase change composites with anisotropic thermal conductivity and good shape stability. J. Mater. Chem. A 2019, 7, 4934–4940. [Google Scholar] [CrossRef]

- Yao, T.T.; Liu, Y.T.; Zhu, H.; Zhang, X.F.; Wu, G.P. Controlling of resin impregnation and interfacial adhesion in carbon fiber/polycarbonate composites by a spray-coating of polymer on carbon fibers. Compos. Sci. Technol. 2019, 182. [Google Scholar] [CrossRef]

- Misumi, J.; Oyama, T. Low viscosity and high toughness epoxy resin modified by in situ radical polymerization method for improving mechanical properties of carbon fiber reinforced plastics. Polymer 2018, 156, 1–9. [Google Scholar] [CrossRef]

- Lee, Y.S.; Lee, S.-Y.; Kim, K.S.; Noda, S.; Shim, S.E.; Yang, C.-M. Effective heat transfer pathways of thermally conductive networks formed by one-dimensional carbon materials with different sizes. Polymers 2019, 11, 1661. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Zhang, L.; Liu, Y.; Li, X.; Cheng, L.; Bai, H. Fabrication of SiCf-CNTs/SiC composites with high thermal conductivity by vacuum filtration combined with CVI. Mater. Sci. Eng. A 2016, 662, 506–510. [Google Scholar] [CrossRef]

- Hosseinpour, A.; Abdizadeh, H.; Golobostanfard, M.R. Comparing the electrophoretic deposition process of graphene oxides synthesized through different methods. Thin Solid Film. 2017, 631, 118–123. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, C.; Su, Y.; Guo, Q.; Liu, F.; Deng, C.; Yao, X.; Zhou, L. Influence of carbon nanotube coatings on carbon fiber by ultrasonically assisted electrophoretic deposition on its composite interfacial property. Polymers 2016, 8, 302. [Google Scholar] [CrossRef] [PubMed]

- Katagiri, K.; Sasaki, K.; Honda, S.; Nakashima, H.; Tomizawa, Y.; Yamaguchi, S.; Ozaki, T.; Sonomura, H.; Kakitsuji, A. Resin molding by using electro-activated deposition for efficient manufacturing of carbon fiber reinforced plastic. Compos. Struct. 2017, 182, 666–673. [Google Scholar] [CrossRef]

- Huang, S.-Y.; Wu, G.-P.; Chen, C.-M.; Yang, Y.; Zhang, S.-C.; Lu, C.-X. Electrophoretic deposition and thermal annealing of a graphene oxide thin film on carbon fiber surfaces. Carbon 2013, 52, 613–616. [Google Scholar] [CrossRef]

- Talic, B.; Wulff, A.C.; Molin, S.; Andersen, K.B.; Zielke, P.; Frandsen, H.L. Investigation of electrophoretic deposition as a method for coating complex shaped steel parts in solid oxide cell stacks. Surf. Coat. Technol. 2019, 380. [Google Scholar] [CrossRef]

- Szydlo, A.; Goossen, J.D.; Linte, C.; Uphoff, H.; Bredol, M. Preparation of platinum-based electrocatalytic layers from catalyst dispersions with adjusted colloidal stability via a pulsed electrophoretic deposition method. Mater. Chem. Phys. 2020, 242. [Google Scholar] [CrossRef]

- Yan, F.; Liu, L.; Li, M.; Zhang, M.; Xiao, L.; Ao, Y. Preparation of carbon nanotube/copper/carbon fiber hierarchical composites by electrophoretic deposition for enhanced thermal conductivity and interfacial properties. J. Mater. Sci. 2018, 53, 8108–8119. [Google Scholar] [CrossRef]

- Ammam, M. Electrophoretic deposition under modulated electric fields: A review. RSC Adv. 2012, 2, 7633–7646. [Google Scholar] [CrossRef]

- Liu, H.C.; Chien, A.T.; Newcomb, B.A.; Davijani, A.A.B.; Kumar, S. Stabilization kinetics of gel spun polyacrylonitrile/lignin blend fiber. Carbon 2016, 101, 382–389. [Google Scholar] [CrossRef]

- Khayyam, H.; Jazar, R.N.; Nunna, S.; Golkarnarenji, G.; Badii, K.; Fakhrhoseini, S.M.; Kumar, S.; Naebe, M. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: Experimental and mathematical modelling. Prog. Mater. Sci. 2020, 107. [Google Scholar] [CrossRef]

- Lee, H.M.; Lee, B.H.; Kim, J.H.; An, K.H.; Park, S.J.; Kim, B.J. Determination of the optimum porosity for 2-CEES adsorption by activated carbon fiber from various precursors. Carbon Lett. 2019, 29, 649–654. [Google Scholar] [CrossRef]

- Xi, X.; Chung, D.D.L. Colossal electric permittivity discovered in polyacrylonitrile (PAN) based carbon fiber, with comparison of PAN-based and pitch-based carbon fibers. Carbon 2019, 145, 734–739. [Google Scholar] [CrossRef]

- Inoue, R.; Arai, Y.; Kubota, Y.; Goto, K.; Kogo, Y. Development of short- and continuous carbon fiber-reinforced ZrB2-SiC-ZrC matrix composites for thermal protection systems. Ceram. Int. 2018, 44, 15859–15867. [Google Scholar] [CrossRef]

- Huang, J.; Ouyang, Q.; Li, M.; Heng, F.; Ma, H.; Chen, Y. Thermal behavior and thermal stabilization of guanidine hydrochloride-modified acrylic fiber for preparation of low-cost carbon fiber. J. Therm. Anal. Calorim. 2019, 136, 2195–2203. [Google Scholar] [CrossRef]

- Yin, L.; Wang, J.; Lin, F.; Yang, J.; Nuli, Y. Polyacrylonitrile/graphene composite as a precursor to a sulfur-based cathode material for high-rate rechargeable Li–S batteries. Energy Environ. Sci. 2012, 5, 6966–6972. [Google Scholar] [CrossRef]

- Marathe, U.N.; Bijwe, J. High performance polymer composites—Influence of processing technique on the fiber length and performance properties. Wear 2020, 446–447. [Google Scholar] [CrossRef]

- Xu, H.H.K.; Eichmiller, F.C.; Barndt, P.R. Effects of fiber length and volume fraction on the reinforcement of calcium phosphate cement. J. Mater. Sci. Mater. Med. 2001, 12, 57–65. [Google Scholar] [CrossRef]

- Lee, G.W.; Lee, J.I.; Lee, S.S.; Park, M.; Kim, J. Comparisons of thermal properties between inorganic filler and acid-treated multiwall nanotube/polymer composites. J. Mater. Sci. 2005, 40, 1259–1263. [Google Scholar] [CrossRef]

- Ghosh, A.; Goswami, P.; Mahanta, P.; Verma, A. Effect of carbon fiber length and graphene on carbon-polymer composite bipolar plate for PEMFC. J. Solid State Electrochem. 2014, 18, 3427–3436. [Google Scholar] [CrossRef]

- Fang, Z.; Li, M.; Wang, S.; Gu, Y.; Li, Y.; Zhang, Z. Through-thickness thermal conductivity enhancement of carbon fiber composite laminate by filler network. Int. J. Heat Mass Transf. 2019, 137, 1103–1111. [Google Scholar] [CrossRef]

- Murugesan, M.; Zandén, C.; Luo, X.; Ye, L.; Jokubavicius, V.; Syväjärvi, M.; Liu, J. A carbon fiber solder matrix composite for thermal management of microelectronic devices. J. Mater. Chem. C 2014, 2, 7184–7187. [Google Scholar] [CrossRef]

- Cho, J.; Lee, S.K.; Eem, S.H.; Jang, J.G.; Yang, B. Enhanced mechanical and thermal properties of carbon fiber-reinforced thermoplastic polyketone composites. Compos. Part A Appl. Sci. Manuf. 2019, 126. [Google Scholar] [CrossRef]

- Bai, B.C.; Park, D.-W.; Vo, H.V.; Dessouky, S.; Im, J.S. Thermal properties of asphalt mixtures modified with conductive fillers. J. Nanomater. 2015, 2015, 926809. [Google Scholar] [CrossRef]

- Nomura, T.; Tabuchi, K.; Zhu, C.; Sheng, N.; Wang, S.; Akiyama, T. High thermal conductivity phase change composite with percolating carbon fiber network. Appl. Energy 2015, 154, 678–685. [Google Scholar] [CrossRef]

- Nekahi, S.; Moghanlou, F.S.; Vajdi, M.; Ahmadi, Z.; Motallebzadeh, A.; Asl, M.S. Microstructural, thermal and mechanical characterization of TiB2-SiC composites doped with short carbon fibers. Int. J. Refract. Met. Hard Mater. 2019, 82, 129–135. [Google Scholar] [CrossRef]

- Yu, S.; Park, K.; Lee, J.W.; Hong, S.M.; Park, C.; Han, T.H.; Koo, C.M. Enhanced thermal conductivity of epoxy/Cu-plated carbon fiber fabric composites. Macromol. Res. 2017, 25, 559–564. [Google Scholar] [CrossRef]

- Zhao, X.-W.; Zang, C.-G.; Ma, Q.-K.; Wen, Y.-Q.; Jiao, Q.-J. Thermal and electrical properties of composites based on (3-mercaptopropyl) trimethoxysilane- and Cu-coated carbon fiber and silicone rubber. J. Mater. Sci. 2016, 51, 4088–4095. [Google Scholar] [CrossRef]

- Shi, P.-l.; Wang, Y.-y.; Guo, H.-j.; Sun, H.-j.; Zhao, Y.-f. The thermal and mechanical properties of carbon fiber/flake graphite/cyanate ester composites. New Carbon Mater. 2019, 34, 110–114. [Google Scholar] [CrossRef]

- Jiao, W.; Liu, W.; Yang, F.; Jiang, L.; Jiao, W.; Wang, R. Improving the interfacial property of carbon fiber/vinyl ester resin composite by grafting modification of sizing agent on carbon fiber surface. J. Mater. Sci. 2017, 52, 13812–13828. [Google Scholar] [CrossRef]

- Wang, H.; Jin, K.; Wang, C.; Guo, X.; Chen, Z.; Tao, J. Effect of fiber surface functionalization on shear behavior at carbon fiber/epoxy interface through molecular dynamics analysis. Compos. Part A Appl. Sci. Manuf. 2019, 126. [Google Scholar] [CrossRef]

- Hwang, D.; Cho, D. Fiber aspect ratio effect on mechanical and thermal properties of carbon fiber/ABS composites via extrusion and long fiber thermoplastic processes. J. Ind. Eng. Chem. 2019, 80, 335–344. [Google Scholar] [CrossRef]

- Yamamoto, T.; Yabushita, S.; Irisawa, T.; Tanabe, Y. Enhancement of bending strength, thermal stability and recyclability of carbon-fiber-reinforced thermoplastics by using silica colloids. Compos. Sci. Technol. 2019, 181. [Google Scholar] [CrossRef]

- Duy Quang, D.; Rogaume, T.; Luche, J.; Richard, F.; Valencia, L.B.; Ruban, S. Thermal degradation of epoxy resin/carbon fiber composites: Influence of carbon fiber fraction on the fire reaction properties and on the gaseous species release. Fire Mater. 2016, 40, 27–47. [Google Scholar] [CrossRef]

- Zheng, X.; Kim, S.; Park, C.W. Enhancement of thermal conductivity of carbon fiber reinforced polymer composite with copper and boron nitride particles (vol 121, pg 449, 2019). Compos. Part A Appl. Sci. Manuf. 2019, 125. [Google Scholar] [CrossRef]

- Lalet, G.; Kurita, H.; Heintz, J.M.; Lacombe, G.; Kawasaki, A.; Silvain, J.F. Thermal expansion coefficient and thermal fatigue of discontinuous carbon fiber-reinforced copper and aluminum matrix composites without interfacial chemical bond. J. Mater. Sci. 2014, 49, 397–402. [Google Scholar] [CrossRef]

- Raphael, N.; Namratha, K.; Chandrashekar, B.; Sadasivuni, K.K.; Ponnamma, D.; Smitha, A.; Krishnaveni, S.; Cheng, C.; Byrappa, K. Surface modification and grafting of carbon fibers: A route to better interface. Prog. Cryst. Growth Charact. Mater. 2018, 64, 75–101. [Google Scholar] [CrossRef]

- Behr, M.J.; Landes, B.G.; Barton, B.E.; Bernius, M.T.; Billovits, G.F.; Hukkanen, E.J.; Patton, J.T.; Wang, W.; Wood, C.; Keane, D.T. Structure-property model for polyethylene-derived carbon fiber. Carbon 2016, 107, 525–535. [Google Scholar] [CrossRef]

- Hasselman, D.; Bhatt, H.; Donaldson, K.; Thomas, J., Jr. Effect of fiber orientation and sample geometry on the effective thermal conductivity of a uniaxial carbon fiber-reinforced glass matrix composite. J. Compos. Mater. 1992, 26, 2278–2288. [Google Scholar] [CrossRef]

- Qu, M.; Schubert, D.W. Conductivity of melt spun PMMA composites with aligned carbon fibers. Compos. Sci. Technol. 2016, 136, 111–118. [Google Scholar] [CrossRef]

- Stepashkin, А.; Chukov, D.; Senatov, F.; Salimon, A.; Korsunsky, A.; Kaloshkin, S. 3D-printed PEEK-carbon fiber (CF) composites: Structure and thermal properties. Compos. Sci. Technol. 2018, 164, 319–326. [Google Scholar] [CrossRef]

- Schuster, J.; Heider, D.; Sharp, K.; Glowania, M. Thermal conductivities of three-dimensionally woven fabric composites. Compos. Sci. Technol. 2008, 68, 2085–2091. [Google Scholar] [CrossRef]

- John, R.; Atxaga, G.; Frerker, H.; Newerla, A. Advancement of Multifunctional support structure technologies (AMFSST). In Proceedings of the 2007 13th International Workshop on Thermal Investigation of ICs and Systems (THERMINIC), Budapest, Hungary, 17–19 September 2007; pp. 98–103. [Google Scholar] [CrossRef]

- Yu, G.-C.; Wu, L.-Z.; Feng, L.-J.; Yang, W. Thermal and mechanical properties of carbon fiber polymer-matrix composites with a 3D thermal conductive pathway. Compos. Struct. 2016, 149, 213–219. [Google Scholar] [CrossRef]

- Sheng, N.; Rao, Z.; Zhu, C.; Habazaki, H. Honeycomb carbon fibers strengthened composite phase change materials for superior thermal energy storage. Appl. Therm. Eng. 2020, 164, 114493. [Google Scholar] [CrossRef]

- He, X.; Huang, Y.; Liu, Y.; Zheng, X.; Kormakov, S.; Sun, J.; Zhuang, J.; Gao, X.; Wu, D. Improved thermal conductivity of polydimethylsiloxane/short carbon fiber composites prepared by spatial confining forced network assembly. J. Mater. Sci. 2018, 53, 14299–14310. [Google Scholar] [CrossRef]

| Filler | Fraction | TC (W/m·K) | Year | Reference |

|---|---|---|---|---|

| Chopped CF | 13 wt% | 2.84 | 2020 | [7] |

| CF bundles | 12.8 wt% | 1.73 | 2020 | [111] |

| CF + Al2O3 | 6.4 wt% CF + 74 wt% Al2O3 | 3.84 | 2020 | [34] |

| Chopped CF | 2 wt% | 55 | 2019 | [92] |

| Short CF | 12.8 vol% | 6.04 | 2019 | [8] |

| CF felt + graphene oxide(GO) | 4.25 wt% | 0.53 | 2019 | [48] |

| CF bundle + graphite sheet | 60 vol% CF | 6.20 | 2019 | [31] |

| CF + flaked G | 60 vol% CF + 10 wt% FG | 0.6~1.36 | 2019 | [95] |

| Chopped CF | 18 wt% | 2.95 | 2018 | [112] |

| M-Cu-CF | 4 wt% | 1.99 | 2016 | [94] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, Z.; Gao, Y.; Tang, B.; Wu, X.; Wang, Y.; Li, M.; Hou, X.; Li, L.; Jiang, N.; Yu, J. Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications. Polymers 2021, 13, 169. https://doi.org/10.3390/polym13010169

Ali Z, Gao Y, Tang B, Wu X, Wang Y, Li M, Hou X, Li L, Jiang N, Yu J. Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications. Polymers. 2021; 13(1):169. https://doi.org/10.3390/polym13010169

Chicago/Turabian StyleAli, Zulfiqar, Yuan Gao, Bo Tang, Xinfeng Wu, Ying Wang, Maohua Li, Xiao Hou, Linhong Li, Nan Jiang, and Jinhong Yu. 2021. "Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications" Polymers 13, no. 1: 169. https://doi.org/10.3390/polym13010169

APA StyleAli, Z., Gao, Y., Tang, B., Wu, X., Wang, Y., Li, M., Hou, X., Li, L., Jiang, N., & Yu, J. (2021). Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications. Polymers, 13(1), 169. https://doi.org/10.3390/polym13010169