Fabrication of Enhanced Mechanical Properties and Intrinsic Flame-Retardant Polyurethane Elastomer Containing 4-(Phenylethynyl) Di(Ethylene Glycol) Phthalate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

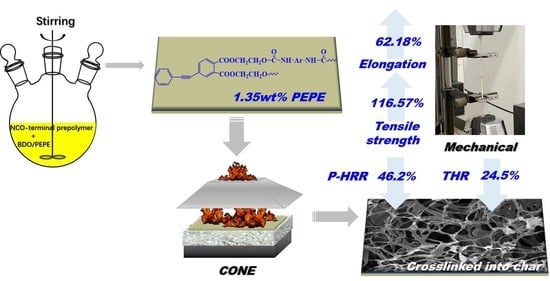

2.2. Preparation of Flame-Retardant TPU

2.3. Measurements

2.3.1. Molecular Weight of PEPE

2.3.2. The Mechanical Properties Test

2.3.3. Thermogravimetry Analysis Test

2.3.4. Cone Calorimeter Test

2.3.5. Limiting Oxygen Index Test

2.3.6. Scanning Electron Microscopy

3. Results and Discussion

3.1. Molecular Weight and Mechanical Properties

3.2. Thermal Stability and LOI

3.3. Cone Calorimetry

3.4. Scanning Electron Microscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saiani, A.; Daunch, W.A.; Verbeke, H.; Leenslag, J.W.; Higgins, J.S. Origin of multiple melting endotherms in a high hard block content polyurethane. 1. Thermodynamic investigation. Macromolecules 2001, 34, 9059–9068. [Google Scholar] [CrossRef]

- Pichaiyut, S.; Nakason, C.; Vennemann, N. Thermoplastic elastomers-based natural rubber and thermoplastic polyurethane blends. Iran. Polym. J. 2012, 21, 65–79. [Google Scholar] [CrossRef]

- Saiani, A.; Rochas, C.; Eeckhaut, G.; Daunch, W.A.; Leenslag, J.W.; Higgins, J.S. Origin of multiple melting endotherms in a high hard block content polyurethane. 2. Structural investigation. Macromolecules 2004, 37, 1411–1421. [Google Scholar] [CrossRef]

- Saiani, A.; Novak, A.; Rodier, L.; Eeckhaut, G.; Leenslag, J.W.; Higgins, J.S. Origin of multiple melting endotherms in a high hard block content polyurethane: Effect of annealing temperature. Macromolecules 2007, 40, 7252–7262. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, J.; Nedolisa, C.; Saiani, A.; Assender, H.E. Phase separation and crystallization in high hard block content polyurethane thin films. Macromolecules 2015, 48, 5358–5366. [Google Scholar] [CrossRef]

- Linliu, K.; Chen, A.S.; Yu, T.L.; Lin, T.L.; Lee, C.H.; Kai, J.J.; Chang, S.L.; Lin, J.S. A small-angle X-ray scattering study of microphase separation transition of polyurethanes: Effect of hard segments. J. Polym. Res. 1995, 2, 63–70. [Google Scholar] [CrossRef]

- Ishida, M.; Yoshinaga, K.; Horii, F. Solid-State 13C NMR Analyses of the microphase-separated structure of polyurethane elastomer. Macromolecules 1996, 29, 8824–8829. [Google Scholar] [CrossRef]

- Lempesis, N.; Veld, P.J.I.; Rutledge, G.C. Simulation of the structure and mechanics of crystalline 4,4′-diphenyl methane diisocyanate (MDI) with n-butanediol (BDO) as chain extender. Polymer 2016, 107, 233–239. [Google Scholar] [CrossRef] [Green Version]

- Seymour, W.R.; Cooper, S.L. Thermal analysis of polyurethane block polymers. Macromolecules 1973, 6, 48–53. [Google Scholar] [CrossRef]

- Harrell, L.L. Segmented polyurethanes. Properties as a function of segment size and distribution. Macromolecules 1969, 2, 607–612. [Google Scholar] [CrossRef]

- Hepburn, C. Thermoplastic (linear) polyurethane elastomers. In Polyurethane Elastomers; Springer: Dordrecht, The Netherlands, 1992; pp. 244–280. [Google Scholar] [CrossRef]

- Datta, J.; Kasprzyk, P. Thermoplastic polyurethanes derived from petrochemical or renewable resources: A comprehensive review. Polym. Eng. Sci. 2018, 58, E14–E35. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.W.; Qiao, H.; Guo, J.; Sun, J.; Li, H.F.; Zhang, S.; Gu, X.Y. Preparation of cobalt-based metal organic framework and its application as synergistic flame retardant in thermoplastic polyurethane (TPU). Compos. B Eng. 2020, 182, 107498. [Google Scholar] [CrossRef]

- Cai, W.; Wang, B.B.; Liu, L.X.; Zhou, X.; Chu, F.K.; Zhan, J.; Hu, Y.; Kan, Y.C.; Wang, X. An operable platform towards functionalization of chemically inert boron nitride nanosheets for flame retardancy and toxic gas suppression of thermoplastic polyurethane. Compos. B Eng. 2019, 178, 107462. [Google Scholar] [CrossRef]

- Shan, X.Y.; Zhang, P.; Song, L.; Hu, Y.; Lo, S. Compound of nickel phosphate with Ni(OH)(PO4)(2-) layers and synergistic application with intumescent flame retardants in thermoplastic polyurethane elastomer. Ind. Eng. Chem. Res. 2011, 50, 7201–7209. [Google Scholar] [CrossRef]

- Chen, Y.H.; Peng, H.Q.; Li, J.H.; Xia, Z.X.; Tan, H. A novel flame retardant containing phosphorus, nitrogen, and sulfur. J. Therm. Anal. Calorim. 2014, 115, 1639–1649. [Google Scholar] [CrossRef]

- Liu, L.B.; Xue, Y.; Li, S.; Xu, M.J.; He, Y.T.; Shi, Z.X.; Li, B. A novel strategy for simultaneously improving the fire safety, water resistance and compatibility of thermoplastic polyurethane composites through the construction of biomimetic hydrophobic structure of intumescent flame retardant synergistic system. Compos. B Eng. 2019, 176, 107218. [Google Scholar] [CrossRef]

- El Khatib, W.; Youssef, W.B.; Bunel, C.; Mortaigne, B. Fireproofing of polyurethane elastomers by reactive organophosphonates. Polym. Int. 2003, 52, 146–152. [Google Scholar] [CrossRef]

- Wazarkar, K.; Kathalewar, M.; Sabnis, A. Improvement in flame retardancy of polyurethane dispersions by newer reactive flame retardant. Prog. Org. Coat. 2015, 87, 75–82. [Google Scholar] [CrossRef]

- Tang, Q.H.; Song, Y.; He, J.Y.; Yang, R.J. Synthesis and characterization of inherently flame-retardant and anti-dripping thermoplastic poly(imides-urethane)s. J. Appl. Polym. Sci. 2014, 131, 40801. [Google Scholar] [CrossRef]

- Morgan, A.B.; Tour, J.M. Synthesis and testing of nonhalogenated alkyne-containing flame-retarding polymer additives. Macromolecules 1998, 31, 2857–2865. [Google Scholar] [CrossRef]

- Morgan, A.B.; Tour, J.M. Synthesis and testing of nonhalogenated alkyne/phosphorus-containing polymer additives: Potent condensed-phase flame retardants. J. Appl. Polym. Sci. 1999, 73, 707–718. [Google Scholar] [CrossRef]

- Tang, Q.H.; Ai, Q.S.; He, J.Y.; Li, X.D.; Yang, R.J. Synthesis and characterization of thermally stable poly(urethane-imide)s based on novel diols-containing imide and alkynyl groups. High Perform. Polym. 2013, 25, 798–812. [Google Scholar] [CrossRef]

- Holland, T.V.; Glass, T.E.; McGrath, J.E. Investigation of the thermal curing chemistry of the phenylethynyl group using a model aryl ether imide. Polymer 2000, 41, 4965–4990. [Google Scholar] [CrossRef]

- Zhao, H.B.; Chen, L.; Yang, J.C.; Ge, X.G.; Wang, Y.Z. A novel flame-retardant-free copolyester: Cross-linking towards self extinguishing and non-dripping. J. Mater. Chem. 2012, 22, 19849–19857. [Google Scholar] [CrossRef]

- Shi, J.B.; Tong, B.; Li, Z.; Shen, J.B.; Zhao, W.; Fu, H.H.; Zhi, J.G.; Dong, Y.P.; Ha1ussler, M.; Lam, J.W.; et al. Hyperbranched Poly(ferrocenylphenylenes): Synthesis, Characterization, Redox Activity, Metal Complexation, PyrolyticCeramization, and Soft Ferromagnetism. Macromolecules 2007, 40, 8195–8204. [Google Scholar] [CrossRef]

- Ye, X.M.; Li, J.J.; Zhang, W.C.; Yang, R.J.; Li, J.R. Fabrication of eco-friendly and multifunctional sodium- containing polyhedral oligomeric silsesquioxane and its flame retardancy on epoxy resin. Compos. B Eng. 2020, 191, 107961. [Google Scholar] [CrossRef]

| Sample | Molar Ratio (MDI:PTMG:BDO:PEPE) | PEPE Content (%) |

|---|---|---|

| Blank-TPU | 2:1:1:0 | 0 |

| 0.68%PEPE-TPU | 2:1:0.95:0.05 | 0.68 |

| 1.35%PEPE-TPU | 2:1:0.90:0.10 | 1.35 |

| 2.68%PEPE-TPU | 2:1:0.80:0.20 | 2.68 |

| 5.25%PEPE-TPU | 2:1:0.60:0.40 | 5.25 |

| Sample | Mn (104) | Mw/Mn | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| Blank-TPU | 5.01 | 2.06 | 18.1 | 907 |

| 0.68%PEPE-TPU | 4.69 | 2.43 | 19.8 | 1354 |

| 1.35%PEPE-TPU | 7.50 | 2.16 | 39.2 | 1471 |

| 2.68%PEPE-TPU | 7.74 | 2.03 | 31.3 | 1509 |

| 5.25%PEPE-TPU | 4.36 | 2.21 | 13.7 | 1600 |

| Sample | T5% (°C) | Tmax (°C) | MLRmax (%/min) | Residual Mass (%) |

|---|---|---|---|---|

| Blank-TPU | 301.3 | 417.0 | −22.31 | 0.27 |

| 0.68%PEPE-TPU | 300.6 | 403.3 | −21.91 | 1.79 |

| 1.35%PEPE-TPU | 298.6 | 403.5 | −19.30 | 3.82 |

| 2.68%PEPE-TPU | 297.4 | 416.4 | −19.40 | 6.03 |

| 5.25%PEPE-TPU | 299.7 | 418.3 | −19.23 | 6.74 |

| Sample | TTI (s) | p-HRR (kW/m2) | THR (MJ/m2) |

|---|---|---|---|

| Blank-TPU | 28 | 1476.4 | 102 |

| 0.68%PEPE-TPU | 30 | 1068.9 | 84.14 |

| 1.35%PEPE-TPU | 30 | 794.4 | 76.98 |

| 2.68%PEPE-TPU | 26 | 998.2 | 64.96 |

| 5.25%PEPE-TPU | 30 | 1129.0 | 76.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, M.; Jia, D.; Hu, J.; He, J.; Li, X.; Yang, R. Fabrication of Enhanced Mechanical Properties and Intrinsic Flame-Retardant Polyurethane Elastomer Containing 4-(Phenylethynyl) Di(Ethylene Glycol) Phthalate. Polymers 2021, 13, 2388. https://doi.org/10.3390/polym13152388

Xie M, Jia D, Hu J, He J, Li X, Yang R. Fabrication of Enhanced Mechanical Properties and Intrinsic Flame-Retardant Polyurethane Elastomer Containing 4-(Phenylethynyl) Di(Ethylene Glycol) Phthalate. Polymers. 2021; 13(15):2388. https://doi.org/10.3390/polym13152388

Chicago/Turabian StyleXie, Meina, Daikun Jia, Jin Hu, Jiyu He, Xiangmei Li, and Rongjie Yang. 2021. "Fabrication of Enhanced Mechanical Properties and Intrinsic Flame-Retardant Polyurethane Elastomer Containing 4-(Phenylethynyl) Di(Ethylene Glycol) Phthalate" Polymers 13, no. 15: 2388. https://doi.org/10.3390/polym13152388

APA StyleXie, M., Jia, D., Hu, J., He, J., Li, X., & Yang, R. (2021). Fabrication of Enhanced Mechanical Properties and Intrinsic Flame-Retardant Polyurethane Elastomer Containing 4-(Phenylethynyl) Di(Ethylene Glycol) Phthalate. Polymers, 13(15), 2388. https://doi.org/10.3390/polym13152388