Effect of the Incorporation of Polycaprolactone (PCL) on the Retrogradation of Binary Blends with Cassava Thermoplastic Starch (TPS)

Abstract

:1. Introduction

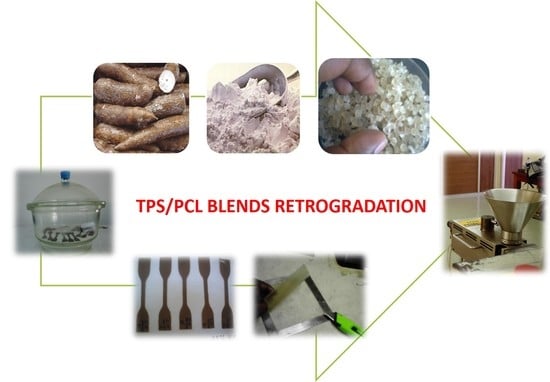

2. Materials

3. Experimental Procedure

3.1. Obtaining the TPS

3.2. Preparation of the Binary Blends TPS/PCL

3.3. FTIR Spectroscopy

3.4. Moisture Adsorption

3.5. Scanning Electron Microscopy (SEM)

3.6. Thermogravimetric Analysis (TGA)

3.7. X-ray Diffraction (XRD)

3.8. Tension Test

4. Results and Discussion

4.1. FTIR Spectroscopy

4.2. Scanning Electron Microscopy (SEM)

4.3. Moisture Adsorption

4.4. Thermogravimetric Analysis (TGA)

4.5. X-ray Diffraction (XRD)

4.6. Tensile Strength

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, M.; Yu, J.; Ma, X. Ethanolamine as a novel plasticizer for thermoplastic starch. Polym. Degrad. Stab. 2005, 90, 501–507. [Google Scholar] [CrossRef]

- Guan, J.; Eskridge, K.; Hanna, M. Acetylated starch-polylactic acid loose-fill packaging materials. Ind. Crop. Prod. 2005, 22, 109–123. [Google Scholar] [CrossRef]

- Correa, A.C.; Carmona, V.B.; Simão, J.A.; Capparelli, L.H.; Marconcini, J.M. Biodegradable blends of urea plasticized thermoplastic starch (UTPS) and poly(ε-caprolactone) (PCL): Morphological, rheological, thermal and mechanical properties. Carbohydr. Polym. 2017, 167, 177–184. [Google Scholar] [CrossRef] [PubMed]

- Ortega-Toro, R.; Contreras, J.; Talens, P.; Chiralt, A. Physical and structural properties and thermal behaviour of starch-poly(e-caprolactone) blend films for food packaging. Food Packag. Shelf Life 2015, 5, 10–20. [Google Scholar] [CrossRef]

- Ortega-Toro, R.; Santagata, G.; Gomez, G.; Cerruti, P.; Talens, P.; Chiralt, A.; Malinconico, M. Enhancement of interfacial adhesion between starch and grafted poly(ε-caprolactone). Carbohydr. Polym. 2016, 147, 16–27. [Google Scholar] [CrossRef] [PubMed]

- Lai, S.M.; Don, T.M.; Huang, Y.C. Preparation and Properties of Biodegradable Thermoplastic Starch/Poly (hydroxyl butyrate) Blends. J. Appl. Polym. Sci. 2006, 100, 2371–2379. [Google Scholar] [CrossRef]

- Tappibana, P.; Smith, D.; Triwitayakornb, K.; Bao, J. Recent understanding of starch biosynthesis in cassava for quality improvement: A review. Trends Food Sci. Technol. 2019, 83, 167–180. [Google Scholar] [CrossRef]

- Mina, J.; Valadez, A.; Herrera-Franco, P.; Toledano, T. Influencia del tiempo de almacenamiento en las propiedades estructurales de un almidón termoplástico de yuca (TPS). Ing. Y Compet. 2009, 11, 95–106. [Google Scholar]

- Mali, L.; Sakanaka, F.; Yamashita, M. Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohydr. Polym. 2005, 60, 283–289. [Google Scholar] [CrossRef]

- Fekete, E.; Bella, É.; Csiszár, E.; Móczó, J. Improving physical properties and retrogradation of thermoplastic starch by incorporating agar. Int. J. Biol. Macromol. 2019, 136, 1026–1033. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.; Lumdubwong, N. Fabrication of starch blend films with different matrices and their mechanical properties. Polym. Test. 2020, 90, 106694. [Google Scholar] [CrossRef]

- Thire, R.; Simao, R.; Andrade, C. Investigation of the Surface Morphology of Plasticized Corn starch Films. Acta Microsc. 2003, 12, 175–179. [Google Scholar]

- Gudmundsson, M. Retrogradation of starch and the role of its components. Thermochim. Acta 1994, 246, 329–341. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J. The plasticizer containing amide groups for thermoplastic starch. Carbohydr. Polym. 2004, 57, 197–203. [Google Scholar] [CrossRef]

- Ma, X.; Yu, G.; Wan, J. Urea and ethanolamine as a mixed plasticizer for thermoplastic starch. Carbohydr. Polym. 2006, 64, 267–273. [Google Scholar] [CrossRef]

- Curvelo, A.; Carvalho, A.; Agnelli, J. Thermoplastic starch-cellulosic fibers composites: Preliminary results. Carbohydr. Polym. 2001, 45, 183–188. [Google Scholar] [CrossRef]

- Zhanga, C.-W.; Nair, S.; Chen, H.; Yan, N.; Farnood, R.; Li, F.-Y. Thermally stable, enhanced water barrier, high strength starch biocomposite reinforced with lignin containing cellulose nanofibrils. Carbohydr. Polym. 2020, 230, 115626. [Google Scholar] [CrossRef]

- Garalde, R.A.; Thipmanee, R.; Jariyasakoolroj, P. The effects of blend ratio and storage time on thermoplastic starch/poly(butylene adipate-co-terephthalate) films. Heliyon 2019, 5, e01251. [Google Scholar] [CrossRef] [Green Version]

- Rosa, R.; Ferreira, F.; Saravia, A.; Rocco, S.; Sforca, M.; Gouveia, R.; Lona, L. A Combined Computational and Experimental Study on the Polymerization of ε-Caprolactone. Ind. Eng. Chem. Res. 2018, 57, 13387–13395. [Google Scholar] [CrossRef]

- Wang, Y.; Onozawa, S.Y.; Kunioka, M. Ring-opening polymerization of ε-caprolactone with yttrium triflate. Green Chem. 2003, 5, 571–574. [Google Scholar] [CrossRef]

- Wang, X.L.; Yang, K.K.; Wang, Y.Z. Studies on Biodegradable Poly(Hexano-6-Lactone) Fibers. Part 3. Enzymatic Degradation in Vitro. IupacPure Appl. Chem. 2002, 74, 869–880. [Google Scholar]

- Wang, X.L.; Yang, K.K.; Wang, Y.Z. Properties of Starch Blends with Biodegradable Polymers. J. Macromol. Sci. Part. C 2003, 43, 385–409. [Google Scholar] [CrossRef]

- Averous, L.; Moro, L.; Dole, P.; Fringant, C. Properties of thermoplastic blend: Starch-polycaprolactone. Polymer 2000, 41, 4157–4167. [Google Scholar] [CrossRef]

- Derval, R.; Guedes, C.; Pedroso, A. Gelatinized and Nongelatinized Corn Starch/Poly(ε-Caprolactone) Blends: Characterization by Rheological, Mechanical and Morphological Properties. Polímeros: Cienc. Y Tecnol. 2004, 14, 181–186. [Google Scholar]

- Matzinos, P.; Tserki, V.; Kontoyiannis, A.; Panayiotou, C. Processing and characterization of starch/polycaprolactone products. Polym. Degrad. Stab. 2002, 77, 17–24. [Google Scholar] [CrossRef]

- Shin, B.Y.; Lee, S.I.; Sub Shin, Y.; Balakrishnan, S.; Narayan, R. Rheological, Mechanical and Biodegradation Studies on Blends of Thermoplastic Starch and Polycaprolactone. Polym. Eng. Sci. 2004, 44, 1429–1438. [Google Scholar] [CrossRef]

- Sarazin, P.; Li, G.; Orts, W.; Favis, B. Binary and ternary blends of polylactide, polycaprolactone and thermoplastic starch. Polymer 2008, 49, 599–609. [Google Scholar] [CrossRef]

- Mano, J.; Koniarova, D.; Reis, R. Thermal properties of thermoplastic starch/synthetic polymer blends with potential biomedical applicability. J. Mater. Sci. Mater. Med. 2003, 14, 127–135. [Google Scholar] [CrossRef]

- ASTM. ASTM D638-14. In Standard Test. Method for Tensile Properties of Plastics; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM. ASTM E104-02. In Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Nara, S.; Komiya, T. Studies on the Relationship Between Water-satured State and Crystallinity by the Diffraction Method for Moistened Potato Starch. Starch Stärke 1983, 35, 407–410. [Google Scholar] [CrossRef]

- Balmayor, E.; Tuzlakoglu, K.; Azevedo, H.; Reis, R. Preparation and characterization of starch-poly-ε-caprolactone microparticles incorporating bioactive agents for drug delivery and tissue engineering applications. Biomaterialia 2009, 5, 1035–1045. [Google Scholar] [CrossRef] [Green Version]

- Cesteros, L. Aplicaciones de la FTIR al estudio de las interacciones polímero-polímero. Rev. Iberoam. Polímeros 2004, 5, 111–132. [Google Scholar]

- Cuenca, P.; Ferrero, S.; Albani, O. Preparation and characterization of cassava starch acetate with high substitution degree. Food Hydrocolloid 2020, 100, 105430. [Google Scholar] [CrossRef]

- Rodrigues dos Santos, T.; Franco, C.; Demiate, I.; Li, X.H.; Garcia, E.; Jane, J.L.; Leonel, M. Spray-drying and extrusion processes: Effects on morphology and physicochemical characteristics of starches isolated from Peruvian carrot and cassava. Int. J. Biol. Macromol. 2018, 118, 1346–1353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wurzburg, O. Modified Starches: Properties and Uses; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Tsuji, H.; Horikawa, G.; Itsuno, S. Melt-processed biodegradable polyester blends on poly(L-lactic acid) and poly(ε-caprolactone): Effects of processing conditions on biodegradation. J. Appl. Polym. Sci. 2007, 104, 831–841. [Google Scholar] [CrossRef]

- Ishiaku, U.S.; Pang, K.W.; Lee, W.S.; Mohd, Z.A. Mechanical properties and enzymic degradation of thermoplastic and granular sago starch filled poly(ε-caprolactone). Eur. Polym. J. 2002, 38, 393–401. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J.; Kennedy, J. Studies on the properties of natural fibers-reinforced thermoplastic starch composites. Carbohydr. Polym. 2005, 62, 19–24. [Google Scholar] [CrossRef]

- Huang, M.; Yu, J. Structure and Properties of Thermoplastic Corn Starch/Montmorillonite Biodegradable Composites. J. Appl. Polym. Sci. 2006, 99, 170–176. [Google Scholar] [CrossRef]

- Liu, Z.; Yi, X.; Feng, Y. Effects of glycerin and glycerol monostearate on performance of thermoplastic starch. J. Mater. Sci. 2001, 36, 1809–1815. [Google Scholar] [CrossRef]

- Thunwall, M.; Kuthanová, V.; Boldizar, A.; Rigdahl, M. Film blowing of thermoplastic starch. Carbohydr. Polym. 2008, 71, 583–590. [Google Scholar] [CrossRef]

- Ma, X.; Yu, G.; Wan, N. Fly ash-reinforced thermoplastic starch composites. Carbohydr. Polym. 2007, 67, 32–39. [Google Scholar] [CrossRef]

- Teixeira, E.; Pasquini, D.; Curvelo, A.; Corradini, E. Cassava bagasse cellulose nanofibrils reinforced thermoplastic cassava starch. Carbohydr. Polym. 2009, 78, 422–431. [Google Scholar] [CrossRef]

- Da Róz, A.; Zambon, M.; Curvelo, A.; Carvalho, A. Thermoplastic starch modified during melt processing with organic acids: The effect of molar mass on thermal and mechanical properties. Ind. Crop. Prod. 2011, 33, 152–157. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Wang, X.; Cen, R.; Wang, Y. Effect of carbonyl content on the properties of thermoplastic oxidized starch. Carbohydr. Polym. 2009, 78, 157–161. [Google Scholar] [CrossRef]

- Mina, J.; Valadez-González, A.; Herrera-Franco, P.; Zuluaga, F.; Delvasto, S. Physicochemical Characterization of Natural and Acetylated Thermoplastic Cassava Starch. Dyna 2011, 78, 185–193. [Google Scholar]

- Aoyagi, Y.; Yamashita, K.; Doi, Y. Thermal degradation of poly[(R)-3-hydroxybutyrate], poly[ε-caprolactone], and poly[(S)-lactide]. Polym. Degrad. Stab. 2002, 76, 53–59. [Google Scholar] [CrossRef]

- Valles, A.; Martinez, A.; Ribes, A.; Cadenato, A.; Ramis, X.; Salla, J.M.; Morancho, J.M. Thermal Analysis Characterization of the Degradation of Biodegradable Starch Blends in Soil. J. Appl. Polym. Sci. 2005, 96, 358–371. [Google Scholar]

- Arberlaiz, A.; Fernández, B.; Valea, A.; Mondragon, I. Mechanical properties of short flax fibre bundle/poly(3-caprolactone) composites: Influence of matrix modification and fibre content. Carbohydr. Polym. 2006, 64, 224–232. [Google Scholar] [CrossRef]

- Sandoval, A.; Rodríguez, E.; Fernández, A. Aplicación del análisis por calorimetría diferencial de barrido (DSC) para la caracterización de las modificaciones del almidón. Dyna 2005, 72, 45–53. [Google Scholar]

- Van Soest, J.; Hulleman, S.; De Wit, D.; Vliegenthart, J. Crystallinity in starch bioplastics. Ind. Crop. Prod. 1996, 5, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Atichokudomchai, N.; Shobsngob, S.; Chinachoti, P.; Varavinit, S. A Study of Some Physicochemical Properties of High-Crystalline Tapioca Starch. Starch Stärke 2001, 53, 577–581. [Google Scholar] [CrossRef]

- Wang, X.; Gao, W.Y.; Zhang, L.; Xiao, P.; Yao, L.; Liu, Y.; Li, K. Study on the morphology, crystalline structure and thermal properties of yam starch acetates with different degrees of substitution. Sci. China Ser. B Chem. 2008, 51, 859–865. [Google Scholar] [CrossRef]

- Choi, E.; Kim, C.; Park, J. Structure–Property Relationship in PCL/Starch Blend Compatibilized with Starch-g-PCL Copolymer. J. Polym. Sci. Part. B Polym. Phys. 1999, 37, 2430–2438. [Google Scholar] [CrossRef]

- Rosa, D.S.; Lopes, D.R.; Calil, M.R. Thermal properties and enzymatic degradation of blends of poly(3-caprolactone) with starches. Polym. Test. 2005, 24, 756–761. [Google Scholar] [CrossRef]

- Van Soest, J.; Knooren, N. Influences of glycerol and water content on the structure and properties of extruded starch plastic sheets during aging. Carbohydr. Polym. 1996, 29, 1411–1422. [Google Scholar] [CrossRef]

- Van Soest, J.; Hulleman, S.; De Wit, D.; Vliegenthart, J. Changes in the mechanical properties of thermoplastic potato starch in relation with changes in B-type crystallinity. Carbohydr. Polym. 1996, 29, 225–232. [Google Scholar] [CrossRef] [Green Version]

- Shogren, R. Effect of moisture content on the melting and subsequent physical aging of corn starch. Carbohydr. Polym. 1992, 19, 83–90. [Google Scholar] [CrossRef]

- Lourdin, D.; Bizot, H.; Colonna, P. Antiplasticization in Starch–Glycerol Films? J. Appl. Polym. Sci. 1997, 63, 1047–1053. [Google Scholar] [CrossRef]

- Ruiz, G. Obtención y caracterización de un polímero biodegradable a partir del almidón de yuca. Ing. Y Cienc. 2007, 2, 5–28. [Google Scholar]

- Yu, J.; Wang, N.; Ma, X. The Effects of Citric Acid on the Properties of Thermoplastic Starch Plasticized by Glycerol. Starch Stärke 2005, 57, 494–504. [Google Scholar]

| Functional Group/Assignment | Group Frequency, Wavenumber (cm−1) | |

|---|---|---|

| Experimental Dates | Balmayor et al. [32] | |

| Hydroxyl O–H stretch of the starch | 3331 | 3362 |

| Methylene CH2 asymmetric/symmetric stretch of the polycaprolactone | 2945/2866 | 2944/2864 |

| Carbonyl C=O stretch of the polycaprolactone (ester) | 1724 | 1724 |

| C–O single bond C–O–C stretch of the polycaprolactone | 1242 | 1244 |

| Glycosidic C–O–C stretch of the starch | 1043/1029 | 1048/1021 |

| Materials Starch/Plasticizer | * Plastizicer Content (%) | Conditions for the Adsorption Determination | Moisture Adsorption (%) | Reference | ||

|---|---|---|---|---|---|---|

| Drying Temperature (°C) | Drying Time (hours) | Relative Humidity | ||||

| Corn/Glycerol | 23 | 105 | 12 | 43 | 9.0 | Curvelo et al. [16] |

| 100 | 65.0 | |||||

| Corn/Glycerol | 23 | 105 | 12 | 75 | 37.0 | Ma et al. [39] |

| Corn/Urea-ethanolamine | 23 | 105 | 24 | 25 | 16.0 | Huang and Yu [40] |

| 50 | 23.0 | |||||

| Wheat/Glycerol | 30 | N.R. | N.R. | 90 | 35.0 | Liu et al. [41] |

| Potato/Glycerol | 23 | 105 | N.R. | 53 | 13.0 | Thunwall et al. [42] |

| Corn/Glycerol | 23 | 105 | 12 | 100 | 46.0 | Ma et al. [43] |

| Cassava/Glycerol | 38 | N.R. | N.R. | 53 | 11.2 | Teixeira et al. [44] |

| Corn/Glycerol | 23 | 110 | 12 | 53 | 11.6 | Da Róz et al. [45] |

| 97 | 60.0 | |||||

| Corn/Glycerol | ** 15 | 110 | 36 | 100 | 30.7 | Zhang et al. [46] |

| Cassava/Glycerol | 30 | 80 | 12 | 54 | 10.5 | Mina et al. [47] |

| Cassava/Glycerol | 30 | 60 | 24 | 54 | 7.0 | Present work |

| Cassava/Glycerol | 30 | 60 | 24 | 29 | 1.0 | Present work |

| Material | Angle (°, 2θ) | Intensity | Type | |

|---|---|---|---|---|

| Experimental Dates | Reference | |||

| Native starch | 15.1 | N.R. [52] | Very strong | C |

| 17.2 | 17.6 [52] | Strong | ||

| 18.0 | N.R. [52] | Strong | ||

| 22.9 | 22.6 [52] | Strong | ||

| 30.2 | 30.2 [52] | Weak | ||

| 33.5 | 33.5 [52] | Weak | ||

| Thermoplastic starch (TPS) | 13.0 | 13.0 [52] | Medium | VH with Residual crystallinity C |

| 17.7 | N.R. [52] | Weak | ||

| 19.8 | 19.8 [52] | Very strong | ||

| 22.7 | N.R. [52] | Weak | ||

| Polycaprolactone (PCL) | 21.4 | 21.6 [5] | Very strong | Planes (110) |

| 22.0 | 22.2 [5] | Weak | Planes (111) | |

| 23.6 | 23.3 [5] | Strong | Planes (200) | |

| Material Starch/Plasticizer | Relative Humidity (%) | Crosshead Rate (mm/min) | Tensile Strength (MPa) | Modulus of Elasticity (MPa) | Tensile Strain (%) | Reference |

|---|---|---|---|---|---|---|

| Corn/23% Glycerol | 50 (14 days) | 10.0 | 5.5 | 38.1 | 7.0 | Huang et al. [1] |

| Corn/23% Glycerol | 60 (14 days) | 50.0 | 5.0 | 125.0 | N.R. | Curvelo et al. [16] |

| Potato/23% Glycerol | 70 (14 days) | 10.0 | 5.4 | 38.0 | 27.0 | Van Soest et al. [58] |

| Corn/Water | 17 (7 days) | 50.0 | 16.7 | 830.0 | 3.3 | Shogren [59] |

| Potato/29% Glycerol | 57 (2 days) | 2.0 | 5.0 | N.R. | 4.0 | Lourdin et al. [60] |

| Corn/23% Urea-Ethanolamine | 50 (14 days) | 10.0 | 6.4 | 124.7 | 116.7 | Huang y Yu [40] |

| Starch/30% Glycerol | N.R. | N.R. | 0.4 | N.R. | 68.9 | Ruiz [61] |

| Corn/23% Urea | 33 (7 days) | 10.0 | 12.6 | 1664.0 | 5.7 | Ma et al. [15] |

| Corn/23% Ethanolamine | 33 (7 days) | 10.0 | 3.1 | 57.0 | 61.6 | |

| Corn/23% Urea-Ethanolamine | 33 (7 days) | 10.0 | 9.0 | 236.0 | 34.4 | |

| Corn/20% Glycerol | 50 (7 days) | 10 | 4.8 | N.R. | 85.0 | Yu et al. [62] |

| Corn/ * 15% Glycerol | 100 (N.R.) | 10 | 2.1 | N.R. | 16.2 | Zhang et al. [46] |

| Corn/23% Glycerol | N.R. (7 days) | 10 | 4.5 | 80.0 | N.R. | Ma et al. [43] |

| Starch/38% Glycerol | 53 (10 days) | 50 | 1.8 | 16.8 | 29.8 | Teixeira et al. [44] |

| Materials | Tensile Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|

| Polycaprolactone (PCL) | 23.9 | 383.0 |

| Binary blend TPS/PCL (40/60) | 7.6 ± 1.0 | 235.3 ± 23.8 |

| Binary blend TPS/PCL (50/50) | 6.9 ± 0.1 | 187.0 ± 3.6 |

| Binary blend TPS/PCL (60/40) | 5.5 ± 0.4 | 138.0 ± 8.5 |

| Thermoplastic starch (TPS) | 2.3 ± 0.3 | 53.5 ± 6.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mina Hernandez, J.H. Effect of the Incorporation of Polycaprolactone (PCL) on the Retrogradation of Binary Blends with Cassava Thermoplastic Starch (TPS). Polymers 2021, 13, 38. https://doi.org/10.3390/polym13010038

Mina Hernandez JH. Effect of the Incorporation of Polycaprolactone (PCL) on the Retrogradation of Binary Blends with Cassava Thermoplastic Starch (TPS). Polymers. 2021; 13(1):38. https://doi.org/10.3390/polym13010038

Chicago/Turabian StyleMina Hernandez, José Herminsul. 2021. "Effect of the Incorporation of Polycaprolactone (PCL) on the Retrogradation of Binary Blends with Cassava Thermoplastic Starch (TPS)" Polymers 13, no. 1: 38. https://doi.org/10.3390/polym13010038

APA StyleMina Hernandez, J. H. (2021). Effect of the Incorporation of Polycaprolactone (PCL) on the Retrogradation of Binary Blends with Cassava Thermoplastic Starch (TPS). Polymers, 13(1), 38. https://doi.org/10.3390/polym13010038