Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

2.1.2. Waste Polyurethane

2.1.3. Styrene-Butadiene-Styrene (SBS)

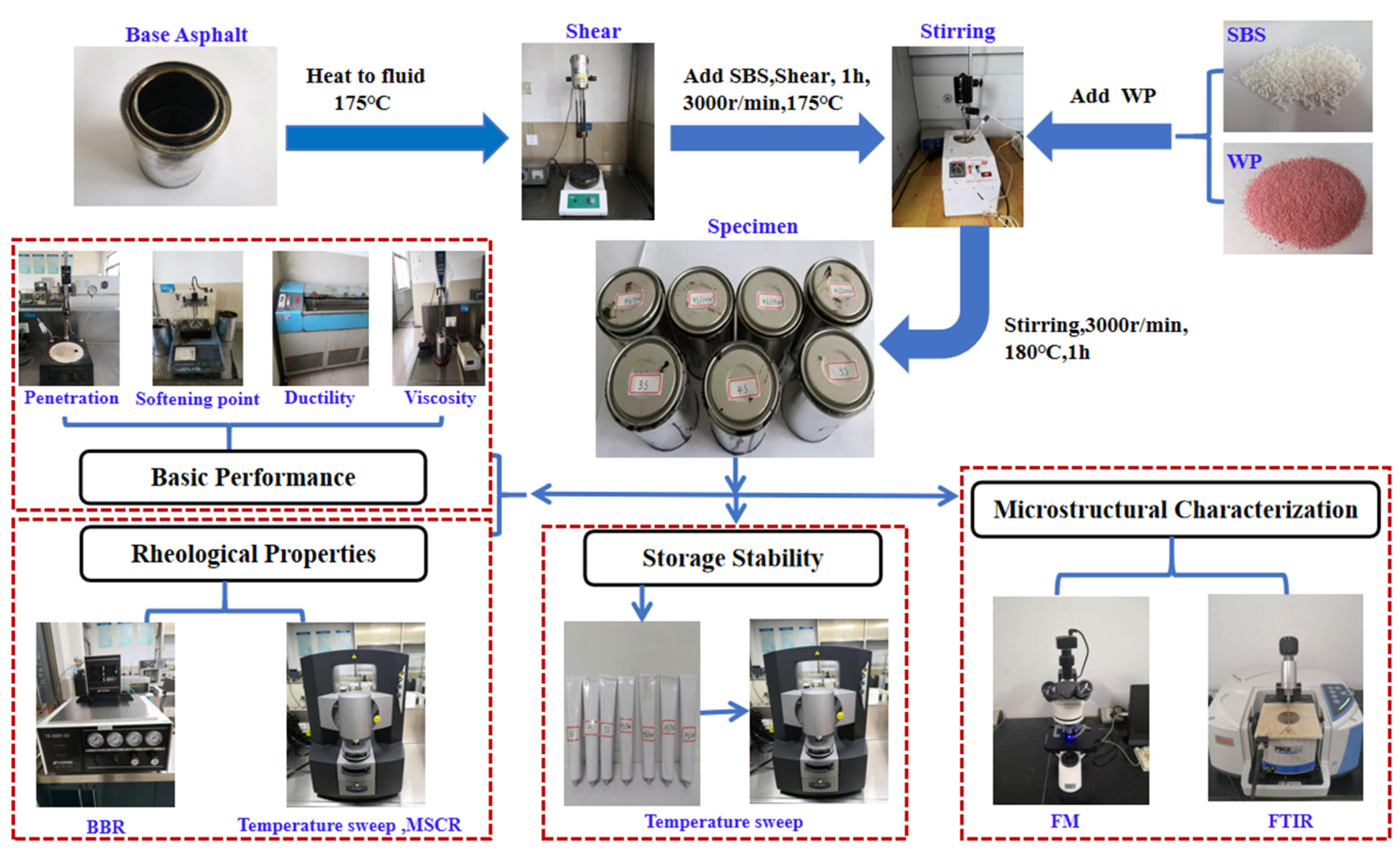

2.2. Preparation of Modified Asphalt

2.2.1. Preparation of SBS Modified Asphalt

2.2.2. Preparation of WPU/SBS Composite Modified Asphalt

2.3. Specimen Preparation

2.4. Test Procedures

2.4.1. Basic Performance Tests

- (1)

- Basic performance tests of modified asphalt

- (2)

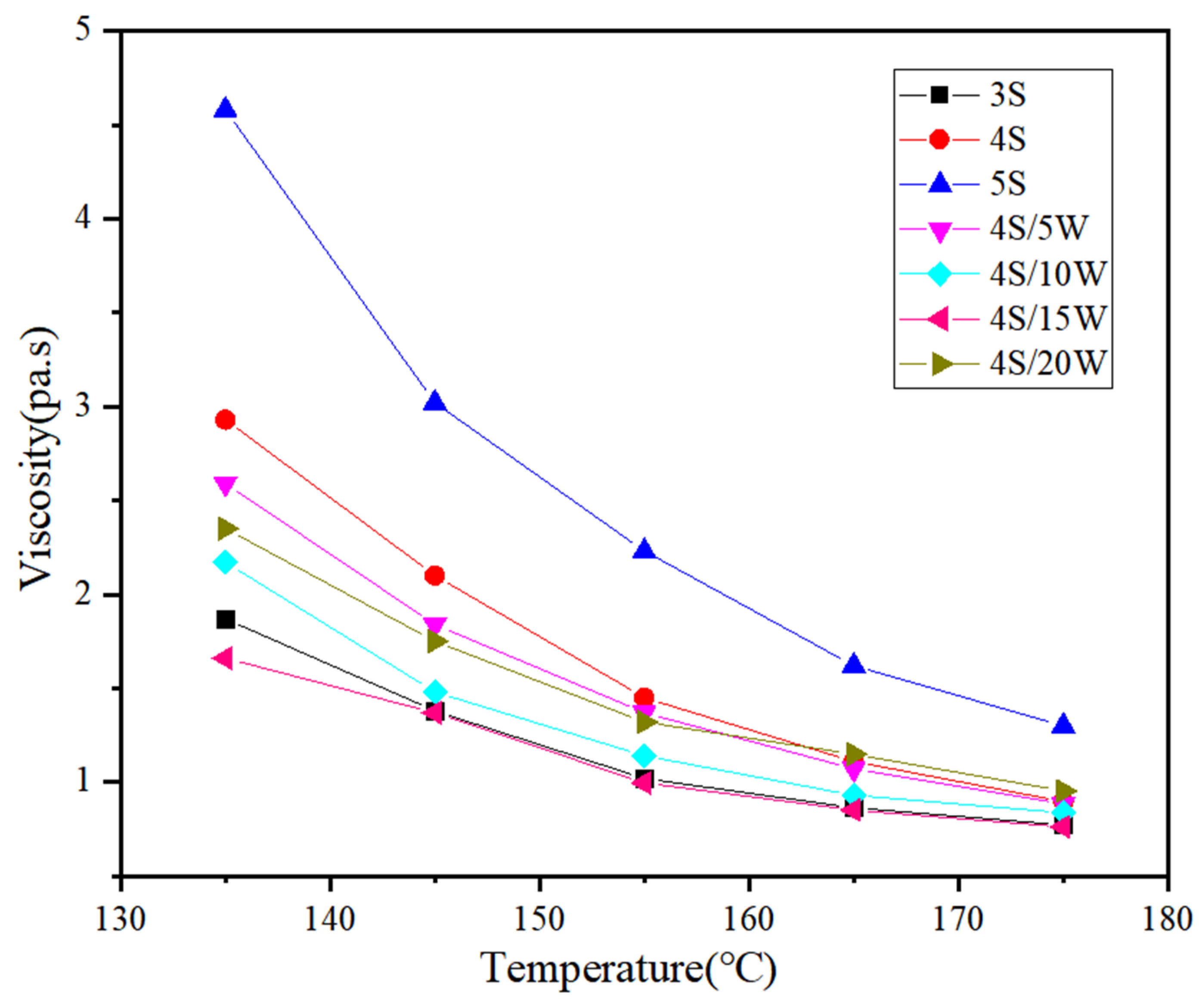

- Rotational viscosity tests of modified asphalt

2.4.2. Rheological Property Tests

- (1)

- Temperature Sweep Tests

- (2)

- Multiple Stress Creep Recovery (MSCR) Tests

- (3)

- Bending Beam Rheometer (BBR) Tests

2.4.3. Storage Stability Tests

2.4.4. Microstructure Analysis

- (1)

- Fluorescence Microscope (FM) tests

- (2)

- Fourier transform infrared spectroscopy (FTIR) tests

3. Results and Discussion

3.1. Basic Performance

3.1.1. Basic Performance of Asphalts

3.1.2. Results of Brookfield Rotational Viscosity Tests

3.2. Rheological Properties

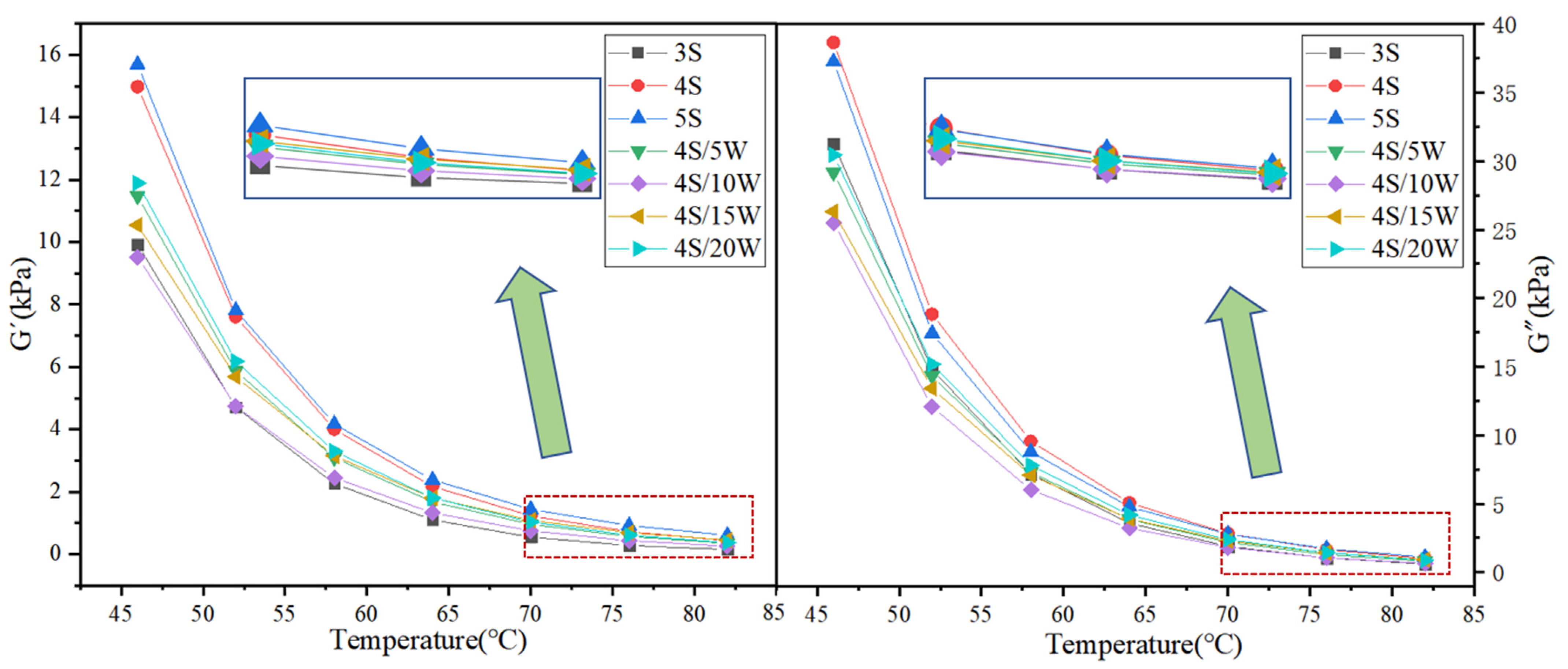

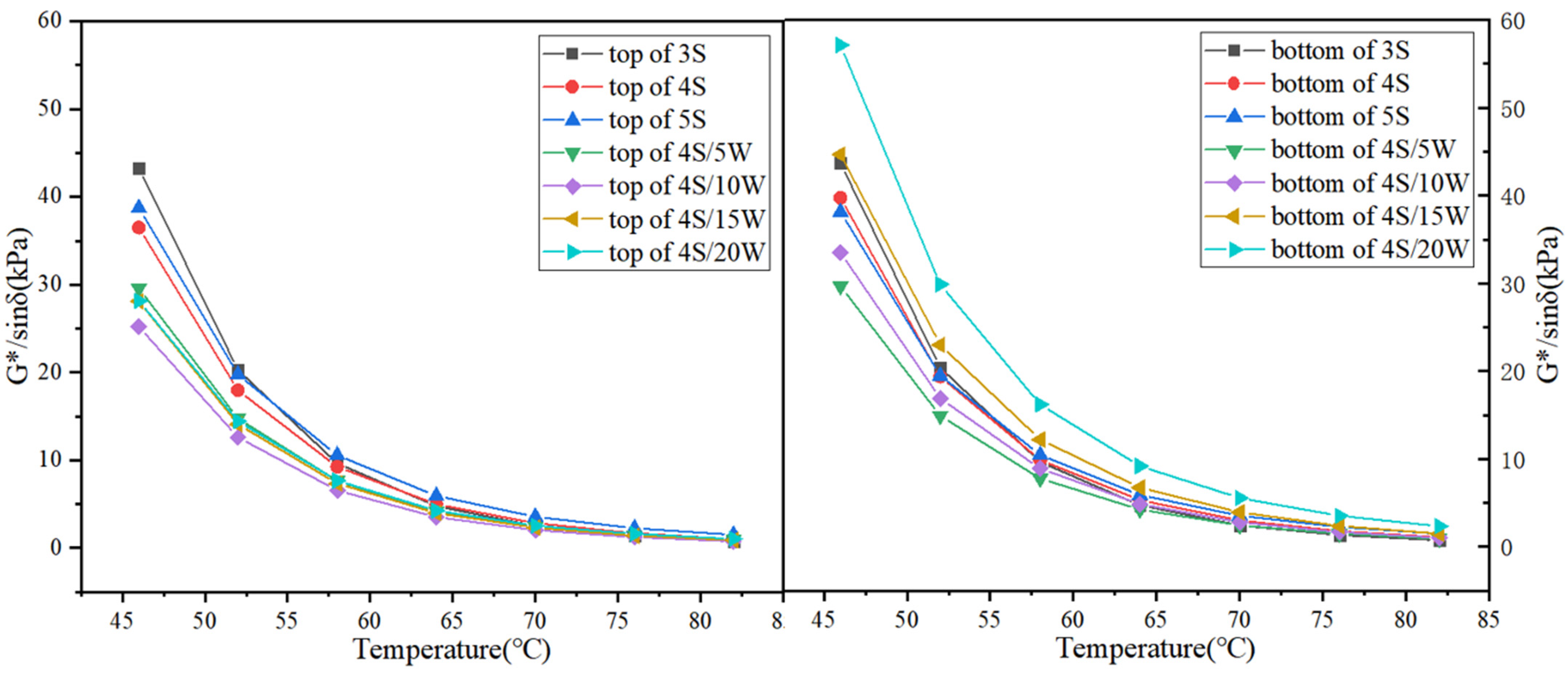

3.2.1. Temperature Sweep Test

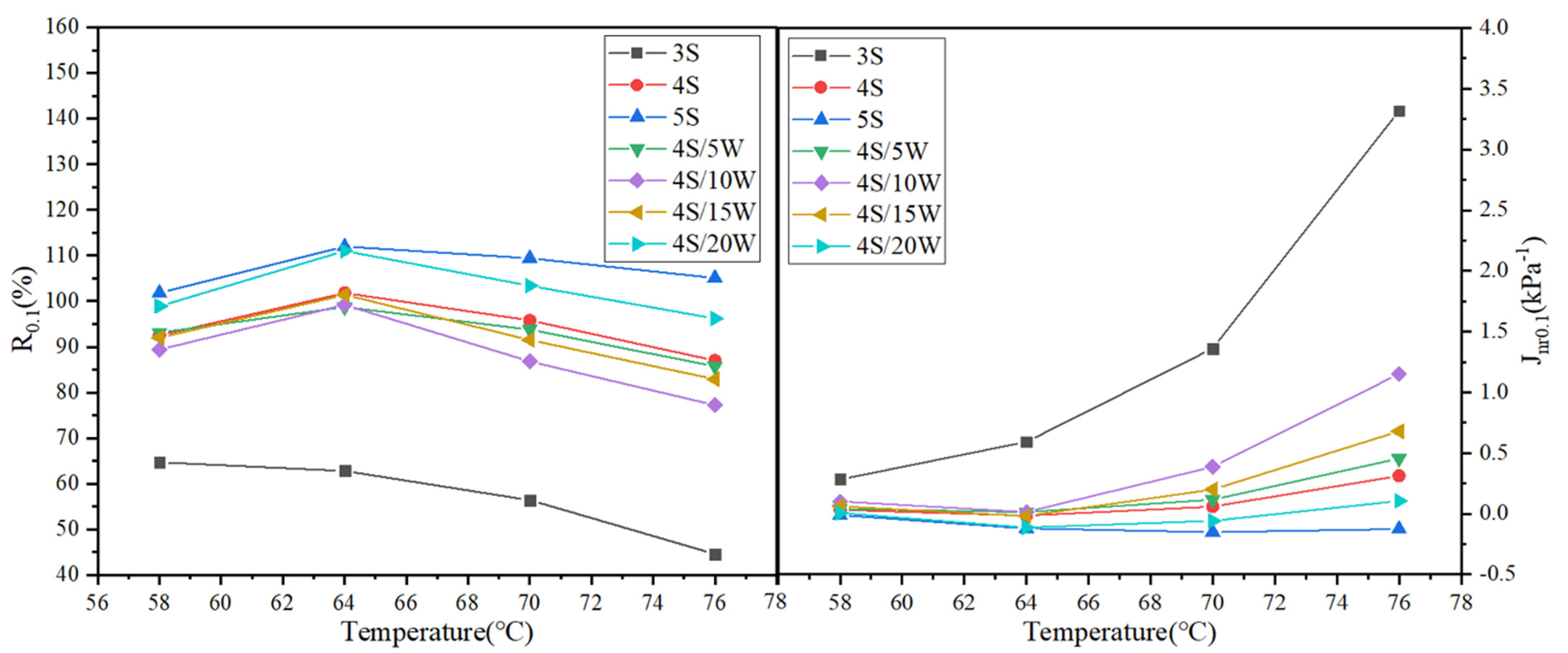

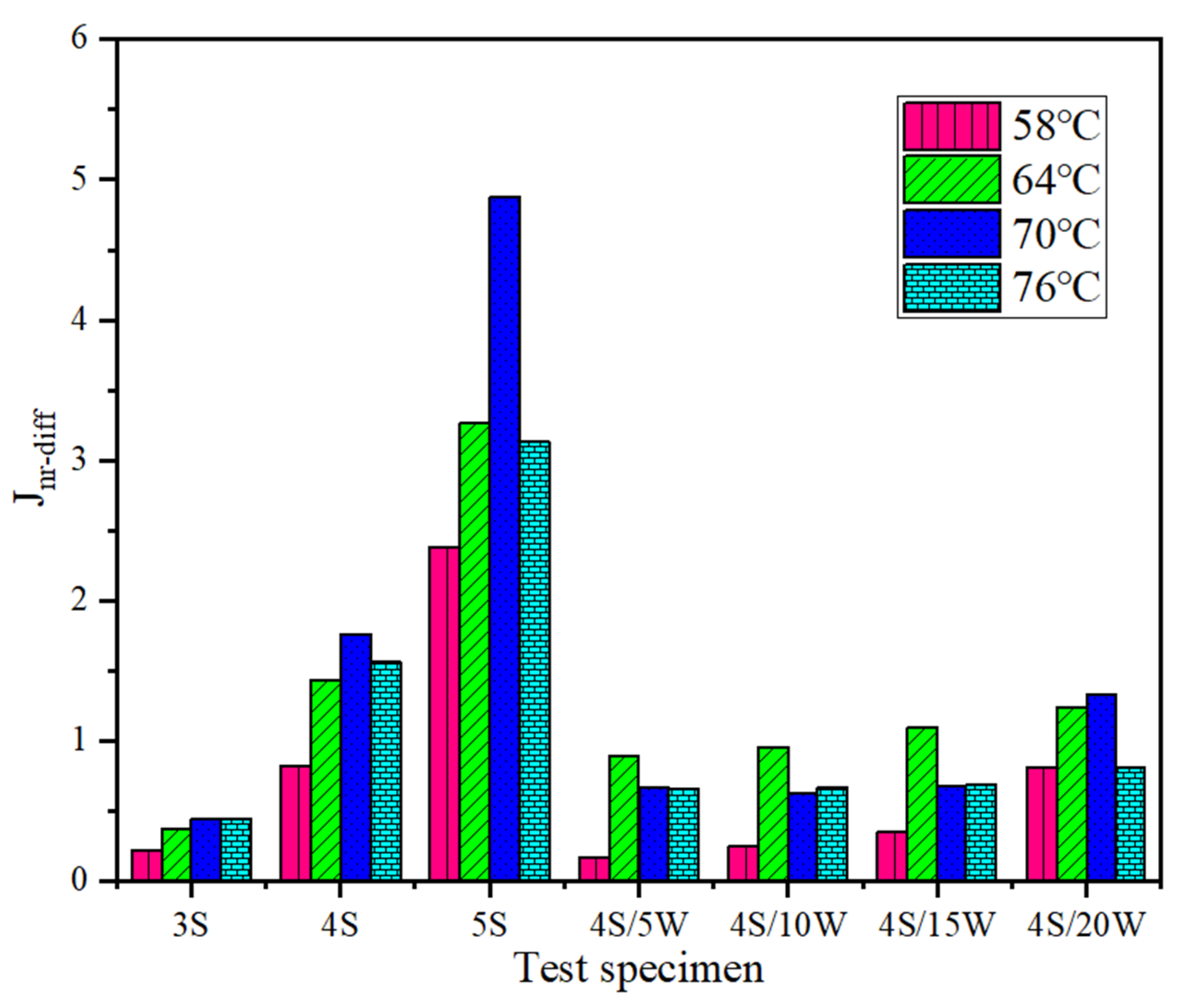

3.2.2. Multiple Stress Creep Recovery (MSCR) Test

3.2.3. Bending Beam Rheometer (BBR) Test

3.2.4. PG

3.3. Results of Storage Stability

3.4. Microstructural Characterization

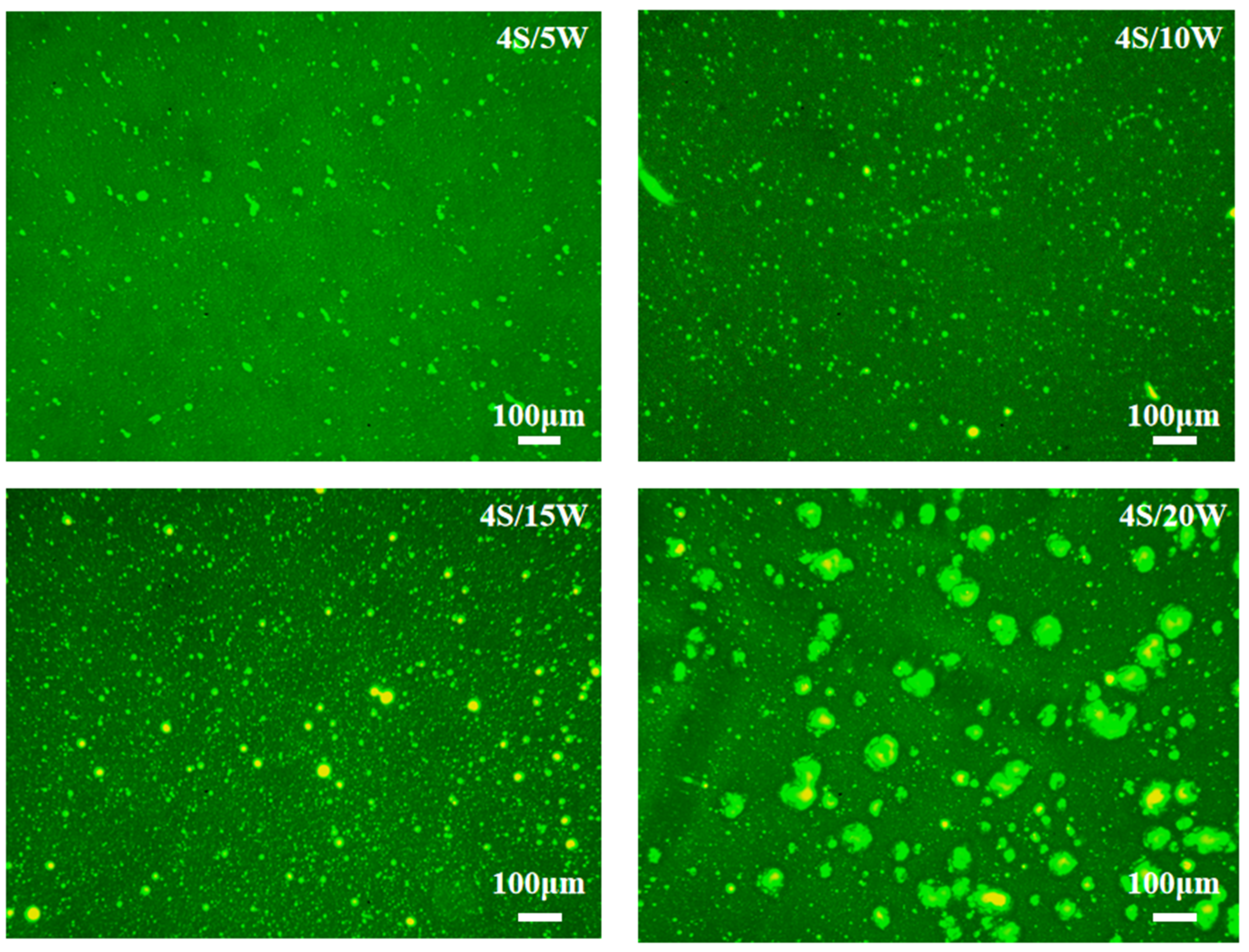

3.4.1. Fluorescence Microscope (FM) Test

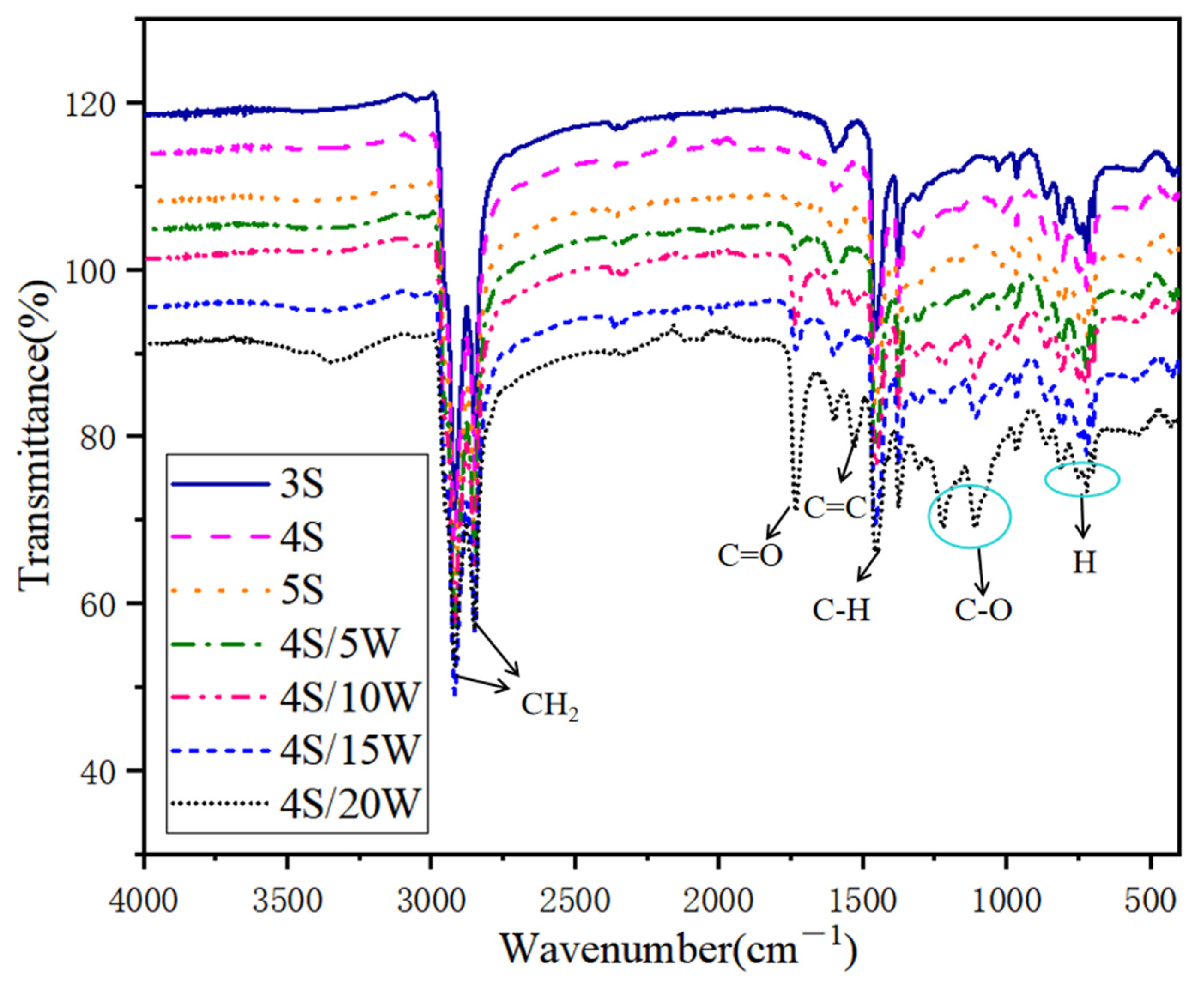

3.4.2. Fourier Transform Infrared Spectroscopy (FTIR) Test

4. Conclusions

- (1)

- With WPU, the penetration, ductility and PI index of composite modified asphalt decreased, as softening points and viscosity of composite modified asphalt increased, with higher viscosity, but lower temperature sensitivity. The feasibility of using WPU as modifier instead of part of SBS was confirmed by viscosity performance.

- (2)

- The incorporation of a small amount of WPU changed the crosslinking state of composite modified asphalt and reduced its rutting resistance. When WPU content was more than 15%, WPU formed a new crosslinking effect in asphalt, which enhanced the rutting resistance of asphalt and improved low-temperature performance of WPU/SBS composite modified asphalt. According to the high- and low-temperature rheological properties, PG grade of WPU/SBS composite modified asphalt was determined.

- (3)

- Adding WPU significantly improved the resistance to permanent deformation of WPU/SBS composite modified asphalt and reduced the dependence of viscous deformation on shear stress, which was more suitable for the construction of pavements with high temperature, heavy load or long steep.

- (4)

- SI value of upper and lower layers of WPU/SBS composite modified asphalt segregation deviated from 1, indicating that the storage stability of WPU/SBS composite modified asphalt was reduced by WPU content.

- (5)

- Through the study of the microstructure of WPU/SBS composite modified asphalt, WPU was mixed into the modified asphalt and evenly coated by asphalt, without new chemical bonds and chemical reactions. When WPU content was 20%, WPU agglomerated in asphalt, which affected the storage and engineering application of WPU/SBS composite modified asphalt. After comprehensive consideration, 4 S/15 W was determined as the suitable type of WPU/SBS composite modified asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cong, P.; Liu, N.; Tian, Y.; Zhang, Y. Effects of long-term aging on the properties of asphalt binder containing diatoms. Constr. Build. Mater. 2016, 123, 534–540. [Google Scholar] [CrossRef]

- Sun, M.; Zheng, M.; Qu, G.; Yuan, K.; Bi, Y.; Wang, J. Performance of polyurethane modified asphalt and its mixtures. Constr. Build. Mater. 2018, 191, 386–397. [Google Scholar] [CrossRef]

- Chen, J.-S.; Wang, T.; Lee, C.-T. Evaluation of a highly-modified asphalt binder for field performance. Constr. Build. Mater. 2018, 171, 539–545. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Hu, D.; Hu, Z.; Pei, J.; Kong, W. Evaluation of asphalt-aggregate interaction based on the rheological properties. Int. J. Pavement Eng. 2018, 19, 586–592. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Song, J.-L.; He, L.; Wang, X.; Luo, L.; Li, W.-G. Microscopic aging mechanism of SBS modified asphalt in RTFOT. J. Highw. Transp. Res. Dev. 2020, 37, 1–7. [Google Scholar]

- Bu, X.; Cheng, F. Research on performance of polyurethane-epoxy resin compound modified asphalt and its mixture. Highway 2016, 61, 171–174. [Google Scholar]

- Liu, X.; Zhang, B.; Zhang, H.; Du, X.; Tang, G. Research of Flame Retardant Mechanism for RPUF/EG Composites Based on TG-FTIR and XPS. Spectrosc. Spectral Anal. 2020, 40, 1626–1633. [Google Scholar]

- Bazmara, B.; Tahersima, M.; Behravan, A. Influence of thermoplastic polyurethane and synthesized polyurethane additive in performance of asphalt pavements. Constr. Build. Mater. 2018, 166, 1–11. [Google Scholar] [CrossRef]

- He, J.; Zhao, Y.; Jiang, H. Preparation and performance evaluation of polyurethane modified asphalt. Highway. 2020, 65, 245–251. [Google Scholar]

- Yu, R. Preparation and Properties of Asphalt Modified with Graphene Oxide/Polyurethane Composite. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2016. [Google Scholar]

- Jin, X.; Guo, N.; You, Z.; Wang, L.; Wen, Y.; Tan, Y. Rheological properties and micro-characteristics of polyurethane composite modified asphalt. Constr. Build. Mater. 2020, 234, 117395. [Google Scholar] [CrossRef]

- DIN 53479, Determination of Density of Plastics and Elastomers. Available online: https://global.ihs.com/doc_detail.cfm?document_name=DIN%2053479&item_s_key=00028722 (accessed on 7 July 2021).

- DIN 53504, Testing of Rubber- Determination of Tensile Strength at Break, Tensile Stress at Yield, Elongation at Break and Stress Values in a Tensile Test. Available online: https://standards.globalspec.com/std/1279073/DIN%2053504 (accessed on 7 July 2021).

- DIN 53515, Determination of Tear Strength of Rubber Elastomers and Plastic Film Using Graves Angle Test Piece with Nick. Available online: https://standards.globalspec.com/std/1864433/DIN%2053515 (accessed on 7 July 2021).

- ISO 306, Plastics-Thermoplastic Materials-Determination of Vicat Softening Temperature (VST). Available online: https://www.iso.org/standard/82176.html (accessed on 7 July 2021).

- JTG E20-2011, Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Available online: https://www.codeofchina.com/standard/JTGE20-2011.html (accessed on 7 July 2021).

- Jin, X.; Guo, N.; Yan, S.; Liu, T.; You, Z. Preparation and properties of Polyurethane Composite modified Asphalt. China J. Highw. Transp. 2021, 34, 80–94. [Google Scholar]

- ASTM 6648-08, Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). Available online: https://www.astm.org/Standards/D6816.htm (accessed on 7 July 2021).

- Dong, F.; Yu, X.; Chen, J.; Liu, S.; Chen, Q. Investigation on compatibility and microstructure of PCBs-modified asphalt. Inc. J. Appl. Polym. Sci. 2017, 134, 44798. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological evaluation of ethylene vinyl acetate polymer modified bitumens. Constr. Build. Mater. 2002, 16, 473–487. [Google Scholar] [CrossRef]

- Liu, S.; Yu, X.; Dong, F. Evaluation of moisture susceptibility of foamed warm asphalt produced by water injection using surface free energy method. Constr. Build. Mater. 2017, 131, 138–145. [Google Scholar] [CrossRef]

- ASTM D5155-01, Standard Test Methods for Polyurethane Raw Materials: Determination of the Isocyanate Content of Aromatic Isocyanates. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D5155-01 (accessed on 7 July 2021).

- Ding, G.; Yu, X.; Si, J.; Mei, J.; Wang, J.; Chen, B. Influence of epoxy soybean oil modified nano-silica on the compatibility of cold-mixed epoxy asphalt. Mater and Struct. 2021, 54, 16. [Google Scholar] [CrossRef]

- ASTM D 4402, Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using Rotational Viscometer. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D4402-06 (accessed on 7 July 2021).

- Xiao, F.; Yao, S.; Wang, J.; Wei, J.; Amirkhanian, S. Physical and chemical properties of plasma treated crumb rubbers and high-temperature characteristics of their rubberised asphalt binders. Road Mater. Pavement Des. 2020, 21, 587–606. [Google Scholar] [CrossRef]

- ASTM D7175, Standard Test Method for Determining the Rheological Properties of Asphalt Binder using a Dynamic Shear Rheometer (DSR). Available online: http://www.astm.org/cgi-bin/resolver.cgi?D7175-15 (accessed on 7 July 2021).

- Xu, L.; Li, X.; Zong, Q.; Xiao, F. Chemical, morphological and rheological investigations of SBR/SBS modified asphalt emulsions with waterborne acrylate and polyurethane. Constr. Build. Mater. 2021, 272, 121972. [Google Scholar] [CrossRef]

- Li, M.Y. Effect of high viscosity modifier on rheological properties of asphalt. Highw. Traffic Sci. Technol. 2018, 35, 14–20. [Google Scholar]

- Wang, C.; Wang, H.; Zhao, L.; Cao, D. Experimental study on rheological characteristics and performance of high modulus asphalt binder with different modifiers. Constr. Build. Mater. 2017, 155, 26–63. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, J.; Huang, Z.; Wang, F.; Jia, M.; Lv, M.; Ye, J. A laboratory study of epoxy/polyurethane modified asphalt binders and mixtures suitable for flexible bridge deck pavement. Constr. Build. Mater. 2021, 274, 122084. [Google Scholar] [CrossRef]

- Sheng, X.; Wang, M.; Xu, T.; Chen, J. Preparation. Properties and modification mechanism of polyurethane modified emulsified asphalt. Constr. Build. Mater. 2018, 189, 375–383. [Google Scholar] [CrossRef]

- Han, L.; Zheng, M.; Li, J.; Li, Y.; Zhu, Y.; Ma, Q. Effect of nano silica and pretreated rubber on the properties of terminal blend crumb rubber modifified asphalt. Constr. Build. Mater. 2017, 157, 277–291. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Z.; Zhao, F.; Liu, F.; Wang, J. Improving the performance of RET modified asphalt with the addition of polyurethane prepolymer (PUP). Constr. Build. Mater. 2019, 206, 560–575. [Google Scholar] [CrossRef]

- Alamawi, M.Y.; Khairuddin, F.H.; Yusoff, N.I.M.; Badri, K.; Ceylan, H. Investigation on physical, thermal and chemical properties of palm kernel oil polyol bio-based binder as a replacement for bituminous binder. Constr. Build. Mater. 2019, 204, 122–131. [Google Scholar] [CrossRef]

- Yu, X.; Leng, Z.; Wei, T. Investigation of the rheological modification mechanism of warm mix additives on crumb-rubber-modified asphalt. J. Mater Civil Eng. 2014, 26, 312–319. [Google Scholar] [CrossRef]

| Parameter | Results | Standard in China (JTG E20-2011) |

|---|---|---|

| Penetration (0.1 mm) | 68 | T0604 |

| Softening point (°C) | 47.8 | T0606 |

| Ductility (15 °C) (cm) | >100 | T0605 |

| Dynamic viscosity at 60 °C (Pa s) | 167.5 | T0620 |

| Density (15 °C) (g/cm−3) | 1.047 | T0603 |

| Flash point (°C) | 345 | T0611 |

| Asphalt | Asphaltenes (%) | Resins (%) | Aromatics (%) | Saturates/ (%) | Colloidal Index |

|---|---|---|---|---|---|

| SK | 11.69 | 29.97 | 48.68 | 9.66 | 3.68 |

| Parameter | Results | Standards |

|---|---|---|

| Density (g/cm3) | 1.16 | DIN 53479 [13] |

| Tensile strength (N/mm2) | 42 | DIN 53504-S2 [14] |

| Tear strength (N/mm2) | 64 | DIN 53515 [15] |

| Softening point (°C) | 71 | ISO 306 [16] |

| Parameter | Results | Standards |

|---|---|---|

| Proportion (g/cm3) | 0.94 | ISO 2781 |

| Melt flow index (g/10 min) | 6 | ASTM D1238 |

| Tensile strength (MPa) | 160 | ASTM D412 |

| Elongation (%) | 680 | ASTM D412 |

| Sample Types | PG Grade | G*/sin δ/kPa | S/MPa | m |

|---|---|---|---|---|

| 3 S | 76-22 | 1.12 | 117 | 0.405 |

| 4 S | 82-22 | 1.19 | 106 | 0.318 |

| 5 S | 82-22 | 1.44 | 124 | 0.322 |

| 4 S/5 W | 76-28 | 1.55 | 263 | 0.328 |

| 4 S/10 W | 76-28 | 1.24 | 238 | 0.335 |

| 4 S/15 W | 82-28 | 1.15 | 226 | 0.355 |

| 4 S/20 W | 82-28 | 1.04 | 217 | 0.372 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Dong, F.; Yu, X.; Zheng, C. Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt. Polymers 2021, 13, 2249. https://doi.org/10.3390/polym13142249

Chen B, Dong F, Yu X, Zheng C. Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt. Polymers. 2021; 13(14):2249. https://doi.org/10.3390/polym13142249

Chicago/Turabian StyleChen, Bei, Fuqiang Dong, Xin Yu, and Changjiang Zheng. 2021. "Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt" Polymers 13, no. 14: 2249. https://doi.org/10.3390/polym13142249

APA StyleChen, B., Dong, F., Yu, X., & Zheng, C. (2021). Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt. Polymers, 13(14), 2249. https://doi.org/10.3390/polym13142249