Digital Sublimation Printing on Knitted Polyamide 6.6 Fabric Treated with Non-Thermal Plasma

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Knitted Fabric

2.1.2. Sublimation Transfer Printing

2.2. Methods

2.2.1. Preparation of Samples and Plasma Treatment

2.2.2. Sublimation

2.2.3. Contact Angle

2.2.4. Wash Fastness

2.2.5. Colour Measurement and Colour Strength

2.2.6. FTIR (Fourier Transform Infrared Spectroscopy)

2.2.7. Scanning Electron Microscopy (SEM)

3. Results

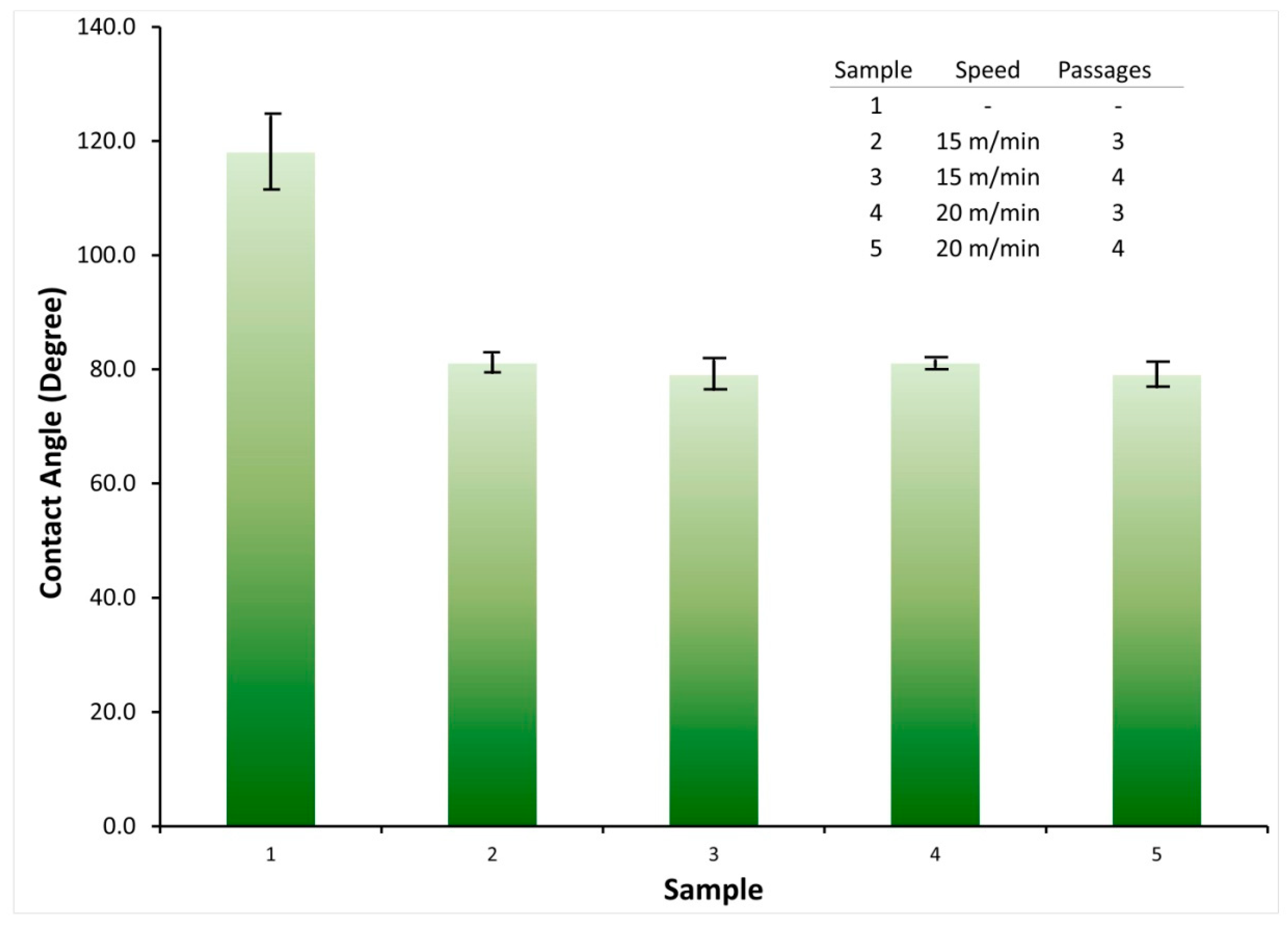

3.1. Contact Angle—θ

3.2. Test for Colourfastness

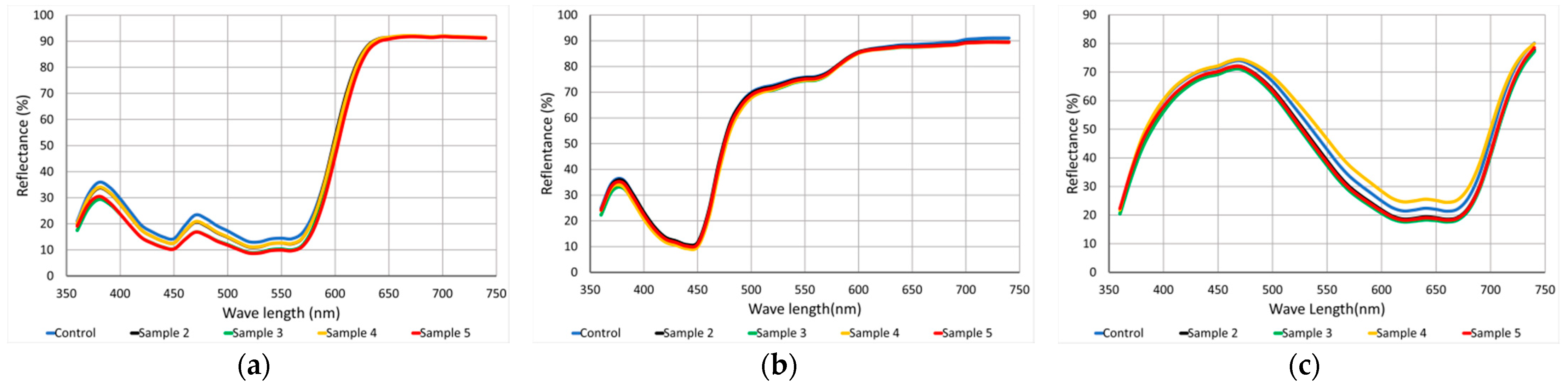

3.3. Colourimetry and Colouristic Strength

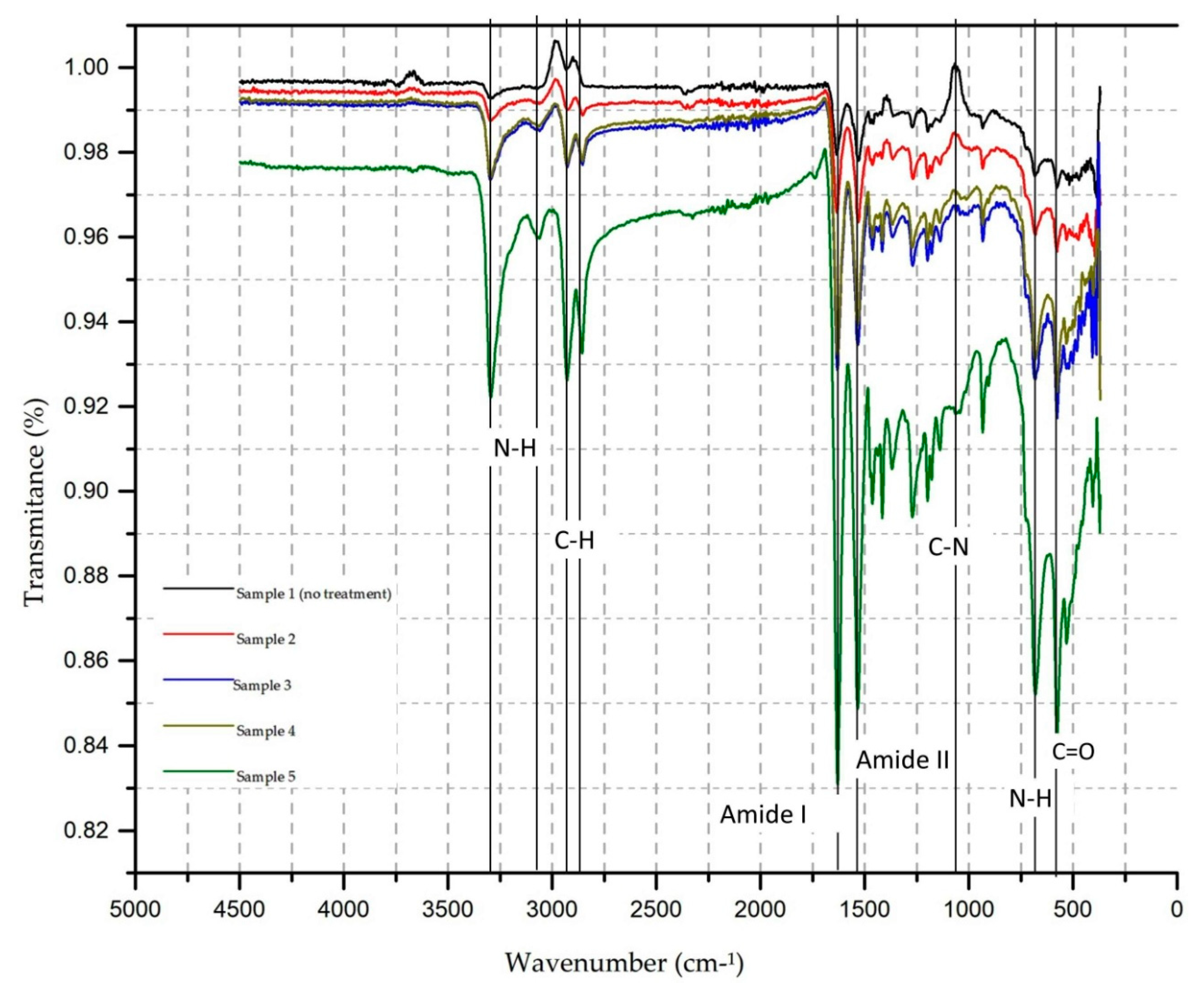

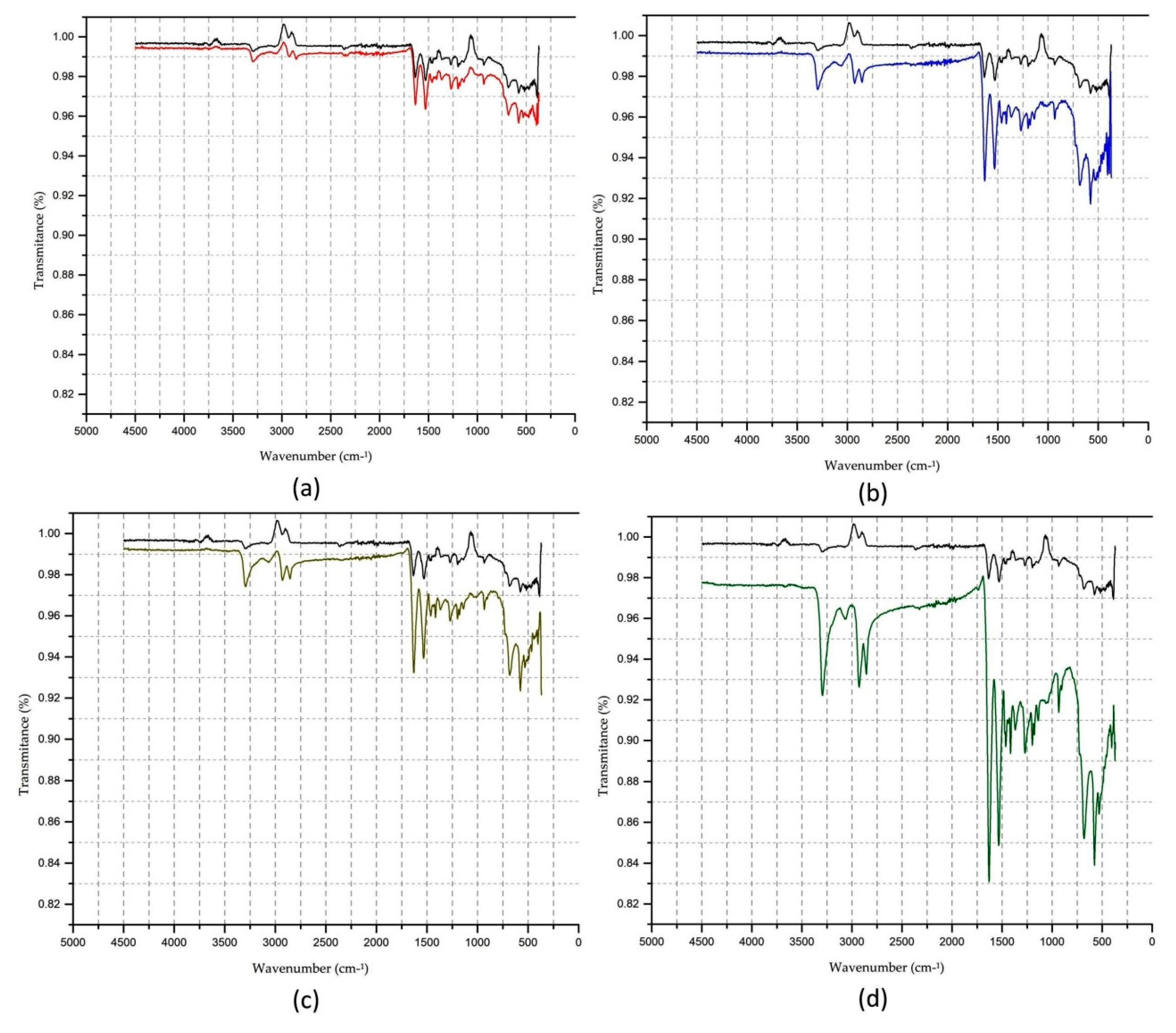

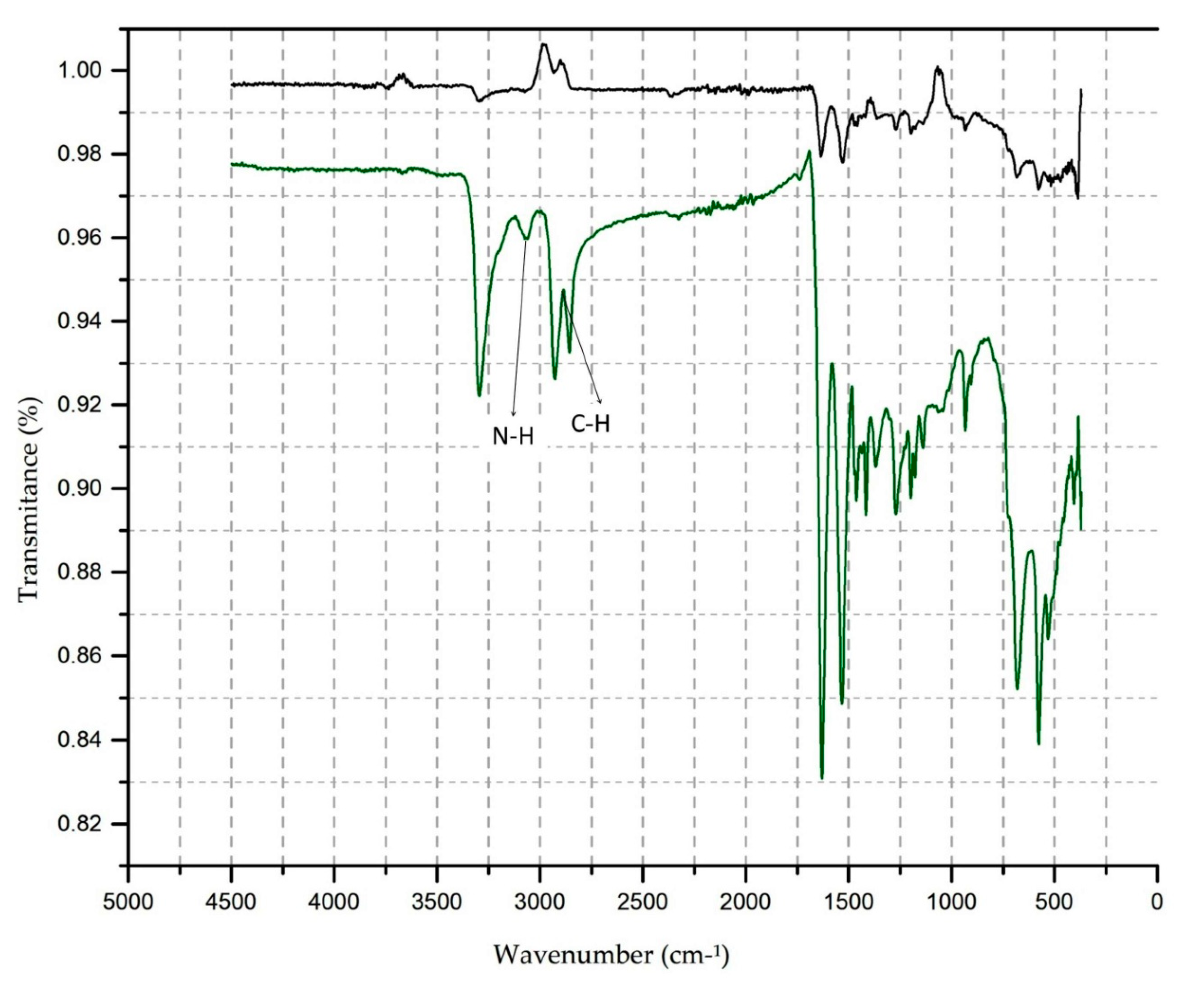

3.4. FTIR Analysis

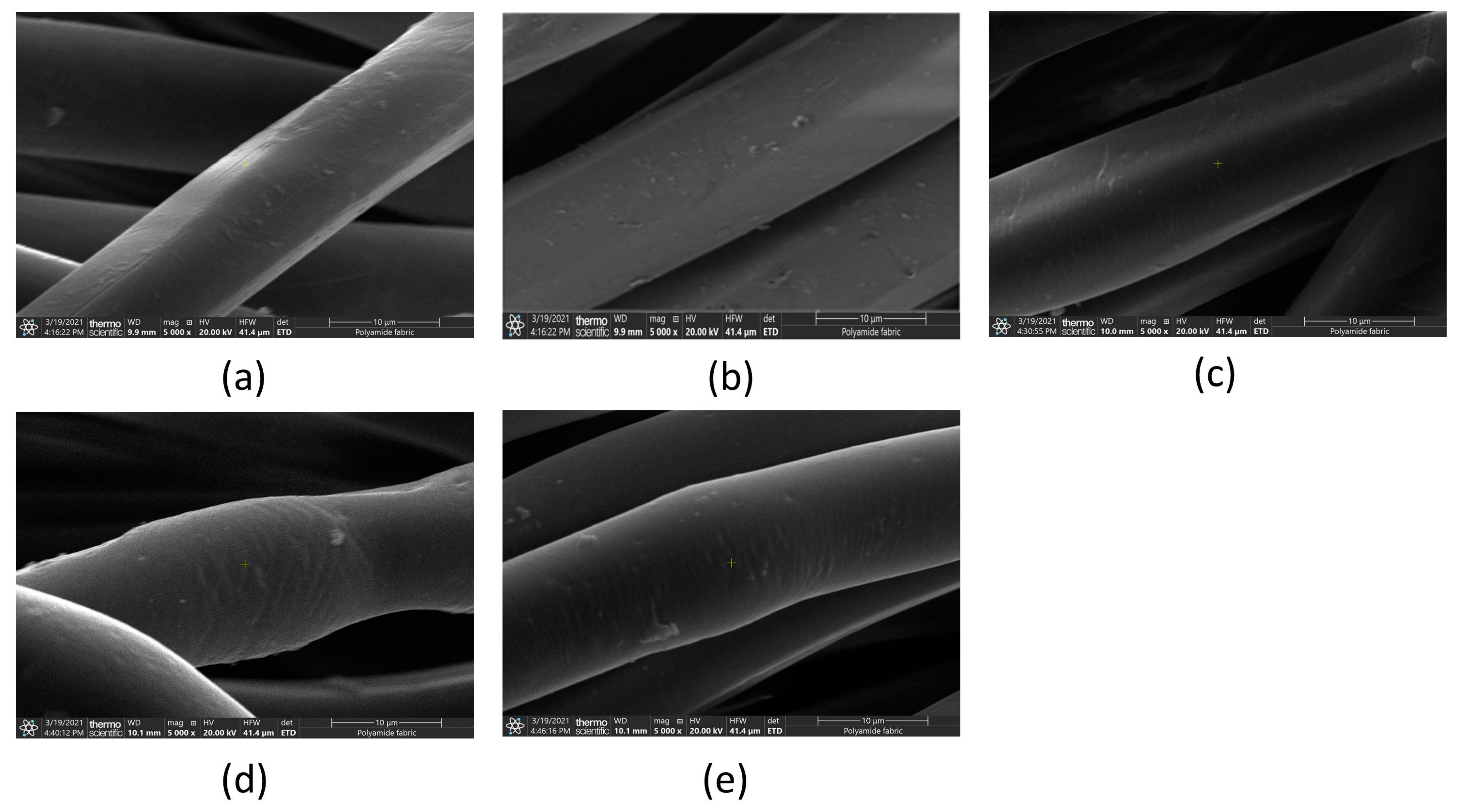

3.5. Scanning Electron Microscopy (SEM)

4. Conclusions

- 1.

- Decrease in the contact angle of the static drop on the material surface. The increase in hydrophilicity on the surface of the textile substrate is essential so that there is a more significant dye absorption at the time of sublimation

- 2.

- Colourimetry and colouristic strength

- 3.

- Test for colourfastness

- 4.

- FTIR analysis

- 5.

- Scanning electron microscopy (SEM)

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, S.; Cho, K.H.; Namgoong, J.W.; Kim, J.Y.; Yoo, E.S.; Lee, W.; Jung, J.W.; Choi, J. The synthesis and characterisation of the perylene acid dye inks for digital textile printing. Dye. Pigment. 2019, 163, 381–392. [Google Scholar] [CrossRef]

- Wang, L.; Yan, K.; Hu, C.; Ji, B. Preparation and investigation of a stable hybrid inkjet printing ink of reactive dye and CHPTAC. Dye. Pigment. 2020, 181, 108584. [Google Scholar] [CrossRef]

- Cie, C. Fixing Inkjet Printed Textiles. In Ink Jet Textile Printing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 99–110. [Google Scholar]

- Ujiie, H. Chapter 20—Fabric Finishing: Printing Textiles. In Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2015; pp. 507–529. ISBN 978-1-84569-931-4. [Google Scholar]

- Cie, C. Inks for digital printing. In Ink Jet Textile Printing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 85–97. [Google Scholar]

- Associação Brasileira da Industria Têxtil e de Confecção Perfil do Setor. Available online: https://www.abit.org.br/cont/perfil-do-setor (accessed on 15 June 2020).

- Louzi, V.C.; de Carvalho Campos, J.S. Corona treatment applied to synthetic polymeric monofilaments (P.P., PET, and PA-6). Surf. Interfaces 2019, 14, 98–107. [Google Scholar] [CrossRef]

- Nascimento, L.; Gasi, F.; Landers, R.; da Silva Sobrinho, A.; Aragão, E.; Fraga, M.; Petraconi, G.; Chiappim, W.; Pessoa, R. Physicochemical Studies on the Surface of Polyamide 6.6 Fabrics Functionalised by DBD Plasmas Operated at Atmospheric and Sub-Atmospheric Pressures. Polymers 2020, 12, 2128. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Etrick, N.R.; Frey, M.W.; Norris, E.J.; Coats, J.R. Structure and Properties of Polyamide Fabrics with Insect-Repellent Functionality Electrospinning and Oxygen Plasma-Treated Surface Coating. Polymers 2020, 12, 2196. [Google Scholar] [CrossRef]

- Starczak, R.; Wąs-Gubała, J. UV–Vis microspectrophotometric study of wool and polyamide fibres dyed with analogous gryfalan dyes. Dye. Pigment. 2016, 132, 58–63. [Google Scholar] [CrossRef]

- Gasi, F. Comparativo das Propriedades de Permeabilidade ao Vapor, Capilaridade e Proteção Ultravioleta em Tecidos de Poliamida 6.6 e Poliéster em Tecido de Malha para Atividade Física; Universidade Estadual de Campinas: Campinas, Brazil, 2010; Available online: http://repositorio.unicamp.br/jspui/handle/REPOSIP/267089 (accessed on 7 May 2021).

- Saleem, M.A.; Pei, L.; Saleem, M.F.; Shahid, S.; Wang, J. Sustainable dyeing of nylon fabric with acid dyes in decamethylcyclopentasiloxane (D5) solvent for improving dye uptake and reducing raw material consumption. J. Clean. Prod. 2021, 279, 123480. [Google Scholar] [CrossRef]

- Hunger, K.; Bauer, W.; Berneth, H.; Clausen, T.; Engel, A.; Filosa, M.; Gregory, P. Industrial Dyes Chemistry, Properties, Applications; WILEY-VCH Verlag GmbH & Co.: Weinheim, Germany, 2003; ISBN 3-527-30426-6. [Google Scholar]

- Nadi, A.; Boukhriss, A.; Bentis, A.; Jabrane, E.; Gmouh, S. Evolution in the surface modification of textiles: A review. Text. Prog. 2018, 50, 67–108. [Google Scholar] [CrossRef]

- Haji, A.; Naebe, M. Cleaner dyeing of textiles using plasma treatment and natural dyes: A review. J. Clean. Prod. 2020, 265, 121866. [Google Scholar] [CrossRef]

- Zanini, S.; Citterio, A.; Leonardi, G.; Riccardi, C. Characterization of atmospheric pressure plasma treated wool/cashmere textiles: Treatment in nitrogen. Appl. Surf. Sci. 2018, 427, 90–96. [Google Scholar] [CrossRef]

- Sohbatzadeh, F.; Shakerinasab, E.; Eshghabadi, M.; Ghasemi, M. Characterization and performance of coupled atmospheric pressure argon plasma jet with n-hexane electrospray for hydrophobic layer coatings on cotton textile. Diam. Relat. Mater. 2019, 91, 34–45. [Google Scholar] [CrossRef]

- Szulc, J.; Urbaniak-Domagała, W.; Machnowski, W.; Wrzosek, H.; Łącka, K.; Gutarowska, B. Low temperature plasma for textiles disinfection. Int. Biodeterior. Biodegrad. 2018, 131, 97–106. [Google Scholar] [CrossRef]

- Muzammil, I.; Dinh, D.K.; Abbas, Q.; Imran, M.; Sattar, H.; Ul Ahmad, A. Controlled Surface Wettability by Plasma Polymer Surface Modification. Surfaces 2019, 2, 349–371. [Google Scholar] [CrossRef] [Green Version]

- Zille, A. Plasma Technology in Fashion and Textiles. In Sustainable Technologies for Fashion and Textiles; Elsevier: Amsterdam, The Netherlands, 2020; pp. 117–142. [Google Scholar]

- Dave, H.; Ledwani, L.; Nema, S.K. Non-Thermal Plasma: A Promising Green Technology to Improve the Environmental Performance of Textile Industries. In The Impact and Prospects of Green Chemistry for Textile Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 199–249. [Google Scholar]

- Gasi, F.; Petraconi, G.; Bittencourt, E.; Lourenço, S.R.; Castro, A.H.R.; Miranda, F.D.S.; Essiptchouk, A.M.; Nascimento, L.; Petraconi, A.; Fraga, M.A.; et al. Plasma Treatment of Polyamide Fabric Surface by Hybrid Corona-Dielectric Barrier Discharge: Material Characterisation and Dyeing/Washing Processes. Mater. Res. 2020, 23. [Google Scholar] [CrossRef]

- Parvinzadeh, M.; Ebrahimi, I. Atmospheric air-plasma treatment of polyester fibre to improve the performance of nanoemulsion silicone. Appl. Surf. Sci. 2011, 257, 4062–4068. [Google Scholar] [CrossRef]

- Amara, I.; Miled, W.; Ben Slama, R.; Chevallier, P.; Mantovani, D.; Ladhari, N. Surface modifications by plasma treatment, chemical grafting and over dyeing of polyamide nets to improve the antifouling performance in the aquaculture field. Dye. Pigment. 2019, 166, 107–113. [Google Scholar] [CrossRef]

- Yan, X.; Liu, G.-S.; Yang, J.; Pu, Y.; Chen, S.; He, H.-W.; Wang, C.; Long, Y.-Z.; Jiang, S. In Situ Surface Modification of Paper-Based Relics with Atmospheric Pressure Plasma Treatment for Preservation Purposes. Polymers 2019, 11, 786. [Google Scholar] [CrossRef] [Green Version]

- López-García, J.; Praveen, K.M. Chapter 10—Wettability Analysis and Water Absorption Studies of Plasma Activated Polymeric Materials. In Non-Thermal Plasma Technology for Polymeric Materials; Thomas, S., Mozetič, M., Cvelbar, U., Špatenka, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 261–285. ISBN 978-0-12-813152-7. [Google Scholar]

- ABNT. ABNT-NBR-ISO 105-A03—Textile—Test for Colour Fastness. Part A03: Grey Scale for Assessing Staining 2006. Available online: https://www.abntcatalogo.com.br/norma.aspx?ID=1462 (accessed on 7 May 2021).

- ABNT. ABNT-NBR-ISO 105-A02—Textile—Test for Colour Fastness. Part A02: Grey Scale for Assessing Change in Colour 2006. Available online: https://www.abntcatalogo.com.br/norma.aspx?ID=1469 (accessed on 7 May 2021).

- ABNT. ABNT-NBR-ISO 105-C06—Textile—Test for Colour Fastness. Part C06: Colourfastness to Domestic and Commercial Laundering 2010. Available online: https://www.abntcatalogo.com.br/norma.aspx?ID=63626 (accessed on 7 May 2021).

- Zhou, Q.; Rather, L.J.; Ali, A.; Wang, W.; Zhang, Y.; Rizwanul Haque, Q.M.; Li, Q. Environmental friendly bioactive finishing of wool textiles using the tannin-rich extracts of Chinese tallow (Sapium sebiferum L.) waste/fallen leaves. Dye. Pigment. 2020, 176, 108230. [Google Scholar] [CrossRef]

- Vandenabeele, C.R.; Lucas, S. Technological challenges and progress in nanomaterials plasma surface modification—A review. Mater. Sci. Eng. R Rep. 2020, 139, 100521. [Google Scholar] [CrossRef]

- Oliveira, F.R.; Zille, A.; Souto, A.P. Dyeing mechanism and optimisation of polyamide 6,6 functionalised with double barrier discharge (DBD) plasma in air. Appl. Surf. Sci. 2014, 293, 177–186. [Google Scholar] [CrossRef] [Green Version]

- Charles, J.; Ramkumaar, G.R.; Azhagiri, S.S. Gunasekaran FTIR and thermal studies on nylon-66 and 30% glass fibre reinforced nylon-66. E-J. Chem. 2009, 6, 23–33. [Google Scholar] [CrossRef] [Green Version]

| Sample | Speed | Passages |

|---|---|---|

| 1 (Control) | - | - |

| 2 | 15 m/min | 3 |

| 3 | 15 m/min | 4 |

| 4 | 20 m/min | 3 |

| 5 | 20 m/min | 4 |

| Colour | Sample | Plasma Application | Colour Change | Colour Staining | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Speed (m/min) | N | WO | PAC | PES | PA | CO | CA | |||

| Red | 1 | Control | 5 | 5 | 4–5 | 4 | 4–5 | 3–4 | ||

| 2 | 15 | 3 | 4–5 | 5 | 5 | 4–5 | 4 | 4–5 | 3–4 | |

| 3 | 15 | 4 | 4 | 4–5 | 5 | 4–5 | 4 | 4–5 | 3–4 | |

| 4 | 20 | 3 | 4 | 4–5 | 5 | 4–5 | 4 | 5 | 3 | |

| 5 | 20 | 4 | 4 | 4–5 | 5 | 4–5 | 4 | 5 | 3 | |

| Blue | 1 | Control | 5 | 5 | 5 | 4–5 | 5 | 4–5 | ||

| 2 | 15 | 3 | 4–5 | 5 | 5 | 5 | 4 | 5 | 4–5 | |

| 3 | 15 | 4 | 4–5 | 5 | 5 | 5 | 4 | 5 | 4 | |

| 4 | 20 | 3 | 4–5 | 5 | 5 | 5 | 4 | 5 | 4–5 | |

| 5 | 20 | 4 | 4–5 | 5 | 5 | 4–5 | 4 | 5 | 4–5 | |

| Yellow | 1 | Control | 5 | 5 | 5 | 4–5 | 5 | 4–5 | ||

| 2 | 15 | 3 | 4–5 | 5 | 5 | 5 | 4–5 | 5 | 4–5 | |

| 3 | 15 | 4 | 4–5 | 5 | 5 | 5 | 4–5 | 5 | 4–5 | |

| 4 | 20 | 3 | 4–5 | 5 | 5 | 5 | 4–5 | 5 | 4–5 | |

| 5 | 20 | 4 | 4–5 | 5 | 5 | 5 | 4–5 | 5 | 4–5 | |

| Colour | Sample | D65/10° | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | ΔE | Colour Strength (%) | ||

| Red | 1 (Control) | 58.89 | 44.93 | 15.85 | ||

| 2 | 57.58 | 48.44 | 18.05 | 1.81 | 119.5 | |

| 3 | 54.85 | 51.21 | 20.01 | 3.58 | 154.99 | |

| 4 | 57.44 | 47.9 | 17.6 | 1.54 | 121.96 | |

| 5 | 54.08 | 50.98 | 19.01 | 3.43 | 159.9 | |

| Blue | 1 (Control) | 72.29 | −18.19 | −26.15 | ||

| 2 | 70.02 | −18.24 | −28.57 | 1.59 | 124.26 | |

| 3 | 69.00 | −18.09 | −29.38 | 2.2 | 134.6 | |

| 4 | 74.24 | −17.74 | −23.26 | 1.72 | 80.95 | |

| 5 | 69.62 | −17.97 | −29.17 | 2 | 127.89 | |

| Yellow | 1 (Control) | 89.11 | −8.14 | 55.00 | ||

| 2 | 88.98 | −7.89 | 54.69 | 0.18 | 99.14 | |

| 3 | 88.50 | −7.6 | 56.89 | 0.85 | 117.83 | |

| 4 | 88.48 | −7.67 | 57.7 | 1.11 | 119.96 | |

| 5 | 88.76 | −7.81 | 55.73 | 0.37 | 106.32 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, M.C.; Petraconi, G.; Cecci, R.R.R.; Passos, A.A.; do Valle, W.F.; Braite, B.; Lourenço, S.R.; Gasi, F. Digital Sublimation Printing on Knitted Polyamide 6.6 Fabric Treated with Non-Thermal Plasma. Polymers 2021, 13, 1969. https://doi.org/10.3390/polym13121969

Silva MC, Petraconi G, Cecci RRR, Passos AA, do Valle WF, Braite B, Lourenço SR, Gasi F. Digital Sublimation Printing on Knitted Polyamide 6.6 Fabric Treated with Non-Thermal Plasma. Polymers. 2021; 13(12):1969. https://doi.org/10.3390/polym13121969

Chicago/Turabian StyleSilva, Marcia Cristina, Gilberto Petraconi, Ricardo Rodrigues Ramos Cecci, Adriano Alves Passos, Wanderson Ferraz do Valle, Bruno Braite, Sérgio Ricardo Lourenço, and Fernando Gasi. 2021. "Digital Sublimation Printing on Knitted Polyamide 6.6 Fabric Treated with Non-Thermal Plasma" Polymers 13, no. 12: 1969. https://doi.org/10.3390/polym13121969

APA StyleSilva, M. C., Petraconi, G., Cecci, R. R. R., Passos, A. A., do Valle, W. F., Braite, B., Lourenço, S. R., & Gasi, F. (2021). Digital Sublimation Printing on Knitted Polyamide 6.6 Fabric Treated with Non-Thermal Plasma. Polymers, 13(12), 1969. https://doi.org/10.3390/polym13121969