Flammability Characteristics of Thermally Modified Meranti Wood Treated with Natural and Synthetic Fire Retardants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wood

- Thermal modification (TM);

- Thermal modification + synthetic fire retardant (SFR);

- Thermal modification + natural fire retardant (NFR).

2.2. Synthetic Fire Retardant

2.3. Natural Fire Retardant

2.4. Methods

2.4.1. Thermal Modification

2.4.2. Physical Properties

2.4.3. Determination of Flammability Characteristics

2.4.4. Calculation of Given Characteristics for the Experiment

2.4.5. Chemical Analyses

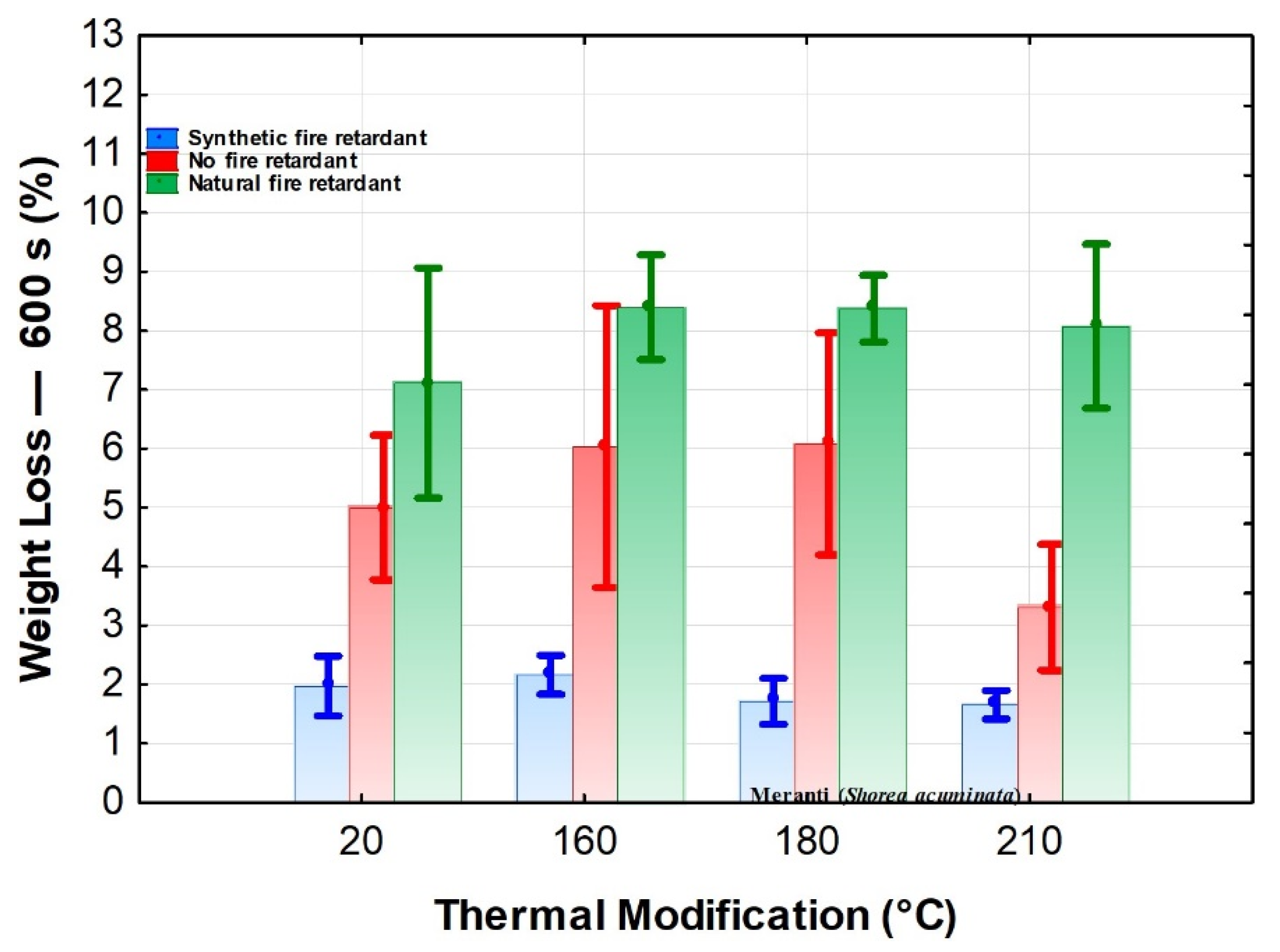

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baral, S.; Gaire, N.P.; Aryal, S.; Pandey, M.; Rayamajhi, S.; Vacik, H. Growth Ring Measurements of Shorea robusta Reveal Responses to Climatic Variation. Forests 2019, 10, 466. [Google Scholar] [CrossRef] [Green Version]

- Baral, S.; Neumann, M.; Basnyat, B.; Gauli, K.; Gautam, S.; Bhandari, S.K.; Vacik, H. Form Factors of an Economically Valuable Sal Tree (Shorea robusta) of Nepal. Forests 2020, 11, 754. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical Thermal, and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 260. ISBN 978-0_470-02172-9. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; p. 703. ISBN 9781439853801. [Google Scholar]

- Militz, H.; Altgen, M. Processes and Properties of Thermally Modified Wood Manufactured in Europe. In Deterioration and Protection of Sustainable Biomaterials; ACS Symposium Series Vol. 1158, Chapter 16; American Chemical Society: Washington, DC, USA, 2014; pp. 269–285. ISBN 13: 9780841230040. [Google Scholar]

- Rosu, L.; Mustata, F.; Varganici, C.D.; Rosu, D.; Rusu, T.; Rosca, I. Thermal behaviour and fungi resistance of composites based on wood and natural and synthetic epoxy resins cured with maleopimaric acid. Polym. Degrad. Stabil. 2019, 160, 148–161. [Google Scholar] [CrossRef]

- Bakar, B.F.A.; Hiziroglu, S.; Tahir, P.M. Properties of some thermally modified wood species. Mater Des. 2013, 43, 348–355. [Google Scholar] [CrossRef] [Green Version]

- Gérardin, V. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef] [Green Version]

- Čekovská, H.; Gaff, M.; Osvald, A.; Kačík, F.; Kubš, J.; Kaplan, L. Fire Resistance of Thermally Modified Spruce Wood. BioResources 2017, 12, 947–959. [Google Scholar] [CrossRef]

- Baysal, E.; Kart, S.; Toker, H.; Degirmentepe, S. Some physical characteristics of thermally modified oriental-beech wood. Maderas Cienc. Tecnol. 2014, 16, 291–298. [Google Scholar] [CrossRef] [Green Version]

- LeVan, S.L. Chemistry of fire retardancy. In The Chemistry of Solid Wood. Advances in Chemistry Series 207; Rowell, R.M., Ed.; American Chemical Society: Washington, DC, USA, 1984; Chapter 14; pp. 531–574. [Google Scholar]

- Poletto, M.; Zattera, A.J.; Forte, M.C.; Mariam, M.C.; Santana, R. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, P.H. Irreversible property changes of small loblolly pine specimens heated in air, nitrogen, or oxygen. Wood Fiber Sci. 1988, 20, 320–355. [Google Scholar]

- Korkut, D.S.; Guller, B. The effects of heat treatment on physical properties and surface roughness of red-bud maple (Acer trautvetteri Med.) wood. Bioresour. Technol. 2008, 99, 2846–2851. [Google Scholar] [CrossRef]

- Cademartori, P.H.G.; Missio, A.L.; Mattos, B.D.; Gatto, D.A. Effect of thermal treatments on the technological properties of wood from two Eucalyptus species. An. Acad. Bras. Cienc. 2015, 87, 471–481. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Šimkovic, I. Trends in thermal stability study of chemically modified lignocellulose materials. In Polymer Degradation and Stability Research Developments; Albertov, L.B., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2007; pp. 217–236. ISBN 978-1-60021-827-9. [Google Scholar]

- Harper, C.A. Handbook of Building Materials for Fire Protection; McGraw-Hill Handbooks: New York, NY, USA, 2003; p. 800. ISBN 13: 978-0071388917. [Google Scholar]

- Alaee, M.; Wenning, R.J. The significance of brominated flame retardants in the environment: Current understanding, issues, and challenges. Chemosphere 2002, 46, 579–582. [Google Scholar] [CrossRef]

- Östman, B.; Voss, A.; Hughes, A.; Hovde, P.J.; Grexa, O. The durability of Fire Retardant Treated Wood Products at Humid and Exterior Conditions Review of Literature. Fire Mater 2001, 25, 95–104. [Google Scholar] [CrossRef]

- Nothnagel, E.A.; Bacic, A.; Clarke, A.E. Cell and Developmental Biology of Arabinogalactan-Proteins; Kluwer Academic/Plenum Publishers: Amsterdam, The Netherlands, 2000; 301 Seiten; p. 301. ISBN 978-0-306-46469-0. [Google Scholar]

- Spiridon, I.; Popa, V.I. Hemicelluloses: Major sources, properties, and applications. In Monomers, Polymers, and Composites from Renewable Resources; Belgacem, M.N., Gandini, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; Chapter 13; pp. 289–304. ISBN 978-0-08-045316-3. [Google Scholar]

- Karaseva, V.; Bergeret, A.; Lacoste, C.; Ferry, L.; Fulcrand, H. Influence of Extraction Conditions on Chemical Composition and Thermal Properties of Chestnut Wood Extracts as Tannin Feedstock. ACS Sustain. Chem. Eng. 2019, 7, 17047–17054. [Google Scholar] [CrossRef]

- LeVan, S.L.; Winandy, J.E. Effect of fire retardant treatments of wood strength: A review. Wood Fiber. Sci. 1990, 22, 113–131. [Google Scholar]

- Unger, A.; Schniewind, A.; Unger, W. Conservation of Wood Artifacts: A Handbook; Springer: Berlin/Heidelberg, Germany; Cham, Switzerland, 2001; p. 578. ISBN 3540415807. [Google Scholar]

- Gottschalk, A. Glycoproteins: Their Composition, Structure, and Function, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 1972; p. 1378. ISBN 13: 9780444409492. [Google Scholar]

- Reid, R.; Clamp, J.R. The biochemical and histochemical nomenclature of mucus. Br. Med. Bull 1978, 34, 5–8. [Google Scholar] [CrossRef] [PubMed]

- Kornfeld, R.; Kornfeld, S. Comparative Aspects of Glycoprotein Structure. Annu. Rev. Biochem. 1976, 45, 217–238. [Google Scholar] [CrossRef]

- Marshall, R.D. Glycoproteins. Annu. Rev. Biochem. 1972, 41, 673–702. [Google Scholar] [CrossRef]

- D’Adamo, P. Larch arabinogalactan. J. Naturopath. Med. 1996, 4, 32–39. [Google Scholar]

- Goellner, E.M.; Utermoehlen, J.; Kramer, R.; Classen, B. Structure of arabinogalactan from Larix laricina and its reactivity with antibodies directed against type-II-arabinogalactans. Carbohydr. Polym. 2011, 86, 1739–1744. [Google Scholar] [CrossRef]

- Grube, B.; Stier, H.; Riede, L.; Gruenwald, L. Tolerability of a proprietary larch arabinogalactan extract: A randomized, double-blind, placebo-controlled clinical trial in healthy subjects. Food Nutr. Sci. 2012, 3, 1533–1538. [Google Scholar] [CrossRef] [Green Version]

- ISO 13061-2. Wood-Determination of Density for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Gaff, M.; Kačík, F.; Gašparík, M.; Todaro, L.; Jones, D.; Corleto, R.; Osvaldová, L.M.; Čekovská, H. The effect of synthetic and natural fire-retardants on burning and chemical characteristics of thermally modified teak (Tectona grandis L. f.) wood. Constr. Build. Mater. 2019, 200, 551–558. [Google Scholar] [CrossRef]

- Aydin, T.Y. Ultrasonic evaluation of time and temperature-dependent orthotropic compression properties of oak wood. J. Mater. Res. Technol. 2020, 9, 6028–6036. [Google Scholar] [CrossRef]

- Corleto, R.; Gaff, M.; Niemz, P.; Sethy, A.K.; Todaro, L.; Ditommaso, G.; Macků, J. Effect of thermal modification on properties and milling behaviour of African padauk (Pterocarpus soyauxii Taub.) wood. J. Mater. Res. Technol. 2020, 9, 9315–9327. [Google Scholar] [CrossRef]

- ISO 13061-1. Wood-Determination of Moisture Content for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- ČSN 73 0862/B-2. Determining the Degree of Flammability of Construction Materials—Amemedment B-2; Czech Standards Institute: Prague, Czech Republic, 1991. [Google Scholar]

- ISO 13061-1. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- ASTM D1107-96. Standard Test Method for Ethanol-Toluene Solubility of Wood; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. In Laboratory Analytical Procedure (LAP); NREL/TP-510-42618; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [Google Scholar]

- Wise, L.E.; Murphy, M.; D’Addieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Paper Trade J. 1946, 122, 35–43. [Google Scholar]

- Seifert, K. Uber ein Neues Verfahren Zur Schnellbestimmung der Rein- Cellulose. Papier 1956, 10, 301–306. [Google Scholar]

- Gašparík, M.; Osvaldová, L.; Čekovská, H.; Potůček, D. Flammability characteristics of thermally modified oak wood treated with fire-retardant. BioResources 2017, 12, 8451–8467. [Google Scholar]

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of thermal modification on color and chemical changes of spruce and oak wood. J. Wood. Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and ecotoxicity of heat-treated pine wood extractives. Wood Sci. Technol. 2011, 45, 661–676. [Google Scholar] [CrossRef] [Green Version]

- Kačíková, D.; Kubovský, I.; Gaff, M.; Kačík, F. Changes of Meranti, Padauk and Merbau Wood Lignin during ThermoWood Process. Polymers 2021, 13, 993. [Google Scholar] [CrossRef]

- Mohamed, A.L.; Hassabo, A.G. Flame Retardant of Cellulosic Materials and Their Composites. In Flame Retardants; Engineering Materials; Visakh, P., Arao, Y., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Hu, F.; Jung, S.; Ragauskas, A. Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresour. Technol. 2012, 117, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Werner, K.; Pommer, L.; Broström, M. Thermal decomposition of hemicelluloses. J. Anal. Appl. Pyrol. 2014, 110, 130–137. [Google Scholar] [CrossRef]

- Rafiqul, I.S.M.; Sakinah, A.M.M.; Karim, M.R. Production of Xylose from Meranti Wood Sawdust by Dilute Acid Hydrolysis. Appl. Biochem. Biotechnol. 2014, 174, 542–555. [Google Scholar] [CrossRef] [PubMed]

- Shinde, S.D.; Meng, X.; Kumar, R.; Ragauskas, A.J. Recent advances in understanding the pseudolignin formation in a lignocellulosic biorefinery. Green Chem. 2018, 20, 2192–2205. [Google Scholar] [CrossRef] [Green Version]

| Thermal Modification Parameters | |||

|---|---|---|---|

| Temperatures (°C) | 160 | 180 | 210 |

| Heating (h) | 13.5 | 13.6 | 18.7 |

| Thermal treatment (h) | 3.0 | 3.0 | 3.0 |

| Cooling (h) | 9.6 | 11.1 | 11.2 |

| Total modification time (h) | 26.1 | 27.7 | 32.9 |

| Temperature | Thermal Modification Temperature | |||

|---|---|---|---|---|

| Unmodifield | 160 °C | 180 °C | 210 °C | |

| Density before TM (kg·m−3) | 626 (9.3) | 662 (11.4) | 634 (10.8) | 626 (8.5) |

| Density after TM (kg·m−3) | 625 (9.2) | 608 (10.4) | 650 (7.2) | |

| Temperature (°C) | Extractives (%) | Fisher’s F-Test Level of Significance | Lignin (%) | Fisher’s F-Test Level of Significance | Cellulose (%) | Fisher’s F-Test Level of Significance |

| Unmodified | 2.51 (2.37) | 297.04 *** | 32.42 (0.25) | 1468 *** | 53.04 (0.89) | 543.5 *** |

| 160 | 3.22 (1.94) | 36.67 (0.26) | 51.02 (0.19) | |||

| 180 | 3.20 (1.47) | 36.29 (0.24) | 52.04 (0.31) | |||

| 210 | 3.92 (2.32) | 35.33 (0.37) | 59.06 (0.60) | |||

| Temperature (°C) | Holocellulose (%) | Fisher’s F-Test Level of Significance | Hemicelluloses (%) | Fisher’s F-Test Level of Significance | ||

| Unmodified | 71.53 (0.58) | 259.2 *** | 18.49 (4.65) | 367.925 *** | ||

| 160 | 66.51 (1.07) | 15.50 (5.14) | ||||

| 180 | 66.12 (0.23) | 14.08 (2.16) | ||||

| 210 | 62.71 (0.54) | 3.65 (6.13) |

| Influence | Sum of Squares | Degrees of Freedom | Variance | Fisher’s F-Test | Significance Level P |

|---|---|---|---|---|---|

| WL.—600 s (%) | |||||

| Intercept | 1495.404 | 1 | 1495.404 | 1430.428 | *** |

| Retardant | 374.391 | 2 | 187.196 | 179.062 | *** |

| TM | 14.324 | 3 | 4.775 | 4.567 | *** |

| Retardant × TM | 17.222 | 6 | 2.870 | 2.746 | *** |

| Error | 50.180 | 48 | 1.045 | ||

| The model corresponds to approximately 89.0% of the total sum of squares. | |||||

| BR.—600 s (%·s−1 × 10−5) | |||||

| Intercept | 17.66190 | 1 | 17.66190 | 174.4060 | *** |

| Retardant | 1.38970 | 2 | 0.69485 | 6.8615 | *** |

| TM | 0.13538 | 3 | 0.04513 | 0.4456 | NS |

| R × TM | 0.79910 | 6 | 0.13318 | 1.3151 | NS |

| Error | 4.86091 | 48 | 0.10127 | ||

| The model corresponds to approximately 32.3% of the total sum of squares. | |||||

| MBR. (%·s−1) | |||||

| Intercept | 531.7951 | 1 | 531.7951 | 1244.976 | *** |

| Retardant | 50.8410 | 2 | 25.4205 | 59.511 | *** |

| TM | 2.3821 | 3 | 0.7940 | 1.859 | NS |

| Retardant × TM | 4.6048 | 6 | 0.7675 | 1.797 | NS |

| Error | 20.5033 | 48 | 0.4272 | ||

| The model corresponds to approximately 73.8% of the total sum of squares. | |||||

| RMBR. (%) | |||||

| Intercept | 0.456095 | 1 | 0.456095 | 558.1834 | *** |

| Retardant | 0.036244 | 2 | 0.018122 | 22.1784 | *** |

| TM | 0.019321 | 3 | 0.006440 | 7.8817 | *** |

| Retardant × TM | 0.026381 | 6 | 0.004397 | 5.3810 | *** |

| Error | 0.039221 | 48 | 0.000817 | ||

| The model corresponds to approximately 67.6% of the total sum of squares. | |||||

| TRMBR. | |||||

| Intercept | 108,800.4 | 1 | 108,800.4 | 464.2151 | *** |

| Retardant | 21,450.8 | 2 | 10,725.4 | 45.7618 | *** |

| TM | 544.6 | 3 | 181.5 | 0.7745 | NS |

| Retardant × TM | 4079.2 | 6 | 679.9 | 2.9007 | *** |

| Error | 11,250.0 | 48 | 234.4 | ||

| The model corresponds to approximately 69.9% of the total sum of squares. | |||||

| Variable | FR. | TM. | WL. | BR. | MBR. | RMBR. | TRMBR. | Ex. | Li. | Hol. | Cell. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FR | |||||||||||

| TM. | 0 | ||||||||||

| WL. | 90 | −4 | |||||||||

| BR. | 14 | 10 | 23 | ||||||||

| MBR. | 81 | 17 | 86 | 24 | |||||||

| RMBR. | −5 | 32 | 3 | 36 | 19 | ||||||

| TRMBR. | 48 | −14 | 43 | −17 | 40 | −79 | |||||

| Ex. | 0 | 84 | −3 | 3 | 18 | 28 | −9 | ||||

| Li. | 0 | 19 | 13 | 6 | 2 | 11 | −8 | 34 | |||

| Hol. | 0 | −97 | 4 | −11 | −17 | −32 | 14 | −84 | −19 | ||

| Cell. | 0 | 39 | −16 | −1 | 8 | 9 | −1 | 28 | −77 | −41 | |

| Hemicell. | 0 | −97 | 4 | −11 | −17 | −31 | 13 | −83 | −19 | 99 | −42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaff, M.; Čekovská, H.; Bouček, J.; Kačíková, D.; Kubovský, I.; Tribulová, T.; Zhang, L.; Marino, S.; Kačík, F. Flammability Characteristics of Thermally Modified Meranti Wood Treated with Natural and Synthetic Fire Retardants. Polymers 2021, 13, 2160. https://doi.org/10.3390/polym13132160

Gaff M, Čekovská H, Bouček J, Kačíková D, Kubovský I, Tribulová T, Zhang L, Marino S, Kačík F. Flammability Characteristics of Thermally Modified Meranti Wood Treated with Natural and Synthetic Fire Retardants. Polymers. 2021; 13(13):2160. https://doi.org/10.3390/polym13132160

Chicago/Turabian StyleGaff, Milan, Hana Čekovská, Jiří Bouček, Danica Kačíková, Ivan Kubovský, Tereza Tribulová, Lingfeng Zhang, Salvio Marino, and František Kačík. 2021. "Flammability Characteristics of Thermally Modified Meranti Wood Treated with Natural and Synthetic Fire Retardants" Polymers 13, no. 13: 2160. https://doi.org/10.3390/polym13132160

APA StyleGaff, M., Čekovská, H., Bouček, J., Kačíková, D., Kubovský, I., Tribulová, T., Zhang, L., Marino, S., & Kačík, F. (2021). Flammability Characteristics of Thermally Modified Meranti Wood Treated with Natural and Synthetic Fire Retardants. Polymers, 13(13), 2160. https://doi.org/10.3390/polym13132160