Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review for Assessment of Recycling and Waste Utilization

Abstract

1. Introduction

- Review the potential advantages of polymer concrete composites for the climate, then present a summary of the most important results concerning their mechanical properties, such as compressive, flexural, and splitting tensile strength.

- Examine the durability performance of polymer-modified concrete under a variety of adverse climatic conditions, and study its structural properties based on research findings.

- Collect data from earlier studies that used SCMs and industrial byproducts to partially replace conventional concrete for a better comparative analysis of their mechanical properties and then propose rankings that will help with the selection of SCM products for sustainable concrete production.

2. Common Wastes for Polymer Concrete

2.1. Use of IW-I in Polymer Concrete

2.2. Use of IW-II in Polymer Concrete

2.3. Use of IW-III in Polymer Concrete

2.4. Use of IW-IV in Polymer Concrete

2.5. Use of IW-V in Polymer Concrete

3. Activation Techniques

4. Manufacture of Polymer Concrete

5. Properties of Polymer Concrete

5.1. Properties of Fresh Concrete

5.1.1. Workability

5.1.2. Segregation Index

5.2. Properties of Hardened Concrete

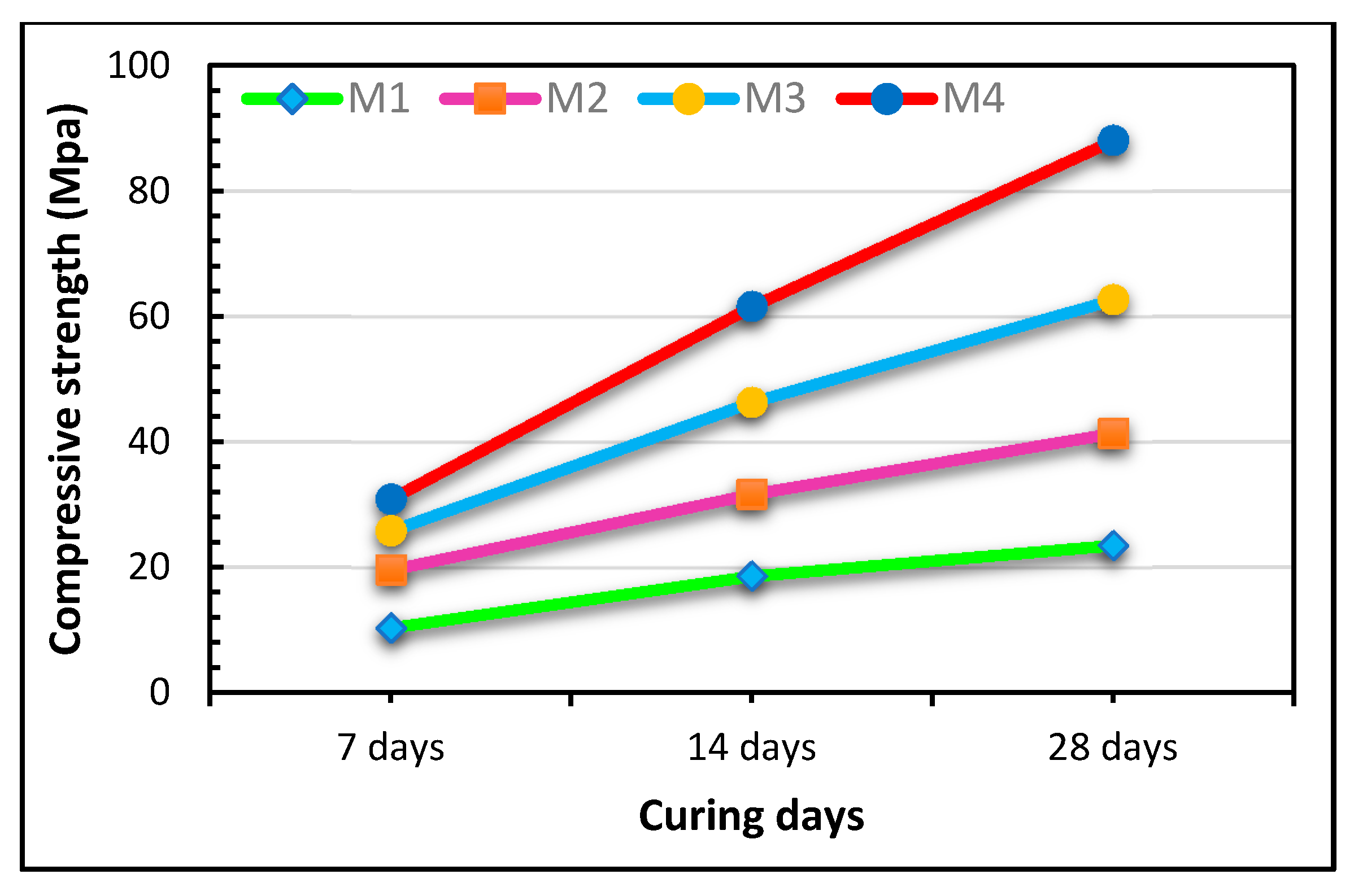

5.2.1. Compressive Strength

5.2.2. Flexural Strength

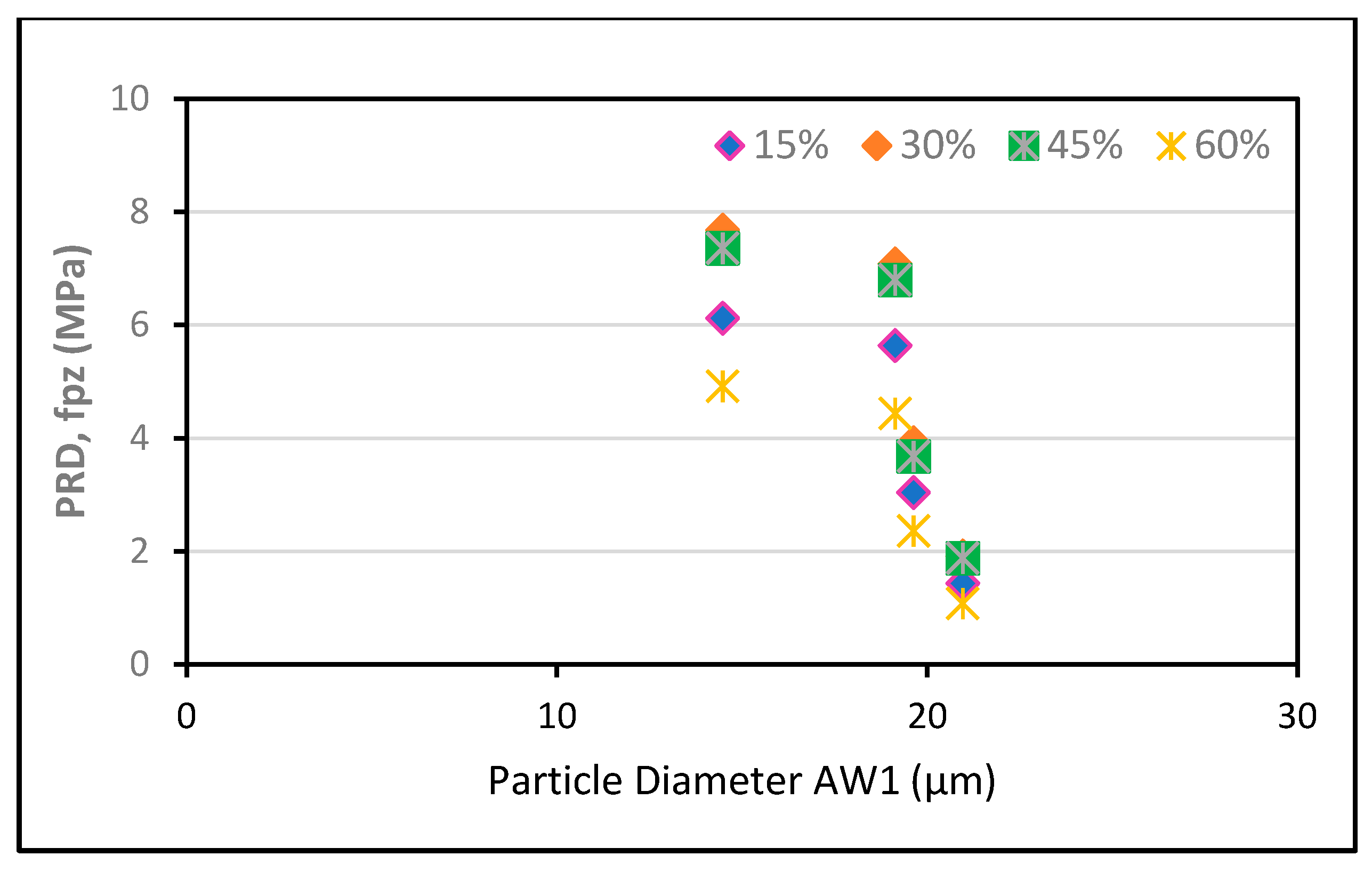

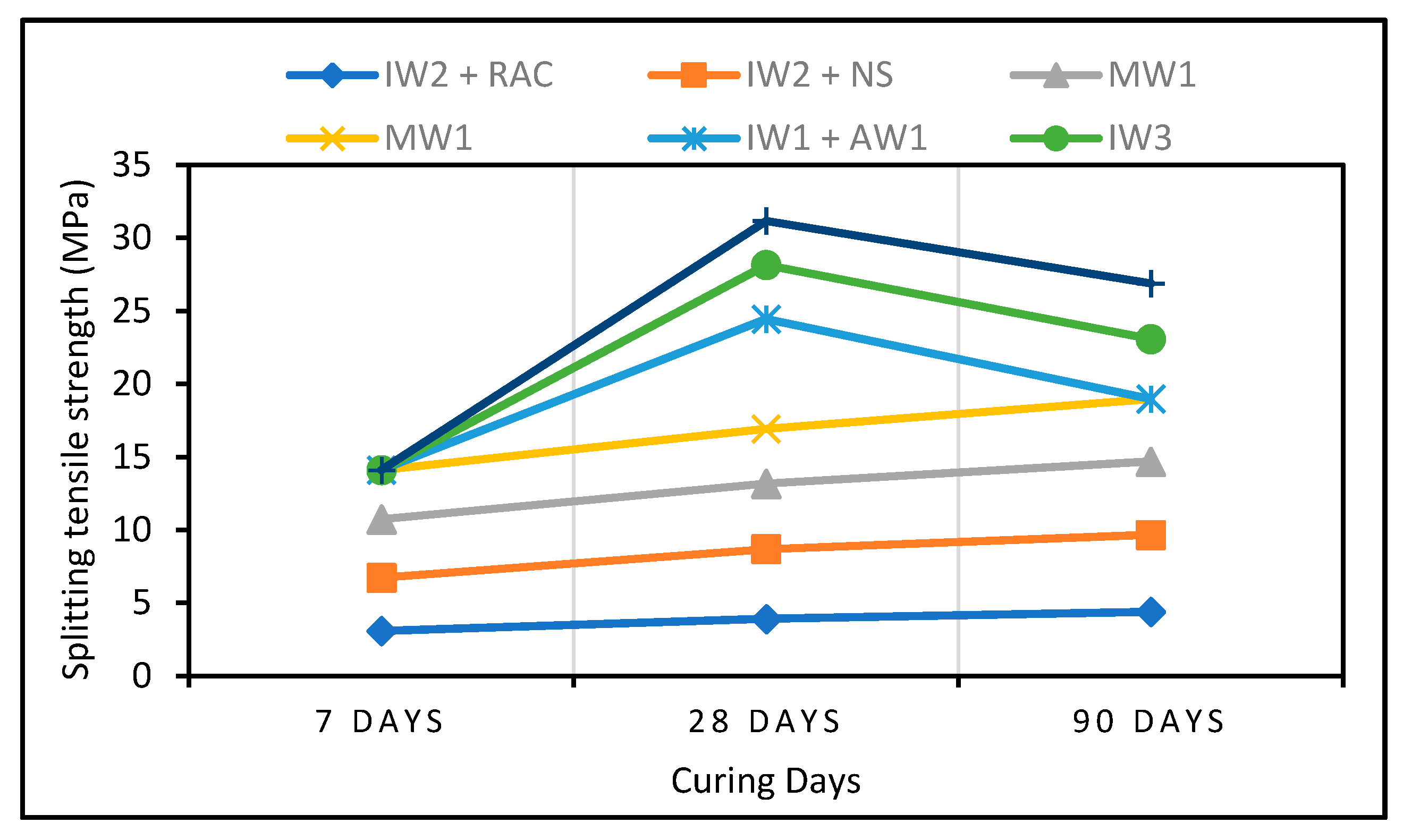

5.2.3. Elastic Modulus and Split Tensile Strength

5.2.4. Shrinkage and Creep

5.3. Durability Properties of Concrete

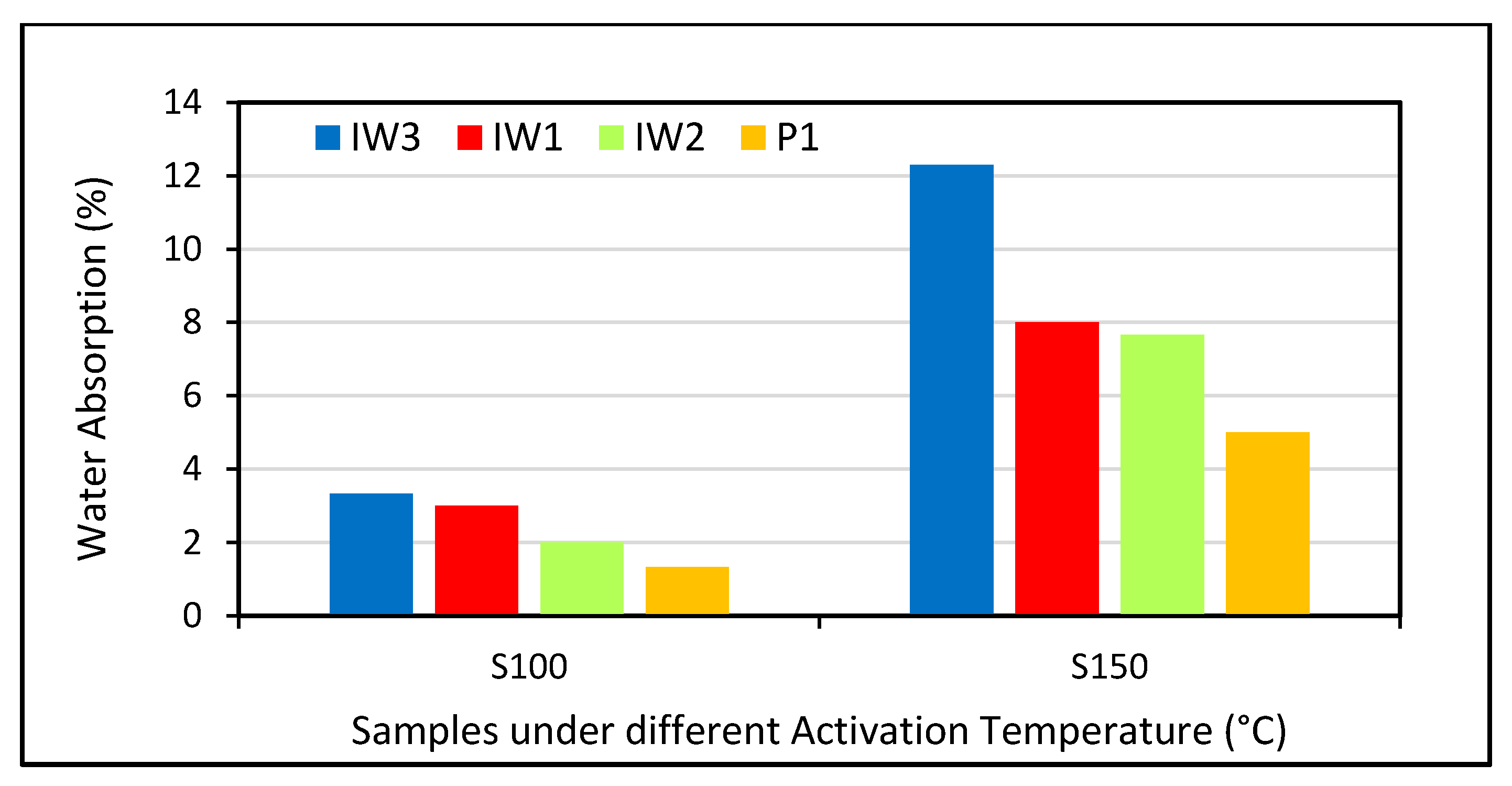

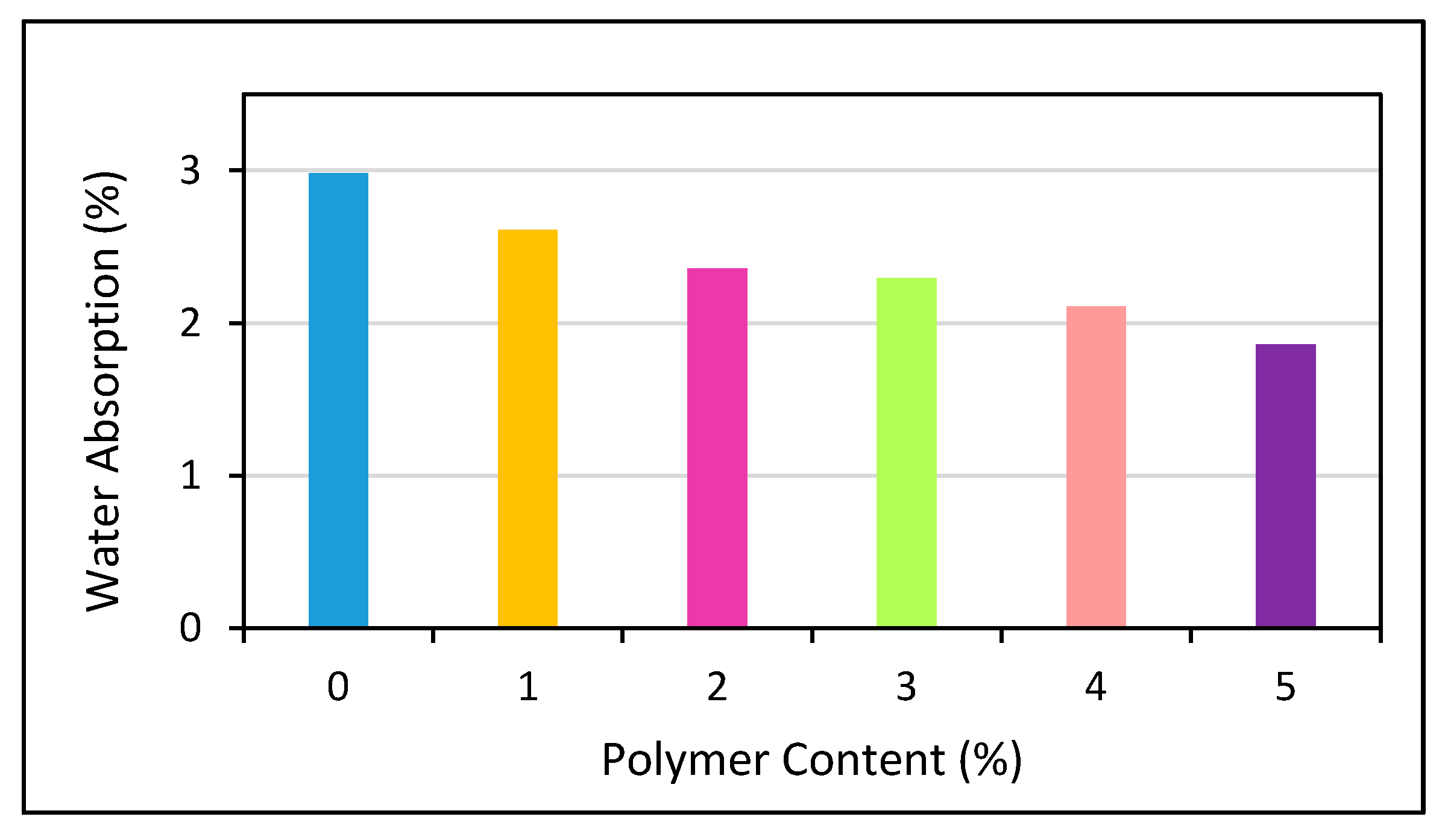

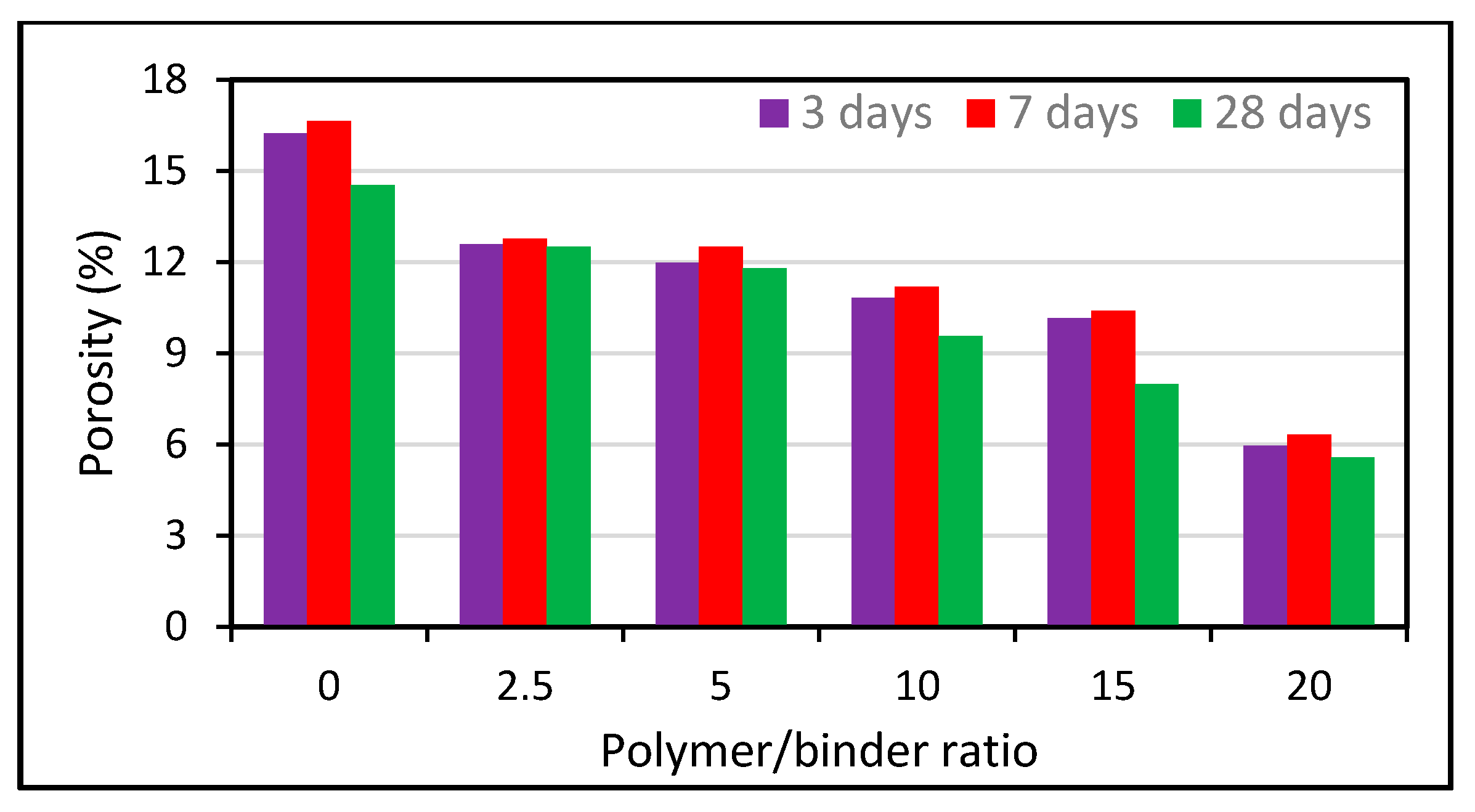

5.3.1. Porosity and Water Absorption

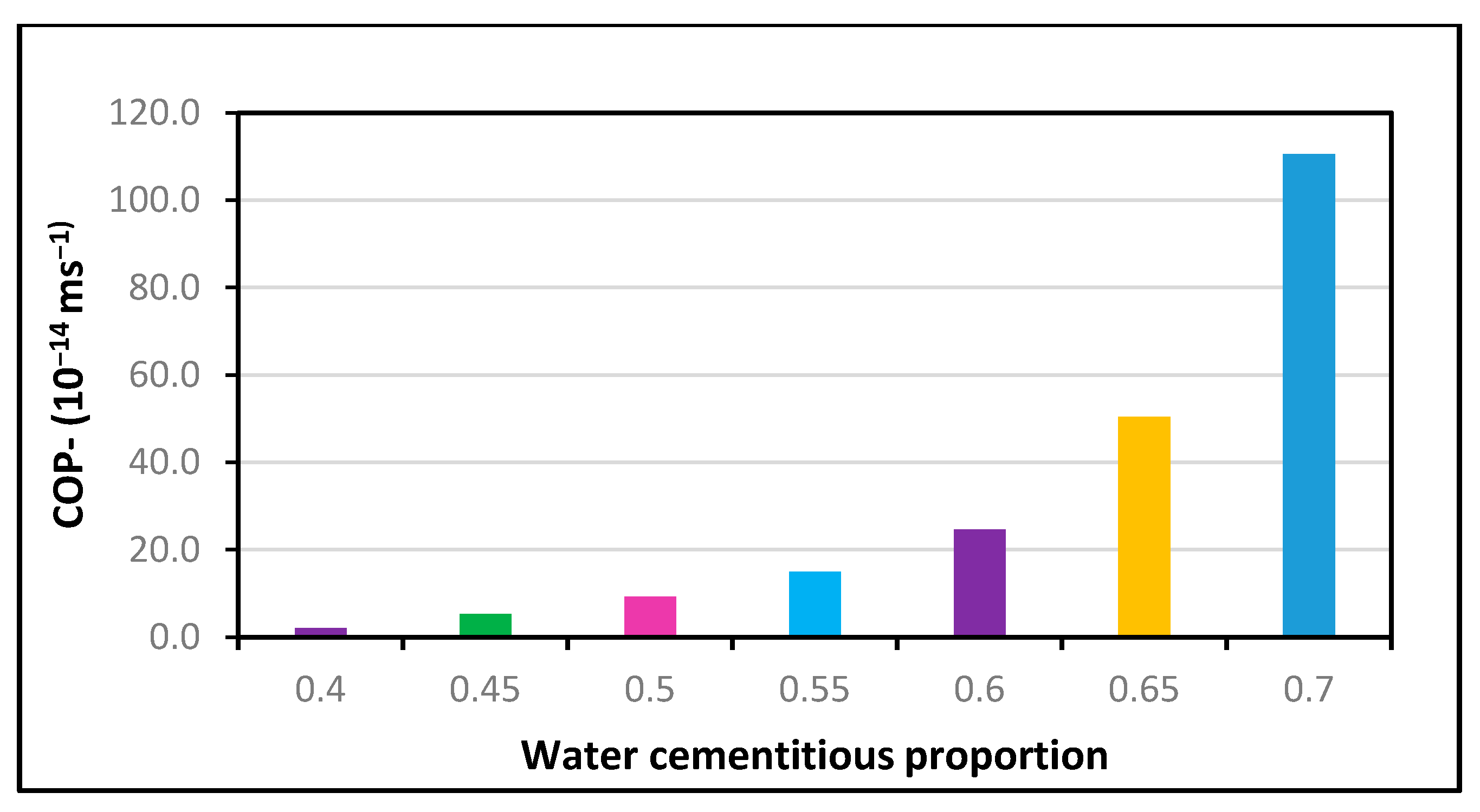

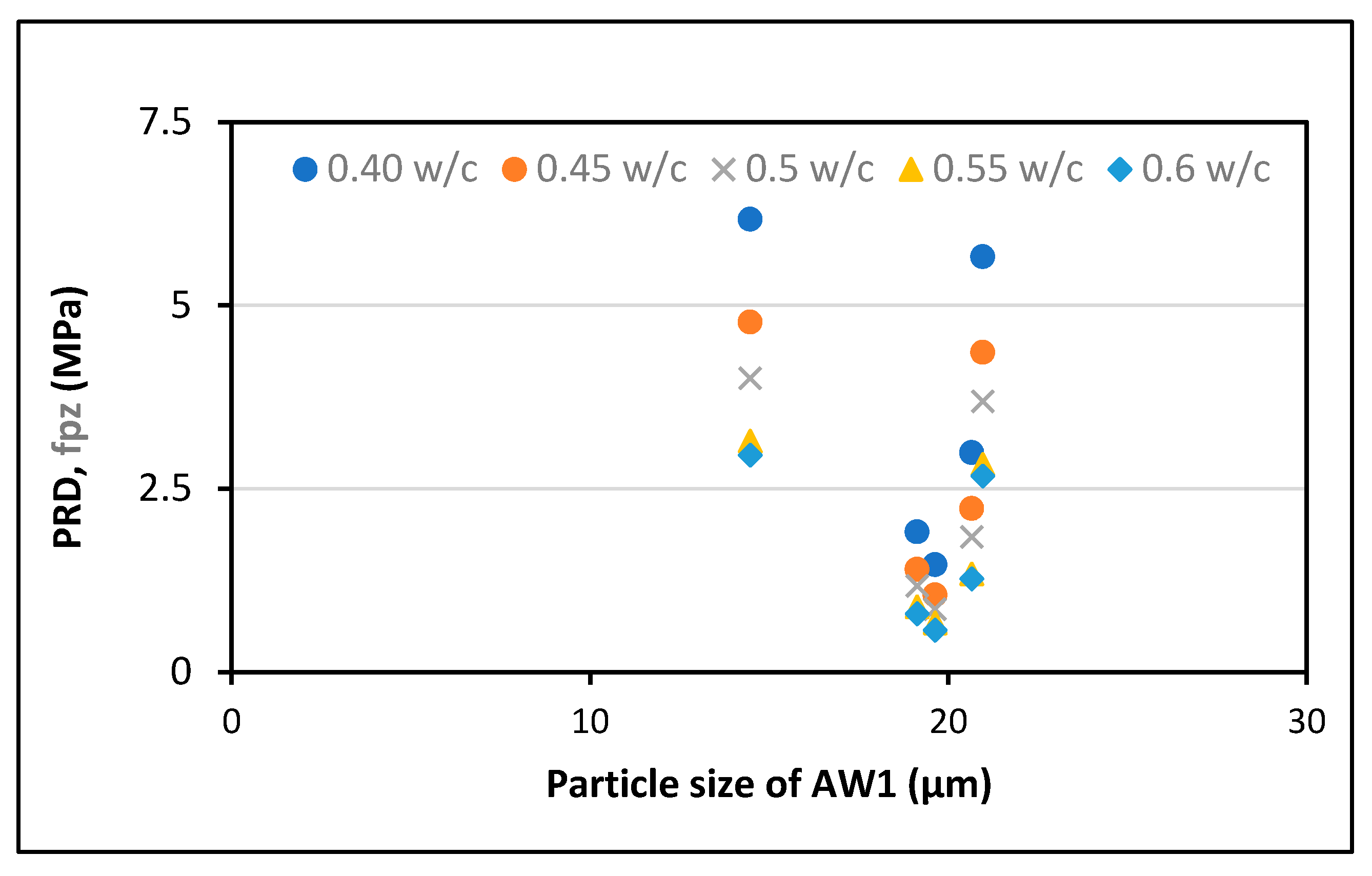

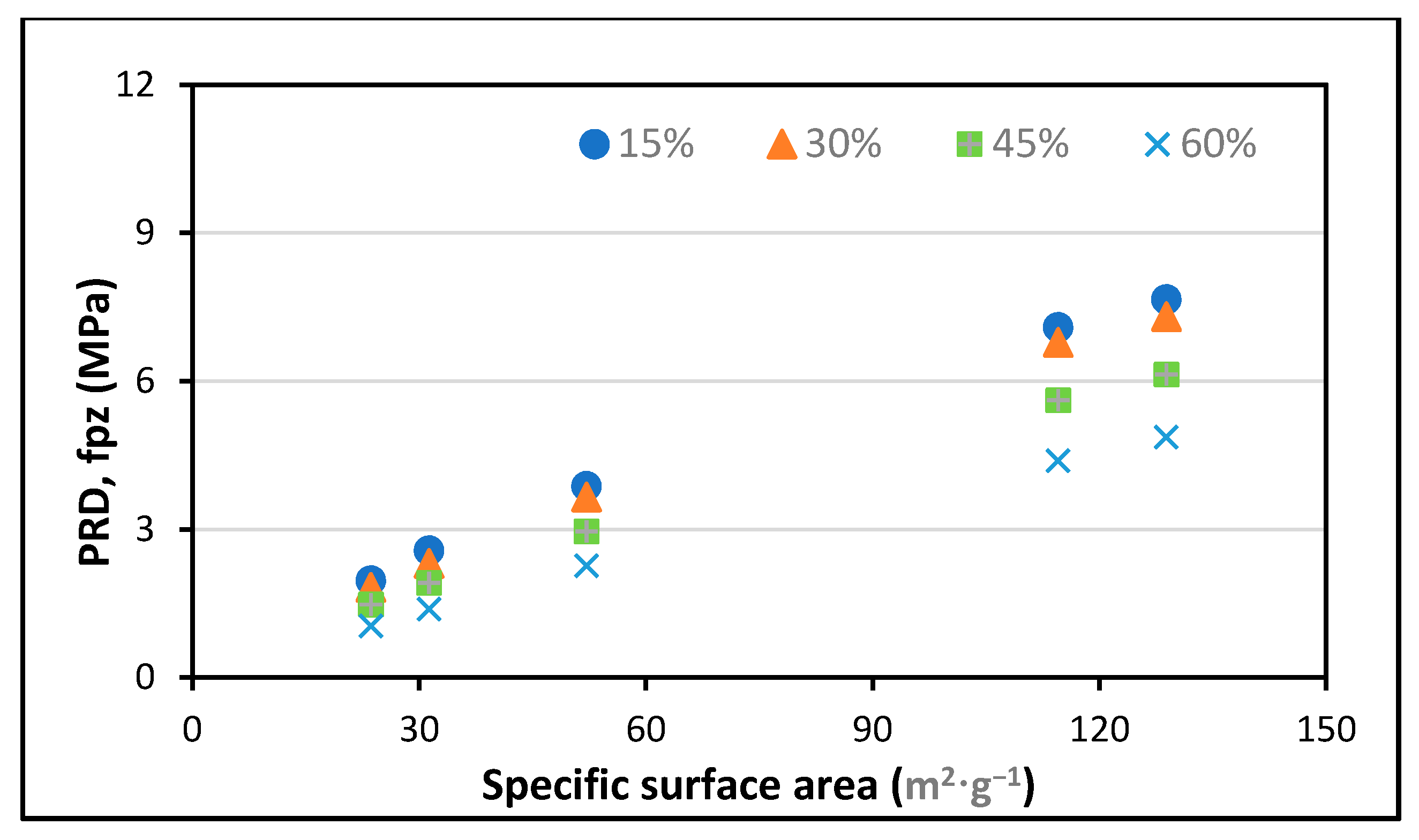

5.3.2. Alkali Silica Reaction and Chloride Penetration

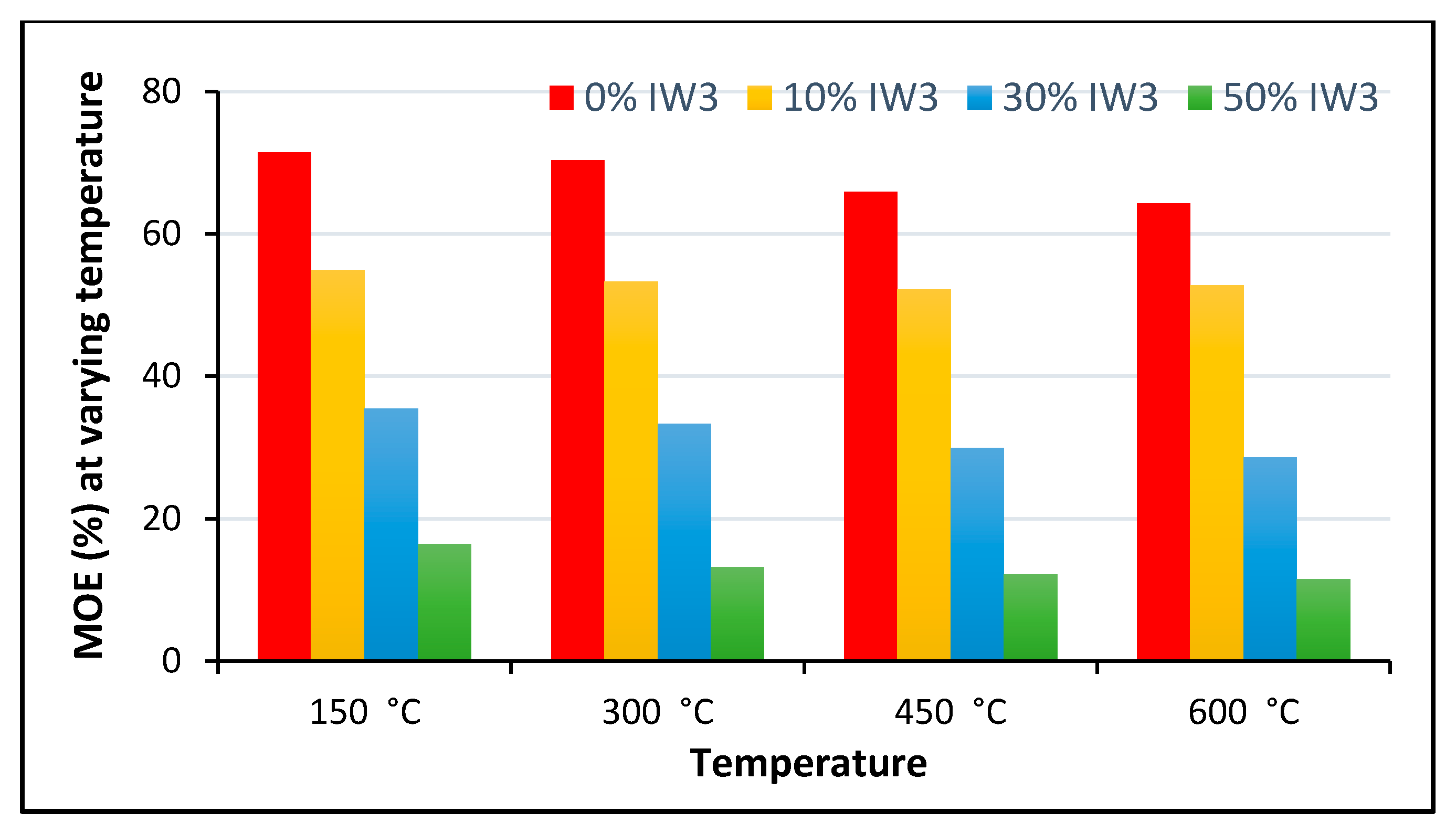

5.3.3. Chemical Attacks and Fire Resistance Behavior

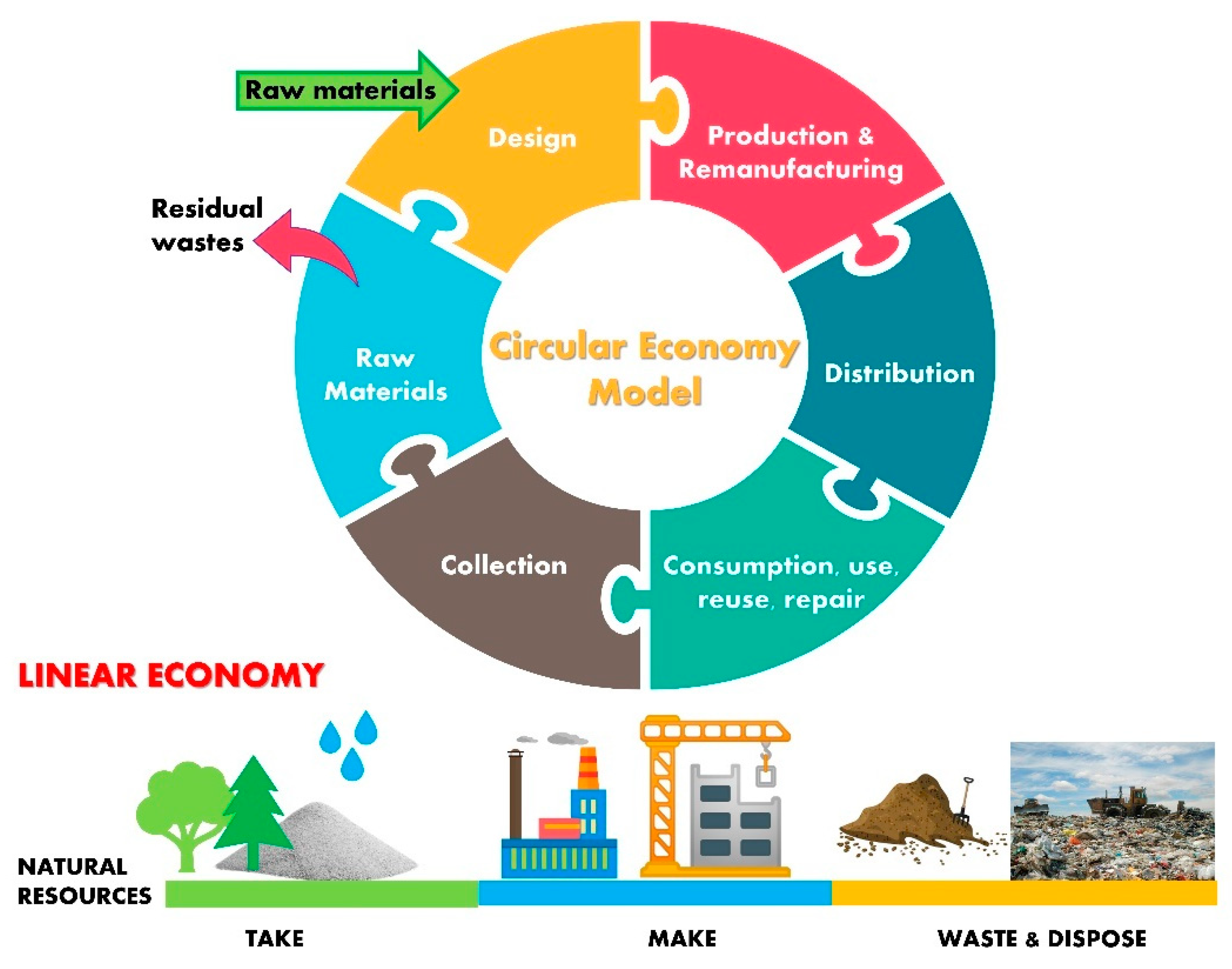

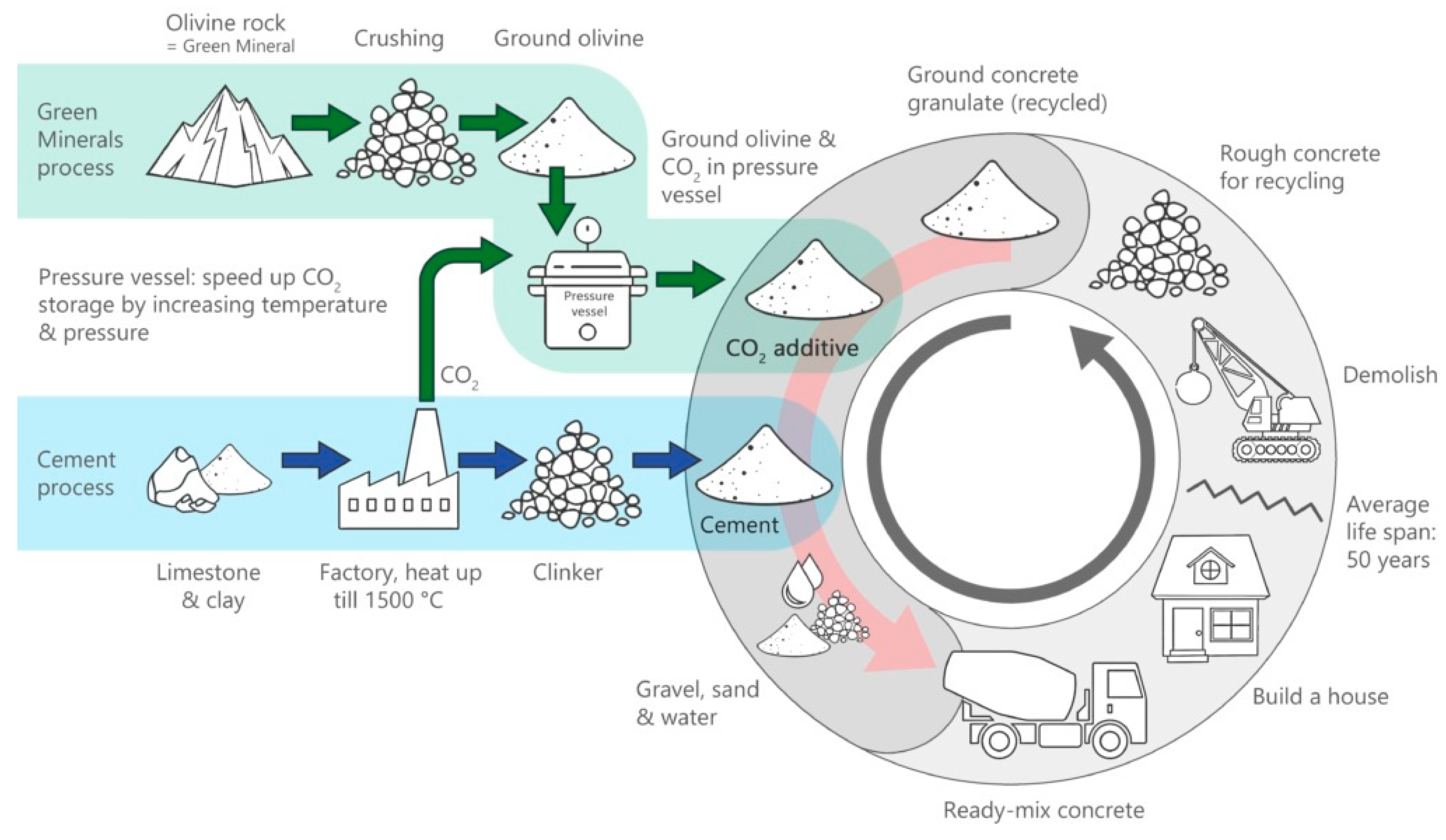

5.4. Circular Economy Model for Polymer Concrete Development

6. Challenges and Future Directions in Polymer Concrete Composites

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AW1 | Rice husk ash (RHA) | CS | Compressive strength |

| AW2 | Corncob ash | SF | Steel Fiber |

| AW3 | Sawdust ash | CIP | Chloride ion penetration |

| IW1 | Fly ash (FA) | WA | Water absorption |

| IW2 | Silica fume (SF) | MOE | Modulus of Elasticity |

| IW3 | Granulated Blast furnace slag (GGBFS) | Seff | Effective surface area |

| MW1 | Waste glass (WG) | BRAC | Bacterial rice husk ash concrete |

| MW2 | Plastics | MW3 | Paper waste |

References

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Anwar, M.; Shah, S.; Alhazmi, H. Recycling and Utilization of Polymers for Road Construction Projects: An Application of the Circular Economy Concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of concrete with recycled aggregates: A circular economy mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Kabir, S.; Al-Shayeb, A.; Khan, I.M. Recycled Construction Debris as Concrete Aggregate for Sustainable Construction Materials. Procedia Eng. 2016, 145, 1518–1525. [Google Scholar] [CrossRef][Green Version]

- Tisserant, A.; Pauliuk, S.; Merciai, S.; Schmidt, J.; Fry, J.; Wood, R.; Tukker, A. Solid Waste and the Circular Economy: A Global Analysis of Waste Treatment and Waste Footprints. J. Ind. Ecol. 2017, 21, 628–640. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. An overview of geopolymers derived from industrial by-products. Constr. Build. Mater. 2016, 127, 183–198. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S. Concrete using agro-waste as fine aggregate for sustainable built environment—A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M. An investigation on Portland cement replaced by high-volume GGBS pastes modified with micro-sized metakaolin subjected to elevated temperatures. Int. J. Sustain. Built Environ. 2017, 6, 91–101. [Google Scholar] [CrossRef]

- Sojobi, A.O. Evaluation of the performance of eco-friendly lightweight interlocking concrete paving units incorporating sawdust wastes and laterite. Cogent Eng. 2016, 3, 1255168. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Autogenous deformation and RH-change in perspective. Cem. Concr. Res. 2001, 31, 1859–1865. [Google Scholar] [CrossRef]

- Thorpe, D.; Zhuge, Y. Advantages and disadvantages in using permeable concrete as a pavement construction material. In Proceedings of the 26th Annual Conference of the Association of Researchers in Construction Management (ARCOM 2010), Leeds, UK, 6–8 September 2010. [Google Scholar]

- Woodward, R.; Duffy, N. Cement and concrete flow analysis in a rapidly expanding economy: Ireland as a case study. Resour. Conserv. Recycl. 2011, 55, 448–455. [Google Scholar] [CrossRef]

- Ma, C.-K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Anuar, K.; Ridzuan, A.; Ismail, S. Strength characteristic of geopolymer concrete containing recycled concrete aggregate. Int. J. Civil Environ. Eng. 2011, 11, 59–62. [Google Scholar]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Jo, B.-W.; Park, S.-K.; Kim, D.-K. Mechanical properties of nano-MMT reinforced polymer composite and polymer concrete. Constr. Build. Mater. 2008, 22, 14–20. [Google Scholar] [CrossRef]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- Rangan, B.V. Geopolymer concrete for environmental protection. Indian Concr. J. 2014, 88, 41–59. [Google Scholar]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Khennane, A.; Kayali, O. Geopolymer concrete-filled pultruded composite beams—Concrete mix design and application. Cem. Concr. Compos. 2015, 58, 1–13. [Google Scholar] [CrossRef]

- Fowler, D. Polymers in concrete: A vision for the 21st century. Cem. Concr. Compos. 1999, 21, 449–452. [Google Scholar] [CrossRef]

- Bedi, R.; Chandra, R.K.; Singh, S.P. Mechanical Properties of Polymer Concrete. J. Compos. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Brockenbrough, T.W.; Patterson, D.N. Fiber reinforced methacrylate polymer concrete. J. Proc. 1982, 79, 322–325. [Google Scholar]

- Mebarkia, S.; Vipulanandan, C. Compressive Behavior of Glass-Fiber Reinforced Polymer Concrete. J. Mater. Civ. Eng. 1992, 4, 91–105. [Google Scholar] [CrossRef]

- Sett, K.; Vipulanandan, C. Properties of polyester polymer concrete with glass and carbon fibers. Mater. J. 2004, 101, 30–41. [Google Scholar]

- Rebeiz, K. Precast use of polymer concrete using unsaturated polyester resin based on recycled PET waste. Constr. Build. Mater. 1996, 10, 215–220. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Dharmarajan, N.; Ching, E. Mechanical behaviour of polymer concrete systems. Mater. Struct. 1988, 21, 268–277. [Google Scholar] [CrossRef]

- Varughese, K.T.; Chaturvedi, B. Fly ash as fine aggregate in polyester based polymer concrete. Cem. Concr. Compos. 1996, 18, 105–108. [Google Scholar] [CrossRef]

- Gorninski, J.; Molin, D.D.; Kazmierczak, C. Strength degradation of polymer concrete in acidic environments. Cem. Concr. Compos. 2007, 29, 637–645. [Google Scholar] [CrossRef]

- Golestaneh, M. Evaluation of Chemical Resistance of Polymer Concrete in Corrosive Environments. Iran. J. Energy Environ. 2013, 4, 304–310. [Google Scholar] [CrossRef]

- Won, J.-P.; Choi, S.-W.; Park, C.-G.; Jang, C.-I. High Strength Polymer-Modified Repair Cementitious Composite for Fire Protection. Polym. Polym. Compos. 2007, 15, 379–388. [Google Scholar] [CrossRef]

- Won, J.-P.; Kang, H.-B.; Lee, S.-J.; Kang, J.-W. Eco-friendly fireproof high-strength polymer cementitious composites. Constr. Build. Mater. 2012, 30, 406–412. [Google Scholar] [CrossRef]

- Park, D.; Ahn, J.; Oh, S.; Song, H.; Noguchi, T. Drying effect of polymer-modified cement for patch-repaired mortar on constraint stress. Constr. Build. Mater. 2009, 23, 434–447. [Google Scholar] [CrossRef]

- Park, D.; Park, S.; Seo, Y.K.; Noguchi, T. Water absorption and constraint stress analysis of polymer-modified cement mortar used as a patch repair material. Constr. Build. Mater. 2011, 28, 819–830. [Google Scholar] [CrossRef]

- Qiao, Y.; Deliwala, J.; Chakravarthula, S.; Kong, X. High-temperature tensile properties of a polymer intercalated/exfoliated cement. Mater. Lett. 2005, 59, 3616–3619. [Google Scholar] [CrossRef]

- Hamasaki, H.; Kim, H.; Noguchi, T. Study on heat release properties of polymer-modified cement mortar. In Proceedings of the Part 1 Effect of the Unit Polymer Weight and Mixed Design, Annual Conference of Architectural Institute of Japan, Sendai, Japan, 26–29 August 2009; pp. 435–436. [Google Scholar]

- Rebeiz, K. Time-temperature properties of polymer concrete using recycled PET. Cem. Concr. Compos. 1995, 17, 119–124. [Google Scholar] [CrossRef]

- Ohama, Y.; Demura, K. Relation between curing conditions and compressive strength of polyester resin concrete. Int. J. Cem. Compos. Light. Concr. 1982, 4, 241–244. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, B.; Lv, J.; Shen, M. Mechanical Properties and Resistance to Acid Corrosion of Polymer Concrete Incorporating Ceramsite, Fly Ash and Glass Fibers. Materials 2019, 12, 2441. [Google Scholar] [CrossRef] [PubMed]

- Sokołowska, J.J.; Woyciechowski, P.P.; Łukowski, P.; Kida, K. Effect of Perlite Waste Powder on Chemical Resistance of Polymer Concrete Composites. Adv. Mater. Res. 2015, 1129, 516–522. [Google Scholar] [CrossRef]

- Garbacz, A.; Sokołowska, J.J. Concrete-like polymer composites with fly ashes—Comparative study. Constr. Build. Mater. 2013, 38, 689–699. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P.; Bombik, A. Physico-Mechanical Properties and Microstructure of Polymer Concrete with Recycled Glass Aggregate. Materials 2018, 11, 1213. [Google Scholar] [CrossRef]

- Sokołowska, J. Technological properties of polymer concrete containing vinyl-ester resin waste mineral powder. J. Build. Chem. 2016, 1, 84–91. [Google Scholar]

- Hu, C.; Han, Y.; Gao, Y.; Zhang, Y.; Li, Z. Property investigation of calcium–silicate–hydrate (C–S–H) gel in cementitious composites. Mater. Charact. 2014, 95, 129–139. [Google Scholar] [CrossRef]

- Saad, S.A.; Nuruddin, M.F.; Shafiq, N.; Ali, M. The Effect of Incineration Temperature to the Chemical and Physical Properties of Ultrafine Treated Rice Husk Ash (UFTRHA) as Supplementary Cementing Material (SCM). Procedia Eng. 2016, 148, 163–167. [Google Scholar] [CrossRef]

- Cordeiro, G.; Filho, R.T.; Tavares, L.; Fairbairn, E. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Huynh, T.-P. Effect of alkali-activator and rice husk ash content on strength development of fly ash and residual rice husk ash-based geopolymers. Constr. Build. Mater. 2015, 101, 1–9. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Abbas, S.; Saleem, M.A.; Munir, M.J.; Khitab, A. Manufacturing of sustainable clay bricks: Utilization of waste sugarcane bagasse and rice husk ashes. Constr. Build. Mater. 2016, 120, 29–41. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Asavapisit, S.; Sombatsompop, K. Properties of autoclaved aerated concrete incorporating rice husk ash as partial replacement for fine aggregate. Cem. Concr. Compos. 2015, 55, 11–16. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Sokrai, P.; Makul, N. Novel ternary blends of Type 1 Portland cement, residual rice husk ash, and limestone powder to improve the properties of self-compacting concrete. Constr. Build. Mater. 2016, 125, 1028–1034. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.-W.; Luhar, I. Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: A review. Compos. Part B Eng. 2019, 175, 107076. [Google Scholar] [CrossRef]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement. Constr. Build. Mater. 2014, 53, 680–691. [Google Scholar] [CrossRef]

- Mohseni, E.; Naseri, F.; Amjadi, R.; Khotbehsara, M.M.; Ranjbar, M.M. Microstructure and durability properties of cement mortars containing nano-TiO2 and rice husk ash. Constr. Build. Mater. 2016, 114, 656–664. [Google Scholar] [CrossRef]

- Zunino, F.; Lopez, M. Decoupling the physical and chemical effects of supplementary cementitious materials on strength and permeability: A multi-level approach. Cem. Concr. Compos. 2016, 65, 19–28. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Filho, R.T.; Tavares, L.M.; Fairbairn, E.D.M.R.; Hempel, S. Influence of particle size and specific surface area on the pozzolanic activity of residual rice husk ash. Cem. Concr. Compos. 2011, 33, 529–534. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Mahmud, H.B. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Constr. Build. Mater. 2010, 24, 2145–2150. [Google Scholar] [CrossRef]

- Zunino, F.; Lopez, M. A methodology for assessing the chemical and physical potential of industrially sourced rice husk ash on strength development and early-age hydration of cement paste. Constr. Build. Mater. 2017, 149, 869–881. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice husk ash blended cement: Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem. Concr. Res. 2006, 36, 264–277. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Filho, R.T.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Le, H.T.; Ludwig, H.-M. Effect of rice husk ash and other mineral admixtures on properties of self-compacting high performance concrete. Mater. Des. 2016, 89, 156–166. [Google Scholar] [CrossRef]

- Nimwinya, E.; Arjharn, W.; Horpibulsuk, S.; Phoo-Ngernkham, T.; Poowancum, A. A sustainable calcined water treatment sludge and rice husk ash geopolymer. J. Clean. Prod. 2016, 119, 128–134. [Google Scholar] [CrossRef]

- Gastaldini, A.; da Silva, M.; Zamberlan, F.; Neto, C.M. Total shrinkage, chloride penetration, and compressive strength of concretes that contain clear-colored rice husk ash. Constr. Build. Mater. 2014, 54, 369–377. [Google Scholar] [CrossRef]

- Jamil, M.; Kaish, A.B.M.A.; Raman, S.N.; Zain, M. Pozzolanic contribution of rice husk ash in cementitious system. Constr. Build. Mater. 2013, 47, 588–593. [Google Scholar] [CrossRef]

- Salazar-Carreño, D.; García-Cáceres, R.G.; Ortíz-Rodriguez, O.O. Laboratory processing of Colombian rice husk for obtaining amorphous silica as concrete supplementary cementing material. Constr. Build. Mater. 2015, 96, 65–75. [Google Scholar] [CrossRef]

- Çakır, Ö.; Sofyanlı, Ö.Ö. Influence of silica fume on mechanical and physical properties of recycled aggregate concrete. HBRC J. 2015, 11, 157–166. [Google Scholar] [CrossRef]

- Choi, P.; Yeon, J.H.; Yun, K.-K. Air-void structure, strength, and permeability of wet-mix shotcrete before and after shotcreting operation: The influences of silica fume and air-entraining agent. Cem. Concr. Compos. 2016, 70, 69–77. [Google Scholar] [CrossRef]

- Jalal, M.; Pouladkhan, A.; Harandi, O.F.; Jafari, D. Comparative study on effects of Class F fly ash, nano silica and silica fume on properties of high performance self compacting concrete. Constr. Build. Mater. 2015, 94, 90–104. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Papa, E.; Medri, V.; Kpogbemabou, D.; Morinière, V.; Laumonier, J.; Vaccari, A.; Rossignol, S. Porosity and insulating properties of silica-fume based foams. Energy Build. 2016, 131, 223–232. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Saraya, M. Study physico-chemical properties of blended cements containing fixed amount of silica fume, blast furnace slag, basalt and limestone, a comparative study. Constr. Build. Mater. 2014, 72, 104–112. [Google Scholar] [CrossRef]

- Tamimi, A.; Hassan, N.M.; Fattah, K.; Talachi, A. Performance of cementitious materials produced by incorporating surface treated multiwall carbon nanotubes and silica fume. Constr. Build. Mater. 2016, 114, 934–945. [Google Scholar] [CrossRef]

- Li, Z.; Venkata, H.K.; Rangaraju, P.R. Influence of silica flour–silica fume combination on the properties of high performance cementitious mixtures at ambient temperature curing. Constr. Build. Mater. 2015, 100, 225–233. [Google Scholar] [CrossRef]

- Sobhani, J.; Najimi, M. Electrochemical impedance behavior and transport properties of silica fume contained concrete. Constr. Build. Mater. 2013, 47, 910–918. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, B.; Yan, P. Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Constr. Build. Mater. 2016, 105, 82–93. [Google Scholar] [CrossRef]

- Khatri, R.; Sirivivatnanon, V.; Gross, W. Effect of different supplementary cementitious materials on mechanical properties of high performance concrete. Cem. Concr. Res. 1995, 25, 209–220. [Google Scholar] [CrossRef]

- Buil, M.; Acker, P. Creep of a silica fume concrete. Cem. Concr. Res. 1985, 15, 463–466. [Google Scholar] [CrossRef]

- De Larrard, F.; Bostvironnois, J.-L. On the long–term strength losses of silica–fume high–strength concretes. Mag. Concr. Res. 1991, 43, 109–119. [Google Scholar] [CrossRef]

- Sandberg, P. Chloride Initiated Reinforcement Corrosion in Marine Concrete; Lund University: Lund, Sweden, 1998. [Google Scholar]

- Chen, R.; Li, Y.; Xiang, R.; Li, S. Effect of particle size of fly ash on the properties of lightweight insulation materials. Constr. Build. Mater. 2016, 123, 120–126. [Google Scholar] [CrossRef]

- Chousidis, N.; Ioannou, I.; Rakanta, E.; Koutsodontis, C.; Batis, G. Effect of fly ash chemical composition on the reinforcement corrosion, thermal diffusion and strength of blended cement concretes. Constr. Build. Mater. 2016, 126, 86–97. [Google Scholar] [CrossRef]

- Fan, W.-J.; Wang, X.-Y.; Park, K.-B. Evaluation of the Chemical and Mechanical Properties of Hardening High-Calcium Fly Ash Blended Concrete. Materials 2015, 8, 5933–5952. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Shaikh, F.U.A.; Hao, Y.; Hao, H. Synthesis of high strength ambient cured geopolymer composite by using low calcium fly ash. Constr. Build. Mater. 2016, 125, 809–820. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Uy, B.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016, 73, 136–146. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Bin Mahmud, H.; Jumaat, M.Z. Engineering properties of lightweight aggregate concrete containing limestone powder and high volume fly ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, Y.; Ye, L.; Yang, C. Mechanical behaviours of green hybrid fibre-reinforced cementitious composites. Constr. Build. Mater. 2015, 95, 152–163. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Salem, H.A. Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 123, 581–593. [Google Scholar] [CrossRef]

- Park, Y.; Abolmaali, A.; Kim, Y.H.; Ghahremannejad, M. Compressive strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Constr. Build. Mater. 2016, 118, 43–51. [Google Scholar] [CrossRef]

- Thomas, M. Optimizing the Use of Fly Ash in Concrete. Portl. Cem. Assoc. 2007, 24. [Google Scholar]

- Madhavi, T.C.; Raju, L.S.; Mathur, D. Durabilty and strength properties of high volume fly ash concrete. J. Civil Eng. Res. 2014, 4, 7–11. [Google Scholar]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Wang, S.; Baxter, L. Comprehensive study of biomass fly ash in concrete: Strength, microscopy, kinetics and durability. Fuel Process. Technol. 2007, 88, 1165–1170. [Google Scholar] [CrossRef]

- Neupane, K. Fly ash and GGBFS based powder-activated geopolymer binders: A viable sustainable alternative of portland cement in concrete industry. Mech. Mater. 2016, 103, 110–122. [Google Scholar] [CrossRef]

- Rakhimova, N.; Rakhimov, R. Individual and combined effects of Portland cement-based hydrated mortar components on alkali-activated slag cement. Constr. Build. Mater. 2014, 73, 515–522. [Google Scholar] [CrossRef]

- Li, Y.; Qiao, C.; Ni, W. Green concrete with ground granulated blast-furnace slag activated by desulfurization gypsum and electric arc furnace reducing slag. J. Clean. Prod. 2020, 269, 122212. [Google Scholar] [CrossRef]

- Çakır, Ö.; Aköz, F.; Çakır, Ö.; Aköz, F. Effect of curing conditions on the mortars with and without GGBFS. Constr. Build. Mater. 2008, 22, 308–314. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Chidiac, S.; Panesar, D. Evolution of mechanical properties of concrete containing ground granulated blast furnace slag and effects on the scaling resistance test at 28 days. Cem. Concr. Compos. 2008, 30, 63–71. [Google Scholar] [CrossRef]

- Shariq, M.; Prasad, J.; Masood, A. Effect of GGBFS on time dependent compressive strength of concrete. Constr. Build. Mater. 2010, 24, 1469–1478. [Google Scholar] [CrossRef]

- Yim, H.J.; Kim, J.H.; Han, S.H.; Kwak, H.-G. Influence of Portland cement and ground-granulated blast-furnace slag on bleeding of fresh mix. Constr. Build. Mater. 2015, 80, 132–140. [Google Scholar] [CrossRef]

- Wiebenga, J. Durability of concrete structures along the North Sea coast of the Netherlands. Spec. Publ. 1980, 65, 437–452. [Google Scholar]

- Szcześniak, A.; Zychowicz, J.; Stolarski, A. Influence of Fly Ash Additive on the Properties of Concrete with Slag Cement. Materials 2020, 13, 3265. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, P.; Morales, M.P.; Letelier, V.; Mendivil, M.A. Fired clay bricks made by adding wastes: Assessment of the impact on physical, mechanical and thermal properties. Constr. Build. Mater. 2016, 241–252. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Seabra, M.P.; Labrincha, J. Waste glass from end-of-life fluorescent lamps as raw material in geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef]

- Wang, X.; Feng, D.; Zhang, B.; Li, Z.; Li, C.; Zhu, Y. Effect of KNO3 on the microstruture and physical properties of glass foam from solid waste glass and SiC powder. Mater. Lett. 2016, 169, 21–23. [Google Scholar] [CrossRef]

- Wei, Y.-L.; Cheng, S.-H.; Ko, G.-W. Effect of waste glass addition on lightweight aggregates prepared from F-class coal fly ash. Constr. Build. Mater. 2016, 112, 773–782. [Google Scholar] [CrossRef]

- Yu, R.; van Onna, D.; Spiesz, P.; Yu, Q.; Brouwers, H. Development of Ultra-Lightweight Fibre Reinforced Concrete applying expanded waste glass. J. Clean. Prod. 2016, 112, 690–701. [Google Scholar] [CrossRef]

- Karimaei, M.; Dabbaghi, F.; Sadeghi-Nik, A.; Dehestani, M. Mechanical performance of green concrete produced with untreated coal waste aggregates. Constr. Build. Mater. 2020, 233, 117264. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Ramachandran, D. Green Concrete mix using solid waste and nanoparticles as alternatives—A review. Constr. Build. Mater. 2018, 162, 96–103. [Google Scholar] [CrossRef]

- Calmon, J.L.; Sauer, A.S.; Vieira, G.L.; Teixeira, J.E.S.L. Effects of windshield waste glass on the properties of structural repair mortars. Cem. Concr. Compos. 2014, 53, 88–96. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Igarashi, T. Performance of pavements incorporating waste glass: The current state of the art. Renew. Sustain. Energy Rev. 2016, 64, 211–236. [Google Scholar] [CrossRef]

- Juoi, J.M.; Arudra, D.; Rosli, Z.M.; Hussain, K.; Jaafar, A.J. Microstructural properties of glass composite material made from incinerated scheduled waste slag and soda lime silicate (SLS) waste glass. J. Non Cryst. Solids 2013, 367, 8–13. [Google Scholar] [CrossRef]

- Pastor, J.; García, L.; Quintana, S.; Peña, J. Glass reinforced concrete panels containing recycled tyres: Evaluation of the acoustic properties of for their use as sound barriers. Constr. Build. Mater. 2014, 54, 541–549. [Google Scholar] [CrossRef]

- Kim, J.; Moon, J.-H.; Shim, J.W.; Sim, J.; Lee, H.-G.; Zi, G. Durability properties of a concrete with waste glass sludge exposed to freeze-and-thaw condition and de-icing salt. Constr. Build. Mater. 2014, 66, 398–402. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. A novel polymer concrete made with recycled glass aggregates, fly ash and metakaolin. Constr. Build. Mater. 2013, 41, 146–151. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Madandoust, R.; Ghavidel, R. Mechanical properties of concrete containing waste glass powder and rice husk ash. Biosyst. Eng. 2013, 116, 113–119. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Day, R.L. Pozzolanic reaction in the presence of chemical activators: Part I. Reaction kinetics. Cem. Concr. Res. 2000, 30, 51–58. [Google Scholar] [CrossRef]

- Sajedi, F.; Razak, H.A. Effects of thermal and mechanical activation methods on compressive strength of ordinary Portland cement–slag mortar. Mater. Des. 2011, 32, 984–995. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef]

- Shi, C.; Day, R.L. Comparison of different methods for enhancing reactivity of pozzolans. Cem. Concr. Res. 2001, 31, 813–818. [Google Scholar] [CrossRef]

- Qian, J.; Shi, C.; Wang, Z. Activation of blended cements containing fly ash. Cem. Concr. Res. 2001, 31, 1121–1127. [Google Scholar] [CrossRef]

- Ibrahim, M.; Johari, M.A.M.; Rahman, M.K.; Maslehuddin, M. Effect of alkaline activators and binder content on the properties of natural pozzolan-based alkali activated concrete. Constr. Build. Mater. 2017, 147, 648–660. [Google Scholar] [CrossRef]

- Vayghan, A.G.; Khaloo, A.; Rajabipour, F. The effects of a hydrochloric acid pre-treatment on the physicochemical properties and pozzolanic performance of rice husk ash. Cem. Concr. Compos. 2013, 39, 131–140. [Google Scholar] [CrossRef]

- Wu, Z.; Naik, T.R. Properties of concrete produced from multicomponent blended cements. Cem. Concr. Res. 2002, 32, 1937–1942. [Google Scholar] [CrossRef]

- Živica, V. Effects of type and dosage of alkaline activator and temperature on the properties of alkali-activated slag mixtures. Constr. Build. Mater. 2007, 21, 1463–1469. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Effect of admixtures on properties of alkali-activated slag concrete. Cem. Concr. Res. 2000, 30, 1367–1374. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effects of TiO2 nanoparticles on physical, thermal and mechanical properties of concrete using ground granulated blast furnace slag as binder. Mater. Sci. Eng. A 2011, 528, 2085–2092. [Google Scholar] [CrossRef]

- Kawashima, S.; Hou, P.; Corr, D.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Antiohos, S.; Papageorgiou, A.; Papadakis, V.; Tsimas, S. Influence of quicklime addition on the mechanical properties and hydration degree of blended cements containing different fly ashes. Constr. Build. Mater. 2008, 22, 1191–1200. [Google Scholar] [CrossRef]

- Antiohos, S.; Tsimas, S. Activation of fly ash cementitious systems in the presence of quicklime: Part I. Compressive strength and pozzolanic reaction rate. Cem. Concr. Res. 2004, 34, 769–779. [Google Scholar] [CrossRef]

- Federico, L.; Chidiac, S. Waste glass as a supplementary cementitious material in concrete—Critical review of treatment methods. Cem. Concr. Compos. 2009, 31, 606–610. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Gastaldini, A.; Isaia, G.; Gomes, N.; Sperb, J. Chloride penetration and carbonation in concrete with rice husk ash and chemical activators. Cem. Concr. Compos. 2007, 29, 176–180. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P. Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; De Gutiérrez, R.M.; Provis, J.L.; Delvasto, S. Activation of Metakaolin/Slag Blends Using Alkaline Solutions Based on Chemically Modified Silica Fume and Rice Husk Ash. Waste Biomass Valoriz. 2011, 3, 99–108. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, S.; Mehrotra, S. Towards sustainable solutions for fly ash through mechanical activation. Resour. Conserv. Recycl. 2007, 52, 157–179. [Google Scholar] [CrossRef]

- Blanco, F.; Garcia, M.; Ayala, J. Variation in fly ash properties with milling and acid leaching. Fuel 2005, 84, 89–96. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem. Concr. Res. 2005, 35, 1984–1992. [Google Scholar] [CrossRef]

- De Vargas, A.S.; Molin, D.C.D.; Vilela, A.; da Silva, F.J.; Pavão, B.; Veit, H.M. The effects of Na2O/SiO2molar ratio, curing temperature and age on compressive strength, morphology and microstructure of alkali-activated fly ash-based geopolymers. Cem. Concr. Compos. 2011, 33, 653–660. [Google Scholar] [CrossRef]

- Rashad, A.M.; Khalil, M.H. A preliminary study of alkali-activated slag blended with silica fume under the effect of thermal loads and thermal shock cycles. Constr. Build. Mater. 2013, 40, 522–532. [Google Scholar] [CrossRef]

- Shatat, M. Hydration behavior and mechanical properties of blended cement containing various amounts of rice husk ash in presence of metakaolin. Arab. J. Chem. 2016, 9, S1869–S1874. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Wang, H.; Ye, H. Influence of rice husk ash on strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2017, 149, 621–628. [Google Scholar] [CrossRef]

- Müller, H.S.; Breiner, R.; Moffatt, J.S.; Haist, M. Design and Properties of Sustainable Concrete. Procedia Eng. 2014, 95, 290–304. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Hillemeier, B. Combined effect of fine fly ash and packing density on the properties of high performance concrete: An experimental approach. Constr. Build. Mater. 2014, 58, 225–233. [Google Scholar] [CrossRef]

- Kar, A.; Ray, I.; Unnikrishnan, A.; Davalos, J.F. Microanalysis and optimization-based estimation of C–S–H contents of cementitious systems containing fly ash and silica fume. Cem. Concr. Compos. 2012, 34, 419–429. [Google Scholar] [CrossRef]

- Hua, S.; Wang, K.; Yao, X. Developing high performance phosphogypsum-based cementitious materials for oil-well cementing through a step-by-step optimization method. Cem. Concr. Compos. 2016, 72, 299–308. [Google Scholar] [CrossRef]

- Proske, T.; Hainer, S.; Rezvani, M.; Graubner, C.-A. Eco-friendly concretes with reduced water and cement contents—Mix design principles and laboratory tests. Cem. Concr. Res. 2013, 51, 38–46. [Google Scholar] [CrossRef]

- Cepuritis, R.; Jacobsen, S.; Onnela, T. Sand production with VSI crushing and air classification: Optimising fines grading for concrete production with micro-proportioning. Miner. Eng. 2015, 78, 1–14. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Akcay, B.; Taşdemir, M.A. Optimisation of using lightweight aggregates in mitigating autogenous deformation of concrete. Constr. Build. Mater. 2009, 23, 353–363. [Google Scholar] [CrossRef]

- Jimma, B.E.; Rangaraju, P.R. Chemical admixtures dose optimization in pervious concrete paste selection—A statistical approach. Constr. Build. Mater. 2015, 101, 1047–1058. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Optimization of properties of fly ash aggregates for high-strength lightweight concrete production. Mater. Des. 2011, 32, 3586–3593. [Google Scholar] [CrossRef]

- Tošić, N.; Marinković, S.; Dašić, T.; Stanić, M. Multicriteria optimization of natural and recycled aggregate concrete for structural use. J. Clean. Prod. 2015, 87, 766–776. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Cagatay, I.H.; Tokyay, M.; Emsen, E. The effect of particle size distribution on the properties of blended cements incorporating GGBFS and natural pozzolan (NP). Powder Technol. 2007, 177, 140–147. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ferraris, C.F.; Snyder, K.A. Best Practices Guide for High-Volume Fly Ash Concretes: Assuring Properties and Performance; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013. [Google Scholar]

- Alaka, H.A.; Oyedele, L.O. High volume fly ash concrete: The practical impact of using superabundant dose of high range water reducer. J. Build. Eng. 2016, 8, 81–90. [Google Scholar] [CrossRef]

- Yijin, L.; Shiqiong, Z.; Jian, Y.; Yingli, G. The effect of fly ash on the fluidity of cement paste, mortar, and concrete. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004. [Google Scholar]

- Mukherjee, S.; Mandal, S.; Adhikari, U. Comparative study on physical and mechanical properties of high slump and zero slump high volume fly ash concrete (HVFAC). Glob. NEST J. 2013, 20, 1–7. [Google Scholar]

- Keertana, B.; Gobhiga, S. Experimental study of concrete with partial replacement of cement with rice husk ash and fine aggregate with granite dust. Eng. Sci. Technol. Int. J. 2016, 6, 36–41. [Google Scholar]

- Abalaka, A.E. Strength and Some Durability Properties of Concrete Containing Rice Husk Ash Produced in a Charcoal Incinerator at Low Specific Surface. Int. J. Concr. Struct. Mater. 2013, 7, 287–293. [Google Scholar] [CrossRef]

- Huchante, S.R.; Chandupalle, S.; Ghorpode, V.G.; TC, V.R. Mix design of high performance concrete using silica fume and superplasticizer. Pan 2014, 18, 100. [Google Scholar]

- Amarkhail, N. Effects of silica fume on properties of high-strength concrete. Int. J. Tech. Res. Appl. 2015, 32, 13–19. [Google Scholar]

- Tamilarasan, V.; Perumal, P.; Maheswaran, D.J. Workability studies on concrete with GGBS as a Replacement material for cement with and without superplasticizer. Int. J. Adv. Res. Eng. Technol. 2012, 3, 11–21. [Google Scholar]

- Le, H.T.; Siewert, K.; Ludwig, H.-M. Alkali silica reaction in mortar formulated from self-compacting high performance concrete containing rice husk ash. Constr. Build. Mater. 2015, 88, 10–19. [Google Scholar] [CrossRef]

- Ikpong, A.; Okpala, D. Strength characteristics of medium workability ordinary Portland cement-rice husk ash concrete. Build. Environ. 1992, 27, 105–111. [Google Scholar] [CrossRef]

- Venkatanarayanan, H.K.; Rangaraju, P.R. Effect of grinding of low-carbon rice husk ash on the microstructure and performance properties of blended cement concrete. Cem. Concr. Compos. 2015, 55, 348–363. [Google Scholar] [CrossRef]

- Malik, M.I. Study of Concrete Involving Use of Waste Glass as Partial Replacement of Fine Aggregates. IOSR J. Eng. 2013, 3, 08–13. [Google Scholar] [CrossRef]

- Liang, H.; Zhu, H.; Byars, E.A. Use of waste glass as aggregate in concrete. In Proceedings of the 7th UK CARE Annual General Meeting, Greenwich, UK, 15 September 2007. [Google Scholar]

- Abdallah, S.; Fan, M. Characteristics of concrete with waste glass as fine aggregate replacement. Int. J. Eng. Tech. Res. IJETR 2014, 2, 11–17. [Google Scholar]

- Xu, H.; Gong, W.; Syltebo, L.; Izzo, K.; Lutze, W.; Pegg, I.L. Effect of blast furnace slag grades on fly ash based geopolymer waste forms. Fuel 2014, 133, 332–340. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Lachemi, M. Self-compacting concrete incorporating high volumes of class F fly ash: Preliminary results. Cem. Concr. Res. 2001, 31, 413–420. [Google Scholar] [CrossRef]

- Brooks, J.; Johari, M.A.M.; Mazloom, M. Effect of admixtures on the setting times of high-strength concrete. Cem. Concr. Compos. 2000, 22, 293–301. [Google Scholar] [CrossRef]

- Ravina, D.; Mehta, P. Properties of fresh concrete containing large amounts of fly ash. Cem. Concr. Res. 1986, 16, 227–238. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Lin, K.-L.; Shiu, H.-S.; Shie, J.-L.; Cheng, T.-W.; Hwang, C.-L. Effect of composition on characteristics of thin film transistor liquid crystal display (TFT-LCD) waste glass-metakaolin-based geopolymers. Constr. Build. Mater. 2012, 36, 501–507. [Google Scholar] [CrossRef]

- Wang, H.-Y. The effect of the proportion of thin film transistor–liquid crystal display (TFT–LCD) optical waste glass as a partial substitute for cement in cement mortar. Constr. Build. Mater. 2011, 25, 791–797. [Google Scholar] [CrossRef]

- Shen, L. Role of Aggregate Packing in Segregation Resistance and Flow Behavior of Self-Consolidating Concrete; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2007. [Google Scholar]

- Xie, Y.; Liu, B.; Yin, J.; Zhou, S. Optimum mix parameters of high-strength self-compacting concrete with ultrapulverized fly ash. Cem. Concr. Res. 2002, 32, 477–480. [Google Scholar] [CrossRef]

- Rahman, M.; Muntohar, A.; Pakrashi, V.; Nagaratnam, B.; Sujan, D. Self compacting concrete from uncontrolled burning of rice husk and blended fine aggregate. Mater. Des. 2014, 55, 410–415. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Y.; Zheng, J.; Ding, Y. An experimental study on the workability of self-compacting lightweight concrete. Constr. Build. Mater. 2009, 23, 2087–2092. [Google Scholar] [CrossRef]

- Yazıcı, H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of self-compacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Tohumcu, I. Effects of different curing regimes on the compressive strength properties of self compacting concrete incorporating fly ash and silica fume. Mater. Des. 2013, 51, 12–18. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Özbay, E. Properties of self-compacting concretes made with binary, ternary, and quaternary cementitious blends of fly ash, blast furnace slag, and silica fume. Construct. Build. Mater. 2009, 23, 1847–1854. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E. Influence of Silica Fume on the Workability and the Compressive Strength of High-Performance Concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Schmidt, W.; Rogge, A.; Kühne, H.-C. Performance of rice husk ash blended cementitious systems with added superplasticizers. Cem. Concr. Compos. 2017, 83, 202–208. [Google Scholar] [CrossRef]

- Karthik, A.; Sudalaimani, K.; Kumar, C.V. Investigation on mechanical properties of fly ash-ground granulated blast furnace slag based self curing bio-geopolymer concrete. Constr. Build. Mater. 2017, 149, 338–349. [Google Scholar] [CrossRef]

- Ismail, M.S.; Waliuddin, A. Effect of rice husk ash on high strength concrete. Constr. Build. Mater. 1996, 10, 521–526. [Google Scholar] [CrossRef]

- Heikal, M.; Morsy, M.; Aiad, I. Effect of treatment temperature on the early hydration characteristics of superplasticized silica fume blended cement pastes. Cem. Concr. Res. 2005, 35, 680–687. [Google Scholar] [CrossRef]

- Ujhelyi, J.E.; Ibrahim, A.J. Hot weather concreting with hydraulic additives. Cem. Concr. Res. 1991, 21, 345–354. [Google Scholar] [CrossRef]

- Ali, E.E.; Al-Tersawy, S.H. Recycled glass as a partial replacement for fine aggregate in self compacting concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Vinai, R.; Rafeet, A.; Soutsos, M.; Sha, W. The Role of Water Content and Paste Proportion on Physico-mechanical Properties of Alkali Activated Fly Ash–Ggbs Concrete. J. Sustain. Metall. 2015, 2, 51–61. [Google Scholar] [CrossRef]

- Boukendakdji, O.; Kadri, E.-H.; Kenai, S. Effects of granulated blast furnace slag and superplasticizer type on the fresh properties and compressive strength of self-compacting concrete. Cem. Concr. Compos. 2012, 34, 583–590. [Google Scholar] [CrossRef]

- Siddique, R.; Bennacer, R. Use of iron and steel industry by-product (GGBS) in cement paste and mortar. Resour. Conserv. Recycl. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Wainwright, P.; Ait-Aider, H. The influence of cement source and slag additions on the bleeding of concrete. Cem. Concr. Res. 1995, 25, 1445–1456. [Google Scholar] [CrossRef]

- Xu, W.; Lo, Y.T.; Ouyang, D.; Memon, S.A.; Xing, F.; Wang, W.; Yuan, X. Effect of rice husk ash fineness on porosity and hydration reaction of blended cement paste. Constr. Build. Mater. 2015, 89, 90–101. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext. Geomembranes 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Chalee, W.; Rattanasak, U. Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag. 2009, 29, 539–543. [Google Scholar] [CrossRef]

- Mohseni, E.; Mehrinejad, M.; Naseri, F.; Monazami, M. Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Walczak, P.; Małolepszy, J.; Reben, M.; Rzepa, K. Mechanical Properties of Concrete Mortar Based on Mixture of CRT Glass Cullet and Fluidized Fly Ash. Procedia Eng. 2015, 108, 453–458. [Google Scholar] [CrossRef]

- Patil, S.P.; Sangle, K.K. Shear and flexural behaviour of prestressed and non-prestressed plain and SFRC concrete beams. J. King Saud Univ. Eng. Sci. 2017, 29, 321–328. [Google Scholar] [CrossRef]

- Sathawane, S.H.; Vairagade, V.S.; Kene, K.S. Combine Effect of Rice Husk Ash and Fly Ash on Concrete by 30% Cement Replacement. Procedia Eng. 2013, 51, 35–44. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Mukherjee, S.; Nikraz, H. Effects of nano-Al2O3 on early-age microstructural properties of cement paste. Constr. Build. Mater. 2014, 52, 189–193. [Google Scholar] [CrossRef]

- Karadelis, J.N.; Lin, Y. Flexural strengths and fibre efficiency of steel-fibre-reinforced, roller-compacted, polymer modified concrete. Constr. Build. Mater. 2015, 93, 498–505. [Google Scholar] [CrossRef]

- Benaicha, M.; Roguiez, X.; Jalbaud, O.; Burtschell, Y.; Alaoui, A.H. Influence of silica fume and viscosity modifying agent on the mechanical and rheological behavior of self compacting concrete. Constr. Build. Mater. 2015, 84, 103–110. [Google Scholar] [CrossRef]

- Chik, F.A.; Bakar, B.H.; Johari, M.A.; Jaya, R.P. Properties of concrete block containing rice husk ash subjected to GIRHA. Int. J. Res. Rev. Appl. Sci. 2011, 8, 57–64. [Google Scholar]

- Siddique, R.; Kaur, D. Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. J. Adv. Res. 2012, 3, 45–51. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Sun, M.; He, Z.; Xu, H.; Tan, J. Mechanical and permeability properties of polymer-modified concrete using hydrophobic agent. J. Build. Eng. 2020, 31, 101337. [Google Scholar] [CrossRef]

- Andayani, S.W.; Suratman, R.; Imran, I. Mardiyati Polymer Modified Concrete of Blended Cement and Natural Latex Copolymer: Static and Dynamic Analysis. Open J. Civ. Eng. 2018, 08, 205–220. [Google Scholar] [CrossRef]

- Borhan, T.M.; Al Karawi, R.J. Experimental investigations on polymer modified pervious concrete. Case Stud. Constr. Mater. 2020, 12, e00335. [Google Scholar] [CrossRef]

- Yang, W.; Xue, Y.; Wu, S.; Xiao, Y.; Zhou, M. Performance investigation and environmental application of basic oxygen furnace slag—Rice husk ash based composite cementitious materials. Constr. Build. Mater. 2016, 123, 493–500. [Google Scholar] [CrossRef]

- Boğa, A.R.; Öztürk, M.; Topcu, I.B. Using ANN and ANFIS to predict the mechanical and chloride permeability properties of concrete containing GGBFS and CNI. Compos. Part B Eng. 2013, 45, 688–696. [Google Scholar] [CrossRef]

- Esmaeili, J.; Andalibi, K.; Gencel, O.; Maleki, F.K.; Maleki, V.A. Pull-out and bond-slip performance of steel fibers with various ends shapes embedded in polymer-modified concrete. Constr. Build. Mater. 2021, 271, 121531. [Google Scholar] [CrossRef]

- Ardalan, R.B.; Emamzadeh, Z.N.; Rasekh, H.; Joshaghani, A.; Samali, B. Physical and mechanical properties of polymer modified self-compacting concrete (SCC) using natural and recycled aggregates. J. Sustain. Cem. Mater. 2019, 9, 1–16. [Google Scholar] [CrossRef]

- Karri, S.K.; MVGR College of Eng; Rao, G.; Raju, P. Strength and Durability Studies on GGBS Concrete. Int. J. Civ. Eng. 2015, 2, 34–41. [Google Scholar] [CrossRef]

- Rovnaník, P.; Řezník, B.; Rovnaníková, P. Blended Alkali-activated Fly Ash / Brick Powder Materials. Procedia Eng. 2016, 151, 108–113. [Google Scholar] [CrossRef]

- Kayali, O. Fly ash lightweight aggregates in high performance concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- Dondi, M.; Guarini, G.; Raimondo, M.; Zanelli, C. Recycling PC and TV waste glass in clay bricks and roof tiles. Waste Manag. 2009, 29, 1945–1951. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Hanif, A.; Patnaikuni, I. Thermal performance evaluation of eco-friendly bricks incorporating waste glass sludge. J. Clean. Prod. 2018, 172, 1867–1880. [Google Scholar] [CrossRef]

- Haranki, B. Strength, Modulus of Elasticity, Creep and Shrinkage of Concrete Used in Florida; University of Florida: Gainesville, FL, USA, 2009. [Google Scholar]

- Serdar, M.; Bjegovic, D.; Oslakovic, I.S. Shrinkage and Creep of Concrete Prepared with Quaternary Blended Cement. IABSE Symp. Rep. 2009, 96, 123–131. [Google Scholar]

- Mazloom, M.; Ramezanianpour, A.; Brooks, J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Kristiawan, S.A.; Nugroho, A.P. Creep Behaviour of Self-compacting Concrete Incorporating High Volume Fly Ash and its Effect on the Long-term Deflection of Reinforced Concrete Beam. Procedia Eng. 2017, 171, 715–724. [Google Scholar] [CrossRef]

- Alvarez, M. Strength and Durability of Rice Husk Ash-Modified Concrete in the Marine Environment. Master’s Thesis, Florida Atlantic University, Boca Raton, FL, USA, 2006. [Google Scholar]

- Li, Q.; Li, Z.; Yuan, G. Effects of elevated temperatures on properties of concrete containing ground granulated blast furnace slag as cementitious material. Constr. Build. Mater. 2012, 35, 687–692. [Google Scholar] [CrossRef]

- Barrett, T.J.; De la Varga, I.; Schlitter, J.; Weiss, W.J. Reducing the risk of cracking in high volume fly ash concrete by using internal curing. In Proceedings of the World of Coal Ash Conference, Denver, CO, USA, 9 May 2011. [Google Scholar]

- Atis, C. High-Volume Fly Ash Concrete with High Strength and Low Drying Shrinkage. J. Mater. Civ. Eng. 2003, 15, 153–156. [Google Scholar] [CrossRef]

- Havlásek, P.; Jirásek, M. Multiscale modeling of drying shrinkage and creep of concrete. Cem. Concr. Res. 2016, 85, 55–74. [Google Scholar] [CrossRef]

- Wallah, S.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Curtin University of Technology: Bentley, Australia, 2006. [Google Scholar]

- Folliard, K.; Smith, C.; Sellers, G.; Brown, M.; Breen, J.E. Evaluation of Alternative Materials to Control Drying-Shrinkage Cracking in Concrete Bridge Decks; University of Texas: Austin, TX, USA, 2003. [Google Scholar]

- Hung, H.-H. Properties of High Volume Fly Ash Concrete; University of Sheffield: Sheffield, UK, 1997. [Google Scholar]

- Gifford, P.; Ward, M. Results of laboratory tests on lean mass concrete utilizing to a high level of cement replacement. In The Use of PFA in Concrete; University of Leeds: Leeds, UK, 1982; pp. 221–230. [Google Scholar]

- Yuan, R.L.; Cook, J.E. Study of a class C fly ash concrete. Spec. Publ. 1983, 79, 307–320. [Google Scholar]

- Lohtia, R.; Nautiyal, B.; Jain, O. Creep af Fly Ash Concrete. J. Proc. 1976, 73, 469–472. [Google Scholar]

- Klausen, A.E.; Kanstad, T.; Bjøntegaard, Ø.; Sellevold, E. Comparison of tensile and compressive creep of fly ash concretes in the hardening phase. Cem. Concr. Res. 2017, 95, 188–194. [Google Scholar] [CrossRef]

- Forth, J. Predicting the tensile creep of concrete. Cem. Concr. Compos. 2015, 55, 70–80. [Google Scholar] [CrossRef]

- Hasan, M.R.; Siddika, A.; Akanda, M.P.; Islam, M.R. Effects of waste glass addition on the physical and mechanical properties of brick. Innov. Infrastruct. Solut. 2021, 6, 1–13. [Google Scholar] [CrossRef]

- Parghi, A.; Alam, M.S. Physical and mechanical properties of cementitious composites containing recycled glass powder (RGP) and styrene butadiene rubber (SBR). Constr. Build. Mater. 2016, 104, 34–43. [Google Scholar] [CrossRef]

- Binici, H. Engineering properties of geopolymer incorporating slag, fly ash, silica sand and pumice. Adv. Civ. Environ. Eng. 2013, 1, 108–123. [Google Scholar]

- Tian, H.; Zhang, Y. The influence of bagasse fibre and fly ash on the long-term properties of green cementitious composites. Constr. Build. Mater. 2016, 111, 237–250. [Google Scholar] [CrossRef]

- Momtazi, A.S.; Zanoosh, R.Z. The effects of polypropylene fibers and rubber particles on mechanical properties of cement composite containing rice husk ash. Procedia Eng. 2011, 10, 3608–3615. [Google Scholar] [CrossRef]

- Ismail, M.; Muhammad, B.; Yatim, J.M.; Noruzman, A.H.; Soon, Y.W.; Yatim, J.M. Behavior of Concrete with Polymer Additive at Fresh and Hardened States. Procedia Eng. 2011, 14, 2230–2237. [Google Scholar] [CrossRef]

- Yassene, A.A.M.; Ismail, M.R.; Afify, M.S. Physicomechanical properties of irradiated SBR latex polymer-modified cement mortar composites. J. Vinyl Addit. Technol. 2019, 26, 144–154. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Al-Shaer, A.; AlKizwini, R.S.; Hashim, K.; Al Hawesah, H.; Sadique, M. Investigating the influence of cement replacement by high volume of GGBS and PFA on the mechanical performance of cement mortar. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 584, p. 012022. [Google Scholar]

- Siddique, R.; Singh, K.; Kunal; Singh, M.; Corinaldesi, V.; Rajor, A. Properties of bacterial rice husk ash concrete. Constr. Build. Mater. 2016, 121, 112–119. [Google Scholar] [CrossRef]

- Hassan, K.; Cabrera, J.; Maliehe, R. The effect of mineral admixtures on the properties of high-performance concrete. Cem. Concr. Compos. 2000, 22, 267–271. [Google Scholar] [CrossRef]

- Rostami, M.; Behfarnia, K. The effect of silica fume on durability of alkali activated slag concrete. Constr. Build. Mater. 2017, 134, 262–268. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Stud. Constr. Mater. 2017, 7, 73–81. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Cheng, A.; Huang, R.; Wu, J.-K.; Chen, C.-H. Influence of GGBS on durability and corrosion behavior of reinforced concrete. Mater. Chem. Phys. 2005, 93, 404–411. [Google Scholar] [CrossRef]

- Mokarem, D.W.; Weyers, R.E.; Lane, D.S. Development of a shrinkage performance specifications and prediction model analysis for supplemental cementitious material concrete mixtures. Cem. Concr. Res. 2005, 35, 918–925. [Google Scholar] [CrossRef]

- Balapour, M.; Ramezanianpour, A.; Hajibandeh, E. An investigation on mechanical and durability properties of mortars containing nano and micro RHA. Constr. Build. Mater. 2017, 132, 470–477. [Google Scholar] [CrossRef]

- Fapohunda, C.; Akinbile, B.; Shittu, A. Structure and properties of mortar and concrete with rice husk ash as partial replacement of ordinary Portland cement—A review. Int. J. Sustain. Built Environ. 2017, 6, 675–692. [Google Scholar] [CrossRef]

- Ramachandran, V. Alkali-aggregate expansion inhibiting admixtures. Cem. Concr. Compos. 1998, 20, 149–161. [Google Scholar] [CrossRef]

- Xu, G.J.; Watt, D.F.; Hudec, P.P. Effectiveness of mineral admixtures in reducing ASR expansion. Cem. Concr. Res. 1995, 25, 1225–1236. [Google Scholar] [CrossRef]

- Hasparyk, N.P.; Monteiro, P.J.; Carasek, H. Effect of silica fume and rice husk ash on alkali-silica reaction. Mater. J. 2000, 97, 486–492. [Google Scholar]

- Le, H.T. Behaviour of Rice Husk Ash in Self-Compacting High Performance Concrete; FA Finger-Institut für Baustoffkunde: Weimar, Germany, 2015. [Google Scholar]

- Zerbino, R.; Giaccio, G.; Batic, O.; Isaia, G. Alkali–silica reaction in mortars and concretes incorporating natural rice husk ash. Constr. Build. Mater. 2012, 36, 796–806. [Google Scholar] [CrossRef]

- De Sensale, G.R. Effect of rice-husk ash on durability of cementitious materials. Cem. Concr. Compos. 2010, 32, 718–725. [Google Scholar] [CrossRef]

- Oberholster, R.; Westra, W. The effectiveness of mineral admixtures in reducing expansion due to alkali-aggregate reaction with Malmesbury Group aggregates. In Proceedings of the 5th International Conference Alkali-Aggregate Reaction in Concrete, Cape Town, South Africa, 30 March 1981. [Google Scholar]

- Buck, A.D. Use of cementitious materials other than portland cement. Spec. Publ. 1987, 100, 1863–1882. [Google Scholar]

- Lindgård, J.; Andiç-Çakır, Ö.; Fernandes, I.; Rønning, T.F.; Thomas, M.D. Alkali–silica reactions (ASR): Literature review on parameters influencing laboratory performance testing. Cem. Concr. Res. 2012, 42, 223–243. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Boğa, A.R.; Bilir, T. Alkali–silica reactions of mortars produced by using waste glass as fine aggregate and admixtures such as fly ash and Li2CO3. Waste Manag. 2008, 28, 878–884. [Google Scholar] [CrossRef] [PubMed]

- Özkan, Ö.; Yüksel, I. Studies on mortars containing waste bottle glass and industrial by-products. Constr. Build. Mater. 2008, 22, 1288–1298. [Google Scholar] [CrossRef]

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Mejía de Gutiérrez, R.; Provis, J.L. Performance at high temperature of alkali-activated slag pastes produced with silica fume and rice husk ash based activators. Mater. Constr. 2015, 65, e049. [Google Scholar] [CrossRef]

- Rashad, A.M. A brief on high-volume Class F fly ash as cement replacement—A guide for Civil Engineer. Int. J. Sustain. Built Environ. 2015, 4, 278–306. [Google Scholar] [CrossRef]

- Janotka, I.; Nürnbergerová, T. Effect of temperature on structural quality of the cement paste and high-strength concrete with silica fume. Nucl. Eng. Des. 2005, 235, 2019–2032. [Google Scholar] [CrossRef]

- Kong, D.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Murphy, T.; Wuhrer, R. High temperature performance of mortars containing fine glass powders. J. Clean. Prod. 2017, 162, 16–26. [Google Scholar] [CrossRef]

- Poon, C.-S.; Azhar, S.; Anson, M.; Wong, Y.-L. Comparison of the strength and durability performance of normal- and high-strength pozzolanic concretes at elevated temperatures. Cem. Concr. Res. 2001, 31, 1291–1300. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M.; Hassan, H.A. An investigation on blast-furnace stag as fine aggregate in alkali-activated slag mortars subjected to elevated temperatures. J. Clean. Prod. 2016, 112, 1086–1096. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Coskun, A. The effect of high temperature on compressive strength and splitting tensile strength of structural lightweight concrete containing fly ash. Constr. Build. Mater. 2008, 22, 2269–2275. [Google Scholar] [CrossRef]

- Terro, M. Properties of concrete made with recycled crushed glass at elevated temperatures. Build. Environ. 2006, 41, 633–639. [Google Scholar] [CrossRef]

- Xu, Y.; Wong, Y.; Poon, C.; Anson, M. Impact of high temperature on PFA concrete. Cem. Concr. Res. 2001, 31, 1065–1073. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Kanchanda, P.; Sathonsaowaphak, A.; Cao, H. Sulfate resistance of blended cements containing fly ash and rice husk ash. Constr. Build. Mater. 2007, 21, 1356–1361. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P. Durability of conventional concretes containing black rice husk ash. J. Environ. Manag. 2011, 92, 59–66. [Google Scholar] [CrossRef]

- Khan, R.; Jabbar, A.; Ahmad, I.; Khan, W.; Khan, A.N.; Mirza, J. Reduction in environmental problems using rice-husk ash in concrete. Constr. Build. Mater. 2012, 30, 360–365. [Google Scholar] [CrossRef]

- Roy, D.; Arjunan, P.; Silsbee, M. Effect of silica fume, metakaolin, and low-calcium fly ash on chemical resistance of concrete. Cem. Concr. Res. 2001, 31, 1809–1813. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Sirivivatnanon, V. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Torii, K.; Taniguchi, K.; Kawamura, M. Sulfate resistance of high fly ash content concrete. Cem. Concr. Res. 1995, 25, 759–768. [Google Scholar] [CrossRef]

- Ouyang, C.; Nanni, A.; Chang, W.F. Internal and external sources of sulfate ions in portland cement mortar: Two types of chemical attack. Cem. Concr. Res. 1988, 18, 699–709. [Google Scholar] [CrossRef]

- Tasong, W.A.; Wild, S.; Tilley, R.J. Mechanisms by which ground granulated blastfurnace slag prevents sulphate attack of lime-stabilised kaolinite. Cem. Concr. Res. 1999, 29, 975–982. [Google Scholar] [CrossRef]

- Rozière, E.; Loukili, A.; El Hachem, R.; Grondin, F. Durability of concrete exposed to leaching and external sulphate attacks. Cem. Concr. Res. 2009, 39, 1188–1198. [Google Scholar] [CrossRef]

- Skaropoulou, A.; Tsivilis, S.; Kakali, G.; Sharp, J.; Swamy, R. Thaumasite form of sulfate attack in limestone cement mortars: A study on long term efficiency of mineral admixtures. Constr. Build. Mater. 2009, 23, 2338–2345. [Google Scholar] [CrossRef]

- Osborne, G. Durability of Portland blast-furnace slag cement concrete. Cem. Concr. Compos. 1999, 21, 11–21. [Google Scholar] [CrossRef]

- Higgins, D. Increased sulfate resistance of ggbs concrete in the presence of carbonate. Cem. Concr. Compos. 2003, 25, 913–919. [Google Scholar] [CrossRef]

- Uysal, M.; Yilmaz, K. Effect of mineral admixtures on properties of self-compacting concrete. Cem. Concr. Compos. 2011, 33, 771–776. [Google Scholar] [CrossRef]

- O’Connell, M.; McNally, C.; Richardson, M.G. Performance of concrete incorporating GGBS in aggressive wastewater environments. Constr. Build. Mater. 2012, 27, 368–374. [Google Scholar] [CrossRef]

- Omran, A.F.; D.-Morin, E.; Harbec, D.; Tagnit-Hamou, A. Long-term performance of glass-powder concrete in large-scale field applications. Constr. Build. Mater. 2017, 135, 43–58. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.; Nanukuttan, S.; Khan, Q. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Ganjian, E.; Pouya, H.S. The effect of Persian Gulf tidal zone exposure on durability of mixes containing silica fume and blast furnace slag. Constr. Build. Mater. 2009, 23, 644–652. [Google Scholar] [CrossRef]

- Makhloufi, Z.; Aggoun, S.; Benabed, B.; Kadri, E.; Bederina, M. Effect of magnesium sulfate on the durability of limestone mortars based on quaternary blended cements. Cem. Concr. Compos. 2016, 65, 186–199. [Google Scholar] [CrossRef]

- Aziz, M.A.; Aleem, S.A.; Heikal, M.; Didamony, H.E. Hydration and durability of sulphate-resisting and slag cement blends in Caron’s Lake water. Cem. Concr. Res. 2005, 35, 1592–1600. [Google Scholar] [CrossRef]

- Green Minerals. Concrete: Process Infographic—CO2 Based Concrete & Circular Economy. Available online: https://www.green-minerals.nl/concrete/ (accessed on 12 June 2021).

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

| Researcher | Description of Work |

|---|---|

| Mohseni et al. [56] | RHA and PPO used as a replacement for OPC |

| Çakır and Sofyanlı [70] | RAC + SF used as a replacement for OPC |

| Jalal et al. [72] | SF + NS used as a replacement for OPC |

| Aliabdo et al. [92] | Glass powder used as a replacement for OPC |

| Xu et al. [204] | RHA used as a replacement for OPC |

| Liu, B., et al. [217] | FA used as a replacement for OPC |

| Andayani, S.W., et al. [218] | Natural Latex-KOLAM used as a replacement for OPC |

| Borhan, and Al Karawi [219] | SBR used as a replacement for OPC |

| Yang et al. [220] | BOFS + RHA used as a replacement for OPC |

| Boga et al. [221] | CNI + GGBFS used as a replacement for OPC |

| Researcher | Description of Work |

|---|---|

| Mohseni et al. [56] | Cement+ PPF + RHA used in composite concrete development |

| Jalal et al. [72] | SF + NS used in composite concrete development |

| Walczak et al. [208] | CRT + FFA used in composite concrete development |

| Patil and Sangle [209] | Steel fibers + FA used in composite concrete development |

| Sathawane et al. [210] | RHA + FA used in composite concrete development |

| Benaicha et al. [214] | SF + LF used in composite concrete development |

| Borhan and Al Karawi [219] | SBR used in composite concrete development |

| Yang et al. [220] | RHA + BOF used in composite concrete development |

| Esmaeili, J., et al. [222] | Steel fibers used for polymer-modified concrete |

| Ardalan et al. [223] | Polymer + recycled aggregates used in SSC development |

| Karri et al. [224] | GGBFS used in composite concrete development |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhazmi, H.; Shah, S.A.R.; Anwar, M.K.; Raza, A.; Ullah, M.K.; Iqbal, F. Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review for Assessment of Recycling and Waste Utilization. Polymers 2021, 13, 2135. https://doi.org/10.3390/polym13132135

Alhazmi H, Shah SAR, Anwar MK, Raza A, Ullah MK, Iqbal F. Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review for Assessment of Recycling and Waste Utilization. Polymers. 2021; 13(13):2135. https://doi.org/10.3390/polym13132135

Chicago/Turabian StyleAlhazmi, Hatem, Syyed Adnan Raheel Shah, Muhammad Kashif Anwar, Ali Raza, Muhammad Kaleem Ullah, and Fahad Iqbal. 2021. "Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review for Assessment of Recycling and Waste Utilization" Polymers 13, no. 13: 2135. https://doi.org/10.3390/polym13132135

APA StyleAlhazmi, H., Shah, S. A. R., Anwar, M. K., Raza, A., Ullah, M. K., & Iqbal, F. (2021). Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review for Assessment of Recycling and Waste Utilization. Polymers, 13(13), 2135. https://doi.org/10.3390/polym13132135