Self-Healing Structural Materials

Abstract

1. Introduction

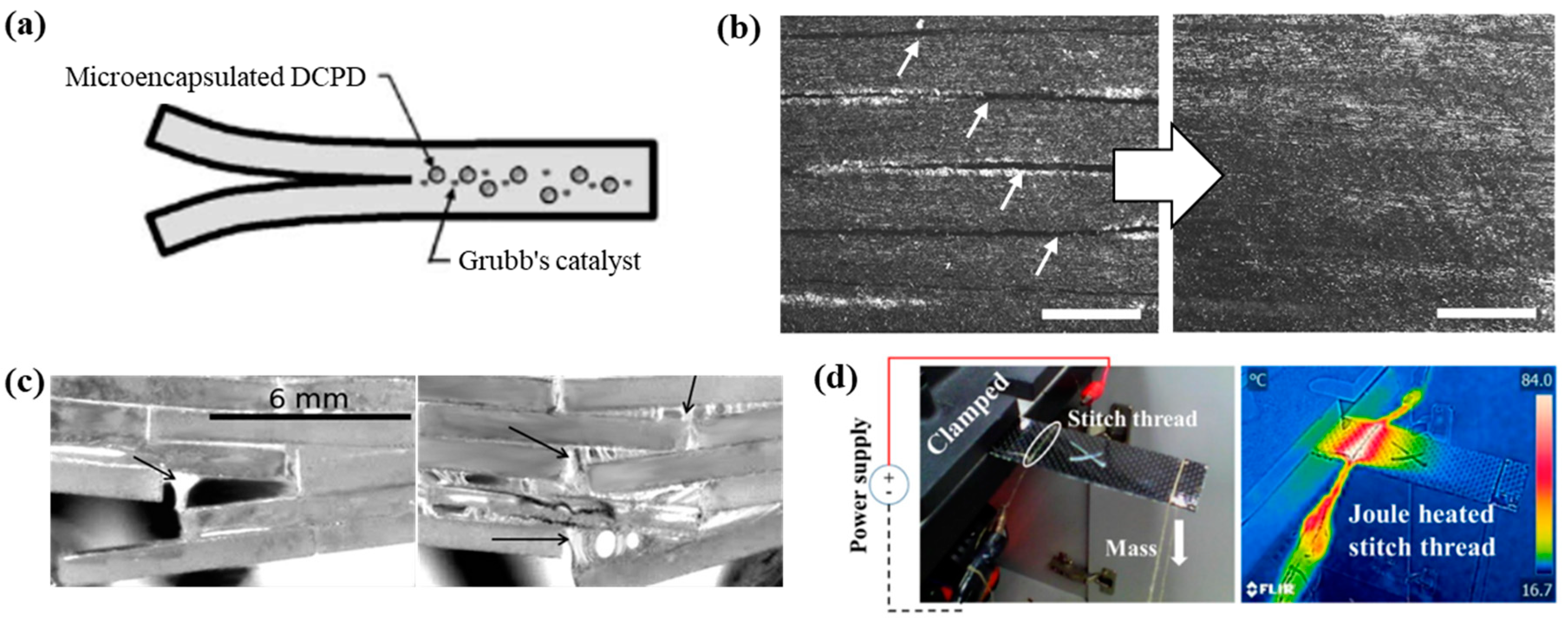

2. Self-Healing in Polymers and Their Composites

3. Self-Healing in Cement-Based Materials

4. Self-Healing in Metals and Metal Matrix Composites

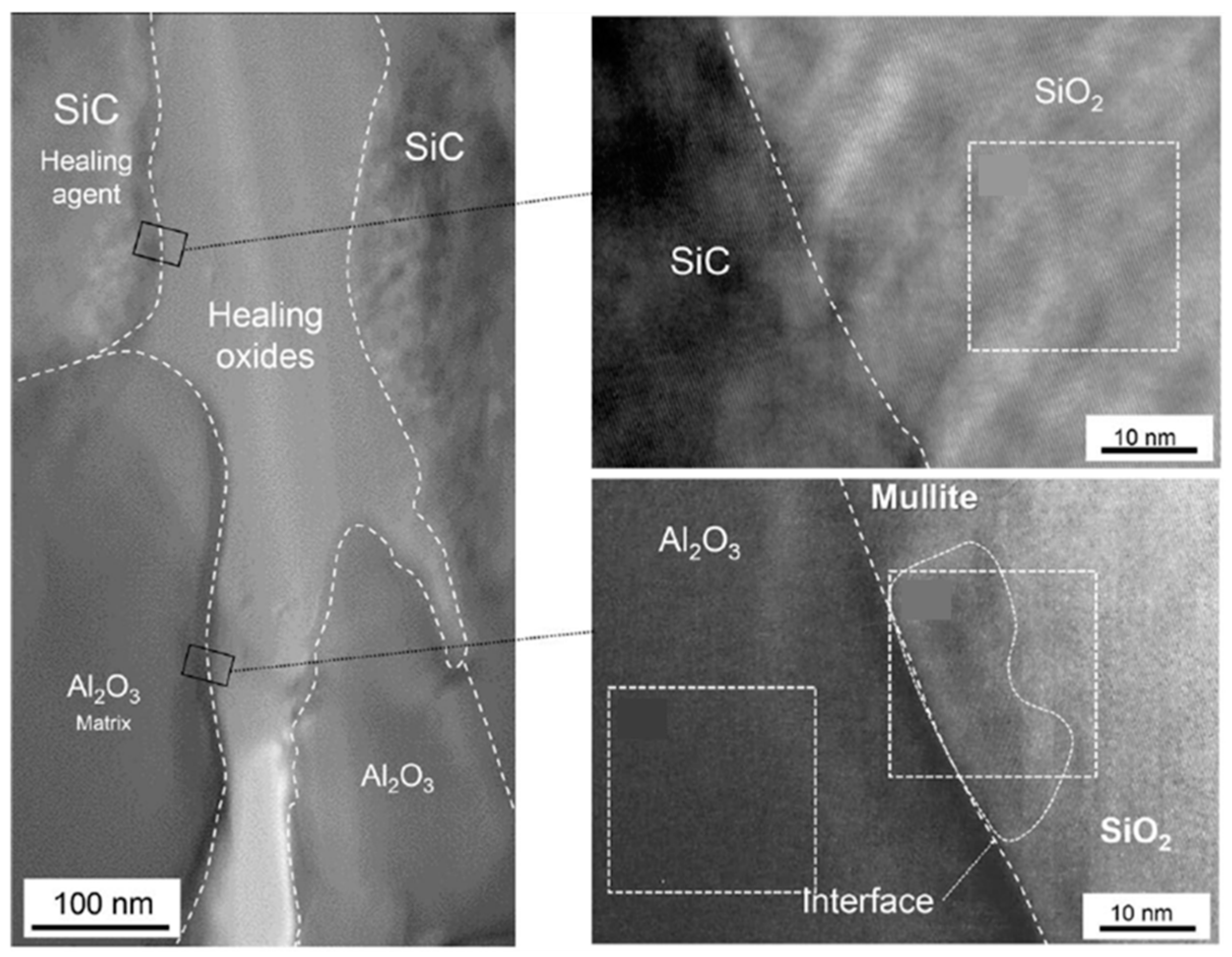

5. Self-Healing in Ceramics and Ceramic Composites

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Dry, C. Passive tuneable fibers and matrices. Int. J. Mod. Phys. B 1992, 6, 2763–2771. [Google Scholar] [CrossRef]

- Dry, C. Procedures developed for self-repair of polymer matrix composite materials. Compos. Struct. 1996, 35, 263–269. [Google Scholar] [CrossRef]

- Davami, K.; Mohsenizadeh, M.; Mitcham, M.; Damasus, P.; Williams, Q.; Munther, M. Additively manufactured self-healing structures with embedded healing agent reservoirs. Sci. Rep. 2019, 9, 7474. [Google Scholar] [CrossRef] [PubMed]

- Diba, M.; Wang, H.; Kodger, T.E.; Parsa, S.; Leeuwenburgh, S.C.G. Highly elastic and self-healing composite colloidal gels. Adv. Mater. 2017, 29, 1604672. [Google Scholar] [CrossRef]

- Yıldırım, G.; Khiavi, A.H.; Yeşilmen, S.; Şahmaran, M. Self-healing performance of aged cemetitious composites. Cem. Concr. Compos. 2018, 87, 172–186. [Google Scholar] [CrossRef]

- Beglarigale, A.; Seki, Y.; Demir, N.Y.; Yazici, H. Sodium silicate/polyurethane microcapsules used for self-healing in cemetitious materials: Monomer optimization, characterization, and fracture behavior. Constr. Build. Mater. 2018, 162, 57–64. [Google Scholar] [CrossRef]

- Hung, C.C.; Su, Y.F.; Hung, H.H. Impact of natural weathering on medium-term self-healing performance of fiber reinforced cemetitious composites with intrinsic crack-width control capability. Cem. Concr. Compos. 2017, 80, 200–209. [Google Scholar] [CrossRef]

- Alazhari, M.; Sharma, T.; Heath, A.; Cooper, R.; Paine, K. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr. Build. Mater. 2018, 160, 610–619. [Google Scholar] [CrossRef]

- Teall, O.; Pilegis, M.; Davies, R.; Sweeney, J.; Jefferson, T.; Lark, R.; Gardner, D. A shape memory polymer concrete crack closure system activated by electrical current. Smart Mater. Struct. 2018, 27, 075016. [Google Scholar] [CrossRef]

- Khan, N.I.; Halder, S. Chapter 15—Self-healing fiber-reinforced polymer composites for their potential structural applications. In Self-Healing Polymer-Based Systems; Thomas, S., Surendran, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 455–472. [Google Scholar]

- Lee, M.W. Prospects and future directions of self-healing fiber-reinforced composite materials. Polymers 2020, 12, 379. [Google Scholar] [CrossRef]

- Coope, T.S.; Wass, D.F.; Trask, R.S.; Bond, I.P. Repeated self-healing of microvascular carbon fibre reinforced polymer composites. Smart Mater. Struct. 2014, 23, 115002. [Google Scholar] [CrossRef]

- Lumley, R. Self Healing in Aluminium Alloys. In Self-Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Springer Series in Materials Science; Sybrand, v.d.Z.; Springer: Dordrecht, The Netherlands, 2007; pp. 219–254. [Google Scholar]

- Shinya, N. Self-healing of metallic materials: Self-healing of creep cavity and fatigue cavity/crack. In Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Ghosh, S.K., Ed.; Wiley: Weinheim, Germany, 2009; pp. 219–250. [Google Scholar]

- Manuel, M.V. Principles of self-healing in metals and alloys: An introduction. In Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Ghosh, S.K., Ed.; Wiley: Weinheim, Germany, 2009; pp. 251–266. [Google Scholar]

- Grabowski, B.; Tasan, C.C. Self-Healing Materials. In Advances in Polymer Science; Springer: Cham, Switzerland, 2016; Volume 273. [Google Scholar]

- Lee, M.W.; An, S.; Lee, C.; Liou, M.; Yarin, A.L.; Yoon, S.S. Hybrid self-healing matrix using core−shell nanofibers and capsuleless microdroplets. ACS Appl. Mater. Interfaces 2014, 6, 10461–10468. [Google Scholar] [CrossRef]

- Joshi, L.N.A.P. Composites Market-Global Forecast to 2024; Lucintel: Dallas, TX, USA, 2019. [Google Scholar]

- Goldsmith, S. Southwest Airlines Flight 2294 Lands in West Virginia with Football-Sized Hole in Fuselage. Available online: http://www.nydailynews.com/news/world/southwest-airlines-flight-2294-lands-west-virginia-football-sized-hole-fuselage-article-1.397715 (accessed on 10 July 2021).

- EPRI. Probabilistic Seismic Hazard Evaluations at Nuclear Plant Sites in the Central and Eastern United States: Resolution of the Charleston Earthquake Issue; EPRI NP 6395D; Electric Power Research Institute: Palo Alto, CA, USA, 1989. [Google Scholar]

- Aircraft Health Monitoring Market by Platform (Commercial, Business & General, Military Aviation), Installation (Onboard, On Ground), Fit (Linefit, Retrofit), End User, Solution, System, Operation Mode and Region—Global Forecast to 2025Research and Markets. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/aircraft-health-monitoring-systems-market-954.html (accessed on 12 July 2021).

- Thomas, S.; Surendran, A. (Eds.) Self-Healing Polymer-Based Systems, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Binder, W.H. (Ed.) Self-Healing Polymers: From Principles to Applications; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Zhang, M.Q.; Rong, M.Z. Self-Healing Polymers and Polymer Composites; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ghosh, S.K. Self-Healing Materials: Fundamentals, Design Strategies, and Applications. In Self-Healing Materials: Fundamentals, Design Strategies, and Applications; Ghosh, S.K., Ed.; Wiley: Weinheim, Germany, 2008; pp. 1–28. [Google Scholar]

- Yarin, A.L.; Lee, M.W.; An, S.; Yoon, S.S. Self-Healing Nanotextured Vascular Engineering Materials; Springer International Publishing: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Kessler, M.R.; Sottos, N.R.; White, S.R. Self-healing structural composite materials. Compos. Part A 2003, 34, 743–753. [Google Scholar] [CrossRef]

- Heo, Y.; Sodano, H.A. Thermally responsive self-healing composites with continuous carbon fiber reinforcement. Compos. Sci. Technol. 2015, 118, 244–250. [Google Scholar] [CrossRef]

- D’Elia, E.; Eslava, S.; Miranda, M.; Georgiou, T.K.; Saiz, E. Autonomous self-healing structural composites with bio-inspired design. Sci. Rep. 2016, 6, 25059. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Ryu, K.H.; Na, W.; Yu, J.; Lee, M.W. Origami-inspired reforming method for carbon fiber-reinforced thermoplastics via simple thermal stitching. Compos. Part B 2020, 193, 108043. [Google Scholar] [CrossRef]

- Cordier, P.; Tournilhac, F.; Soulie-Ziakovic, C.; Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 2008, 451, 977–980. [Google Scholar] [CrossRef] [PubMed]

- Sordo, F.; Mougnier, S.J.; Loureiro, N.; Tournilhac, F.; Michaud, V. Design of self-healing supramolecular rubbers with a tunable number of chemical cross-links. Macromolecules 2015, 48, 4394–4402. [Google Scholar] [CrossRef]

- Rahbar, N. Extending the life of self-healing structural materials. Matter 2020, 2, 284–296. [Google Scholar] [CrossRef]

- Schlangen, E. Self-Healing Phenomena in Cement-Based Materials; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Past and present techniques of self-healing in cementitious materials: A critical review on efficiency of implemented treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Wang, X.F.; Yang, Z.H.; Fang, C.; Han, N.X.; Zhu, G.M.; Tang, J.N.; Xing, F. Evaluation of the mechanical performance recovery of self-healing cementitious materials—Its methods and future development: A review. Constr. Build. Mater. 2019, 212, 400–421. [Google Scholar] [CrossRef]

- Zhu, B.; Li, Q.; Chen, W.; Zou, W.; Chen, W. A novel method of self-healing in cementitious materials by using polyacrylic hydrogel. KSCE J. Civ. Eng. 2020, 24, 3406–3415. [Google Scholar] [CrossRef]

- Justo-Reinoso, I.; Heath, A.; Gebhard, S.; Paine, K. Aerobic non-ureolytic bacteria-based self-healing cementitious composites: A comprehensive review. J. Build. Eng. 2021, 42, 102834. [Google Scholar] [CrossRef]

- Lv, L.; Liu, P.G.G.; Han, N.; Xing, F. Light induced self-healing in concrete using novel cementitious capsules containing uv curable adhesive. Cem. Concr. Compos. 2020, 105, 103445. [Google Scholar] [CrossRef]

- Song, Y.K.; Jo, Y.H.; Lim, Y.J.; Cho, S.Y.; Yu, H.C.; Ryu, B.C.; Lee, S.I.; Chung, C.M. Sunlight-induced self-healing of a microcapsule-type protective coating. ACS Appl. Mater. Interfaces 2013, 5, 1378–1384. [Google Scholar] [CrossRef]

- Kim, D.M.; Song, I.H.; Choi, J.Y.; Jin, S.W.; Nam, Y.N.; Chung, C.M. Self-healing coatings based on linseed-oil-loaded microcapsules for protection of cementitious materials. Coatings 2018, 8, 404. [Google Scholar] [CrossRef]

- Yang, H.I.; Kim, D.M.; Yu, H.C.; Chung, C.M. Microcapsule-type organogel-based self-healing system having secondary damage preventing capability. ACS Appl. Mater. Interfaces 2016, 8, 11070–11075. [Google Scholar] [CrossRef] [PubMed]

- Kanellopoulos, A.; Qureshi, T.S.; Al-Tabbaa, A. Glass encapsulated minerals for self-healing in cement based composites. Constr. Build. Mater. 2015, 98, 780–791. [Google Scholar] [CrossRef]

- Giannaros, P.; Kanellopoulos, A.; Al-Tabbaa, A. Sealing of cracks in cement using microencapsulated sodium silicate. Smart Mater. Struct. 2016, 25, 084005. [Google Scholar] [CrossRef]

- Davies, R.; Teall, O.; Pilegis, M.; Kanellopoulos, A.; Sharma, T.; Jefferson, A.; Gardner, D.; Al-Tabbaa, A.; Paine, K.; Lark, R. Large scale application of self-healing concrete: Design, construction, and testing. Front. Mater. 2018, 5, 51. [Google Scholar] [CrossRef]

- Ersan, Y.C.; Palin, D.; Tasdemir, S.B.Y.; Tasdemir, K.; Jonkers, H.M.; Boon, N.; Belie, N.D. Volume fraction, thickness, and permeability of the sealing layer in microbial self-healing concrete containing biogranules. Front. Built Environ. 2018, 4, 70. [Google Scholar] [CrossRef]

- Belleghem, B.V.; Van den Heede, P.; Tittelboom, K.V.; Belie, N.D. Quantification of the service life extension and environmental benefit of chloride exposed self-healing concrete. Materials 2017, 10, 5. [Google Scholar] [CrossRef]

- America’s Infrastructure Report Card; American Society of Civil Engineers: Reston, VA, USA, 2017; Available online: https://www.infrastructurereportcard.org/wp-content/uploads/2016/10/2017-Infrastructure-Report-Card.pdf (accessed on 13 July 2021).

- Lee, M.W.; Yang, B.J.; Park, H.M.; Yang, C.M.; Yoo, J.S.; Kim, M. Self-Healing Cement Composite Comprising Conductive Filler and Polymer Filler. 2020. 10-2127983. Available online: http://kpat.kipris.or.kr/kpat/biblioa.do?method=biblioFrame&link=Y (accessed on 13 July 2021).

- Grabowski, B.; Tasan, C.C. Self-healing metals. In Self-Healing Materials; Hager, M.D., Zwaag, S.V.D., Schubert, U.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Zhang, S.; Dijk, N.V.; Zwaag, S.V.D. A review of self-healing metals: Fundamentals, design principles and performance. Acta Metall. Sin. 2020, 33, 1167–1179. [Google Scholar] [CrossRef]

- Wang, H.; Huang, P.; Li, Z. Crack and void healing in metals. In Self-Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Sybrand, v.d.Z.; Springer: Dordrecht, The Netherlands, 2007; pp. 255–277. [Google Scholar]

- Sun, W.W.; Fang, H.; Dijk, N.H.V.; Zwaag, S.V.D.; Hutchinson, C.R. Linking surface precipitation in fe-au alloys to its self-healing potential during creep loading. Metall. Mater. Trans. A 2017, 48, 2109–2114. [Google Scholar] [CrossRef]

- Fu, Y.; Kwakernaak, C.; Sloof, W.G.; Tichelaar, F.D.; Brück, E.; Zwaag, S.V.D.; Dijk, N.H.V. Competitive healing of creep-induced damage in a ternary fe-3au-4w alloy. Metall. Mater. Trans. A 2020, 51, 4442–4455. [Google Scholar] [CrossRef]

- Shinya, N.; Kyono, J.; Laha, K. Self-healing effect of boron nitride precipitation on creep cavitation in austenitic stainless steel. J. Intell. Mater. Syst. Struct. 2006, 17, 1127–1133. [Google Scholar] [CrossRef]

- Karpov, E.G.; Grankin, M.V.; Liu, M.; Ariyan, M. Characterization of precipitative self-healing materials by mechanokinetic modeling approach. J. Mech. Phys. Solids 2012, 60, 250–260. [Google Scholar] [CrossRef]

- Dijk, N.V.; Zwaag, S.V.D. Self-healing phenomena in metals. Adv. Mater. Interfaces 2018, 5, 1800226. [Google Scholar] [CrossRef]

- Fang, H.; Versteylen, C.D.; Zhang, S.; Yang, Y.; Cloetens, P.; Ngan-Tillard, D.; Brück, E.; Zwaag, S.V.D.; Dijk, N.H.V. Autonomous filling of creep cavities in fe-au alloys studied by synchrotron X-ray nano-tomography. Acta Mater. 2016, 121, 352–364. [Google Scholar] [CrossRef]

- Zhang, S.; Fang, H.; Gramsma, M.E.; Kwakernaak, C.; Sloof, W.G.; Tichelaar, F.D.; Kuzmina, M.; Herbig, M.; Raabe, D.; Brück, E.; et al. Autonomous filling of grain-boundary cavities during creep loading in Fe-Mo alloys. Metall. Mater. Trans. A 2016, 47, 4831. [Google Scholar] [CrossRef][Green Version]

- Fridlyander, I.N.; Shevchenko, V.Y.; Barinov, S.M. Ceramic composite materials. Met. Sci. Heat Treat. 2012, 34, 133–138. [Google Scholar] [CrossRef]

- Ando, K.; Chu, M.C.; Tsuji, K.; Hirasawa, T.; Kobayashi, Y.; Sato, S. Crack healing behavior and high-temperature strength of mullite/SiC composite ceramics. J. Eur. Ceram. Soc. 2002, 22, 1313–1319. [Google Scholar] [CrossRef]

- Nakao, W.; Ono, M.; Lee, S.K.; Takahashi, K.; Ando, K. Critical crack-healing condition for SiC whisker reinforced alumina under stress. J. Eur. Ceram. Soc. 2005, 25, 3649–3655. [Google Scholar] [CrossRef]

- Nakao, W.; Takahashi, K.; Ando, K. Threshold stress during crack-healing treatment of structural ceramics having the crack-healing ability. Mater. Lett. 2007, 61, 2711–2713. [Google Scholar] [CrossRef]

- Nakao, W.; Abe, S. Enhancement of the self-healing ability in oxidation induced self-healing ceramic by modifying the healing agent. Smart Mater. Struct. 2012, 21, 025002. [Google Scholar] [CrossRef]

- Ando, K.; Kim, B.S.; Chu, M.C.; Saito, S.; Takahashi, K. Crack-healing and mechanical behaviour of Al2O3/SiC composites at elevated temperature. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 533–541. [Google Scholar] [CrossRef]

- Osada, T.; Kamoda, K.; Mitome, M.; Hara, T.; Abe, T.; Tamagawa, Y.; Nakao, W.; Ohmura, T. A novel design approach for self-crack-healing structural ceramics with 3D networks of healing activator. Sci. Rep. 2017, 7, 17853. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, S.; Yoon, S.S.; Lee, M.W. Self-Healing Structural Materials. Polymers 2021, 13, 2297. https://doi.org/10.3390/polym13142297

An S, Yoon SS, Lee MW. Self-Healing Structural Materials. Polymers. 2021; 13(14):2297. https://doi.org/10.3390/polym13142297

Chicago/Turabian StyleAn, Seongpil, Sam S. Yoon, and Min Wook Lee. 2021. "Self-Healing Structural Materials" Polymers 13, no. 14: 2297. https://doi.org/10.3390/polym13142297

APA StyleAn, S., Yoon, S. S., & Lee, M. W. (2021). Self-Healing Structural Materials. Polymers, 13(14), 2297. https://doi.org/10.3390/polym13142297