Differentiation of Polyamide 6, 6.6, and 12 Contaminations in Polyolefin-Recyclates Using HPLC Coupled to Drift-Tube Ion-Mobility Quadrupole Time-of-Flight Mass Spectrometry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Instrumentation

2.3. Sample Preparation

2.4. Data Evaluation

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat. Generation of Waste by Waste Category. Available online: https://ec.europa.eu/eurostat/databrowser/view/ENV_WASGEN__custom_605013/default/table?lang=en (accessed on 24 February 2021).

- European Commision. Living Well, Within the Limits of Our Planet: General Union Environment Action Programme to 2020; Publication Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste: L 150/141; Official Journal of the European Union: Luxenbourg, 2018.

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Karlsson, S. Recycled Polyolefins. Material Properties and Means for Quality Determination. In Long Term Properties of Polyolefins; Albertsson, A.-C., Ed.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 201–230. ISBN 978-3-540-40769-0. [Google Scholar]

- Plastics Europe. Plastics-the Facts. 2020. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 23 February 2021).

- Pracella, M. Blends and Alloys. In Modification of Polymer Properties; Elsevier: Amsterdam, The Netherlands, 2017; pp. 155–184. ISBN 9780323443531. [Google Scholar]

- Feldman, D. Polyblend Compatibilization. J. Macromol. Sci. Part A 2005, 42, 587–605. [Google Scholar] [CrossRef]

- Van Velzen, E.U.T.; Chu, S.; Chacon, F.A.; Brouwer, M.T.; Molenveld, K. The impact of impurities on the mechanical properties of recycled polyethylene. Packag. Technol. Sci. 2021, 34, 219–228. [Google Scholar] [CrossRef]

- White, J.M.; Yang, J. Miscibility and Characteristics of Polyolefin Blends. In Polyolefin Blends; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 27–65. ISBN 9780471790587. [Google Scholar]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Serranti, S.; Fraunholcz, N.; Di Maio, F.; Bonifazi, G. Recycling-oriented characterization of polyolefin packaging waste. Waste Manag. 2013, 33, 574–584. [Google Scholar] [CrossRef] [PubMed]

- Eriksen, M.K.; Damgaard, A.; Boldrin, A.; Astrup, T.F. Quality Assessment and Circularity Potential of Recovery Systems for Household Plastic Waste. J. Indust. Ecol. 2019, 23, 156–168. [Google Scholar] [CrossRef] [Green Version]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Ebnesajjad, S. Plastic Films in Food Packaging: Materials, Technology, and Applications; William Andrew: Oxford, UK, 2013; ISBN 978-1-4557-3112-1. [Google Scholar]

- Marchildon, K. Polyamides—Still Strong After Seventy Years. Macromol. React. Eng. 2011, 5, 22–54. [Google Scholar] [CrossRef]

- Herzog, B.; Kohan, M.I.; Mestemacher, S.A.; Pagilagan, R.U.; Redmond, K.; Sarbandi, R. Polyamides. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2000; pp. 1–47. ISBN 9783527303854. [Google Scholar]

- Stangenberg, F.; Agren, S.; Karlsson, S. Quality Assessments of Recycled Plastics by Spectroscopy and Chromatography. Chromatographia 2004, 59, 101–106. [Google Scholar]

- Gaymans, R. Polyamides. In Synthetic Methods in Step-Growth Polymers; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 135–195. ISBN 0-471-38769-X. [Google Scholar]

- Gall, M.; Schweighuber, A.; Buchberger, W.; Lang, R. Plastic Bottle Cap Recycling—Characterization of Recyclate Composition and Opportunities for Design for Circularity. Sustainability 2020, 12, 378. [Google Scholar] [CrossRef]

- Žagar, E.; Češarek, U.; Drinčić, A.; Sitar, S.; Shlyapnikov, I.M.; Pahovnik, D. Quantitative Determination of PA6 and/or PA66 Content in Polyamide-Containing Wastes. ACS Sustain. Chem. Eng. 2020, 8, 11818–11826. [Google Scholar] [CrossRef]

- Gramshaw, J.W.; Soto-Valdez, H. Migration from polyamide ‘microwave and roasting bags’ into roast chicken. Food Addit. Contam. 1998, 15, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Guaita, C. HPLC analysis of cyclo-oligoamides 6 and 66. Makromol. Chem. 1984, 185, 459–465. [Google Scholar] [CrossRef]

- Heimrich, M.; Bönsch, M.; Nickl, H.; Simat, T.J. Cyclic oligomers in polyamide for food contact material: Quantification by HPLC-CLND and single-substance calibration. Food Addit. Contam. Part A 2012, 29, 846–860. [Google Scholar] [CrossRef]

- Heimrich, M.; Nickl, H.; Bönsch, M.; Simat, T.J. Migration of Cyclic Monomer and Oligomers from Polyamide 6 and 66 Food Contact Materials into Food and Food Simulants: Direct Food Contact. Packag. Technol. Sci. 2015, 28, 123–139. [Google Scholar] [CrossRef]

- Hoppe, M.; de Voogt, P.; Franz, R. Identification and quantification of oligomers as potential migrants in plastics food contact materials with a focus in polycondensates—A review. Trends Food Sci. Technol. 2016, 50, 118–130. [Google Scholar] [CrossRef]

- Jenke, D.; Poss, M.; Sadain, S.; Story, J.; Smith, W.; Reiber, D. Identification of caprolactam oligomers and related compounds in aqueous extracts of nylon-6. J. Appl. Polym. Sci. 2005, 95, 1262–1274. [Google Scholar] [CrossRef]

- Kappenstein, O.; Ebner, I.; Förster, C.; Richter, S.; Weyer, J.; Pfaff, K.; Luch, A. Validation and application of an LC-MS/MS method for the determination of cyclic oligomers originating from polyamide 6 and polyamide 66 in food simulant. Food Addit. Contam. Part A 2018, 35, 1410–1420. [Google Scholar] [CrossRef]

- Abe, Y.; Mutsuga, M.; Ohno, H.; Kawamura, Y.; Akiyama, H. Isolation and Quantification of Polyamide Cyclic Oligomers in Kitchen Utensils and Their Migration into Various Food Simulants. PLoS ONE 2016, 11, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Schweighuber, A.; Gall, M.; Fischer, J.; Liu, Y.; Braun, H.; Buchberger, W. Development of an LC-MS method for the semiquantitative determination of polyamide 6 contaminations in polyolefin recyclates. Anal. Bioanal. Cchem. 2021, 413, 1091–1098. [Google Scholar] [CrossRef] [PubMed]

- May, J.C.; Knochenmuss, R.; Fjeldsted, J.C.; McLean, J.A. Resolution of Isomeric Mixtures in Ion Mobility Using a Combined Demultiplexing and Peak Deconvolution Technique. Anal. Chem. 2020, 92, 9482–9492. [Google Scholar] [CrossRef] [PubMed]

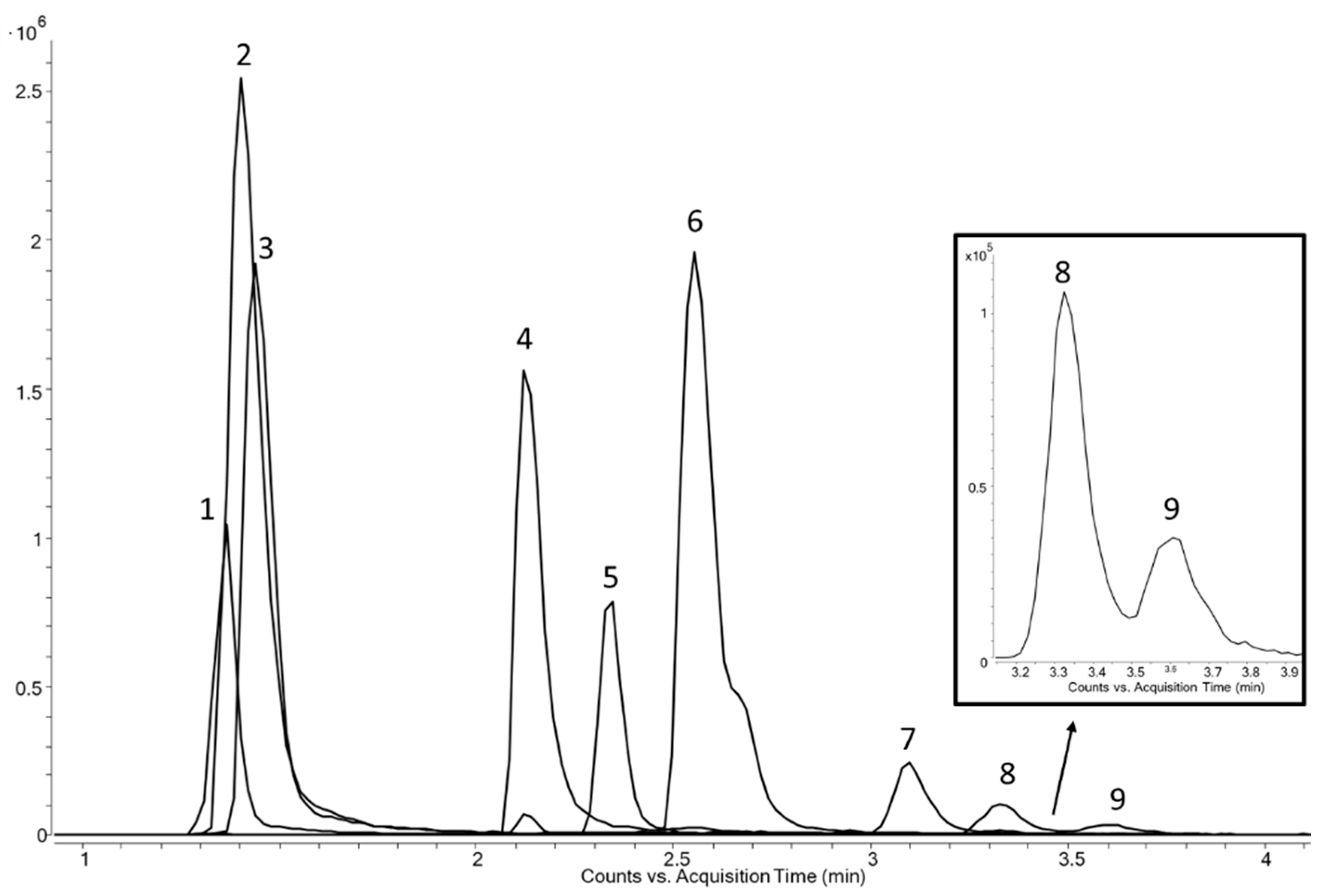

| Polyamide Type | Name | Chemical Formula | Theoretical m/z | Experimental m/z | Retention Time/min |

|---|---|---|---|---|---|

| PA 6 | ε-caprolactam, Azepan-2-one | C6H11NO | 114.0919 | 114.0907 | 1.723 |

| caprolactam cyclic dimer, 1,8-Diazacyclotetra-decane-2,9-dione | C12H22N2O2 | 227.1760 | 227.1773 | 2.119 | |

| caprolactam cyclic trimer, 1,8,15-Triazacyclo-heneicosane-2,9,16-trione | C18H33N3O3 | 340.2600 | 340.2591 | 2.326 | |

| caprolactam cyclic tetramer, 1,8,15,22-Tetraazacyclo-octacosane-2,9,16,23-tetrone | C24H44N4O4 | 453.3441 | 453.3452 | 2.552 | |

| caprolactam cyclic pentamer, 1,8,15,22,29-Pentaazacyclopenta-triacontane-2,9,16,23,30-pentone | C30H55N5O5 | 566.3890 | 566.4271 | 3.098 | |

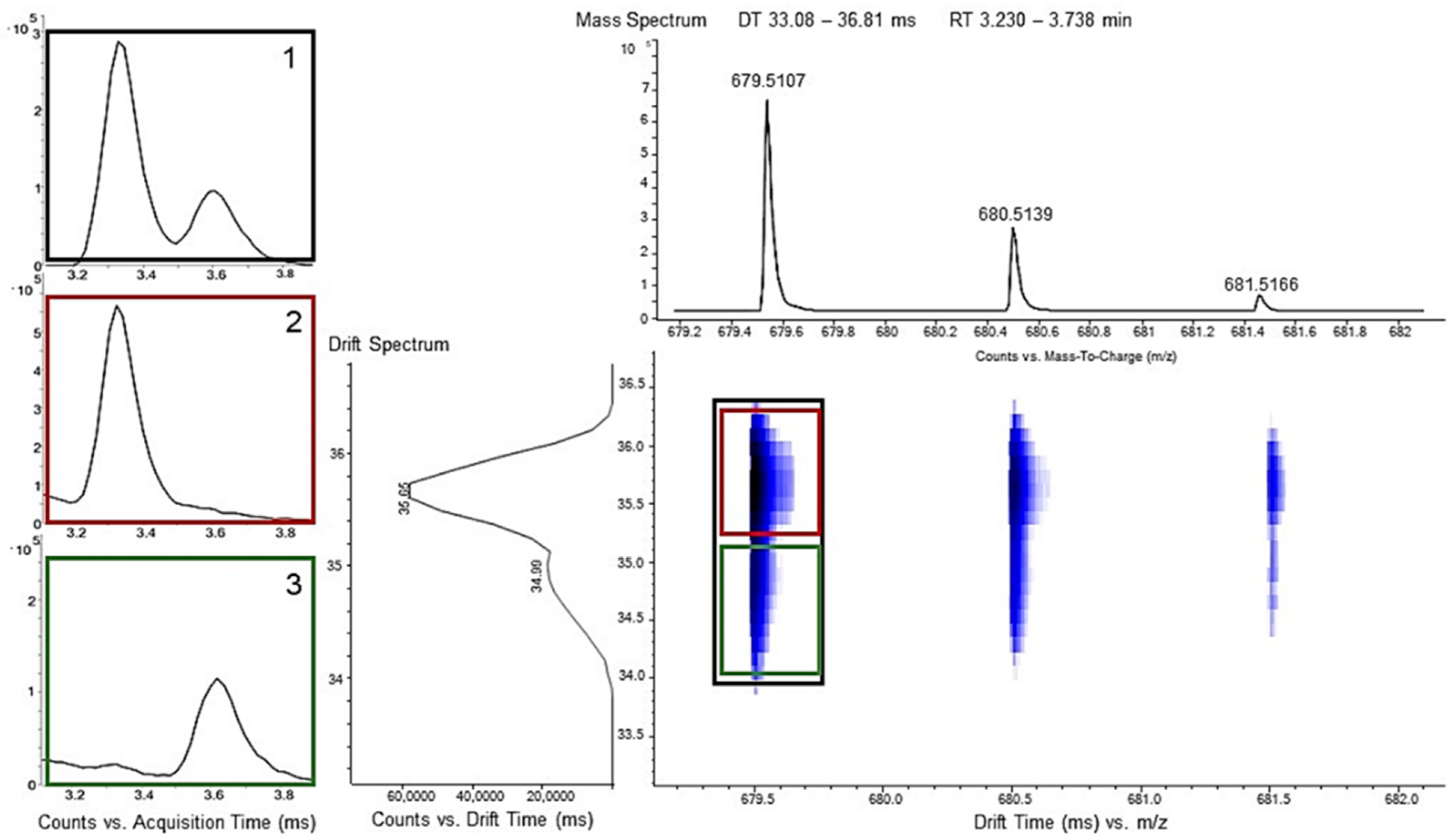

| caprolactam cyclic hexamer, 1,8,15,22,29,36- Hexaazacyclodotetracontane-2,9,16,23,30,37-hexone | C36H66N6O6 | 679.4339 | 679.5105 | 3.606 | |

| PA 6.6 | 1,7-Diazacyclotetra-decane-8,14-dione | C12H22N2O2 | 227.1760 | 227.1770 | 2.119 |

| 1,7,15,21-Tetraazacyclo-octacosane-8,14,22,28-tetrone | C24H44N4O4 | 453.3441 | 453.3449 | 2.683 | |

| 1,7,15,21,29,35- Hexaazacyclodotetracontane-8,14,22,28,36,42-hexone | C36H66N6O6 | 679.4339 | 679.5112 | 3.324 | |

| PA 12 | laurolactam, Azacyclcotridecane-2-one | C12H23NO | 198.1858 | 198.1860 | 1.440 |

| 1,14-diazacyclohexacosane-2,15-dione | C24H46N2O2 | 395.3638 | 395.3635 | 1.403 | |

| 1,14,27-triazacyclononatriacontane-2,15,28-trione | C36H69N3O3 | 592.5417 | 592.5404 | 1.365 |

| PA 6 | PA 6.6 | |

|---|---|---|

| cyclic dimer theoretical m/z: 227.176 |  |  |

| cyclic tetramer theoretical m/z: 453.344 |  |  |

| cyclic hexamer theoretical m/z: 679.512 |  |  |

| m/z | Polyamide Grade | Retention Time/min | Drift Time/ms | DTCCSN2/Å2 |

|---|---|---|---|---|

| 227.1760 (cyclic dimer) | 6 | 2.13 | 19.87 | 150.4 |

| 6.6 | 2.13 | 20.83 | 157.8 | |

| 340.260 (cyclic trimer) | 6 | 2.34 | 23.93 | 178.8 |

| 453.3441 (cyclic tetramer) | 6 | 2.56 | 28.35 | 209.6 |

| 6.6 | 2.56 | 29.49 | 214.7 | |

| 566.3890 (cyclic pentamer) | 6 | 3.10 | 31.47 | 231.5 |

| 679.4339 (cyclic hexamer) | 6 | 3.61 | 34.79 | 255.1 |

| 6.6 | 3.33 | 35.67 | 261.6 | |

| 198.1858 | 12 | 1.45 | 19.46 | 148.5 |

| 395.3638 | 12 | 1.41 | 27.23 | 202.0 |

| 592.5417 | 12 | 1.37 | 33.9 | 249.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schweighuber, A.; Fischer, J.; Buchberger, W. Differentiation of Polyamide 6, 6.6, and 12 Contaminations in Polyolefin-Recyclates Using HPLC Coupled to Drift-Tube Ion-Mobility Quadrupole Time-of-Flight Mass Spectrometry. Polymers 2021, 13, 2032. https://doi.org/10.3390/polym13122032

Schweighuber A, Fischer J, Buchberger W. Differentiation of Polyamide 6, 6.6, and 12 Contaminations in Polyolefin-Recyclates Using HPLC Coupled to Drift-Tube Ion-Mobility Quadrupole Time-of-Flight Mass Spectrometry. Polymers. 2021; 13(12):2032. https://doi.org/10.3390/polym13122032

Chicago/Turabian StyleSchweighuber, Andrea, Jörg Fischer, and Wolfgang Buchberger. 2021. "Differentiation of Polyamide 6, 6.6, and 12 Contaminations in Polyolefin-Recyclates Using HPLC Coupled to Drift-Tube Ion-Mobility Quadrupole Time-of-Flight Mass Spectrometry" Polymers 13, no. 12: 2032. https://doi.org/10.3390/polym13122032