A Hybrid Methodology to Minimize Freshwater Consumption during Shrimp Shell Waste Valorization Combining Multi-Contaminant Pinch Analysis and Superstructure Optimization

Abstract

:1. Introduction

1.1. Pinch Methodology

1.2. Mathematical Programming

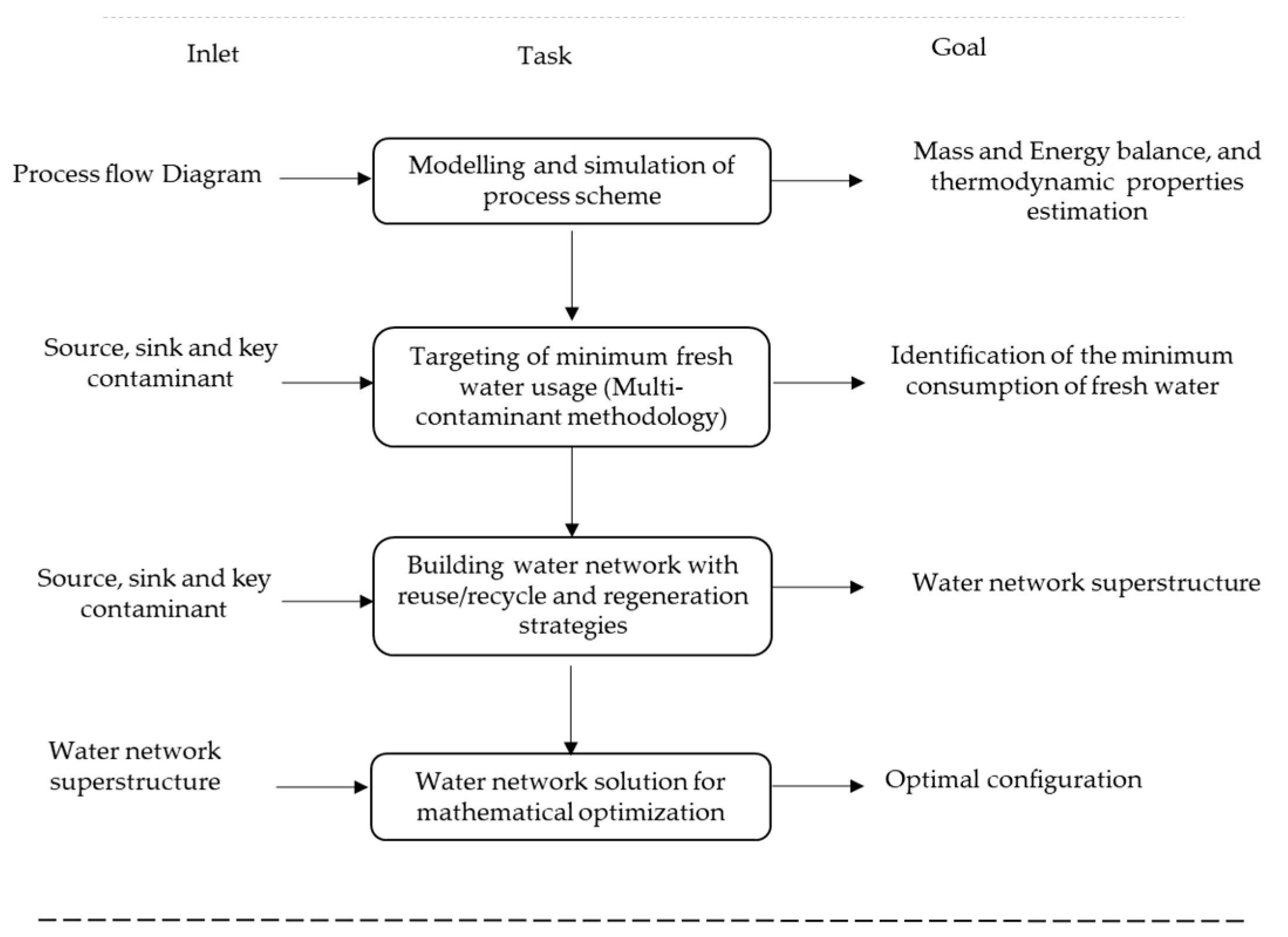

2. Materials and Methods

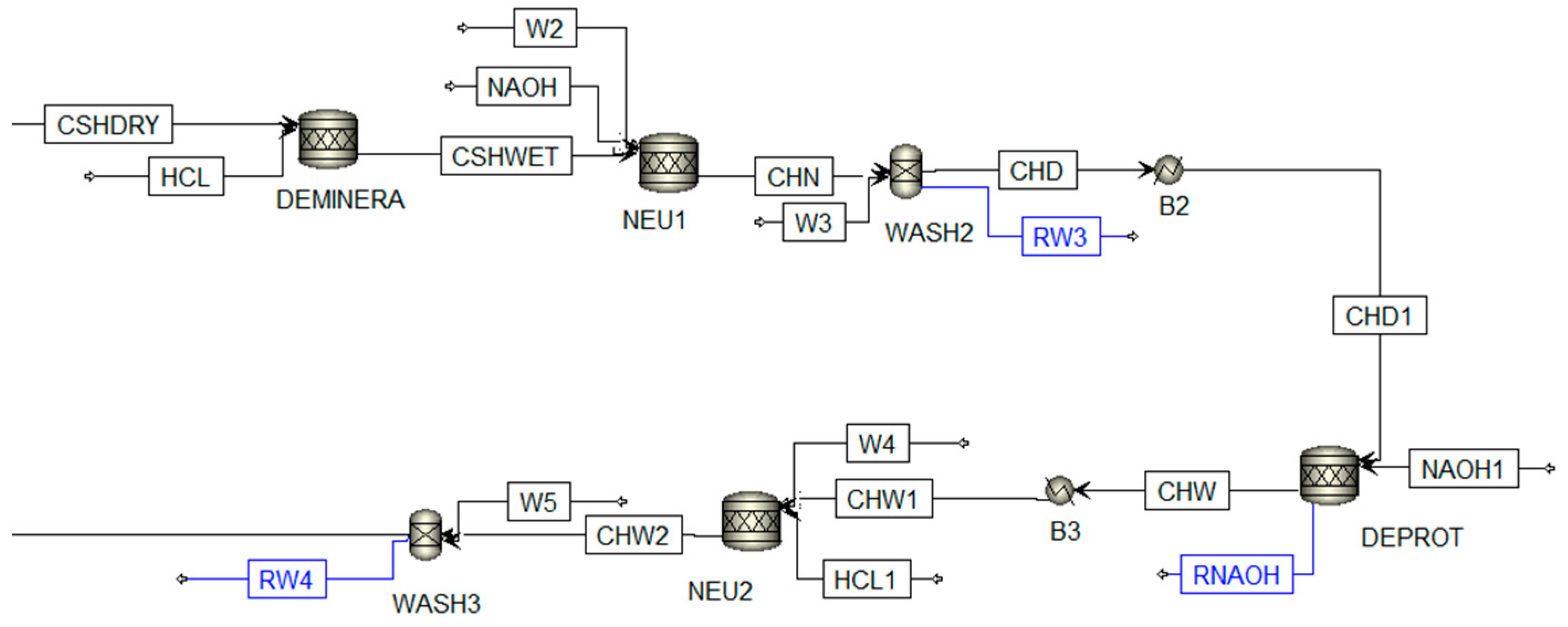

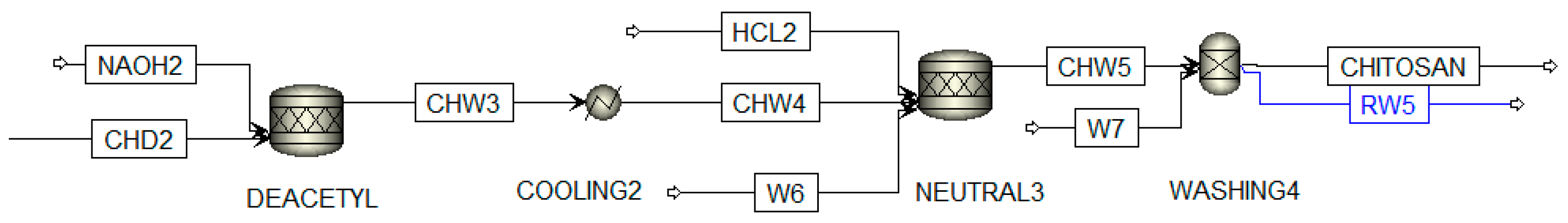

2.1. Modeling and Simulation of Process Scheme

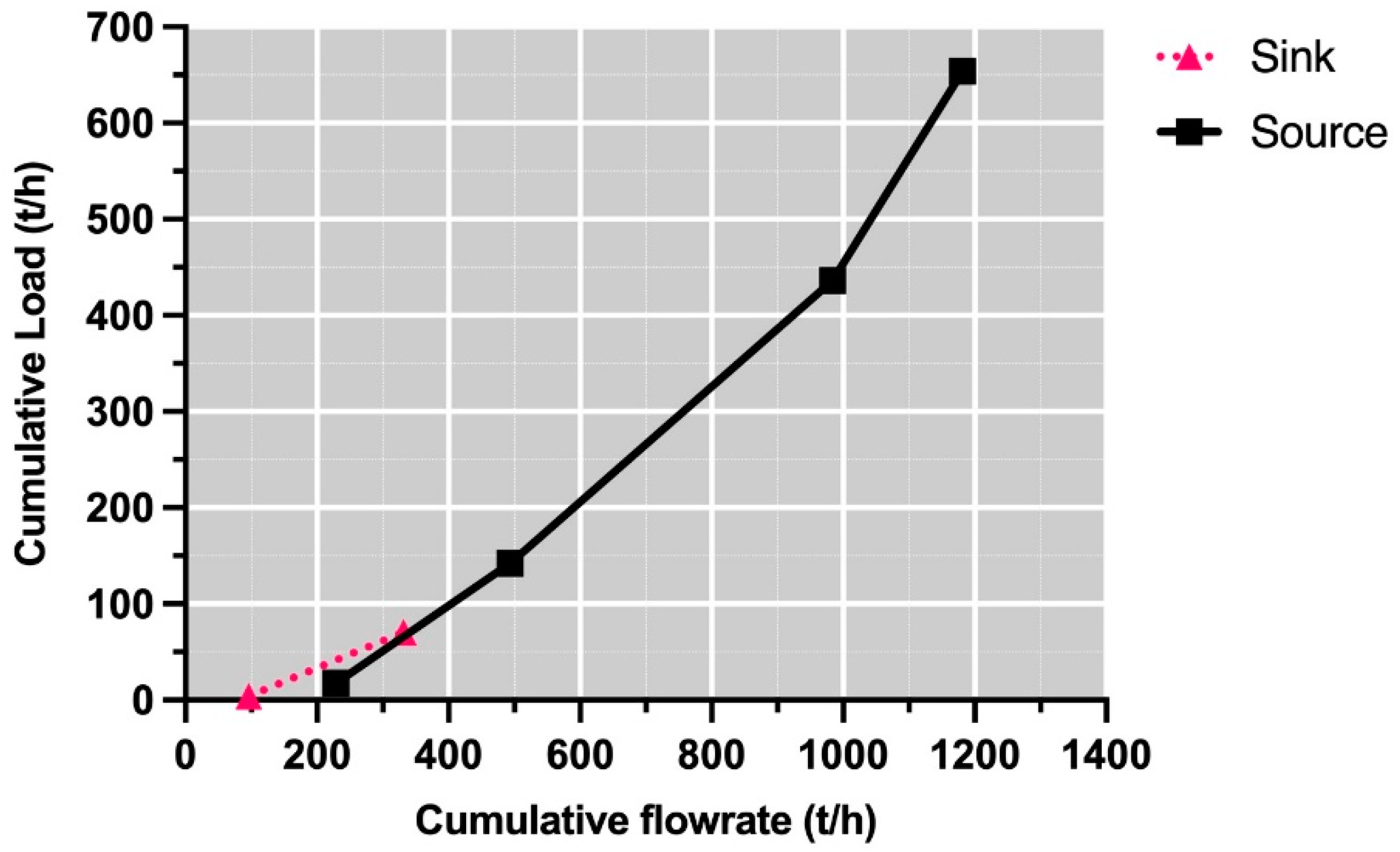

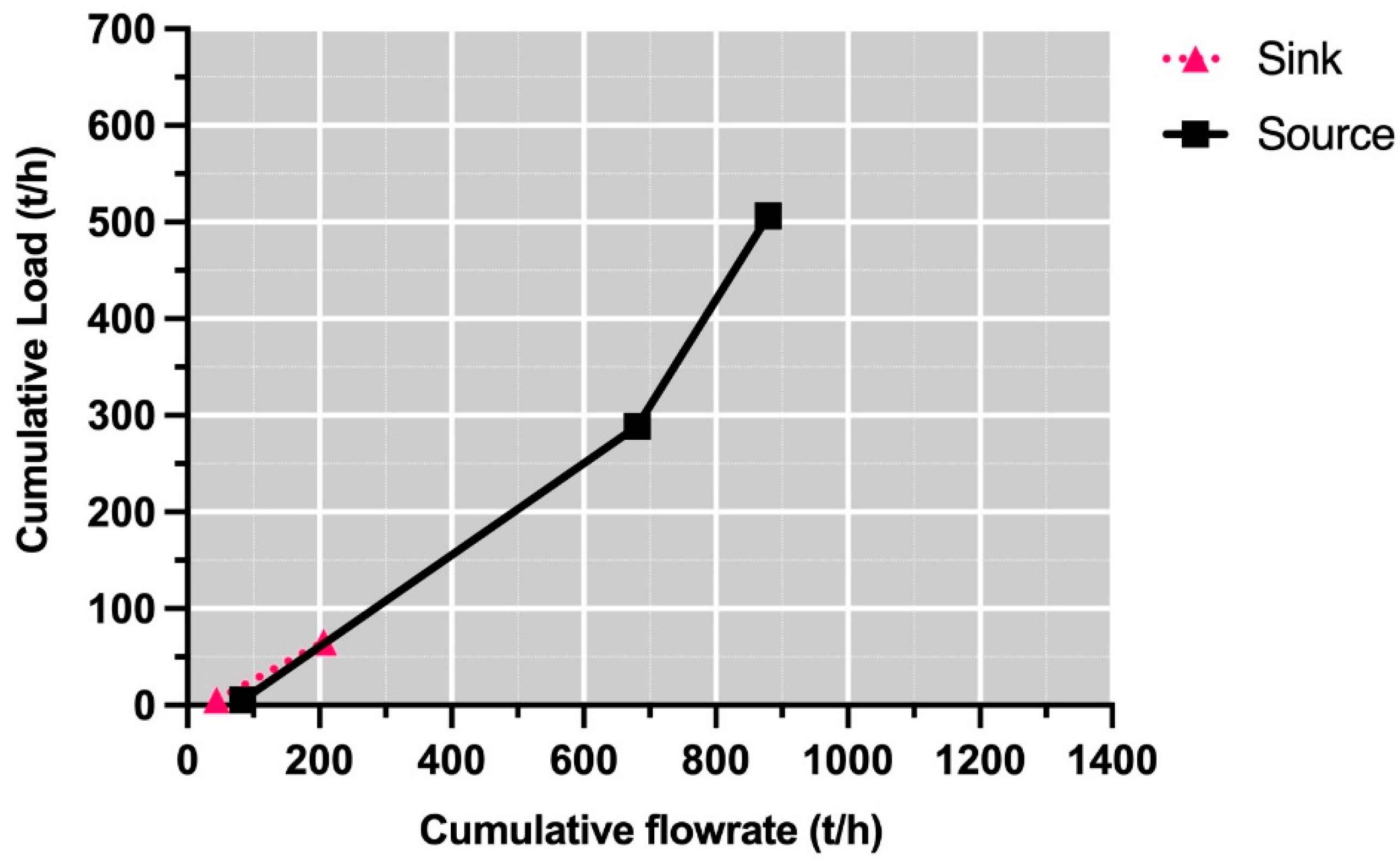

2.2. Targeting of Minimum Freshwater Usage

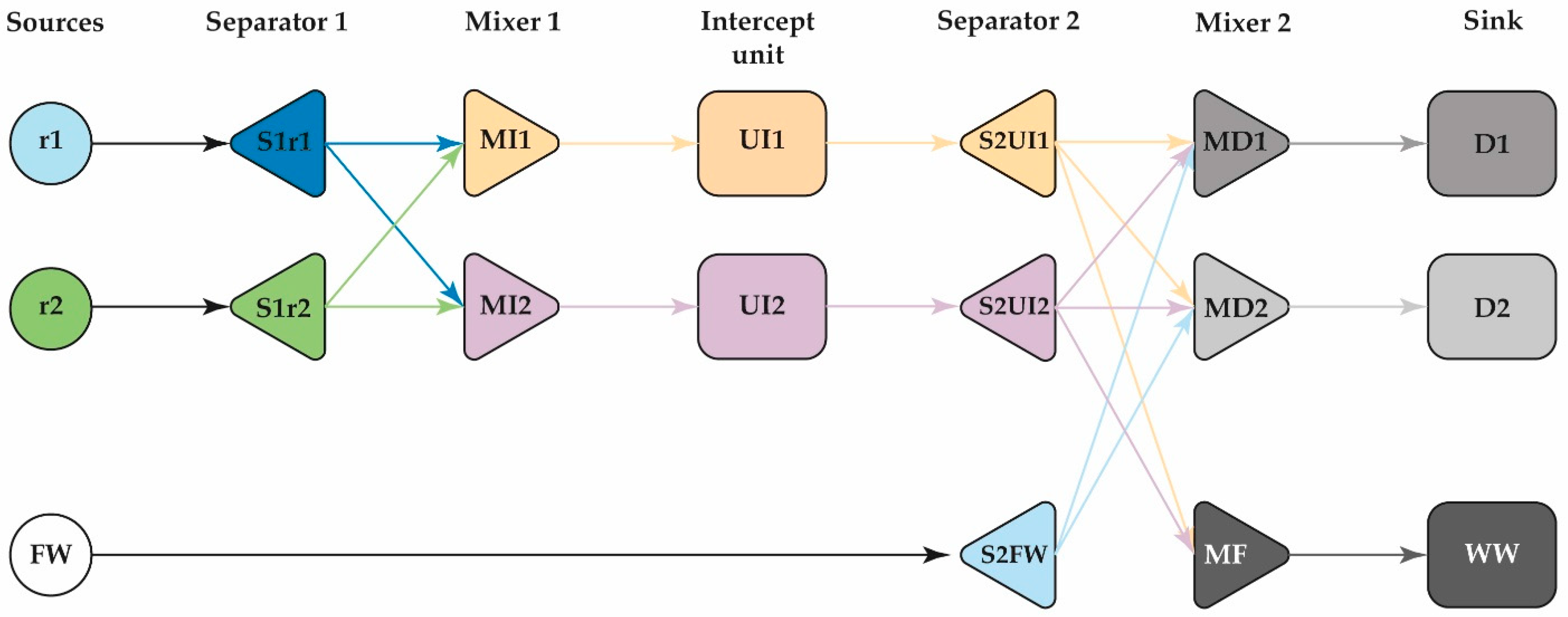

2.3. Building the Water Network with Reuse/Recycle and Regeneration Strategies

2.4. Water Network Solution for Mathematical Optimization

3. Results

3.1. Process Modeling and Simulation

3.2. Targeting of Minimal Freshwater Usage

3.3. Synthesis of the Water Network

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Sets and Indices | |

| k | Contaminant |

| r | Unit source |

| i | Unit intercept |

| IU | Set of intercept unit |

| SU | Set of source unit |

| Parameters | |

| AR | Annualized factor |

| α | Cost exponent for intercept unit |

| H | Hours of plant operation per year |

| CIU | Investment cost of treatment unit |

| Cost of freshwater | |

| mass flowrate of outlet stream from source unit r | |

| concentration of contaminant k in outlet stream from source unit r | |

| % removal of contaminant k in intercept unit t | |

| maximum concentration of contaminant k in inlet stream into demand unit d | |

| Continuous Variables | |

| mass flowrate of stream from unit source r to intercept unit I | |

| mass flowrate of inlet stream intercept unit I | |

| mass flowrate of outlet stream from intercept unit I | |

| mass flowrate of water stream from source unit r to treatment unit i | |

| concentration of contaminant k in inlet stream into intercept unit | |

| concentration of contaminant k in outlet stream from intercept unit I | |

| mass flowrate of stream from unit intercept i to demand unit d | |

| mass flowrate of water stream from intercept unit i to final mixer | |

| concentration of contaminant k in outlet stream from splitter treatment unit I | |

| mass flowrate of inlet water stream in deposit unit d | |

| mass flowrate of freshwater | |

| mass flowrate of water stream from source unit r to deposit unit d | |

| concentration of contaminant k in inlet stream into deposit unit d | |

| concentration of contaminant k in outlet stream from source unit r | |

| minimum concentration of contaminant k in inlet stream into demand unit d | |

References

- Beekma, J.; Bird, J.; Mersha, A.N.; Reinhard, S.; Prathapar, S.A.; Rasul, G.; Richey, J.; Van Campen, J.; Ragab, R.; Perry, C.; et al. Enabling policy environment for water, food and energy security. Irrig. Drain. 2021, 1–18. [Google Scholar] [CrossRef]

- Mathew, G.M.; Mathew, D.C.; Sukumaran, R.K.; Sindhu, R.; Huang, C.-C.; Binod, P.; Sirohi, R.; Kim, S.-H.; Pandey, A. Sustainable and eco-friendly strategies for shrimp shell valorization. Environ. Pollut. 2020, 267, 115656. [Google Scholar] [CrossRef]

- Moreno-Sader, K.A.; Consuegra-Martinez, J.D.; Gonzalez-Delgado, A.D. Development of a biorefinery approach for shrimp processing in North-Colombia: Process simulation and sustainability assessment. Environ. Techn Innov. 2021, 22, 101461. [Google Scholar] [CrossRef]

- Patinõ-Ruiz, D.A.; De Ávila, G.; Alarcón-Suesca, C.; González-Delgado, Á.D.; Herrera, A. Ionic cross-linking fabrication of chitosan-based beads modified with FeO and TiO2 nanoparticles: Adsorption mechanism toward naphthalene removal in seawater from cartagena bay area. ACS Omega 2020, 5, 26463–26475. [Google Scholar] [CrossRef]

- Cavallaro, G.; Micciulla, S.; Chiappisi, L.; Lazzara, G. Chitosan-based smart hybrid materials: A physico-chemical perspective. J. Mater. Chem. B 2021, 9, 594–611. [Google Scholar] [CrossRef]

- Díaz-Montes, E.; Castro-Muñoz, R. Trends in Chitosan as a Primary Biopolymer for Functional Films and Coatings Manufacture for Food and Natural Products. Polymers 2021, 13, 767. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Wei, X.; Zhou, Q.; Su, W. An iterative design method for regeneration reuse water network with internal water mains. Asia-Pac. J. Chem. Eng. 2020, 15, 122–483. [Google Scholar] [CrossRef]

- Moreno-Sader, K.A.; Martínez-Consuegra, J.; González-Delgado, Á.D. An integrated biorefinery approach via material recycle/reuse networks for the extraction of value-added components from shrimp: Computer-aided simulation and environmental. Food Bioprod. Process. 2021, 127, 443–453. [Google Scholar] [CrossRef]

- Ng, W.P.; Ong, B.H.; Pang, Y.S.; Wan, J.Y.; Yap, A.K.; Foo, D.C. A structural-based model for water network synthesis. J. Water Process Eng. 2021, 41, 102024. [Google Scholar] [CrossRef]

- Liu, C.-Z.; Li, A.-H.; Klemeš, J.J.; Liu, Z.-Y. Design of distributed wastewater treatment networks by combining total mixing influence potential indicator with heuristic rules. J. Clean. Prod. 2018, 193, 604–613. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, L.; Yuan, Z.; Gani, R. Synthesis and design of sustainable integrated process, water treatment, and power generation networks. Comput. Chem. Eng. 2020, 141, 107041. [Google Scholar] [CrossRef]

- Hansen, É.; Rodrigues, M.A.S.; Aragão, M.E.; de Aquim, P.M. Water and wastewater minimization in a petrochemical industry through mathematical programming. J. Clean. Prod. 2018, 172, 1814–1822. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Kravanja, Z. Forty years of Heat Integration: Pinch Analysis (PA) and Mathematical Programming (MP). Curr. Opin. Chem. Eng. 2013, 2, 461–474. [Google Scholar] [CrossRef]

- Foo, D.C.Y. State-of-the-Art Review of Pinch Analysis Techniques for Water Network Synthesis. Ind. Eng. Chem. Res. 2009, 48, 5125–5159. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Varbanov, P.S.; Walmsley, T.G.; Jia, X. New directions in the implementation of Pinch Methodology (PM). Renew. Sustain. Energy Rev. 2018, 98, 439–468. [Google Scholar] [CrossRef]

- Jia, X.; Varbanov, P.S.; Alwi, S.R.W.; Yang, D.; Klemeš, J.J. Cost-Based Quantitative-Qualitative Water Footprint Considering Multiple Contaminants. Resour. Conserv. Recycl. 2021, 168, 105339. [Google Scholar] [CrossRef]

- Hosnar, J.; Kralj, A.K. Reduction of water usage in industry by using the MINLP coordinates technique. J. Loss Prev. Process. Ind. 2016, 43, 158–164. [Google Scholar] [CrossRef]

- Silori, G.K.; Khanam, S. Performance analyses of LP and MILP solvers based on newly introduced scale: Case studies of water network problems in chemical processes. Chem. Eng. Res. Des. 2018, 136, 417–430. [Google Scholar] [CrossRef]

- Kermani, M.; Périn-Levasseur, Z.; Benali, M.; Savulescu, L.; Maréchal, F. A novel MILP approach for simultaneous optimization of water and energy: Application to a Canadian softwood Kraft pulping mill. Comput. Chem. Eng. 2017, 102, 238–257. [Google Scholar] [CrossRef]

- Al, S.E. Multi-objective optimization of water distribution networks: An overview. Int. J. Adv. Appl. Sci. 2020, 7, 74–86. [Google Scholar] [CrossRef]

- Foo, D.C.; Sahu, G.C.; Kamat, S.; Bandyopadhyay, S. Synthesis of Heat-integrated Water Network with Interception Unit. Comput. Aided Chem. Eng. 2018, 44, 457–462. [Google Scholar] [CrossRef]

- Kazi, M.-K.; Eljack, F.; Elsayed, N.A.; El-Halwagi, M.M. Integration of Energy and Wastewater Treatment Alternatives with Process Facilities to Manage Industrial Flares during Normal and Abnormal Operations: Multiobjective Extendible Optimization Framework. Ind. Eng. Chem. Res. 2016, 55, 2020–2034. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Tsai, C.-H.; Foo, D.C.Y. Single and multi-objective optimisation for the retrofit of process water networks. J. Taiwan Inst. Chem. Eng. 2020, 117, 39–47. [Google Scholar] [CrossRef]

- Chin, H.H.; Varbanov, P.S.; Liew, P.Y.; Klemeš, J.J. Pinch-based targeting methodology for multi-contaminant material recycle/reuse. Chem. Eng. Sci. 2021, 230, 116129. [Google Scholar] [CrossRef]

- Cai, Z.; Wang, J.; Chen, Y.; Xia, L.; Xiang, S. The Development of Chemical Process Simulation Software According to CAPE-OPEN. Chem. Eng. Trans. 2017, 61, 1819–1824. [Google Scholar] [CrossRef]

- Ahmetović, E.; Grossmann, I.E. Global superstructure optimization for the design of integrated process water networks. AIChE J. 2011, 57, 434–457. [Google Scholar] [CrossRef]

- Ahmetović, E.; Martín, M.; Grossmann, I.E. Optimization of Energy and Water Consumption in Corn-Based Ethanol Plants. Ind. Eng. Chem. Res. 2010, 49, 7972–7982. [Google Scholar] [CrossRef]

- Gómez-Ríos, D.; Barrera-Zapata, R.; Ríos-Estepa, R. Comparison of process technologies for chitosan production from shrimp shell waste: A techno-economic approach using Aspen Plus®. Food Bioprod. Process. 2017, 103, 49–57. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.; Alarcón-Suesca, C.; González-Delgado, Á.D. Exergetic sensibility analysis and environmental evaluation of chitosan production from shrimp exoskeleton in Colombia. J. Clean. Prod. 2020, 248, 119285. [Google Scholar] [CrossRef]

- Mabitla, S.S.; Majozi, T. A hybrid method for synthesis of integrated water and regeneration networks with variable removal ratios. J. Environ. Manag. 2019, 231, 666–678. [Google Scholar] [CrossRef] [PubMed]

- Balla, W.H.; Rabah, A.A.; Abdallah, B.K. Pinch Analysis of Sugarcane Refinery Water Integration. Sugar Tech 2018, 20, 122–134. [Google Scholar] [CrossRef]

| Source | Flow Rate kg/h | ||

| r1 | 58,621 | 300 | 10 |

| r2 | 265,115 | 470 | 200 |

| r3 | 489,905 | 600 | 270 |

| r4 | 197,886 | 1100 | 350 |

| Sink | Flowrate kg/h | ||

| d1 | 235,107 | 50 | 20 |

| d2 | 64,029 | 20 | 10 |

| d3 | 96,132 | 40 | 15 |

| d4 | 142,072 | 25 | 10 |

| Minimum Ratio | Cascade | |||

|---|---|---|---|---|

| d1 | 0.045 | 0.057 | 0.045 | Organic |

| d2 | 0.018 | 0.017 | 0.017 | NaCl |

| d3 | 0.037 | 0.043 | 0.037 | Organic |

| d4 | 0.022 | 0.017 | 0.017 | NaCl |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quintero, V.; Gonzalez-Quiroga, A.; Gonzalez-Delgado, A.D. A Hybrid Methodology to Minimize Freshwater Consumption during Shrimp Shell Waste Valorization Combining Multi-Contaminant Pinch Analysis and Superstructure Optimization. Polymers 2021, 13, 1887. https://doi.org/10.3390/polym13111887

Quintero V, Gonzalez-Quiroga A, Gonzalez-Delgado AD. A Hybrid Methodology to Minimize Freshwater Consumption during Shrimp Shell Waste Valorization Combining Multi-Contaminant Pinch Analysis and Superstructure Optimization. Polymers. 2021; 13(11):1887. https://doi.org/10.3390/polym13111887

Chicago/Turabian StyleQuintero, Viviana, Arturo Gonzalez-Quiroga, and Angel Darío Gonzalez-Delgado. 2021. "A Hybrid Methodology to Minimize Freshwater Consumption during Shrimp Shell Waste Valorization Combining Multi-Contaminant Pinch Analysis and Superstructure Optimization" Polymers 13, no. 11: 1887. https://doi.org/10.3390/polym13111887