On the Mechanical Response of Silicon Dioxide Nanofiller Concentration on Fused Filament Fabrication 3D Printed Isotactic Polypropylene Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Filament Production Process

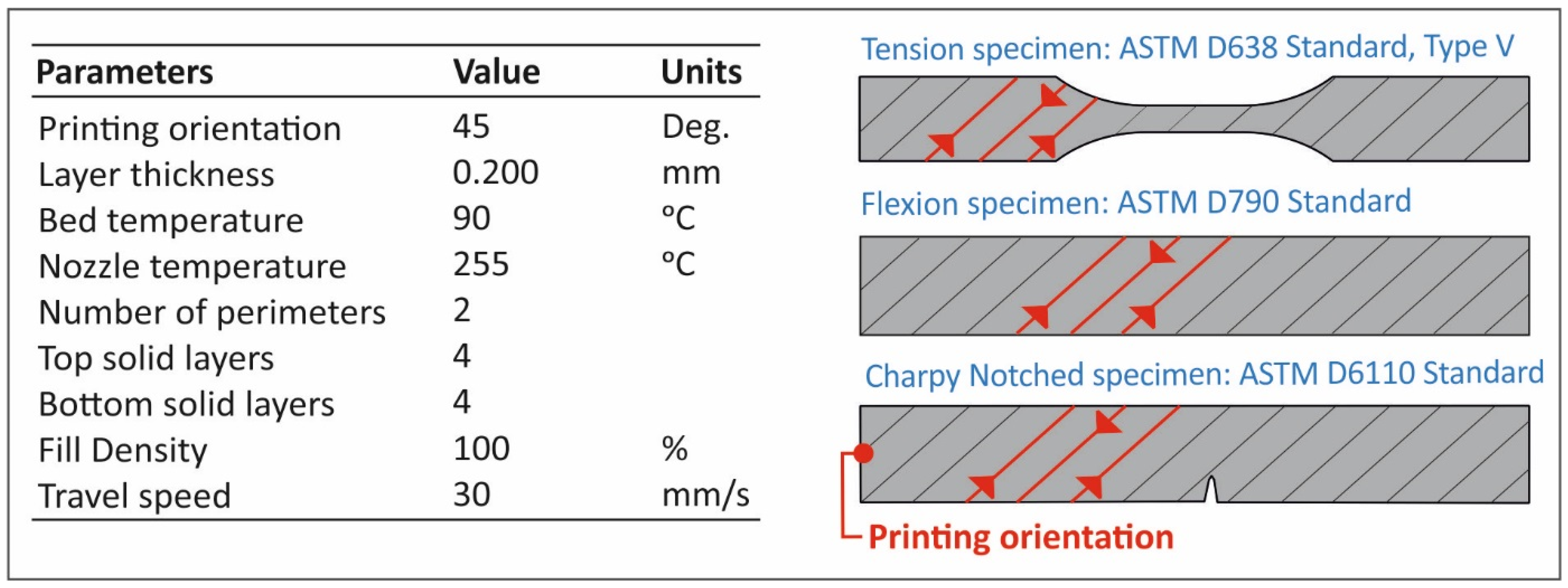

2.2.2. Tensile Specimens Fabrication and Testing

2.2.3. Flexural Specimens Fabrication and Testing

2.2.4. Charpy Impact Specimens Fabrication and Testing

2.2.5. Microhardness Measurements

2.2.6. Dynamic Mechanical Analysis (DMA)

2.2.7. Spectroscopic and Morphological Characterization

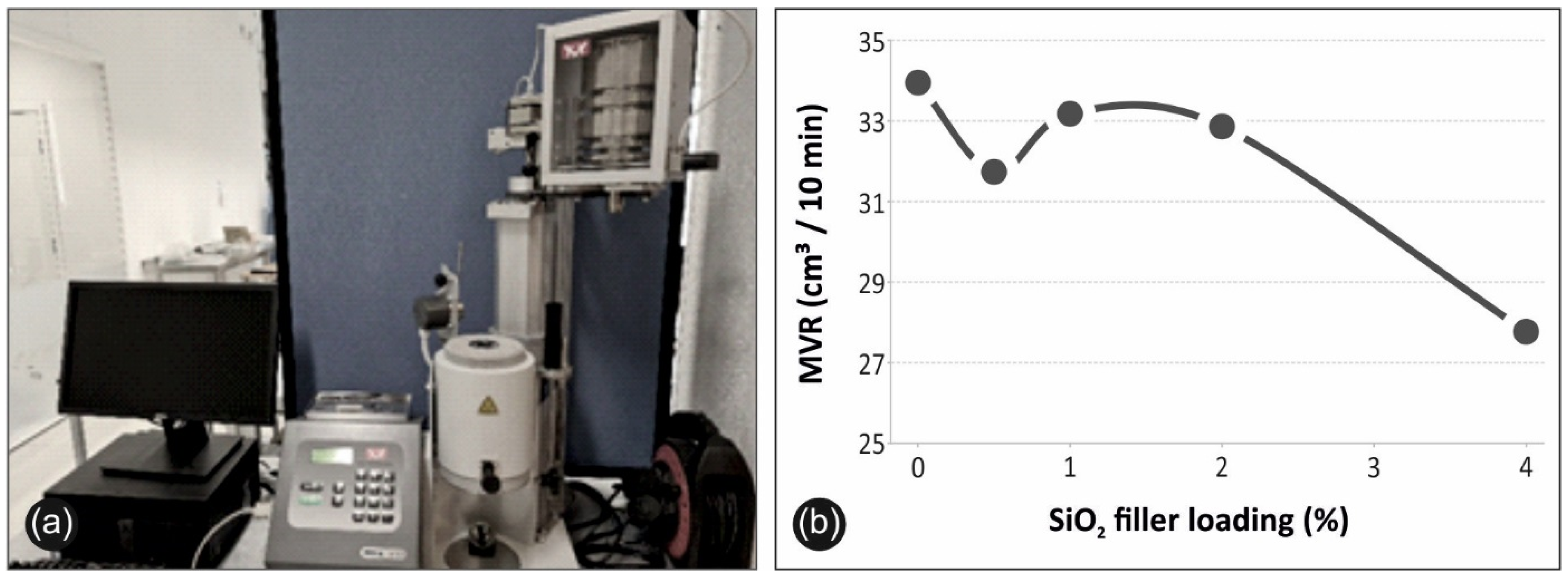

2.2.8. Melt Flow Index

3. Results

3.1. Mechanical Performance

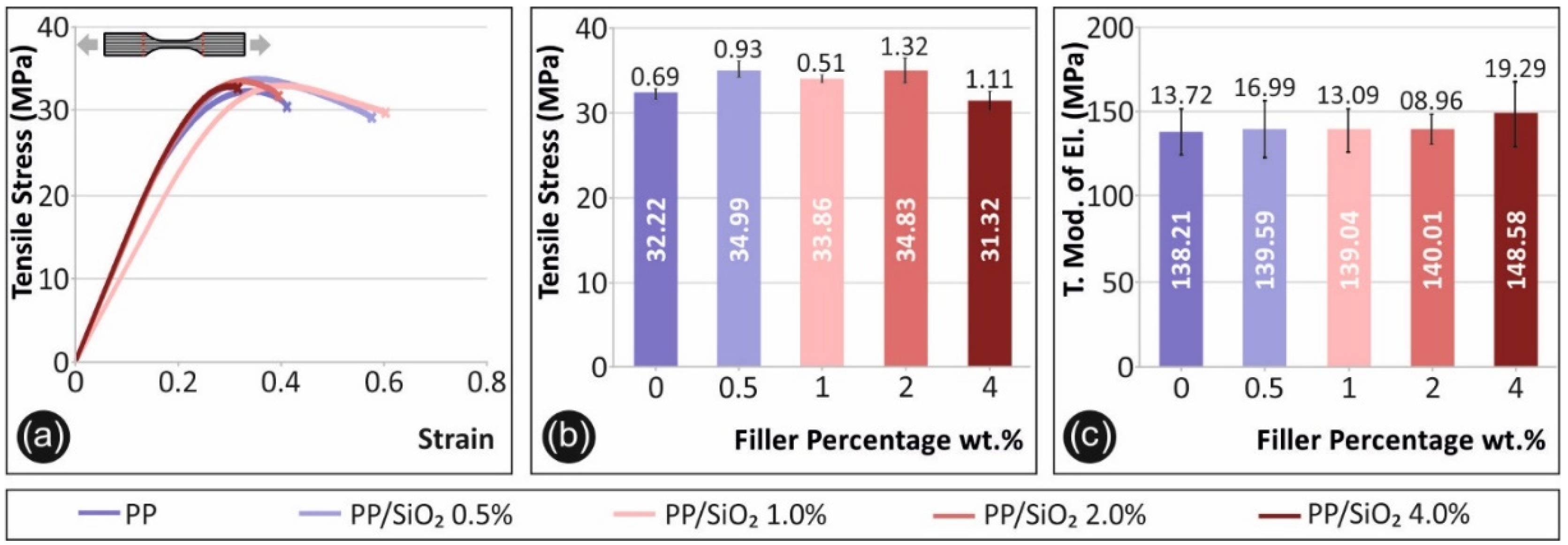

3.1.1. Tensile Test Results

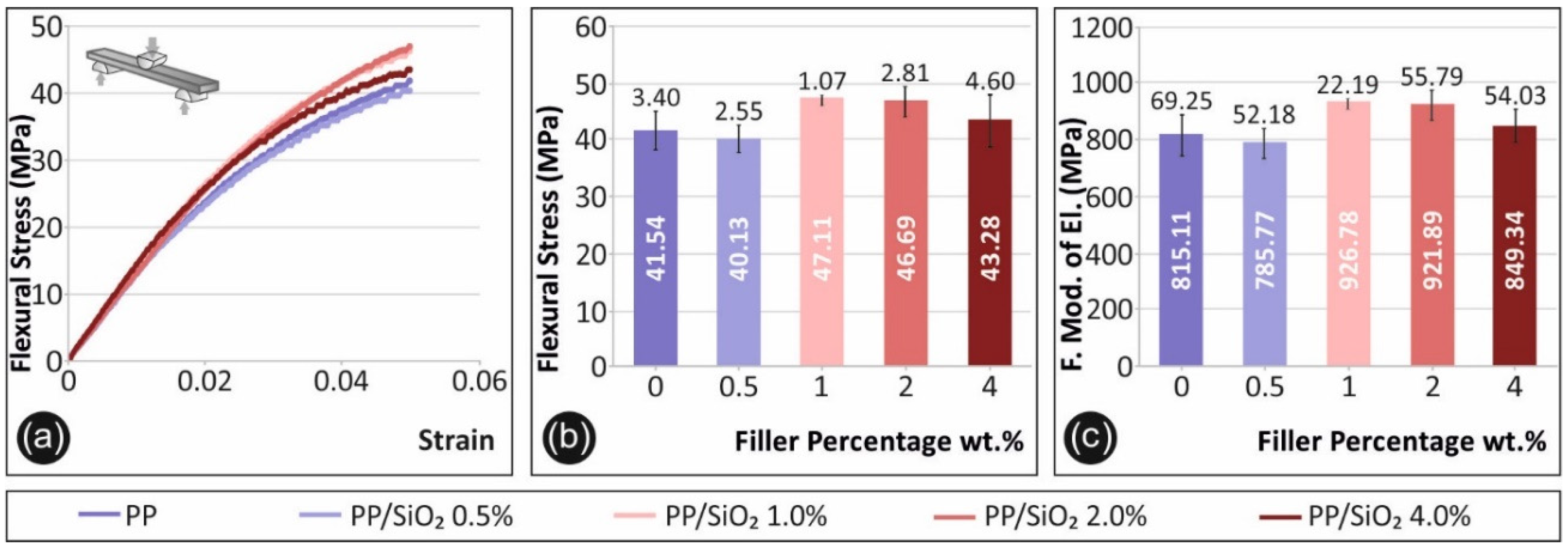

3.1.2. Flexural Test Results

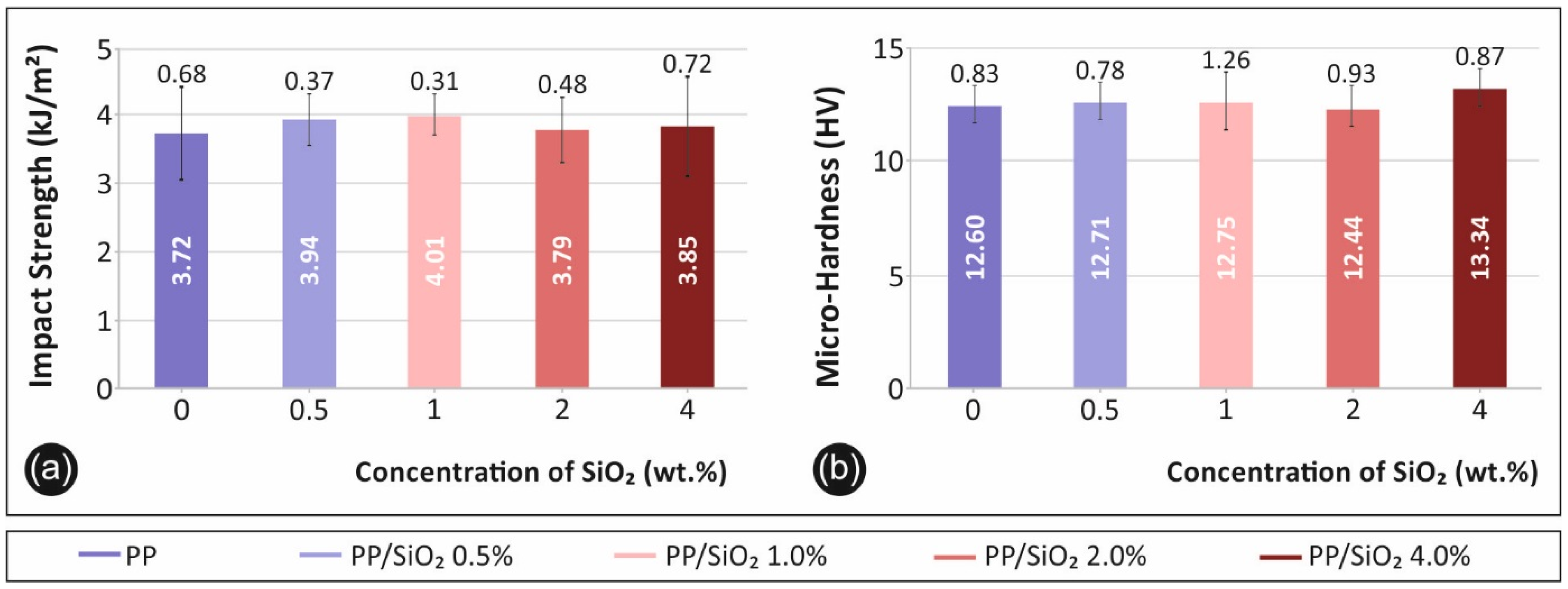

3.1.3. Impact and Microhardness Test Results

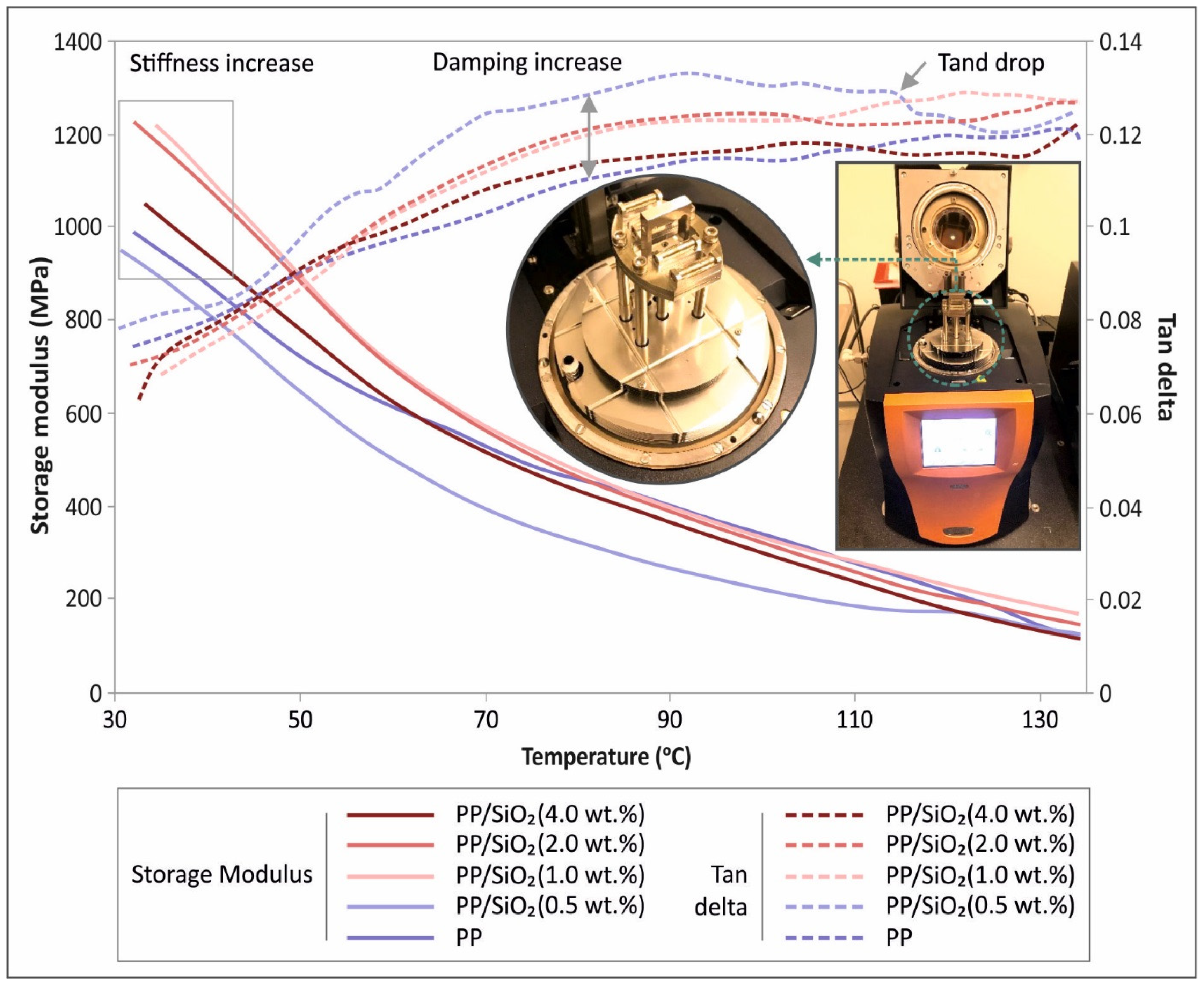

3.2. DMA Results

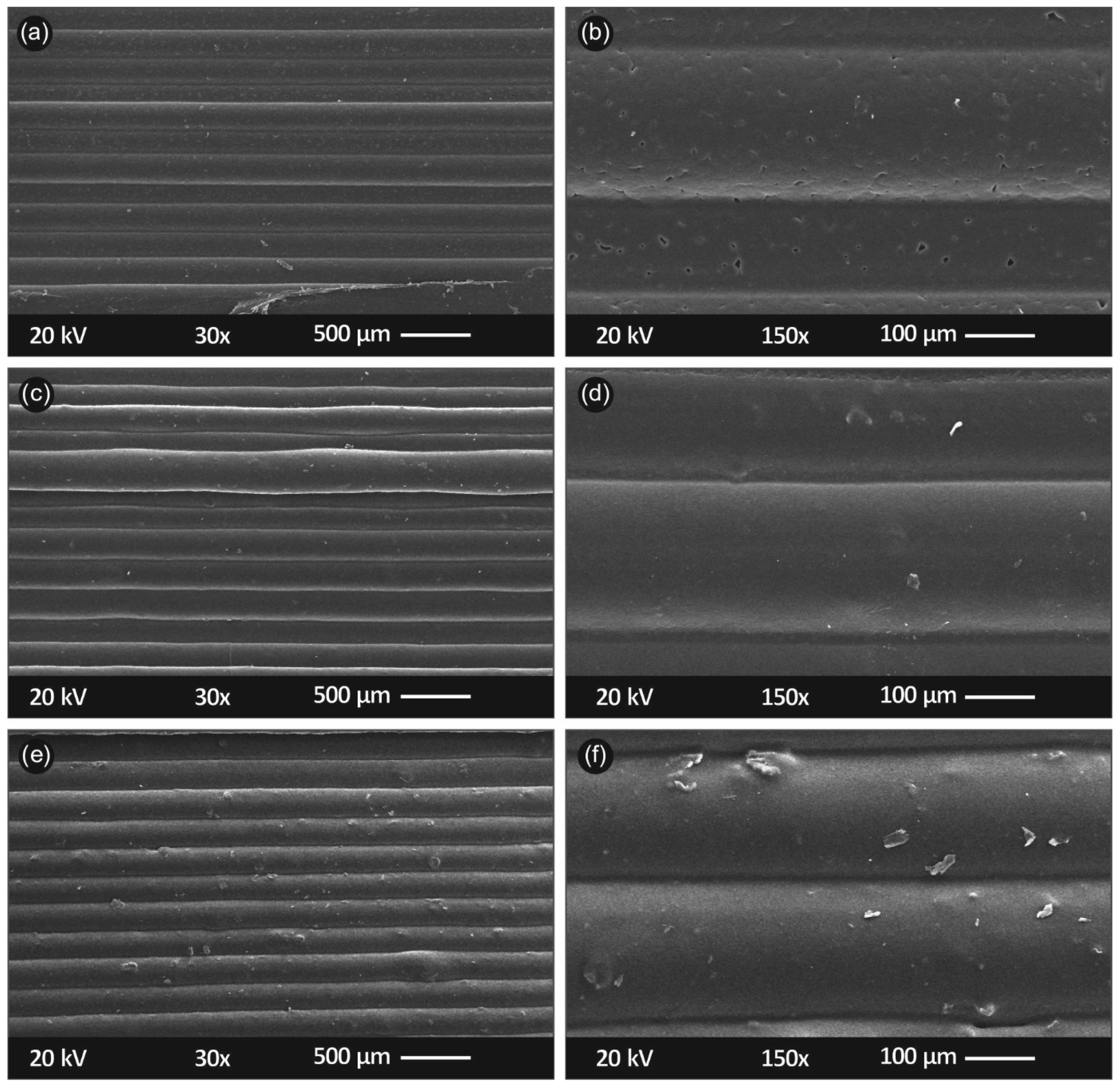

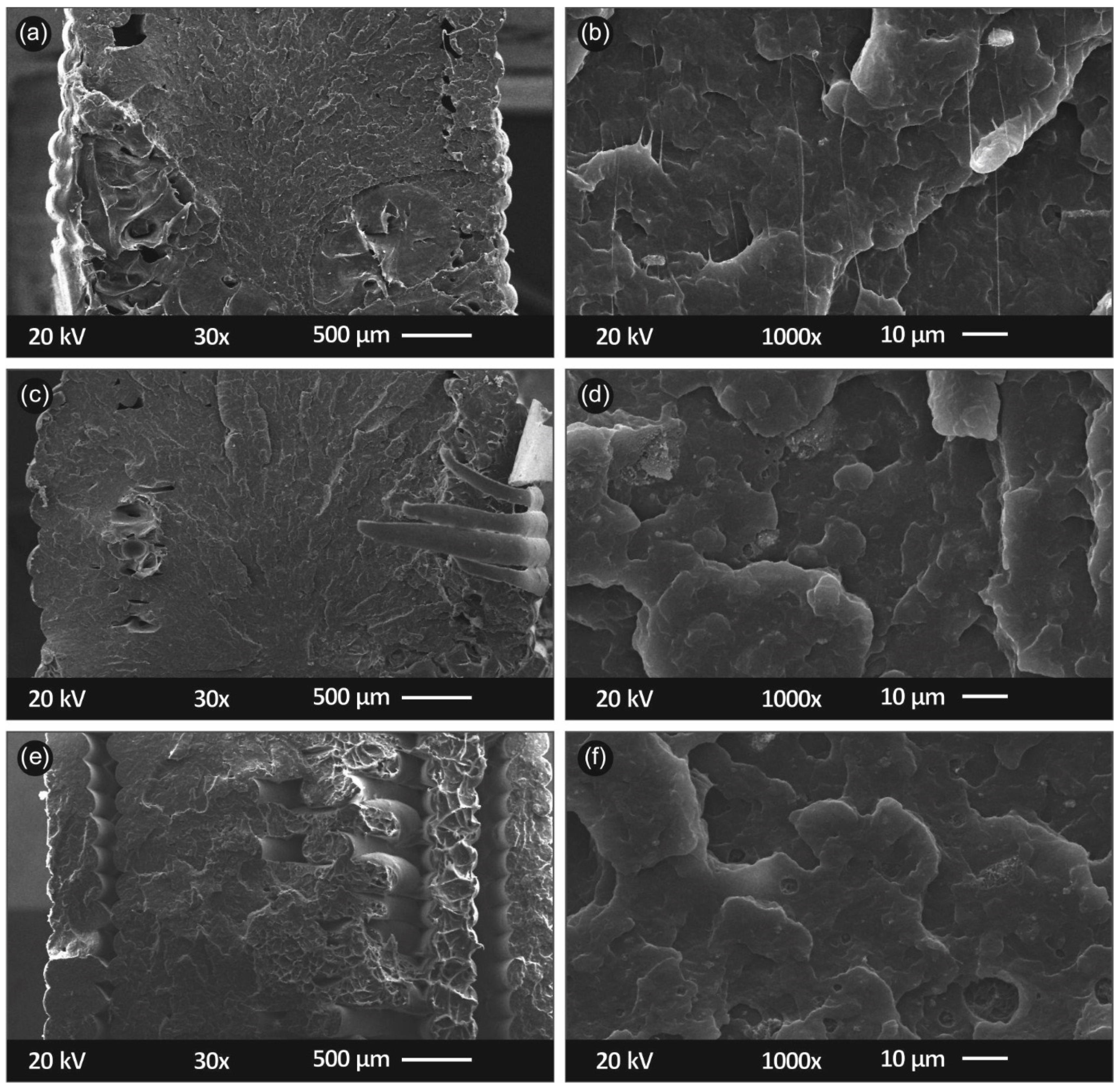

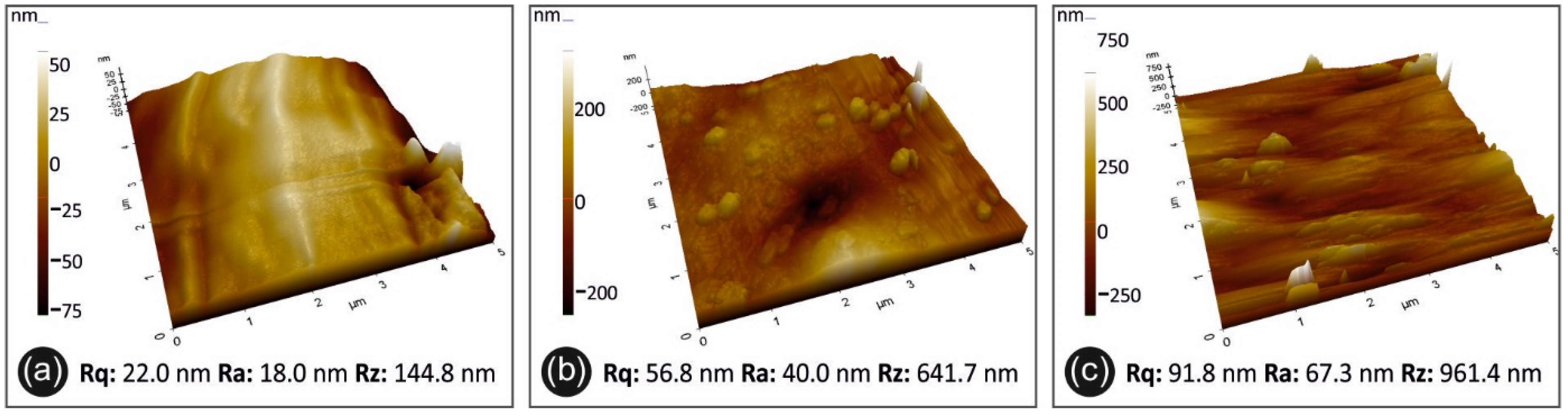

3.3. Spectroscopic and Microstructural Analysis

3.4. Melt Flow Index Results

4. Discussion

4.1. Mechanical Properties Analysis

4.2. DMA Analysis

4.3. Spectroscopic and Microstructural Analysis

4.4. Melt Flow Index Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Peterson, A.M. Review of Acrylonitrile Butadiene Styrene in Fused Filament Fabrication: A Plastics Engineering-Focused Perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models?—Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Delgado Camacho, D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of Additive Manufacturing in the Construction Industry—A Forward-Looking Review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Tzounis, L.; Bangeas, P.I.; Exadaktylos, A.; Petousis, M.; Vidakis, N. Three-Dimensional Printed Polylactic Acid (PLA) Surgical Retractors with Sonochemically Immobilized Silver Nanoparticles: The next Generation of Low-Cost Antimicrobial Surgery Equipment. Nanomaterials 2020, 10, 985. [Google Scholar] [CrossRef] [PubMed]

- Bikas, H.; Stavridis, J.; Stavropoulos, P.; Chryssolouris, G. A Design Framework to Replace Conventional Manufacturing Processes with Additive Manufacturing for Structural Components: A Formula Student Case Study. Procedia CIRP 2016, 57, 710–715. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the Strain Rate Sensitivity of Fused Filament Fabrication (Fff) Processed Pla, Abs, Petg, Pa6, and Pp Thermoplastic Polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef] [PubMed]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Wu, J.H.; Yen, M.S.; Kuo, M.C.; Chen, B.H. Physical Properties and Crystallization Behavior of Silica Particulates Reinforced Poly(Lactic Acid) Composites. Mater. Chem. Phys. 2013, 142, 726–733. [Google Scholar] [CrossRef]

- Savvakis, K.; Petousis, M.; Vairis, A.; Vidakis, N.; Bikmeyev, A.T. Experimental Determination of the Tensile Strength of Fused Deposition Modeling Parts. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition 2014, 14: Emerging Technologies; Engineering Management, Safety, Ethics, Society, and Education; Materials: Genetics to Structures, Montreal, QC, Canada, 14–20 November 2014. V014T11A022. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. On the compressive behavior of an FDM Steward Platform part. J. Comput. Des. Eng. 2017, 4, 339–346. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A parametric determination of bending and Charpy’s impact strength of ABS and ABS-plus fused deposition modeling specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- Valino, A.D.; Ryan, J.; Dizon, C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Gauss, C.; Pickering, K.L.; Muthe, L.P. The Use of Cellulose in Bio-Derived Formulations for 3D/4D Printing: A Review. Compos. Part C Open Access 2021, 4, 100113. [Google Scholar] [CrossRef]

- Valvez, S.; Santos, P.; Parente, J.M.; Silva, M.P.; Reis, P.N.B. 3D Printed Continuous Carbon Fiber Reinforced PLA Composites: A Short Review. In Proceedings of the Procedia Structural Integrity; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 25, pp. 394–399. [Google Scholar]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3d Printing Pla Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Tzounis, L.; Liebscher, M.; Grammatikos, S.A. Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content. Nanomaterials 2021, 11, 1012. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Savvakis, K.; Maniadi, A.; Koudoumas, E. A Comprehensive Investigation of the Mechanical Behavior and the Dielectrics of Pure Polylactic Acid (PLA) and PLA with Graphene (GnP) in Fused Deposition Modeling (FDM). Int. J. Plast. Technol. 2019, 23, 195–206. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Mascolo, I.; Modano, M. On the Applicability of Composite PA6-TiO2 Filaments for the Rapid Prototyping of Innovative Materials and Structures. Compos. Part B Eng. 2018, 143, 132–140. [Google Scholar] [CrossRef]

- Aumnate, C.; Limpanart, S.; Soatthiyanon, N.; Khunton, S. PP/Organoclay Nanocomposites for Fused Filament Fabrication (FFF) 3D Printing. Express Polym. Lett. 2019, 13, 898–909. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability 2020, 13, 159. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Jakubowska, P.; Osinska-Broniarz, M.; Agnieszka, M.; Sztorch, B. Thermal Properties Of Pp-Sio2 Composites Filled With Stöber Silica One-Pot Method in the Sol-Gel Chemistry Materials View Project Polymer Composites Based on an Innovative Thermoplastic Resin with Improved Mechanical and Electrical Properties View Project. Compos. Theory Pract. 2016, 16, 161–166. [Google Scholar]

- Huang, L.; Zhan, R.; Lu, Y. Mechanical Properties and Crystallization Behavior of Polypropylene/Nano-SiO2 Composites. J. Reinf. Plast. Compos. 2006, 25, 1001–1012. [Google Scholar] [CrossRef]

- Van Zyl, W.E.; Boukamp, B.A.; García, M.; van Vliet, G.; Jain, S.; Schrauwen, B.A.G.; Sarkissov, A.; van Zyl, W.E.; Boukamp, B. Polypropylene/SiO2 Nanocomposites with Improved Mechanical Properties 169 Polypropylene/SiO 2 Nanocomposites with Improved Mechanical Properties Polypropylene/Sio 2 Nanocomposites with Improved Mechanical Properties. Rev. Adv. Mater. Sci. 2004, 6, 169. [Google Scholar]

- Jeelani, P.G.; Mulay, P.; Venkat, R.; Ramalingam, C. Multifaceted Application of Silica Nanoparticles. A Review. Silicon 2020, 12, 1337–1354. [Google Scholar] [CrossRef]

- Chen, H.M.; Wang, Y.P.; Chen, J.; Yang, J.H.; Zhang, N.; Huang, T.; Wang, Y. Hydrolytic Degradation Behavior of Poly(l-Lactide)/SiO2 Composites. Polym. Degrad. Stab. 2013, 98, 2672–2679. [Google Scholar] [CrossRef]

- Hakim, R.H.; Cailloux, J.; Santana, O.O.; Bou, J.; Sánchez-Soto, M.; Odent, J.; Raquez, J.M.; Dubois, P.; Carrasco, F.; Maspoch, M.L. PLA/SiO2 Composites: Influence of the Filler Modifications on the Morphology, Crystallization Behavior, and Mechanical Properties. J. Appl. Polym. Sci. 2017, 134, 45367. [Google Scholar] [CrossRef]

- Jia, H.; Hou, W.; Wei, L.; Xu, B.; Liu, X. The Structures and Antibacterial Properties of Nano-SiO2 Supported Silver/Zinc-Silver Materials. Dent. Mater. 2008, 24, 244–249. [Google Scholar] [CrossRef]

- Ren, Z.; Zhou, W.; Qing, Y.; Duan, S.; Pan, H.; Zhou, Y. Improved Mechanical and Microwave Absorption Properties of SiCf/SiC Composites with SiO2 Filler. Ceram. Int. 2021, 47, 14455–14463. [Google Scholar] [CrossRef]

- Narayan, R.; Nayak, U.Y.; Raichur, A.M.; Garg, S. Mesoporous Silica Nanoparticles: A Comprehensive Review on Synthesis and Recent Advances. Pharmaceutics 2018, 10, 118. [Google Scholar] [CrossRef] [Green Version]

- Klapiszewski, L.; Bula, K.; Sobczak, M.; Jesionowski, T. Influence of Processing Conditions on the Thermal Stability and Mechanical Properties of PP/Silica-Lignin Composites. Int. J. Polym. Sci. 2016, 2016, 1627258. [Google Scholar] [CrossRef] [Green Version]

- Bouzakis, K.D.; Vidakis, N. Superficial plastic response determination of hard isotropic materials using ball indentations and a FEM optimization technique. Mater. Charact. 1999, 42, 1–12. [Google Scholar] [CrossRef]

- Pavlidou, E.; Bikiaris, D.; Vassiliou, A.; Chiotelli, M.; Karayannidis, G. Mechanical Properties and Morphological Examination of Isotactic Polypropylene/SiO2 Nanocomposites Containing PP-g-MA as Compatibilizer. J. Phys. Conf. Ser. 2005, 10, 190–193. [Google Scholar] [CrossRef]

- Kruenate, J.; Tongpool, R.; Panyathanmaporn, T.; Kongrat, P. Optical and Mechanical Properties of Polypropylene Modified by Metal Oxides. Proc. Surf. Interface Anal. 2004, 36, 1044–1047. [Google Scholar] [CrossRef]

- Guo, X.; Lin, Z.; Wang, Y.; He, Z.; Wang, M.; Jin, G. In-Line Monitoring the Degradation of Polypropylene under Multiple Extrusions Based on Raman Spectroscopy. Polymers 2019, 11, 1698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukherjee, P.; Roy, M.; Mandal, B.P.; Dey, G.K.; Mukherjee, P.K.; Ghatak, J.; Tyagi, A.K.; Kale, S.P. Green Synthesis of Highly Stabilized Nanocrystalline Silver Particles by a Non-Pathogenic and Agriculturally Important Fungus T. Asperellum. Nanotechnology 2008, 19, 075103. [Google Scholar] [CrossRef]

- Biswas, R.K.; Khan, P.; Mukherjee, S.; Mukhopadhyay, A.K.; Ghosh, J.; Muraleedharan, K. Study of Short Range Structure of Amorphous Silica from PDF Using Ag Radiation in Laboratory XRD System, RAMAN and NEXAFS. J. Non-Cryst. Solids 2018, 488, 1–9. [Google Scholar] [CrossRef]

| Silicon Dioxide Percentage (wt.%) | |||||

|---|---|---|---|---|---|

| Mechanical property | 0 | 0.5 | 1 | 2 | 4 |

| Tensile strength (MPa) | 32.22 | 34.99 | 33.86 | 34.83 | 31.32 |

| Tensile Modulus of elasticity (MPa) | 138.21 | 139.59 | 139.04 | 140.01 | 148.58 |

| Flexural strength (MPa) | 41.54 | 40.13 | 47.11 | 46.69 | 43.28 |

| Flexural Modulus of elasticity (MPa) | 815.11 | 785.77 | 926.78 | 921.89 | 849.34 |

| Impact Resistance (kJ/m2) | 3.72 | 3.94 | 4.01 | 3.79 | 3.85 |

| Microhardness (HV) | 12.60 | 12.71 | 12.75 | 12.44 | 13.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Korlos, A.; Fischer-Griffiths, P.E.; Grammatikos, S. On the Mechanical Response of Silicon Dioxide Nanofiller Concentration on Fused Filament Fabrication 3D Printed Isotactic Polypropylene Nanocomposites. Polymers 2021, 13, 2029. https://doi.org/10.3390/polym13122029

Vidakis N, Petousis M, Velidakis E, Tzounis L, Mountakis N, Korlos A, Fischer-Griffiths PE, Grammatikos S. On the Mechanical Response of Silicon Dioxide Nanofiller Concentration on Fused Filament Fabrication 3D Printed Isotactic Polypropylene Nanocomposites. Polymers. 2021; 13(12):2029. https://doi.org/10.3390/polym13122029

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Emmanouil Velidakis, Lazaros Tzounis, Nikolaos Mountakis, Apostolos Korlos, Peder Erik Fischer-Griffiths, and Sotirios Grammatikos. 2021. "On the Mechanical Response of Silicon Dioxide Nanofiller Concentration on Fused Filament Fabrication 3D Printed Isotactic Polypropylene Nanocomposites" Polymers 13, no. 12: 2029. https://doi.org/10.3390/polym13122029

APA StyleVidakis, N., Petousis, M., Velidakis, E., Tzounis, L., Mountakis, N., Korlos, A., Fischer-Griffiths, P. E., & Grammatikos, S. (2021). On the Mechanical Response of Silicon Dioxide Nanofiller Concentration on Fused Filament Fabrication 3D Printed Isotactic Polypropylene Nanocomposites. Polymers, 13(12), 2029. https://doi.org/10.3390/polym13122029