Accelerated Testing Method for Predicting Long-Term Properties of Carbon Fiber-Reinforced Shape Memory Polymer Composites in a Low Earth Orbit Environment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

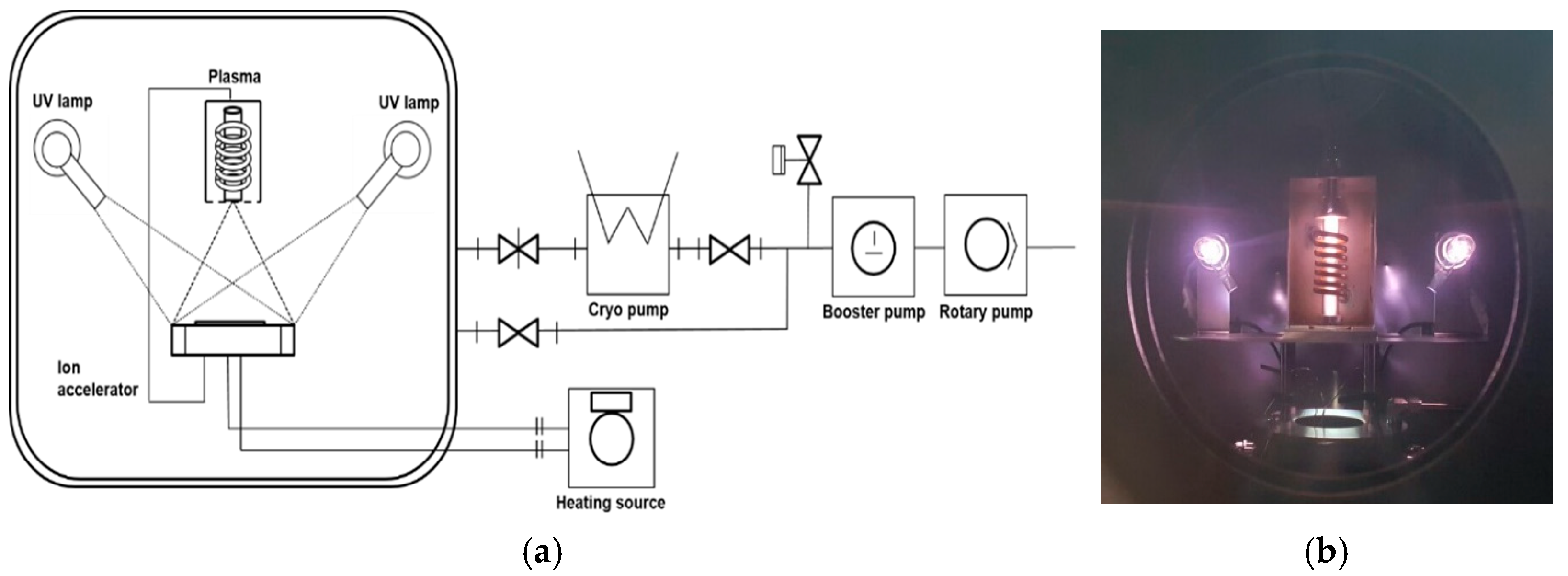

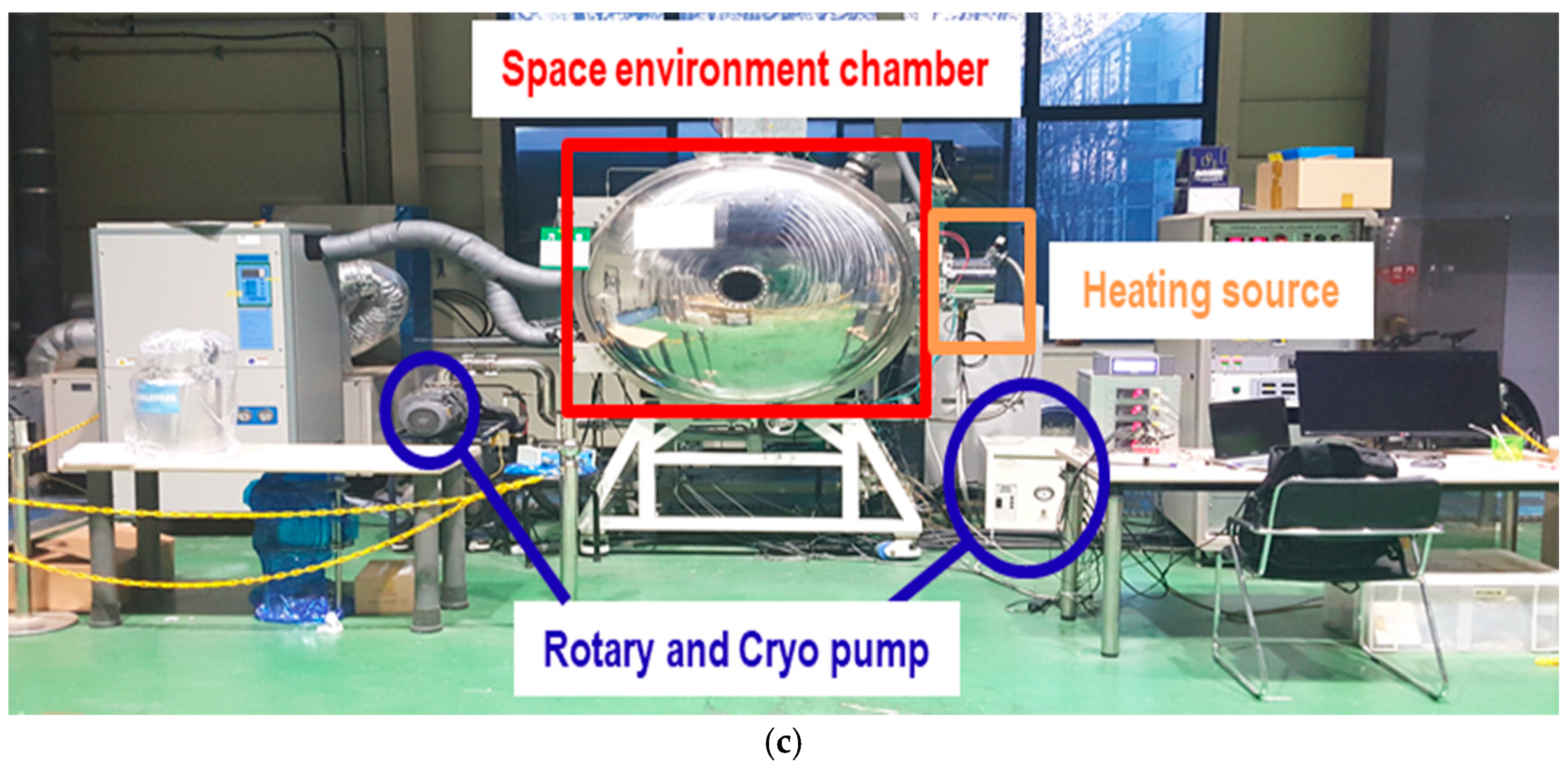

2.2. Environmental Chamber and Acceleration Test Design

2.3. Characterization

3. Results

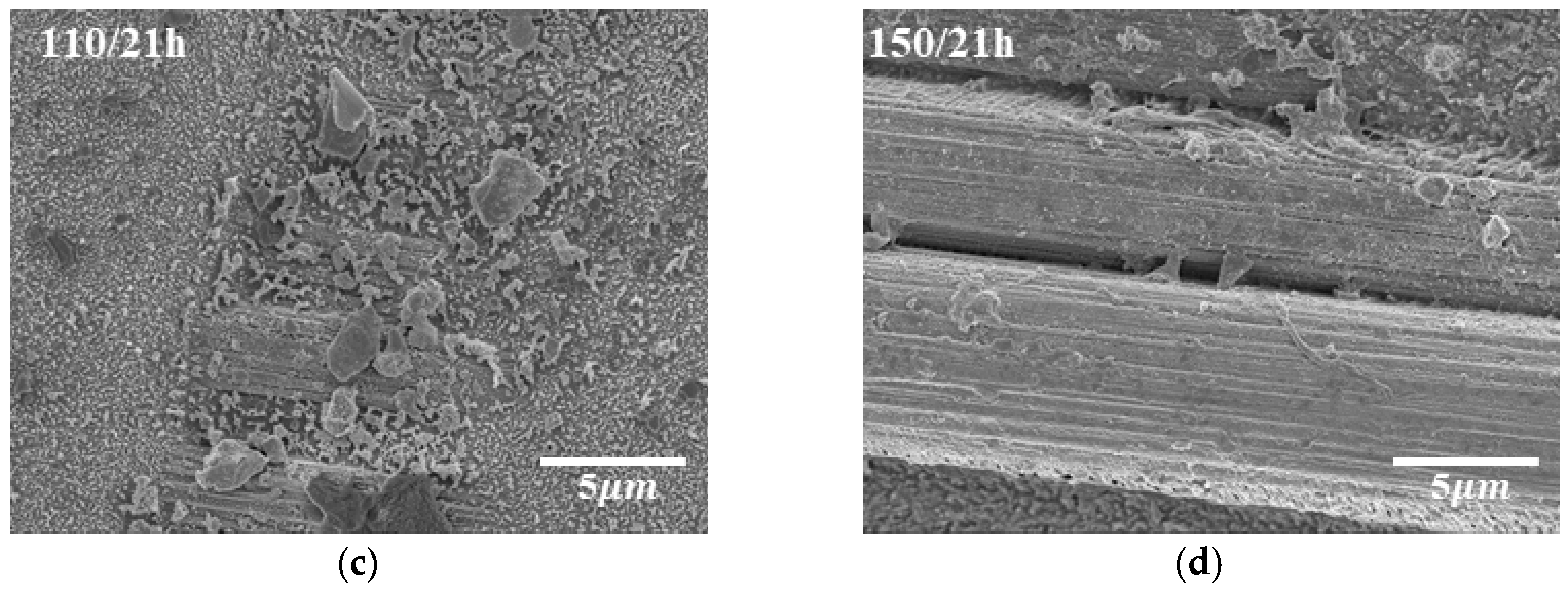

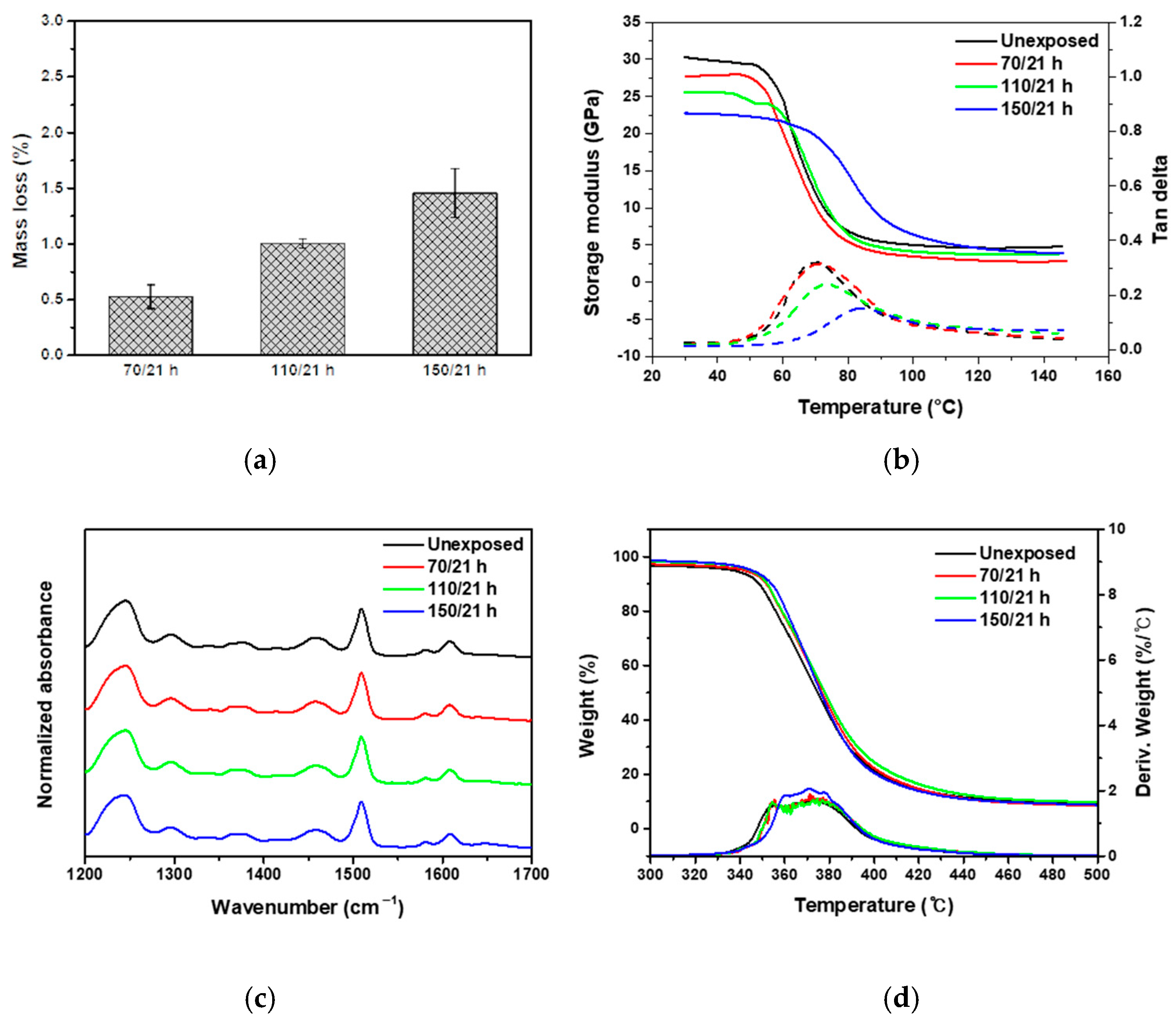

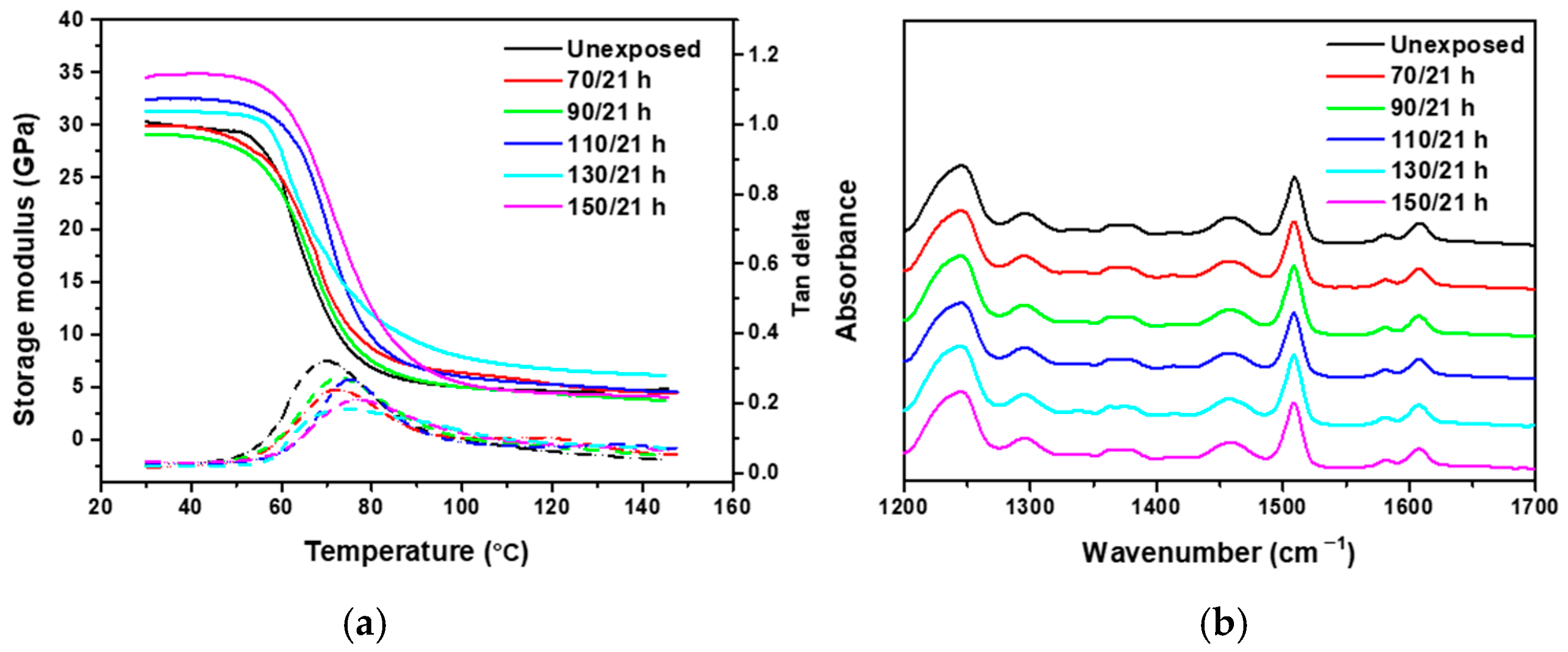

3.1. Effects of AO Irradiation and Temperature on Matrix Erosion

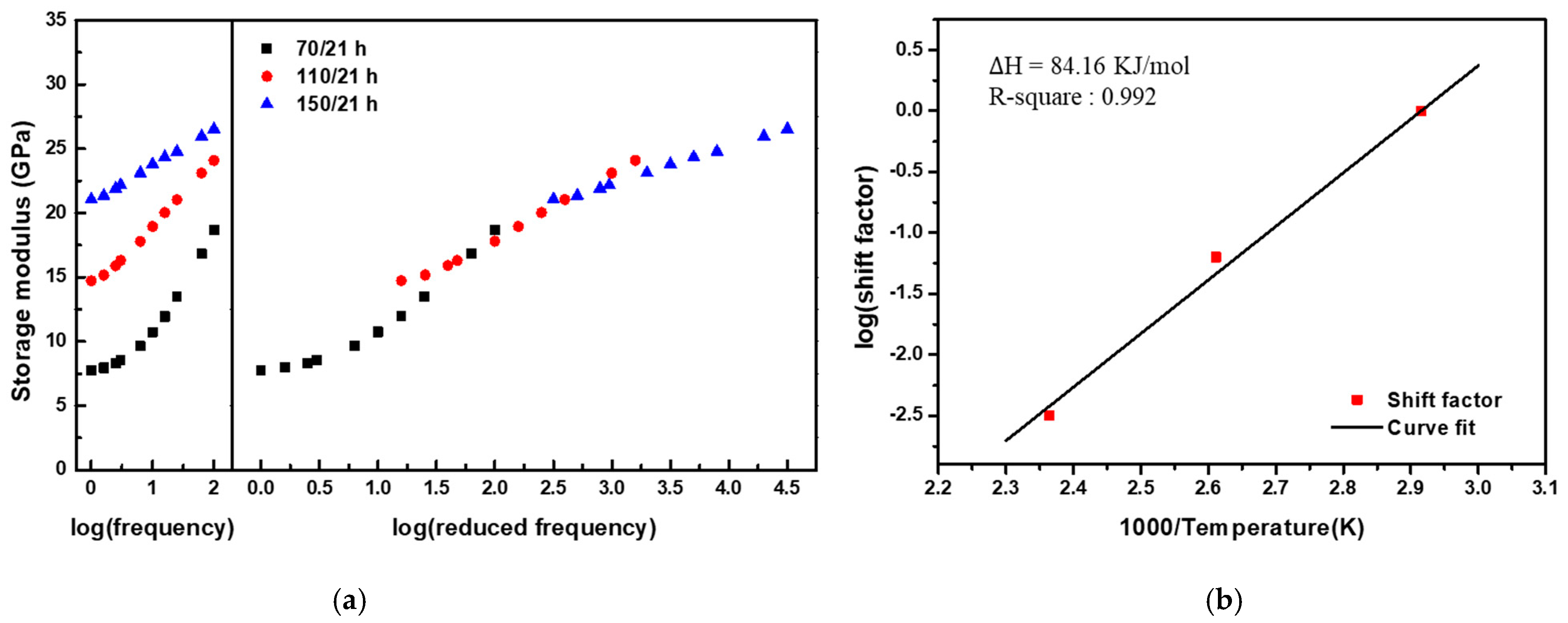

3.2. Quantitative Analysis of the AO Effect on Long-Term Properties

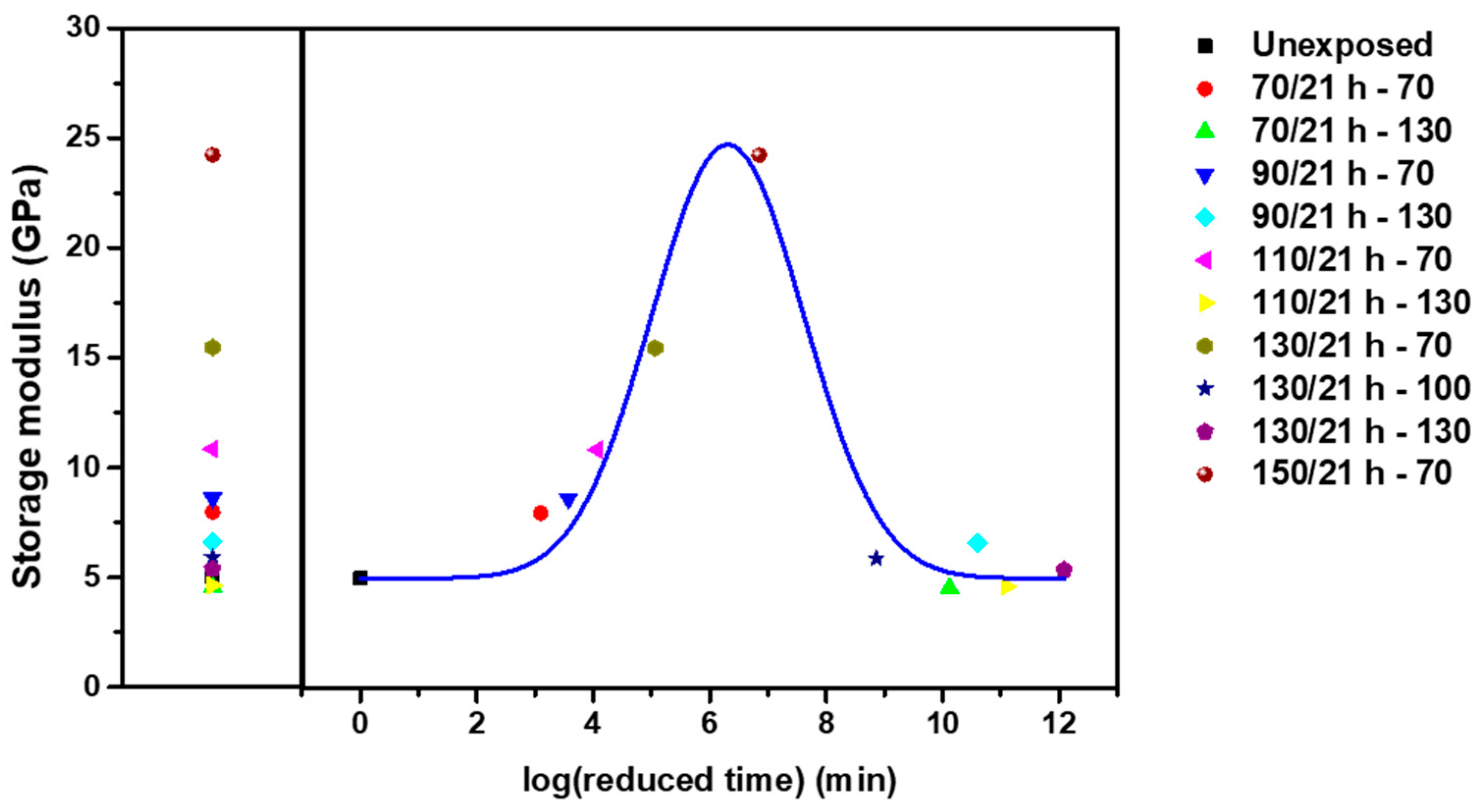

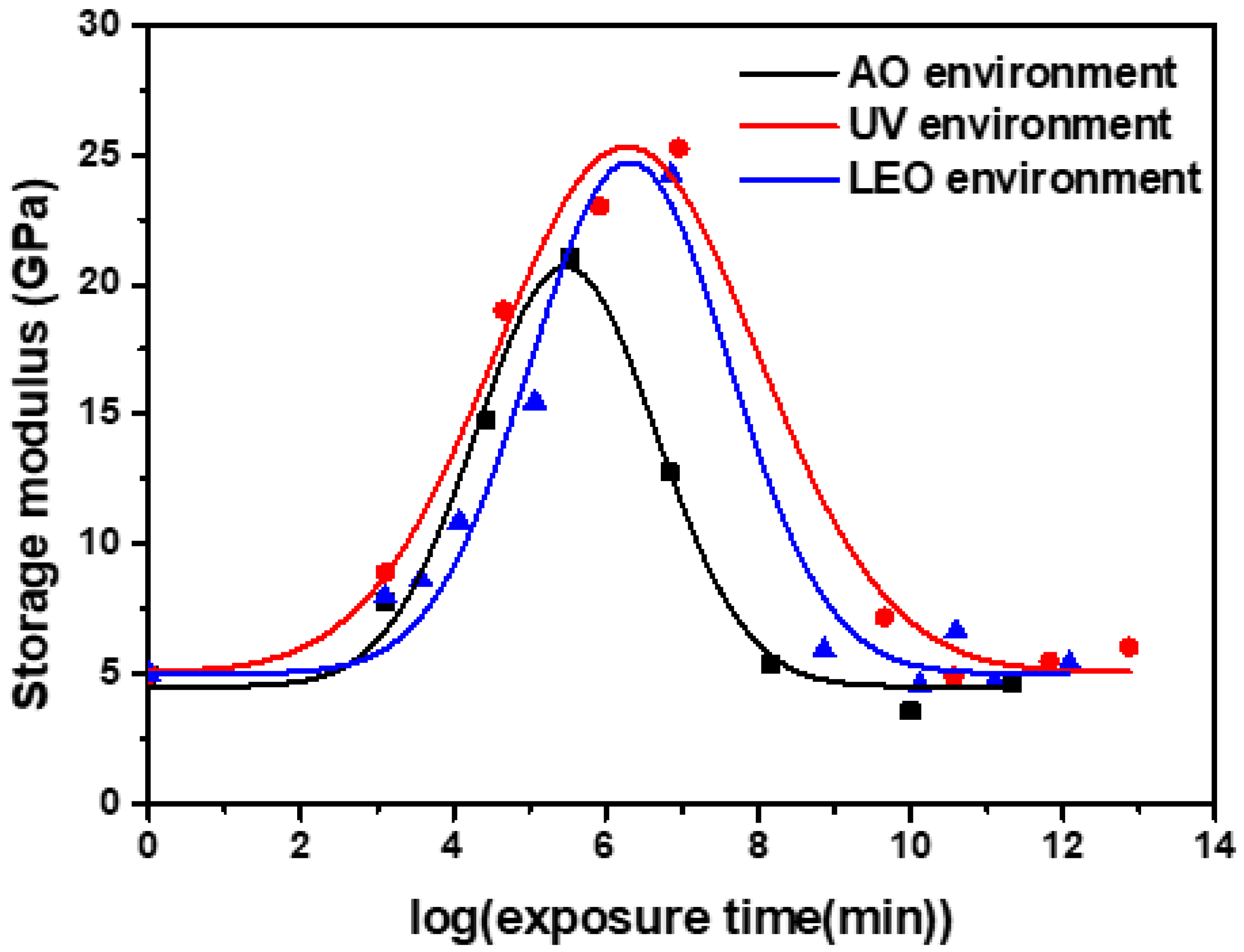

3.3. Acceleration Effects and Long-Term Properties under LEO Environments

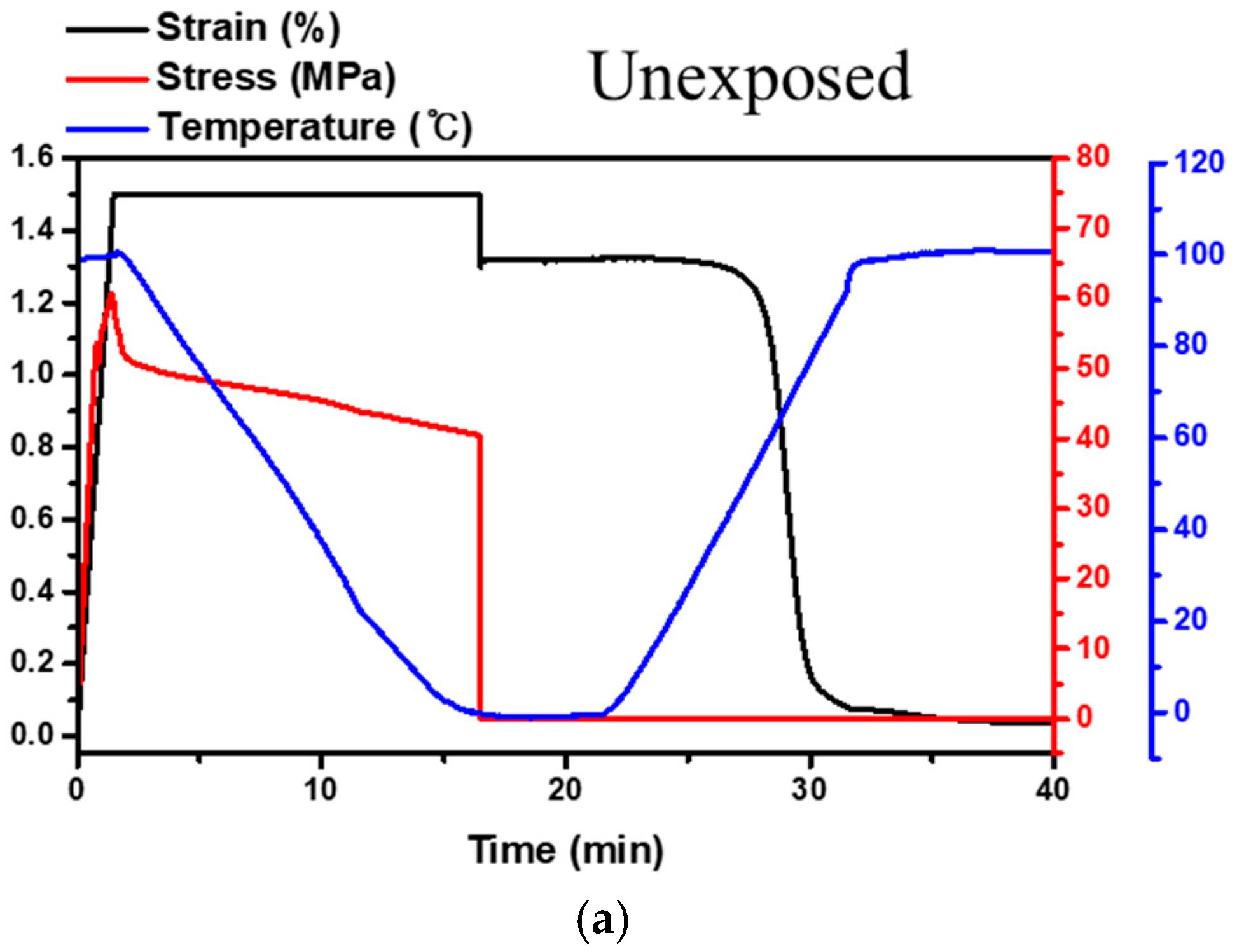

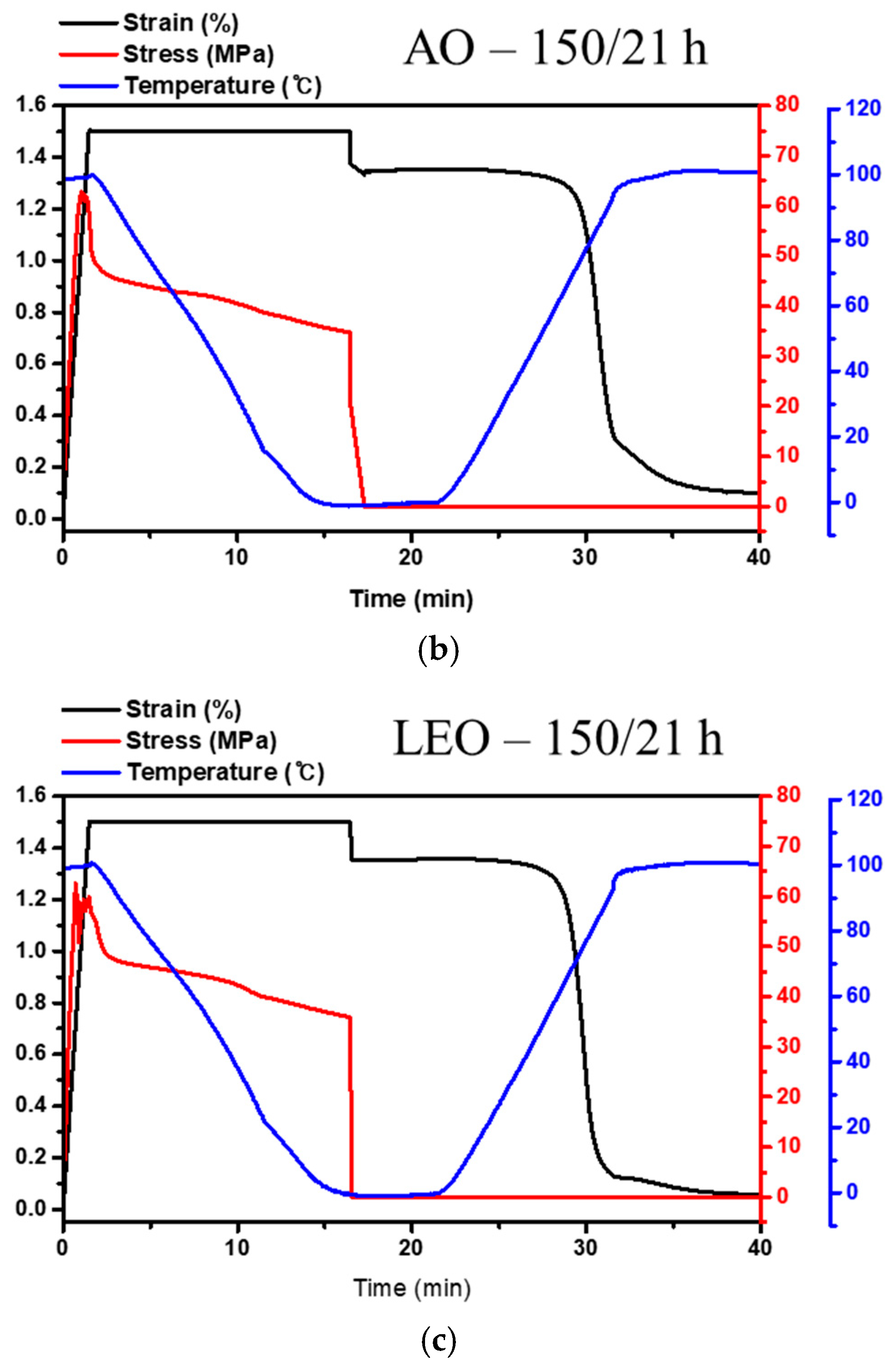

3.4. Shape Memory Properties under AO and LEO Environments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bye, D.; McClure, P. AIAA-2007-2057 Sensor Placement for Damage Detection in Nonlinear Systems using System Augmentations. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007; p. 1728. [Google Scholar]

- Keller, P.; Lake, M.; Francis, W.; Harvey, J.; Ruhl, E.; Winter, J.; Murphey, T.; Scherbarth, M.; Barrett, R.; Wintergerst, J. Development of a Deployable Boom for Microsatellites Using Elastic Memory Composite Material. In Proceedings of the 45th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Palm Springs, CA, USA, 19–22 April 2004. [Google Scholar]

- Lan, X.; Liu, Y.; Lv, H.; Wang, X.; Leng, J.; Du, S. Fiber reinforced shape-memory polymer composite and its application in a deployable hinge. Smart Mater. Struct. 2009, 18, 024002. [Google Scholar] [CrossRef]

- Lin, J.K.; Knoll, C.F.; Willey, C.E. Shape memory rigidizable inflatable (RI) structures for large space systems applications. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RI, USA, 1–4 May 2006. [Google Scholar]

- Cho, J.W.; Kim, J.W.; Jung, Y.C.; Goo, N.S. Electroactive Shape-Memory Polyurethane Composites Incorporating Carbon Nanotubes. Macromol. Rapid Commun. 2005, 26, 412–416. [Google Scholar] [CrossRef]

- Kang, T.-H.; Lee, J.; Yu, W.; Youk, J.H.; Ryu, H.W. Two-way actuation behavior of shape memory polymer/elastomer core/shell composites. Smart Mater. Struct. 2012, 21, 035028. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-Memory Polymers. Angew. Chem. Int. Ed. 2002, 41, 2034–2057. [Google Scholar] [CrossRef]

- Meng, H.; Mohamadian, H.; Stubblefield, M.; Jerro, D.; Ibekwe, S.; Pang, S.; Li, G. Various shape memory effects of stimuli-responsive shape memory polymers. Smart Mater. Struct. 2013, 22, 093001. [Google Scholar] [CrossRef]

- Rose, A.; Zhu, Z.; Madigan, C.F.; Swager, T.M.; Bulović, V. Sensitivity gains in chemosensing by lasing action in organic polymers. Nature 2005, 434, 876–879. [Google Scholar] [CrossRef] [PubMed]

- An, Y.; Kim, J.; Goo, N.S.; Kim, Y.; Park, J.K.; Yu, W.R. Quantitative evaluation of the three-dimensional deployment behavior of a shape memory polymer antenna. Smart Mater. Struct. 2018, 27, 105007. [Google Scholar] [CrossRef]

- Jape, S.; Garza, M.; Ruff, J.; Espinal, F.; Sessions, D.; Huff, G.; Lagoudas, D.C.; Hernandez, E.A.P.; Hartl, D.J. Self-foldable origami reflector antenna enabled by shape memory polymer actuation. Smart Mater. Struct. 2020, 29, 115011. [Google Scholar] [CrossRef]

- Dao, T.D.; Ha, N.S.; Goo, N.S.; Yu, W.R. Design, fabrication, and bending test of shape memory polymer composite hinges for space deployable structures. J. Intell. Mater. Syst. Struct. 2017, 29, 1560–1574. [Google Scholar] [CrossRef]

- Hines, L.; Arabagi, V.; Sitti, M. Shape memory polymer-based flexure stiffness control in a miniature flapping-wing robot. IEEE Trans. Robot. 2012, 28, 987–990. [Google Scholar] [CrossRef]

- Roh, J.-H.; Kim, H.-J.; Bae, J.-S. Shape memory polymer composites with woven fabric reinforcement for self-deployable booms. J. Intell. Mater. Syst. Struct. 2014, 25, 2256–2266. [Google Scholar] [CrossRef]

- Grossman, E.; Gouzman, I. Space environment effects on polymers in low earth orbit. Nuclear Instr. Methods Phys. Res. Sec. B Beam Interact. Mater. Atoms 2003, 208, 48–57. [Google Scholar] [CrossRef]

- Han, J.-H.; Kim, C.-G. Low earth orbit space environment simulation and its effects on graphite/epoxy composites. Compos. Struct. 2006, 72, 218–226. [Google Scholar] [CrossRef]

- Moon, J.-B.; Kim, M.G.; Kim, C.G.; Bhowmik, S. Improvement of tensile properties of CFRP composites under LEO space environment by applying MWNTs and thin-ply. Compos. Part A Appl. Sci. Manuf. 2011, 42, 694–701. [Google Scholar] [CrossRef]

- Shin, K.-B.; Kim, C.G.; Hong, C.S.; Lee, H.H. Prediction of failure thermal cycles in graphite/epoxy composite materials under simulated low earth orbit environments. Compos. Part B Eng. 2000, 31, 223–235. [Google Scholar] [CrossRef]

- Awaja, F.; Moon, J.B.; Zhang, S.; Gilbert, M.; Kim, C.G.; Pigram, P.J. Surface molecular degradation of 3D glass polymer composite under low earth orbit simulated space environment. Polym. Degrad. Stab. 2010, 95, 987–996. [Google Scholar] [CrossRef]

- Tan, Q.; Li, F.; Liu, L.; Liu, Y.; Yan, X.; Leng, J. Study of low earth orbit ultraviolet radiation and vacuum thermal cycling environment effects on epoxy-based shape memory polymer. J. Intell. Mater. Syst. Struct. 2019, 30, 2688–2696. [Google Scholar] [CrossRef]

- Tan, Q.; Li, F.; Liu, L.; Chu, H.; Liu, Y.; Leng, J. Effects of atomic oxygen on epoxy-based shape memory polymer in low earth orbit. J. Intell. Mater. Syst. Struct. 2017, 29, 1081–1087. [Google Scholar] [CrossRef]

- Qian, M.; Murray, V.J.; Wei, W.; Marshall, B.C.; Minton, T.K. Resistance of POSS Polyimide Blends to Hyperthermal Atomic Oxygen Attack. ACS Appl. Mater. Interf. 2016, 8, 33982–33992. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Qian, Y.; Qi, H.; Li, J.; Sun, J. Mechanically Robust Atomic Oxygen-Resistant Coatings Capable of Autonomously Healing Damage in Low Earth Orbit Space Environment. Adv. Mater. 2018, 30, e1803854. [Google Scholar] [CrossRef]

- He, Y.; Suliga, A.; Brinkmeyer, A.; Schenk, M.; Hamerton, I. Atomic oxygen degradation mechanisms of epoxy composites for space applications. Polym. Degrad. Stab. 2019, 166, 108–120. [Google Scholar] [CrossRef]

- Liou, J.C.; Johnson, N.L. A LEO satellite postmission disposal study using legend. Acta Astronaut. 2005, 57, 324–329. [Google Scholar] [CrossRef][Green Version]

- Ishisaka, A.; Kawagoe, M. Examination of the time–water content superposition on the dynamic viscoelasticity of moistened polyamide 6 and epoxy. J. Appl. Polym. Sci. 2004, 93, 560–567. [Google Scholar] [CrossRef]

- Rajaneesh, A.; Satrio, W.; Chai, G.B.; Sridhar, I. Long-term life prediction of woven CFRP laminates under three point flexural fatigue. Compos. Part B Eng. 2016, 91, 539–547. [Google Scholar] [CrossRef]

- Reeder, J.R. Prediction of Long-Term Strength of Thermoplastic Composites Using Time-Temperature Superposition; NASA/TM-2002-211781, NASA Technical Report; NASA: Washington, DC, USA, 2002. [Google Scholar]

- Wolfrum, J.; Eibl, S.; Lietch, L. Rapid evaluation of long-term thermal degradation of carbon fibre epoxy composites. Compos. Sci. Technol. 2009, 69, 523–530. [Google Scholar] [CrossRef]

- Yang, D.-G.; Jansen, K.M.; Ernst, L.J.; Zhang, G.Q.; Van Driel, W.D.; Bressers HJ, L.; Janssen JH, J. Numerical modeling of warpage induced in QFN array molding process. Microelectron. Reliab. 2007, 47, 310–318. [Google Scholar] [CrossRef]

- Gentry, T.; Bank, L.C.; Barkatt, A.; Prian, L. Accelerated test methods to determine the long-term behavior of composite highway structures subject to environmental loading. J. Compos. Technol. Res. 1998, 20, 38–50. [Google Scholar]

- Kim, Y.K.; White, S.R. Stress relaxation behavior of 3501-6 epoxy resin during cure. Polym. Eng. Sci. 1996, 36, 2852–2862. [Google Scholar] [CrossRef]

- Bank, L.C.; Gentry, T.R.; Barkatt, A. Accelerated test methods to determine the long-term behavior of FRP composite structures: Environmental effects. J. Reinf. Plast. Compos. 1995, 14, 559–587. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M.; Sekine, N. Accelerated testing for long-term durability of FRP laminates for marine use. J. Compos. Mater. 2005, 39, 5–20. [Google Scholar] [CrossRef]

- Fukushima, K.; Cai, H.; Nakada, M.; Miyano, Y. Determination of Time-Temperature Shift Factor for Long-Term Life Prediction of Polymer Composites. Proc. ICCM 2009, 17. [Google Scholar]

- Torikai, A.; Hasegawa, H. Accelerated photodegradation of poly (vinyl chloride). Polym. Degrad. Stab. 1999, 63, 441–445. [Google Scholar] [CrossRef]

- Torikai, A.; Takeuchi, A.; Fueki, K. The effect of temperature on the photo-degradation of polystyrene. Polym. Degrad. Stab. 1986, 14, 367–375. [Google Scholar] [CrossRef]

- Zhao, X.-H.; Shen, Z.G.; Xing, Y.S.; Ma, S.L. An experimental study of low earth orbit atomic oxygen and ultraviolet radiation effects on a spacecraft material—Polytetrafluoroethylene. Polym. Degrad. Stab. 2005, 88, 275–285. [Google Scholar] [CrossRef]

- Feng, J.; Guo, Z. Effects of temperature and frequency on dynamic mechanical properties of glass/epoxy composites. J. Mater. Sci. 2016, 51, 2747–2758. [Google Scholar] [CrossRef]

- Feng, J.; Guo, Z. Temperature-frequency-dependent mechanical properties model of epoxy resin and its composites. Compos. Part B Eng. 2016, 85, 161–169. [Google Scholar] [CrossRef]

- Naresh, K.; Khan, K.A.; Umer, R.; Vasudevan, A. Temperature-Frequency–Dependent Viscoelastic Properties of Neat Epoxy and Fiber Reinforced Polymer Composites: Experimental Characterization and Theoretical Predictions. Polymers 2020, 12, 1700. [Google Scholar] [CrossRef] [PubMed]

- Miyano, Y.; Nakada, M.; Muki, R. Applicability of Fatigue Life Prediction Method to Polymer Composites. Mech. Time Depend. Mater. 1999, 3, 141–157. [Google Scholar] [CrossRef]

- Jang, J.H.; Hong, S.B.; Kim, J.G.; Goo, N.S.; Lee, H.; Yu, W.R. Long-term properties of carbon fiber-reinforced shape memory epoxy/polymer composites exposed to vacuum and ultraviolet radiation. Smart Mater. Struct. 2019, 28, 115013. [Google Scholar] [CrossRef]

- Wu, X.L.; Huang, W.M.; Ding, Z.; Tan, H.X.; Yang, W.G.; Sun, K.Y. Characterization of the thermoresponsive shape-memory effect in poly(ether ether ketone) (PEEK). J. Appl. Polym. Sci. 2014, 131, 39844. [Google Scholar] [CrossRef]

- Wu, X.L.; Huang, W.M.; Wang, C.C.; Ding, Z.; Zhao, Y.; Tang, C.; Gao, X.Y. Characterization of polymeric shape memory materials. J. Polym. Eng. 2017, 37, 1. [Google Scholar] [CrossRef]

- Delfini, A.; Santoni, F.; Bisegna, F.; Piergentili, F.; Pastore, R.; Vricella, A.; Albanob, M.; Familiaric, G.; Battaglionec, E.; Matassac, R.; et al. Evaluation of atomic oxygen effects on nano-coated carbon-carbon structures for re-entry applications. Acta Astronaut. 2019, 161, 276–282. [Google Scholar] [CrossRef]

- Stark, A.K.; Berglund, L.A.; Tagawa, M.; Ohmae, N. Effect of atomic oxygen on the mechanical properties of highly graphitized carbon fibers. Carbon 1994, 32, 641–644. [Google Scholar] [CrossRef]

- Zheng, N.; He, J.; Zhao, D.; Huang, Y.; Gao, J.; Mai, Y.W. Improvement of atomic oxygen erosion resistance of carbon fiber and carbon fiber/epoxy composite interface with a silane coupling agent. Mater. Des. 2016, 109, 171–178. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Wang, M.; Shen, Z. An experimental study on improving the atomic oxygen resistance of epoxy resin/silica nanocomposites. Polym. Eng. Sci. 2007, 47, 1156–1162. [Google Scholar] [CrossRef]

- Iisaka, K.; Yama, K.S. Mechanical α-dispersion and interaction in filled polystyrene and polymethylmethacrylate. J. Appl. Polym. Sci. 1978, 22, 3135–3143. [Google Scholar] [CrossRef]

- Hergeth, W.-D.; Steinau, U.J.; Bittrich, H.J.; Simon, G.; Schmutzler, K. Polymerization in the presence of seeds. Part IV: Emulsion polymers containing inorganic filler particles. Polymer 1989, 30, 254–258. [Google Scholar] [CrossRef]

- Kumar, B.G.; Singh, R.P.; Nakamura, T. Degradation of carbon fiber-reinforced epoxy composites by ultraviolet radiation and condensation. J. Compos. Mater. 2002, 36, 2713–2733. [Google Scholar] [CrossRef]

- Kim, H.; Urban, M.W. Molecular Level Chain Scission Mechanisms of Epoxy and Urethane Polymeric Films Exposed to UV/H2O. Multidimensional Spectroscopic Studies. Langmuir 2000, 16, 5382–5390. [Google Scholar] [CrossRef]

- Yang, S.-L.; Wu, Z.H.; Yang, W.; Yang, M.B. Thermal and mechanical properties of chemical crosslinked polylactide (PLA). Polym. Test. 2008, 27, 957–963. [Google Scholar] [CrossRef]

- Hooshangi, Z.; Feghhi, S.A.H.; Saeedzadeh, R. The effects of low earth orbit atomic oxygen on the properties of Polytetrafluoroethylene. Acta Astronaut. 2016, 119, 233–240. [Google Scholar] [CrossRef]

- Karvanis, K.; Rusnáková, S.; Žaludek, M.; Čapka, A. Preparation and Dynamic Mechanical Analysis of Glass or carbon Fiber/Polymer Composites. IOP Conf. Series Mater. Sci. Eng. 2018, 362, 012005. [Google Scholar] [CrossRef]

- Celina, M.; Graham, A.C.; Gillen, K.T.; Assink, R.A.; Minier, L.M. Thermal Degradation Studies of a Polyurethane Propellant Binder. Rubber Chem. Technol. 2000, 73, 678–693. [Google Scholar] [CrossRef]

- Celina, M.; Gillen, K.T.; Assink, R.A. Accelerated aging and lifetime prediction: Review of non-Arrhenius behaviour due to two competing processes. Polym. Degrad. Stab. 2005, 90, 395–404. [Google Scholar] [CrossRef]

- Flynn, J.H. The ‘Temperature Integral’—Its use and abuse. Thermochim. Acta 1997, 300, 83–92. [Google Scholar] [CrossRef]

- Santiago, D.; Fabregat-Sanjuan, A.; Ferrando, F.; De la Flor, S. Improving of Mechanical and Shape-Memory Properties in Hyperbranched Epoxy Shape-Memory Polymers. Shape Mem. Superelast. 2016, 2, 239–246. [Google Scholar] [CrossRef]

| Exposure Temperature | 70 °C | 110 °C | 150 °C |

|---|---|---|---|

| Mass change (g) | 0.002 | 0.005 | 0.008 |

| AO Flux () | |||

| Erosion yield () | / | / |

| AO Exposure | Abbreviation | Glass Transition Temperature (°C) | Mass Loss (%) | TGA Onset Temperature (°C) |

|---|---|---|---|---|

| No treatment | Unexposed | 70.00 | 0 | 344.98 |

| 70 °C/21 h | 70/21 h | 71.00 | 0.525 ± (0.107) | 349.82 |

| 110 °C/21 h | 110/21 h | 73.50 | 1.001 ± (0.040) | 349.17 |

| 150 °C/21 h | 150/21 h | 84.00 | 1.454 ± (0.219) | 351.67 |

| AO Exposure | Glass Transition Temperature (°C) | Storage Modulus of Glass State (GPa) | Mass Loss (%) | TGA Onset Temperature (°C) |

|---|---|---|---|---|

| 150 °C/21 h | 75.00 | 10.00 | 1.454 | 351.67 |

| 136 °C/50 h | 76.50 | 10.25 | 1.119 | 352.19 |

| 124 °C/100 h | 75.50 | 9.78 | 1.496 | 352.95 |

| 118 °C/150 h | 76.00 | 11.39 | 1.394 | 351.65 |

| 113 °C/200 h | 74.50 | 8.71 | 1.165 | 354.04 |

| Average (Stdev) | 75.50 ± (0.79) | 10.03 ± (0.96) | 1.330 ± (0.17) | 352.50 ± (1.01) |

| LEO Exposure | Glass Transition Temperature (°C) | Storage Modulus of Glass State (GPa) | TGA Onset Temperature (°C) |

|---|---|---|---|

| 150 °C/21 h | 77.00 | 34.53 | 352.39 |

| 139 °C/50 h | 78.50 | 33.50 | 352.80 |

| 129 °C/100 h | 77.00 | 35.36 | 352.60 |

| 124 °C/150 h | 75.50 | 34.77 | 352.58 |

| 120 °C/200 h | 76.50 | 36.77 | 352.83 |

| Average (Stdev) | 76.90 ± (1.08) | 34.99 ± (1.08) | 352.64 ± (0.16) |

| AO, LEO—Exposure | Fixity Ratio (%) | Recovery Ratio (%) |

|---|---|---|

| Unexposed | 88 ± (0.01) | 97 ± (0.01) |

| AO—70 °C/21 h | 91 ± (0.56) | 97 ± (1.42) |

| AO—110 °C/21 h | 88 ± (0.23) | 96 ± (0.40) |

| AO—150 °C/21 h | 89 ± (0.89) | 93 ± (0.83) |

| LEO—70 °C/21 h | 90 ± (0.42) | 100 ± (0.50) |

| LEO—110 °C/21 h | 91 ± (0.04) | 98 ± (0.08) |

| LEO—150 °C/21 h | 90 ± (0.06) | 96 ± (0.01) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, J.-H.; Hong, S.-B.; Kim, J.-G.; Goo, N.-S.; Yu, W.-R. Accelerated Testing Method for Predicting Long-Term Properties of Carbon Fiber-Reinforced Shape Memory Polymer Composites in a Low Earth Orbit Environment. Polymers 2021, 13, 1628. https://doi.org/10.3390/polym13101628

Jang J-H, Hong S-B, Kim J-G, Goo N-S, Yu W-R. Accelerated Testing Method for Predicting Long-Term Properties of Carbon Fiber-Reinforced Shape Memory Polymer Composites in a Low Earth Orbit Environment. Polymers. 2021; 13(10):1628. https://doi.org/10.3390/polym13101628

Chicago/Turabian StyleJang, Joon-Hyeok, Seok-Bin Hong, Jin-Gyun Kim, Nam-Seo Goo, and Woong-Ryeol Yu. 2021. "Accelerated Testing Method for Predicting Long-Term Properties of Carbon Fiber-Reinforced Shape Memory Polymer Composites in a Low Earth Orbit Environment" Polymers 13, no. 10: 1628. https://doi.org/10.3390/polym13101628

APA StyleJang, J.-H., Hong, S.-B., Kim, J.-G., Goo, N.-S., & Yu, W.-R. (2021). Accelerated Testing Method for Predicting Long-Term Properties of Carbon Fiber-Reinforced Shape Memory Polymer Composites in a Low Earth Orbit Environment. Polymers, 13(10), 1628. https://doi.org/10.3390/polym13101628