Isolation and Characterization of Alpha and Nanocrystalline Cellulose from Date Palm (Phoenix dactylifera L.) Trunk Mesh

Abstract

:1. Introduction

2. Materials and Methods

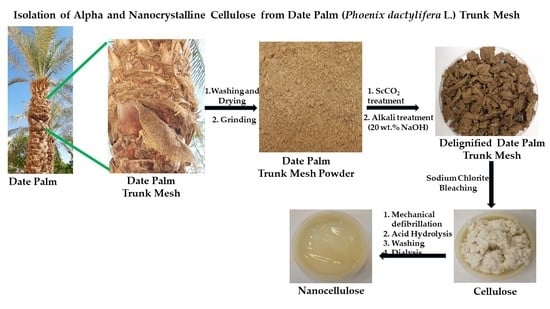

2.1. Isolation of Cellulose

2.2. Extraction of Nanocellulose (NC)

2.3. Assessment of Chemical Composition

2.4. Functional Group Analysis

2.5. Thermal Analysis

2.6. Study of Crystallinity

2.7. Morphological Analysis

3. Results and Discussion

3.1. Compositional Analysis

3.2. Functional Group Analysis by ATR-FTIR

3.3. Thermal Analysis

3.4. Wide-Angle X-ray Diffraction (WAXRD) Analysis

3.5. Morphological Analysis

3.6. Characterization of Nanocellulose

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klemm, D.; Philipp, B.; Heinze, T.; Heinze, U.; Wagenknecht, W. (Eds.) Front Matter. In Comprehensive Cellulose Chemistry; WILEY-VCH Verlag GmbH: Weinheim, Germany, 1998; pp. i–xxii. [Google Scholar] [CrossRef]

- FAOSTAT. Food and Agriculture Organization of the United Nations, Statistics Division. Forestry Production and Trade, Dataset, Date Production In Saudi Arabia. Available online: http://www.fao.org/faostat/en/ (accessed on 28 May 2021).

- Ministry of Environment, Water and Agriculture (MEWA). Annual Statistical Book; Ministry of Environment, Water and Agriculture (MEWA): Riyadh, Saudi Arabia, 2019. [Google Scholar]

- Hussain, A.; Farooq, A.; Bassyouni, M.I.; Sait, H.H.; El-Wafa, M.A.; Hasan, S.W.U.; Ani, F.N. Pyrolysis Of Saudi Arabian Date Palm Waste: A Viable Option For Converting Waste Into Wealth. Life Sci. J. 2014, 11, 667–671. [Google Scholar]

- El-Juhany, L.I. Surveying of Lignocellulosic Agricultural Residues in Some Major Cities of Saudi Arabia; Research Bulletin No. 1-Agricultural Research Center, College of Agriculture, King Saud University: Riyadh, Saudi Arabia, 2001. [Google Scholar]

- Nasser, R.A.; Salem, M.Z.M.; Hiziroglu, S.; Al-Mefarrej, H.A.; Mohareb, A.S.; Alam, M.; Aref, I.M. Chemical Analysis of Different Parts of Date Palm (Phoenix dactylifera L.) Using Ultimate, Proximate and Thermo-Gravimetric Techniques for Energy Production. Energies 2016, 9, 374. [Google Scholar] [CrossRef] [Green Version]

- Hakeem, K.R.; Jawaid, M.; Rashid, U. Biomass and Bioenergy; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Chandrasekaran, M.; Bahkali, A.H. Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology—Review. Saudi J. Biol. Sci. 2013, 20, 105–120. [Google Scholar] [CrossRef] [Green Version]

- Abu-Thabit, N.Y.; Judeh, A.A.; Hakeem, A.S.; Ul-Hamid, A.; Umar, Y.; Ahmad, A. Isolation and characterization of microcrystalline cellulose from date seeds (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2020, 155, 730–739. [Google Scholar] [CrossRef]

- Alotabi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Kian, L.K.; Khan, A.; Jawaid, M. Microcrystalline Cellulose from Fruit Bunch Stalk of Date Palm: Isolation and Characterization. J. Polym. Environ. 2020, 28, 1766–1775. [Google Scholar] [CrossRef]

- Galiwango, E.; Abdel Rahman, N.S.; Al-Marzouqi, A.H.; Abu-Omar, M.M.; Khaleel, A.A. Isolation and characterization of cellulose and α-cellulose from date palm biomass waste. Heliyon 2019, 5, e02937. [Google Scholar] [CrossRef] [Green Version]

- Bendahou, A.; Kaddami, H.; Dufresne, A. Investigation on the effect of cellulosic ”nanoparticles’ morphology on the properties of natural rubber based nanocomposites. Eur. Polym. J. 2010, 46, 609–620. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Tanvir, A.; Popelka, A.; Moffat, J.; Mahmoud, K.A.; Krupa, I. The preparation, properties and applications of electrospun co-polyamide 6,12 membranes modified by cellulose nanocrystals. Mater. Des. 2017, 132, 314–323. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Kian, L.K.; Saba, N.; Jawaid, M.; Khiari, R. Cellulose nanocrystal extracted from date palm fibre: Morphological, structural and thermal properties. Ind. Crop. Prod. 2021, 159, 113075. [Google Scholar] [CrossRef]

- Boufi, S.; Kaddami, H.; Dufresne, A. Mechanical performance and transparency of nanocellulose reinforced polymer nanocomposites. Macromol. Mater. Eng. 2014, 299, 560–568. [Google Scholar] [CrossRef]

- Benhamou, K.; Dufresne, A.; Magnin, A.; Mortha, G.; Kaddami, H. Control of size and viscoelastic properties of nanofibrillated cellulose from palm tree by varying the TEMPO-mediated oxidation time. Carbohydr. Polym. 2014, 99, 74–83. [Google Scholar] [CrossRef] [PubMed]

- El-Mously, H. The palm fibers for the reinforcement of polymer composites: Prospects and challenge. In Proceedings of the First Ain Shams Conference on Environmental Engineering, Aim Shams University, Cairo, Egypt, 14 April 2009. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Global Nanocellulose Market by Type (Nanocrystalline Cellulose, N.C., Others), Application, Region, Global Industry Analysis, Market Size, Share, Growth, Trends, and Forecast 2018 to 2025. Available online: https://www.fiormarkets.com/report/global-nanocellulose-market-by-type-nanocrystalline-cellulose-nanofibrillated-367085.html (accessed on 30 May 2021).

- Foroughi, F.; Rezvani Ghomi, E.; Morshedi Dehaghi, F.; Borayek, R.; Ramakrishna, S. A Review on the Life Cycle Assessment of Cellulose: From Properties to the Potential of Making It a Low Carbon Material. Materials 2021, 14, 714. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D. (Eds.) Engineering Biopolymers: Homopolymers, Blends, and Composites; Carl Hanser Verlag GmbH Co. KG: Munich, Germany, 2015. [Google Scholar]

- TAPPI, T203 om-99. Alpha-, Beta- and Gamma-Cellulose in Pulp; Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 1999. [Google Scholar]

- Rol, F.; Vergnes, B.; El Kissi, N.; Bras, J. Nanocellulose Production by Twin-Screw Extrusion: Simulation of the Screw Profile To Increase the Productivity. ACS Sustain. Chem. Eng. 2020, 8, 50–59. [Google Scholar] [CrossRef]

- Peng, B.L.; Dhar, N.; Liu, H.L.; Tam, K.C. Chemistry and applications of nanocrystalline cellulose and its derivatives: A nanotechnology perspective. Can. J. Chem. Eng. 2011, 89, 1191–1206. [Google Scholar] [CrossRef]

- Chaker, A.; Mutjé, P.; Vilar, M.R.; Boufi, S. Agriculture crop residues as a source for the production of nanofibrillated cellulose with low energy demand. Cellulose 2014, 21, 4247–4259. [Google Scholar] [CrossRef]

- Zheng, D.; Zhang, Y.; Guo, Y.; Yue, J. Isolation and Characterization of Nanocellulose with a Novel Shape from Walnut (Juglans Regia L.) Shell Agricultural Waste. Polymers 2019, 11, 1130. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evstigneyev, E.I.; Shevchenko, S.M. Structure, chemical reactivity and solubility of lignin: A fresh look. Wood Sci. Technol. 2019, 53, 7–47. [Google Scholar] [CrossRef]

- Darmawan, S.; Wistara, N.J.; Pari, G.; Maddu, A.; Syafii, W. Characterization of Lignocellulosic Biomass as Raw Material for the Production of Porous Carbon-Based Materials. Bioresources 2016, 1, 3561–3574. [Google Scholar] [CrossRef]

- Sánchez, R.; Espinosa, E.; Domínguez-Robles, J.; Loaiza, J.M.; Rodríguez, A. Isolation and characterization of lignocellulose nanofibers from different wheat straw pulps. Int. J. Biol. Macromol. 2016, 92, 1025–1033. [Google Scholar] [CrossRef]

- Trilokesh, C.; Uppuluri, K.B. Isolation and characterization of cellulose nanocrystals from jackfruit peel. Sci. Rep. 2019, 9, 16709. [Google Scholar] [CrossRef]

- Xiang, Z.; Gao, W.; Chen, L.; Lan, W.; Zhu, J.Y.; Runge, T. A comparison of cellulose nanofibrils produced from Cladophora glomerata algae and bleached eucalyptus pulp. Cellulose 2016, 23, 493–503. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Bruni, G.P.; Lima, K.O.; Halal, S.; Rosa, G.S.D.; Dias, A.R.G.; Zavareze, E.D.R. Cellulose fibers extracted from rice and oat husks and their application in hydrogel. Food Chem. 2017, 221, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Calahorra, M.E.; Cortázar, M.; Eguiazábal, J.I.; Guzmán, G.M. Thermogravimetric analysis of cellulose: Effect of the molecular weight on thermal decomposition. J. Appl. Polym. Sci. 1989, 37, 3305–3314. [Google Scholar] [CrossRef]

- El-Saied, H.; El-Diwany, A.I.; Basta, A.H.; Atwa, N.A.; El-Ghwas, D.E. Production and Characterization of Economical Bacterial Cellulose. BioResources 2008, 3, 22. [Google Scholar]

- Santmartí, A.; Lee, K.-Y. Crystallinity and thermal stability of nanocellulose. In Nanocellulose and Sustainability, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Mamleev, V.; Bourbigot, S.; Yvon, J. Kinetic analysis of the thermal decomposition of cellulose: The main step of mass loss. J. Anal. Appl. Pyrolysis 2007, 80, 151–165. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S. The mechanism for thermal decomposition of cellulose and its main products. Bioresour. Technol. 2009, 100, 6496–6504. [Google Scholar] [CrossRef]

- Peng, Y.; Gardner, D.J.; Han, Y.; Kiziltas, A.; Cai, Z.; Tshabalala, M.A. Influence of drying method on the material properties of nanocellulose I: Thermostability and crystallinity. Cellulose 2013, 20, 2379–2392. [Google Scholar] [CrossRef]

- Makkawi, Y.; El Sayed, Y.; Salih, M.; Nancarrow, P.; Banks, S.; Bridgwater, T. Fast pyrolysis of date palm (Phoenix dactylifera) waste in a bubbling fluidized bed reactor. Renew. Energy 2019, 143, 719–730. [Google Scholar] [CrossRef]

- Taflick, T.; Schwendler, L.A.; Rosa, S.M.L.; Bica, C.I.D.; Nachtigall, S.M.B. Cellulose nanocrystals from acacia bark–Influence of solvent extraction. Int. J. Biol. Macromol. 2017, 101, 553–561. [Google Scholar] [CrossRef]

- Ye, D.; Yang, J. Ion-responsive liquid crystals of cellulose nanowhiskers grafted with acrylamide. Carbohydr. Polym. 2015, 134, 458–466. [Google Scholar] [CrossRef]

- Mandal, A.; Chakrabarty, D. Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr. Polym. 2011, 86, 1291–1299. [Google Scholar] [CrossRef]

- Da Silva, C.G.; Kano, F.S.; Rosa, D.S. Lignocellulosic Nanofiber from Eucalyptus Waste by a Green Process and Their Influence in Bionanocomposites. Waste Biomass Valoriz. 2020, 11, 3761–3774. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Wang, L.-F.; Shankar, S.; Rhim, J.-W. Properties of alginate-based films reinforced with cellulose fibers and cellulose nanowhiskers isolated from mulberry pulp. Food Hydrocoll. 2017, 63, 201–208. [Google Scholar] [CrossRef]

- Borchani, K.E.; Carrot, C.; Jaziri, M. Untreated and alkali treated fibers from Alfa stem: Effect of alkali treatment on structural, morphological and thermal features. Cellulose 2017, 22, 1577–1589. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Suardana, N.P.G.; Jung, D.Y.; Choi, K.-S.; Lim, J.K. Effect of diameters and alkali treatment on the tensile properties of date palm fiber reinforced epoxy composites. Int. J. Precis. Eng. Manuf. 2012, 13, 1199–1206. [Google Scholar] [CrossRef]

- Krishnan, J.; Sunil Kumar, S.; Krishna Prasad, R. Characterization of kraft pulp delignification using sodium dithionite as bleaching agent. Chem. Eng. Commun. 2020, 207, 837–846. [Google Scholar] [CrossRef]

- Jordan, J.H.; Easson, M.W.; Dien, B.; Thompson, S.; Condon, B.D. Extraction and characterization of nanocellulose crystals from cotton gin motes and cotton gin waste. Cellulose 2019, 26, 5959–5979. [Google Scholar] [CrossRef]

- Hussin, F.N.N.M.; Attan, N.; Wahab, R.A. Extraction and Characterization of Nanocellulose from Raw Oil Palm Leaves (Elaeis guineensis). Arab. J. Sci. Eng. 2020, 45, 175–186. [Google Scholar] [CrossRef]

- Han, Y.; Bai, Y.; Zhang, J.; Liu, D.; Zhao, X. A comparison of different oxidative pretreatments on polysaccharide hydrolyzability and cell wall structure for interpreting the greatly improved enzymatic digestibility of sugarcane bagasse by delignification. Bioresour. Bioprocess. 2020, 7, 24. [Google Scholar] [CrossRef]

- Mohamed Sutan, N.; Mazlan, S.M.; Taib, S.N.L.; Lee, D.T.C.; Hassan, A.; Sahari, S.K.; Mohamad Said, K.A.; Sobuz, H.R. Biomass Morphology Subjected to Different Chemical Treatment. E3S Web Conf. 2018, 34, 02051. [Google Scholar] [CrossRef]

- Shahrousvand, E.; Shahrousvand, M.; Ghollasi, M.; Seyedjafari, E.; Jouibari, I.S.; Babaei, A.; Salimi, A. Preparation and evaluation of polyurethane/cellulose nanowhisker bimodal foam nanocomposites for osteogenic differentiation of hMSCs. Carbohydr. Polym. 2017, 171, 281–291. [Google Scholar] [CrossRef] [PubMed]

| Samples | α-Cellulose % | Kappa No. | Lignin % | Moisture % | Ash% | Yield % | Crystallinity % |

|---|---|---|---|---|---|---|---|

| DPTM | 33.70 (±3.17) | 82.06 (±3.93) | 22.53 (±2.91) | 6.40 (±1.01) | 4.26 (±1.20) | - | 51.33 (±2.06) |

| Delignified DPTM | 65.91 (±2.50) | 54.36 (±1.96) | 2.16 (±0.30) | 5.16 (±0.65) | 2.33 (±0.51) | 71.76 (±2.32) | 57.66 (±2.15) |

| Cellulose | 94.50 (±1.70) | 0.39 (±0.06) | 0.32 (±0.08) | 4.45 (±0.50) | 0.23 (±0.07) | 66.53 (±3.27) | 68.60 (±1.68) |

| Nanocellulose (NC) | 92.26 (±1.35) | 0.25 (±0.03) | 0.13 (±0.05) | 4.20 (±0.30) | - | 35.26 (±4.28) | 89.61 (±1.13) |

| Sample | Tonset (°C) | T10 (°C) | T max (°C) | Residue (W%) |

|---|---|---|---|---|

| DPTM | 221.16 | 241.80 | 321.56 (Cellulose) 461.10 (Lignin) | 17.65 |

| Delignified DPTM | 240.98 | 275.66 | 358.72 | 6.02 |

| Cellulose | 280.50 | 321.09 | 368.50 | 0.62 |

| NC | 292.58 | 302.28 | 319.00 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaikh, H.M.; Anis, A.; Poulose, A.M.; Al-Zahrani, S.M.; Madhar, N.A.; Alhamidi, A.; Alam, M.A. Isolation and Characterization of Alpha and Nanocrystalline Cellulose from Date Palm (Phoenix dactylifera L.) Trunk Mesh. Polymers 2021, 13, 1893. https://doi.org/10.3390/polym13111893

Shaikh HM, Anis A, Poulose AM, Al-Zahrani SM, Madhar NA, Alhamidi A, Alam MA. Isolation and Characterization of Alpha and Nanocrystalline Cellulose from Date Palm (Phoenix dactylifera L.) Trunk Mesh. Polymers. 2021; 13(11):1893. https://doi.org/10.3390/polym13111893

Chicago/Turabian StyleShaikh, Hamid M., Arfat Anis, Anesh Manjaly Poulose, Saeed M. Al-Zahrani, Niyaz Ahamad Madhar, Abdullah Alhamidi, and Mohammad Asif Alam. 2021. "Isolation and Characterization of Alpha and Nanocrystalline Cellulose from Date Palm (Phoenix dactylifera L.) Trunk Mesh" Polymers 13, no. 11: 1893. https://doi.org/10.3390/polym13111893

APA StyleShaikh, H. M., Anis, A., Poulose, A. M., Al-Zahrani, S. M., Madhar, N. A., Alhamidi, A., & Alam, M. A. (2021). Isolation and Characterization of Alpha and Nanocrystalline Cellulose from Date Palm (Phoenix dactylifera L.) Trunk Mesh. Polymers, 13(11), 1893. https://doi.org/10.3390/polym13111893