Using P(Pressure)-T(Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process

Abstract

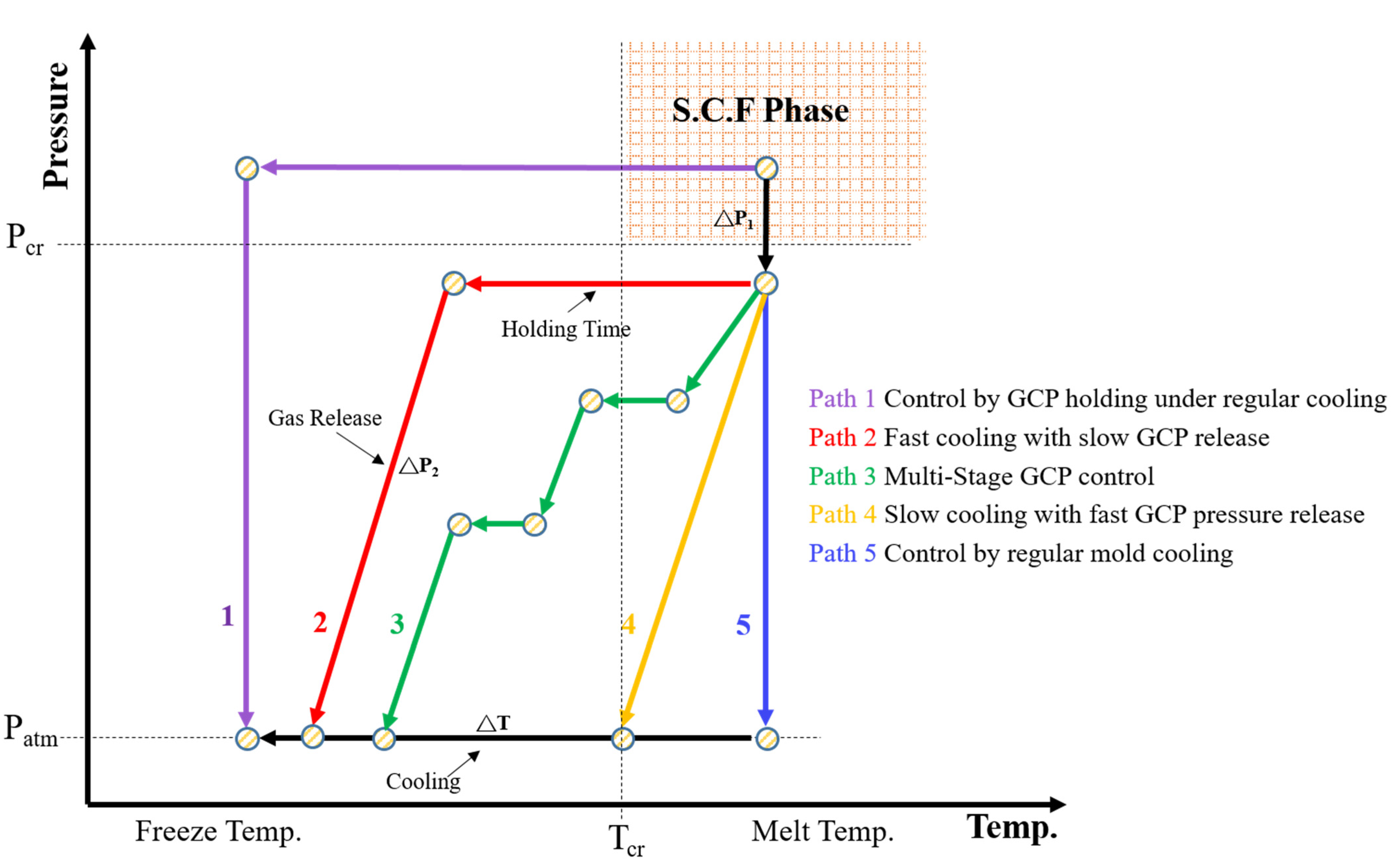

:1. Introduction

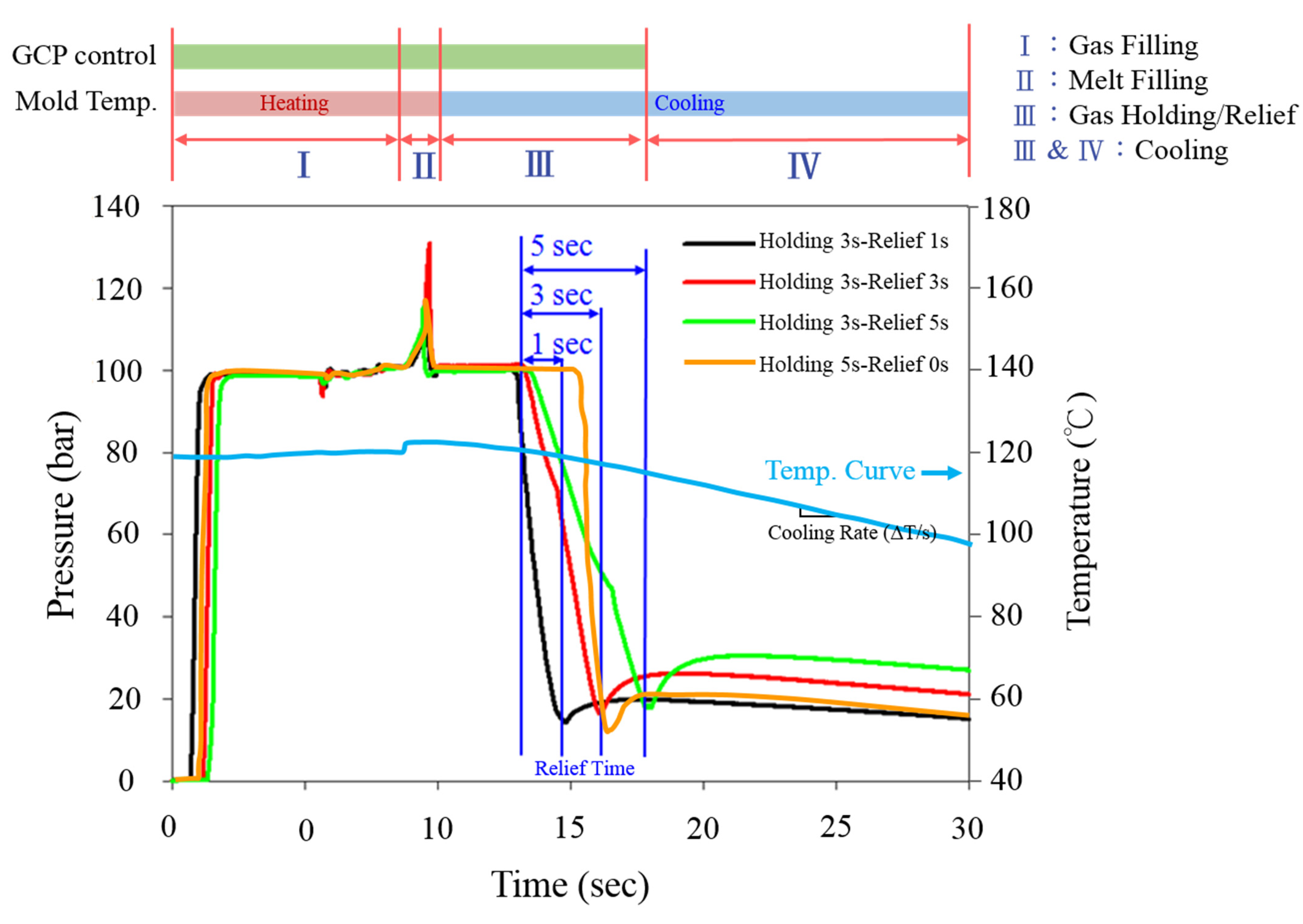

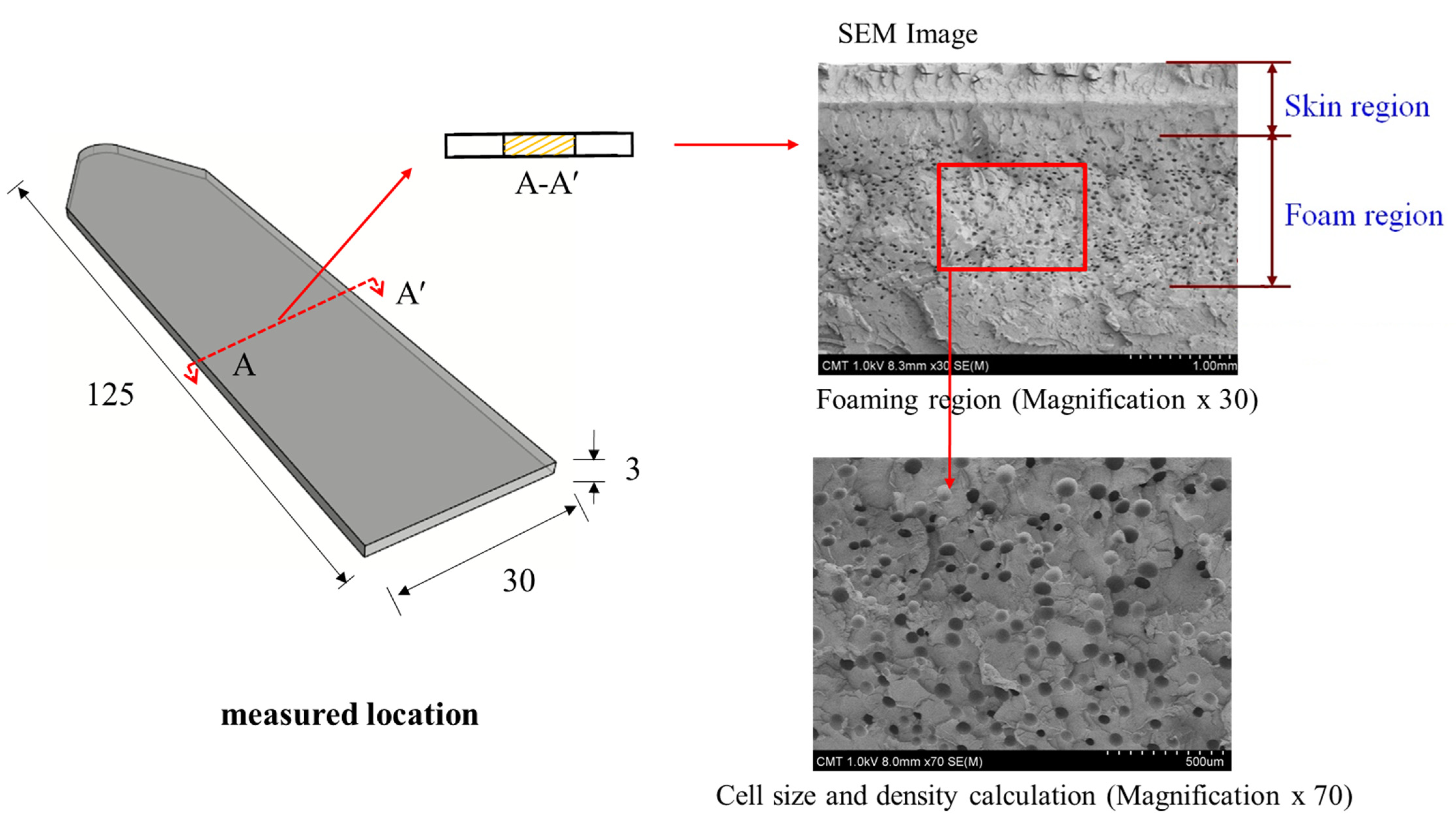

2. Experimental

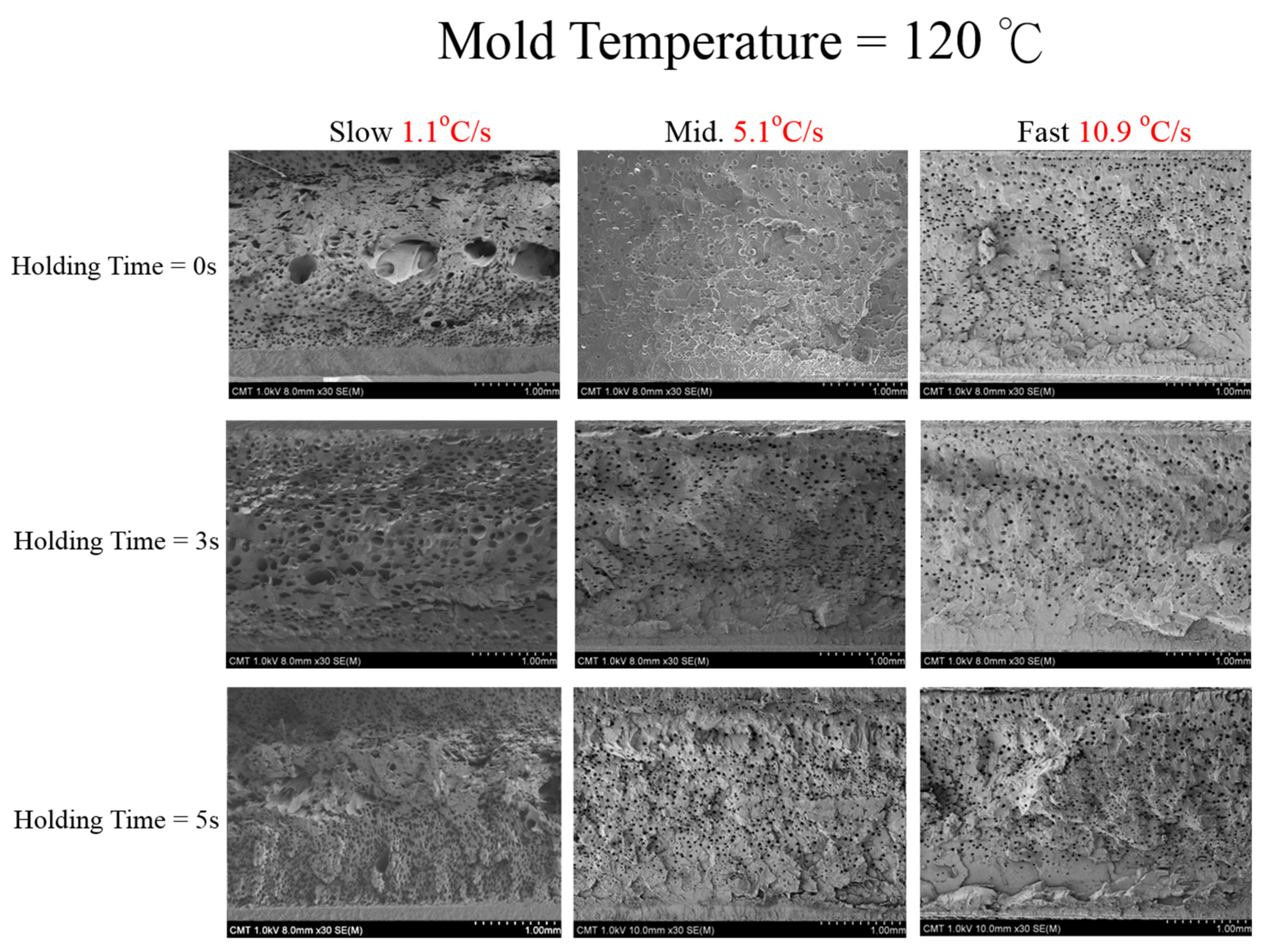

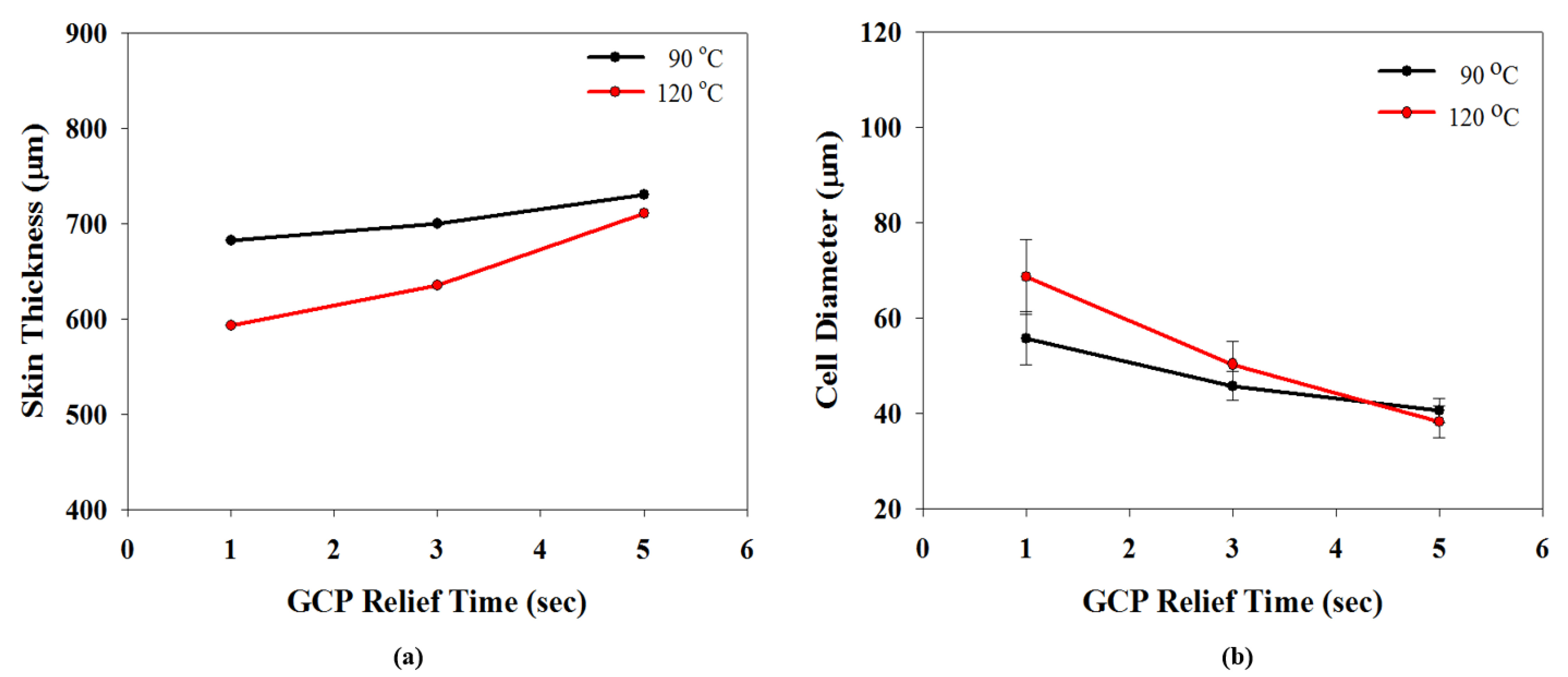

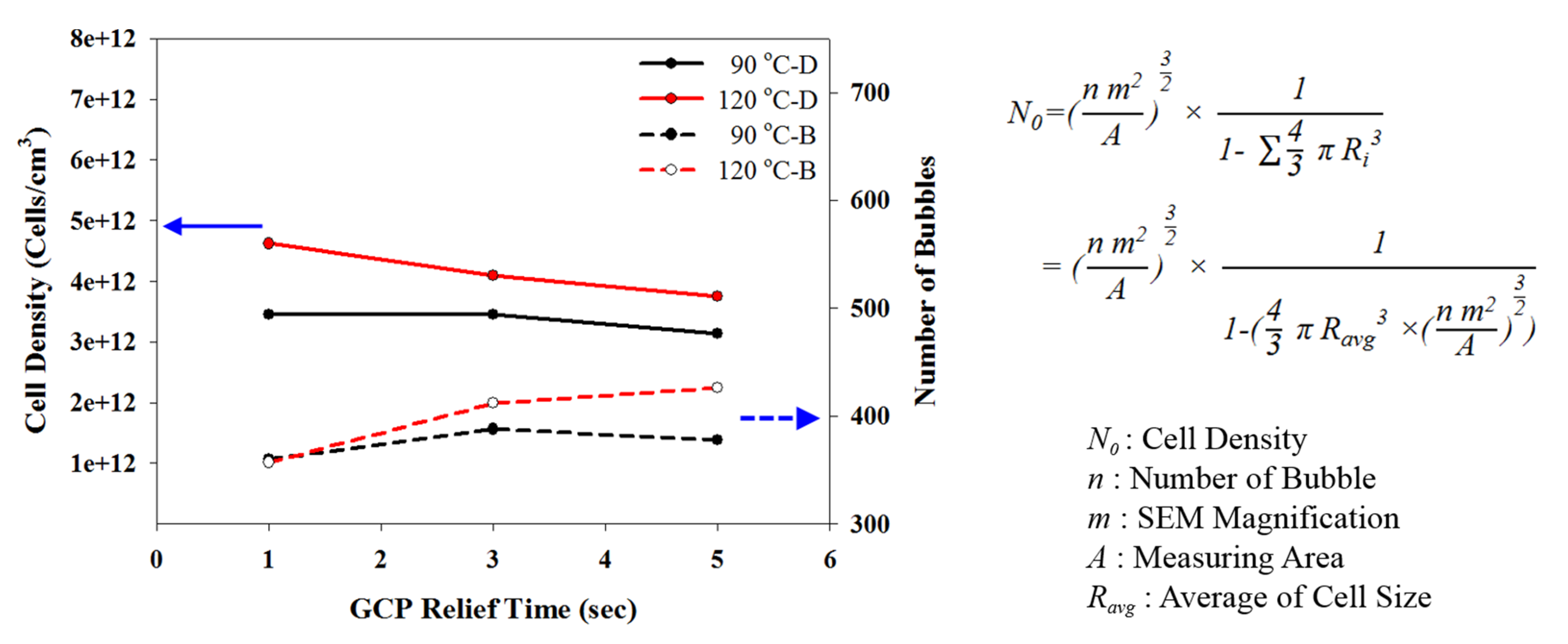

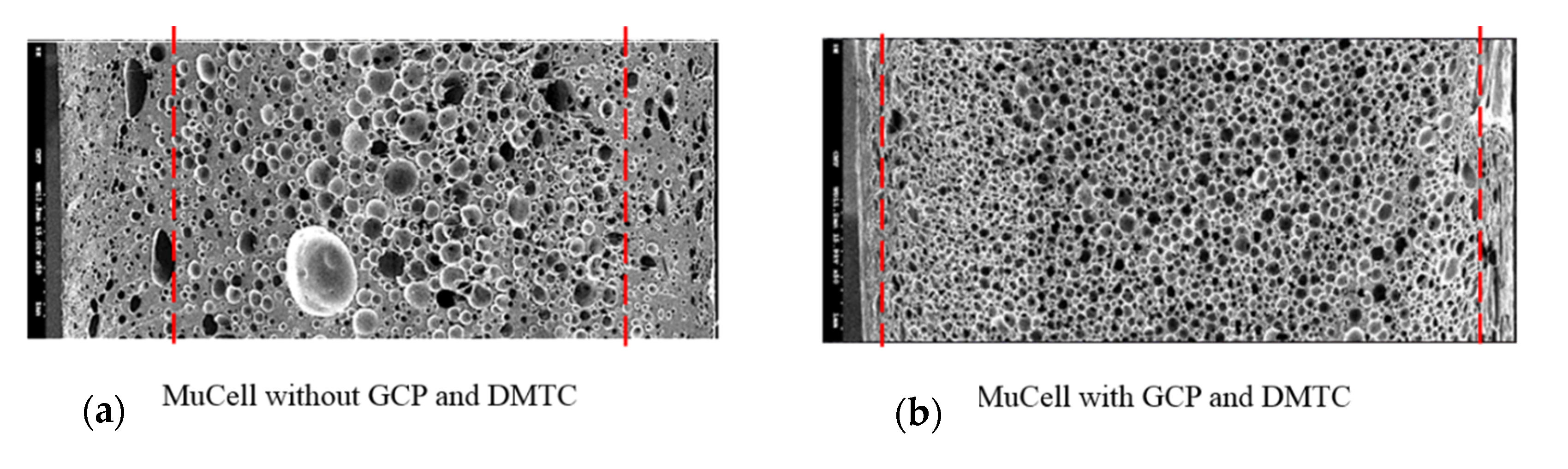

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martini, J.; Waldman, F.A.; Suh, N.P. The production and analysis of microcellular thermoplastic foam. SPE ANTEC Tech. Paper 1982, 28, 674–676. [Google Scholar]

- Suh, N.P. Microcellular Plastics; Hanser Publishers: Munich, Germany, 1996; Volume 93. [Google Scholar]

- Trexel Inc. Trexel Technical Paper; Trexel Inc.: Wilmington, MA, USA, 2001. [Google Scholar]

- Xu, J.; Pierick, D.J. Microcellular Foam Processing in Reciprocating-Screw Injection Molding Machines. Inject. Molding Technol. 2001, 5, 152–159. [Google Scholar]

- Gong, W.; Gao, J.; Jiang, M.; He, L.; Yu, J.; Zhu, J. Influence of cell structure parameters on the mechanical properties of microcellular polypropylene materials. Appl. Polym. Sci. 2011, 122, 2907–2914. [Google Scholar] [CrossRef]

- Kaewmesri, W.; Rachtanapun, P.; Pumchusak, J. Effect of solvent plasticization on polypropylene microcellular foaming process and foam characteristics. Appl. Polym. Sci. 2008, 107, 63–70. [Google Scholar] [CrossRef]

- Huang, H.X.; Wang, J.K. Improving polypropylene microcellular foaming through blending and the addition of nano-calcium carbonate. Appl. Polym. Sci. 2007, 106, 505–513. [Google Scholar] [CrossRef]

- Dong, G.W.; Zhao, G.Q.; Guan, Y.J.; Li, S.; Wang, X.X. Formation mechanism and structural characteristics of unfoamed skin layer in microcellular injection-molded parts. J. Cell. Plast. 2016, 52, 419–439. [Google Scholar] [CrossRef]

- Kumar, V. Microcellular Plastics: Does Microcellular Structure Always Lead to an Improvement in Impact Properties? SPE ANTEC Tech. Paper 2002, 60, 1892. [Google Scholar]

- Lee, J.; Turng, L.S.; Dougherty, E.; Gorton, P. A novel method for improving the surface quality of microcellular injection molded parts. Polymer 2011, 52, 1436–1446. [Google Scholar] [CrossRef]

- Turing, L.S.; Khabas, H. Development of a Hybrid Solid-Microcellular Co-injection Molding Process. Int. Polym. Process. 2004, 19, 77–86. [Google Scholar] [CrossRef]

- Shuartono, E.; Chen, S.C.; Lee, K.H. Improvements on the tensile properties of microcellular injection molded parts using microcellular co-injection molding with the material combinations of PP and PP-GF. Int. J. Plast. Technol. 2017, 21, 351–369. [Google Scholar] [CrossRef]

- Lee, J.; Turing, L.S. Improving surface quality of microcellular injection molded parts through mold surface temperature manipulation with thin film insulation. Polym. Eng. Sci. 2010, 50, 1281–1289. [Google Scholar] [CrossRef]

- Chen, H.L.; Chien, R.D.; Chen, S.C. Using thermally insulated polymer film for mold temperature control to improve surface quality of microcellular injection molded parts. Int. Commun. Heat Mass Transfer. 2008, 35, 991–994. [Google Scholar] [CrossRef]

- Chen, S.C.; Lin, Y.W.; Chien, R.D.; Li, H.M. Variable Mold Temperature to Improve Surface Quality of Microcellular Injection Molded Parts Using Induction Heating Technology. Adv. Polym. Technol. 2008, 27, 224–232. [Google Scholar] [CrossRef]

- Cha, S.W.; Yoon, J.D. The Relationship of Mold Temperatures and Swirl Marks on the Surface of Microcellular Plastics. Polym. Plast. Technol. Eng. 2005, 44, 795–803. [Google Scholar] [CrossRef]

- Semerdjiev, S. Thermoplastische Strukturschaumstoffe. VEB Dtsch. Verlag Grundst. 1980, 19, 595–599. [Google Scholar]

- Guo, W.; He, B.; Mao, H.; Zhang, M.Y.; Hua, L.; Meng, Z.H. Mechanism of Bubble Formation in a Combined In-Mold Decoration and Microcellular Foaming Injection Molding Process. Fibers Polym. 2019, 20, 1526–1537. [Google Scholar] [CrossRef]

- Yoon, J.D.; Hong, S.K.; Kim, J.H.; Cha, S.W. A Mold Surface Treatment for Improving Surface Finish of Injection Molded Microcellular Parts. Cell. Polym. 2004, 23, 39–48. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Kirschling, H.; Steinbichler, G.; Egger, P. Polycarbonate Microfoams with a Smooth Surface and Higher Notched Impact Strength. Cell. Polym. 2004, 40, 489–496. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Kirschling, H.; Steinbichler, G.; Egger, P. Microcellular Moulding with Gas Counter Pressure Using Physical Blowing Agent. Cell. Metals Polym. 2004, 257–260. [Google Scholar]

- Chen, S.C.; Hsu, P.S.; Lin, Y.W. Establishment of Gas Counter Pressure Technology and Its Application to Improve the Surface Quality of Microcellular Injection Molded Parts. Int. Polym. Process. 2011, 26, 275–282. [Google Scholar] [CrossRef]

- Chen, S.C.; Chung, M.H.; Lin, Y.W.; Hsu, P.S.; Hwang, S.S.; Hsu, P.M. Rheological characterization of polystyrene melts dissolved with supercritical nitrogen fluid during microcellular injection moulding. E-Polymers 2010, 10, 128. [Google Scholar] [CrossRef]

- Chen, S.C.; Hsu, P.S.; Hwang, S.S. The effects of gas counter pressure and mold temperature variation on the surface quality and morphology of the microcellular polystyrene foams. Appl. Polym. Sci. 2013, 127, 4769–4776. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Chen, T.Y. Combining foam injection molding with batch foaming to improve cell density and control cellular orientation via multiple gas dissolution and desorption processes. Polym. Adv. Technol. 2020, 31, 2136–2151. [Google Scholar]

- Chang, Y.H.; Chiu, M.C.; Chen, S.C.; Chang, C.W.; Tseng, C.Y. Establishing a rapid cooling complex mold design for the quality improvement of microcellular injection molding. Polym. Eng. Sci. 2020, 60, 3072–3085. [Google Scholar] [CrossRef]

- Chen, S.C.; Chien, M.Y.; Lin, S.H.; Chien, R.D. Effect of gas counter pressure on the carbon fiber orientation and the associated electrical conductivities in injection molded polymer composites. Polym. Eng. 2015, 35, 503–510. [Google Scholar] [CrossRef]

- Shih, M.Y. Effect of Gas Counter Pressure on the Carbon Fiber Orientation and the Associated Electrical Conductivity in Injection Molded Polymer. Ph.D. Thesis, Chung Yuan Christian University, Taiwan, 2012. [Google Scholar]

- Hsieh, C.C. Study on Flow Behavior and Quality Improvement of the Metal Powder Injection Molding by Using Gas Counter Pressure Technology. Master's Thesis, Chung Yuan Christian University, Taiwan, 2014. [Google Scholar]

| Molding Conditions for Microcellular Injection Molding | |

| Plastic resin | GPPS |

| Injection rate (cm3/s) | 5 |

| Specimen thickness (mm) | 3 |

| Melt temperature (°C) | 210 |

| Back pressure (Pa) | 145 |

| SCF ratio (%) | 0.5 |

| SCF injection time (s) | 1.1 |

| SCF injection quantity (Kg/h) | 0.31 |

| SCF injection pressure (Pa) | 170 |

| Delay time of valve gate (s) | 5 |

| Mold Temperature Control | |

| Mold temperature (°C) | 120, 90 |

| Cooling medium temperature (°C) | 10 |

| Cooling speed | Fast, medium, slow |

| GCP Regulation Parameters | |

| GCP (bar) | 100 |

| Holding Time (s) | 0, 3, 5 |

| Relief Time (s) (Holding Time 3 s) | 1, 3, 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.-C.; Chang, C.-W.; Tseng, C.-Y.; Shen, E.-N.; Feng, C.-T. Using P(Pressure)-T(Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process. Polymers 2021, 13, 1843. https://doi.org/10.3390/polym13111843

Chen S-C, Chang C-W, Tseng C-Y, Shen E-N, Feng C-T. Using P(Pressure)-T(Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process. Polymers. 2021; 13(11):1843. https://doi.org/10.3390/polym13111843

Chicago/Turabian StyleChen, Shia-Chung, Che-Wei Chang, Chia-Yen Tseng, En-Nien Shen, and Ching-Te Feng. 2021. "Using P(Pressure)-T(Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process" Polymers 13, no. 11: 1843. https://doi.org/10.3390/polym13111843

APA StyleChen, S.-C., Chang, C.-W., Tseng, C.-Y., Shen, E.-N., & Feng, C.-T. (2021). Using P(Pressure)-T(Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process. Polymers, 13(11), 1843. https://doi.org/10.3390/polym13111843