Electrochemically Obtained Polysulfonates Doped Poly(3,4-ethylenedioxythiophene) Films—Effects of the Dopant’s Chain Flexibility and Molecular Weight Studied by Electrochemical, Microgravimetric and XPS Methods

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

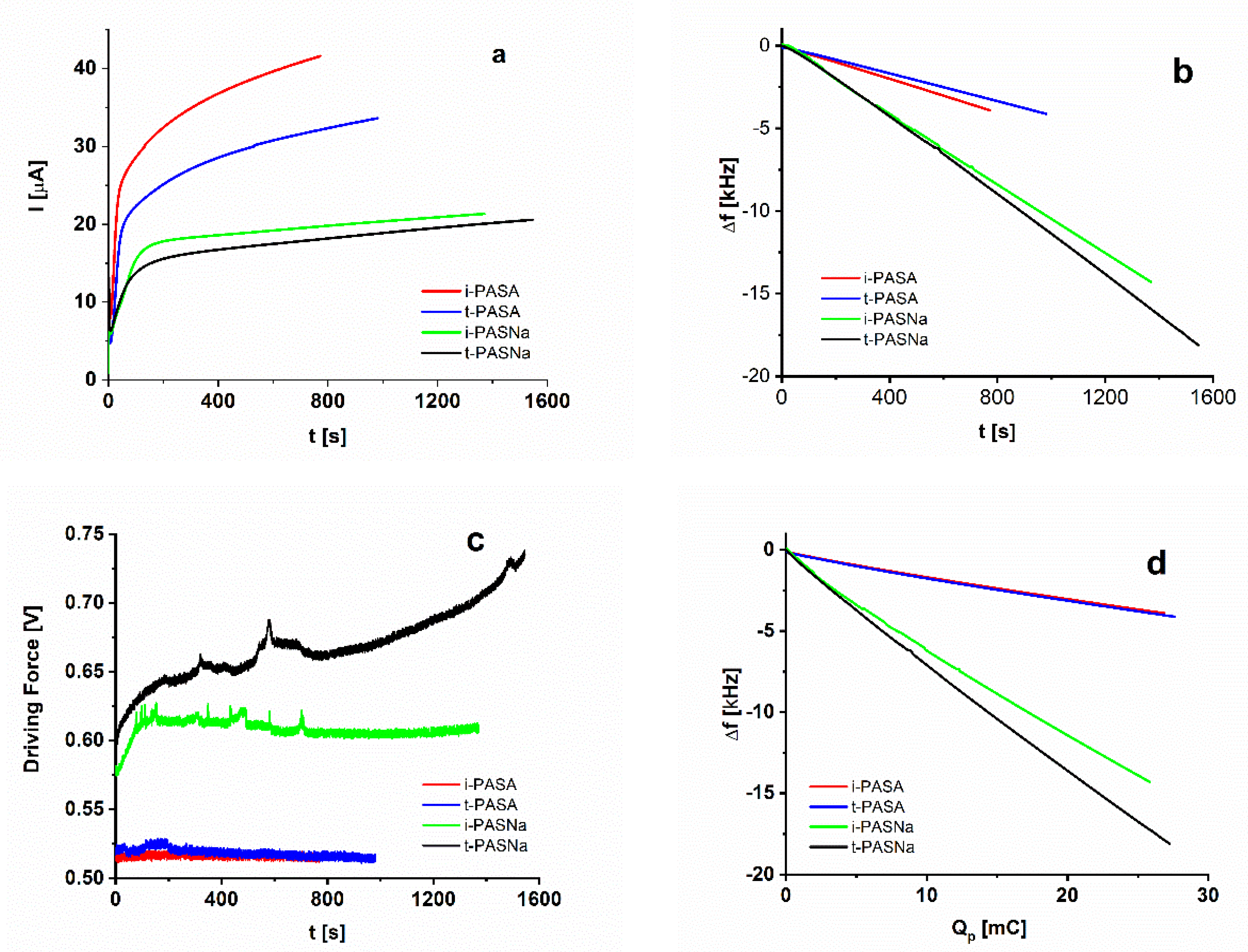

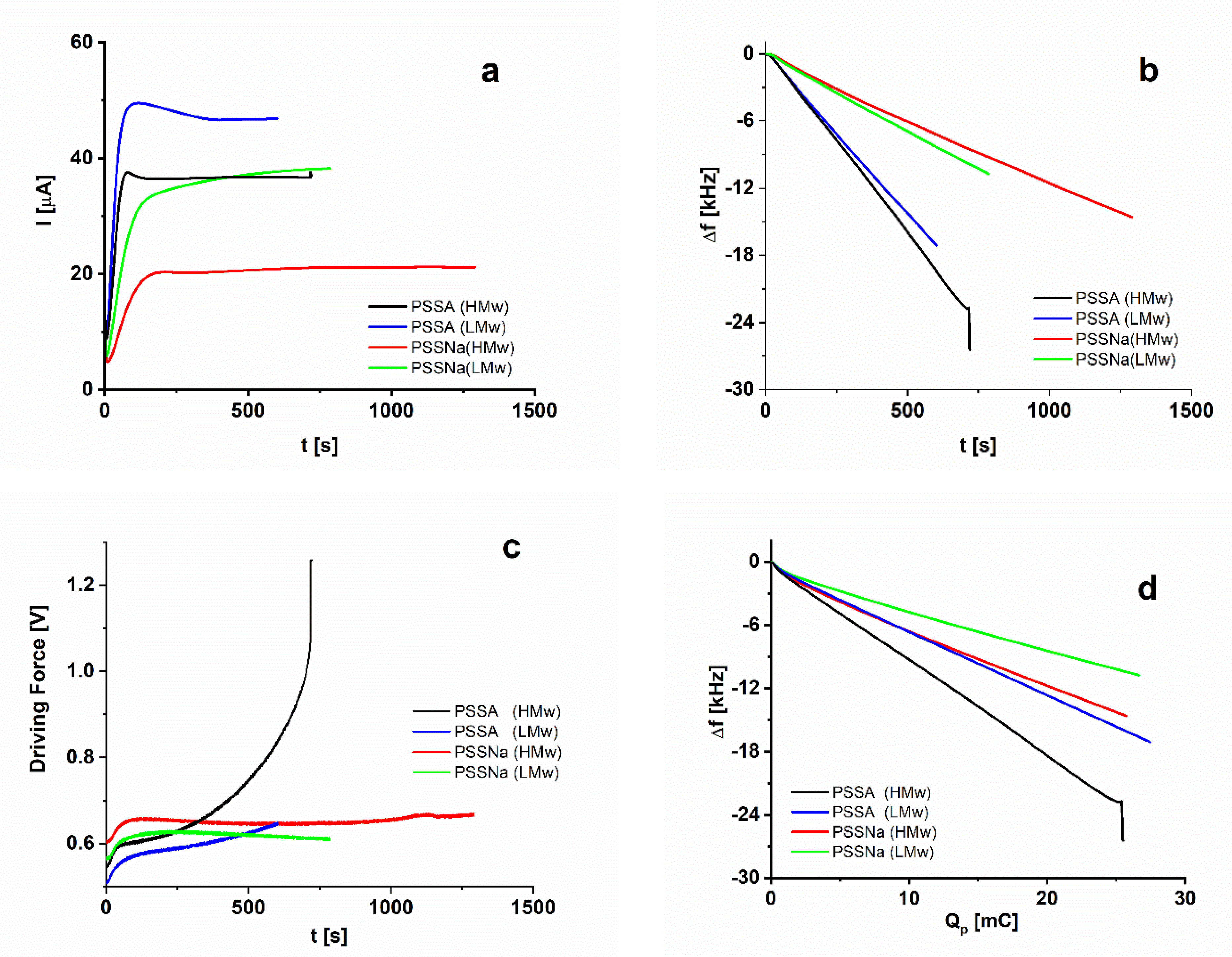

3.1. Electrochemical Polymerization

3.2. XPS Studies

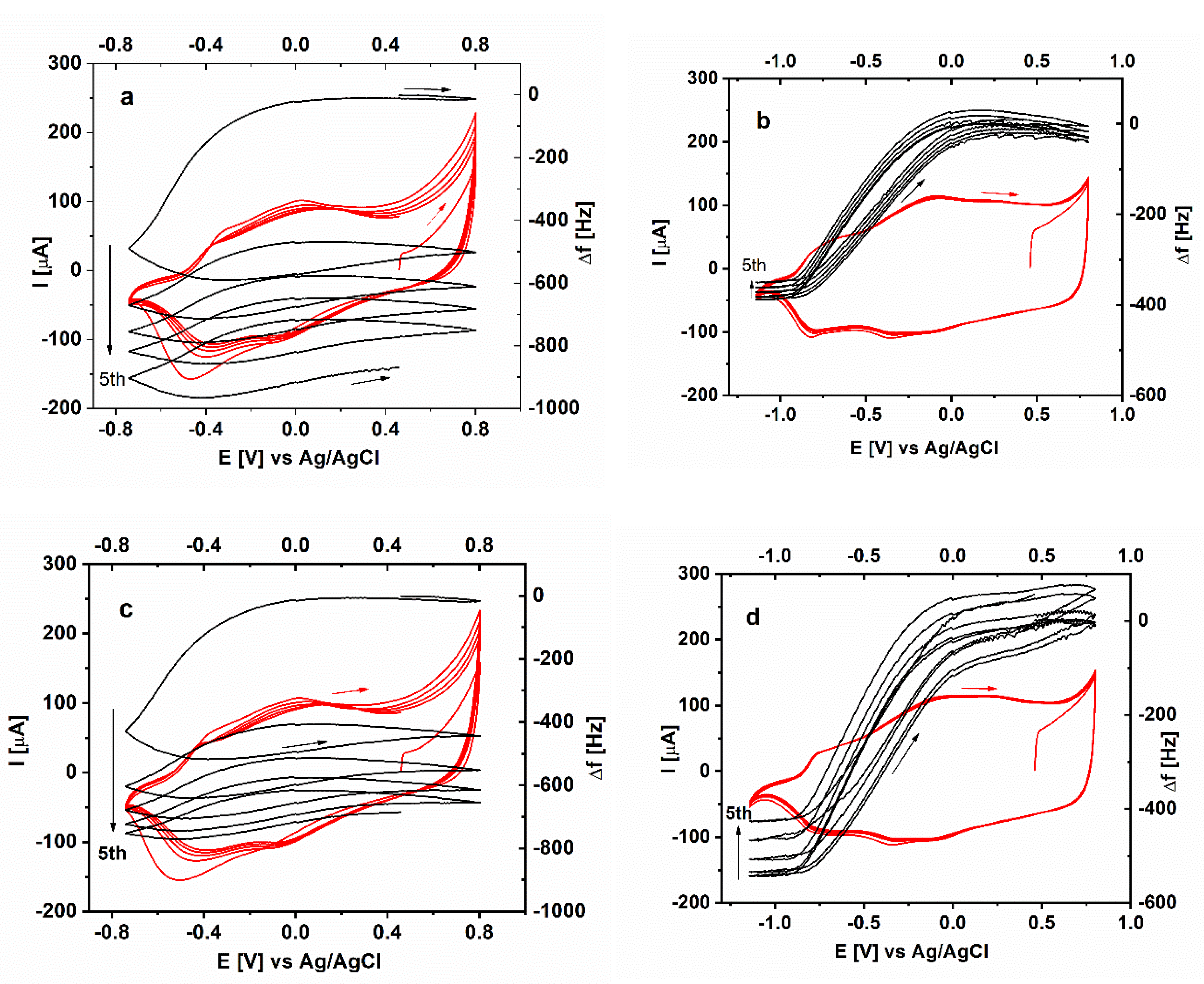

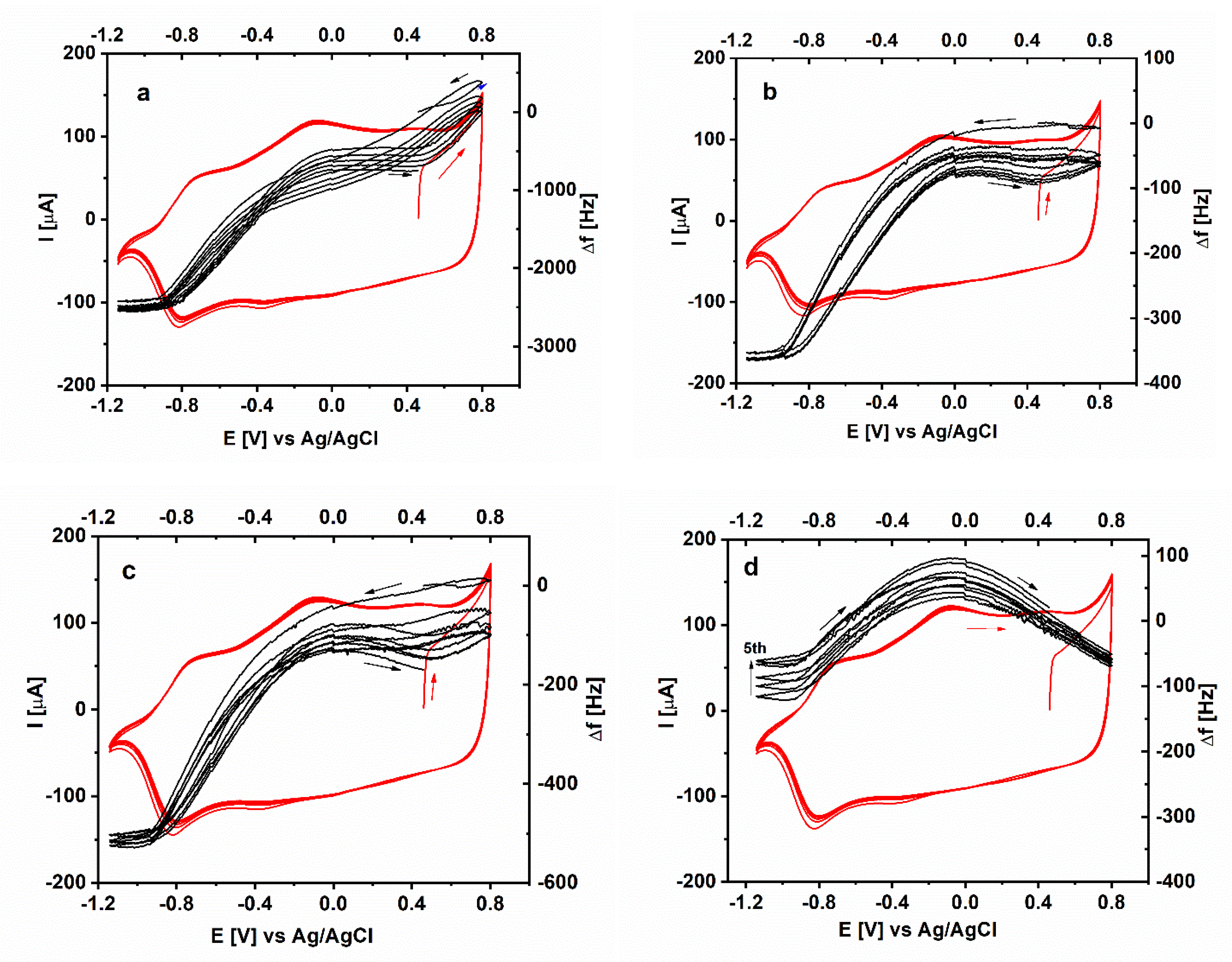

3.3. Electrochemical Redox Activity—EQCM Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hui, Y.; Bian, C.; Xia, S.; Tong, J.; Wang, J. Synthesis and electrochemical sensing application of poly(3,4-ethylenedioxythiophene)-based materials: A review. Analyt. Chim. Acta 2018, 1022, 1–19. [Google Scholar] [CrossRef]

- Hu, L.; Song, J.; Yin, X.; Su, Z.; Li, Z. Research progress on polymer solar cells based on PEDOT:PSS Electrodes. Polymers 2020, 12, 145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Donahue, M.J.; Sanchez-Sanchez, A.; Inal, S.; Qud, J.; Owens, R.M.; Mecerreyes, D.; Malliaras, G.G.; Martin, D.C. Tailoring PEDOT properties for applications in bioelectronics. Mater. Sci. Eng. R 2020, 140, 100546. [Google Scholar] [CrossRef] [Green Version]

- Boehler, C.; Aqrawe, Z.; Asplund, M. Applications of PEDOT in bioelectronics medicine. Bioelectron. Med. 2019, 2, 89–99. [Google Scholar] [CrossRef] [Green Version]

- Tseghai, G.B.; Mengistie, D.A.; Malengier, B.; Fante, K.A.; Van Langenhove, L. PEDOT:PSS–Based conductive textiles and their applications. Sensors 2020, 20, 1881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gueyea, M.N.; Carella, A.; Faure-Vincent, J.; Demadrillec, R.; Simonato, J.-P. Progress in understanding structure and transport properties of PEDOT-based materials: A critical review. Progr. Mater. Sci. 2020, 108, 100616. [Google Scholar] [CrossRef]

- Spanning, S.A.; Martin, D.C.; Chen, Z. X-ray photoelectron spectroscopy study of counterion incorporation in poly(3,4-ethylenedioxythiophene). J. Phys. Chem. C 2009, 113, 5585–5592. [Google Scholar] [CrossRef]

- Spanning, S.A.; Martin, D.C.; Chen, Z. X-ray photoelectron spectroscopy study of counterion incorporation in poly(3,4-ethylenedioxythiophene), 2: Polyanion effect, toluenesulfonate, and small anions. J. Phys. Chem. C 2020, 114, 14992–14997. [Google Scholar] [CrossRef]

- King, Z.A.; Shaw, C.M.; Spanning, S.A.; Martin, D.C. Structural, chemical and electrochemical characterization of poly(3,4-ethylenedioxythiophene) (PEDOT) prepared with various counter-ions and heat treatments. Polymer 2011, 52, 1302–1308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nasybulin, E.; Wei, S.; Kymissis, I.; Levon, K. Effect of solubilizing agent on properties of poly(3,4-ethylenedioxythiophene) (PEDOT) electrodeposited from aqueous solution. Electrochim. Acta 2012, 78, 638–643. [Google Scholar] [CrossRef]

- Lyutov, V.; Efimov, I.; Bund, A.; Tsakova, V. Electrochemical polymerization of 3,4-ethylenedioxythiophene in the presence of dodecylsulfate and polysulfonic anions—An acoustic impedance study. Electrochim. Acta 2014, 122, 21–27. [Google Scholar] [CrossRef]

- Lyutov, V.; Gruia, V.; Efimov, I.; Bund, A.; Tsakova, V. An acoustic impedance study of PEDOT layers obtained in aqueous solution. Electrochim. Acta 2016, 190, 285–293. [Google Scholar] [CrossRef]

- Gribkova, O.L.; Mitina, N.E.; Nekrasov, A.A.; Ivanov, V.F.; Tverskoi, V.A.; Tameev, A.R.; Vannikov, A.V. Complexes of poly-3,4-ethylenedioxythiophene with polymeric sulfonic acids of different structures: Synthesis and optical and electric properties. Protect. Met. Phys. Chem. Surf. 2015, 51, 390–395. [Google Scholar] [CrossRef]

- Gribkova, O.L.; Iakobson, O.D.; Nekrasov, A.A.; Cabanova, V.A.; Tverskoy, V.A.; Vannikov, A.V. The influence of polyacid nature on poly(3,4-ethylenedioxythiophene) electrosynthesis and its spectroelectrochemical properties. J. Solid State Electrochem. 2016, 20, 2991–3001. [Google Scholar] [CrossRef]

- Gribkova, O.L.; Iakobson, O.D.; Nekrasov, A.A.; Cabanova, V.A.; Tverskoy, V.A.; Tameev, A.R.; Vannikov, A.V. Ultraviolet-Visible-Near Infrared and Raman spectroelectrochemistry of poly(3,4-ethylenedioxythiophene) complexes with sulfonated polyelectrolytes. The role of inter- and intra-molecular interactions in polyelectrolyte. Electrochim. Acta 2016, 222, 409–420. [Google Scholar] [CrossRef]

- Iakobson, O.D.; Gribkova, O.L.; Nekrasov, A.A.; Vannikov, A.V. The effect of counterion in polymer sulfonates on the synthesis and properties of poly-3,4-ethylenedioxythiophene. Russ. J. Electrochem. 2016, 52, 1191–1201. [Google Scholar] [CrossRef]

- Ispas, A.; Peipmann, R.; Adolphi, B.; Efimov, I.; Bund, A. Electrodeposition of pristine and composite poly(3,4-ethylenedioxythiophene) layers studied by electro-acoustic impedance measurements. Electrochim. Acta 2011, 56, 3500–3506. [Google Scholar] [CrossRef]

- Checkol, F.; Elfwing, A.; Greczynski, G.; Mehretie, S.; Inganäs, O.; Admassie, S. Highly Stable and Efficient Lignin-PEDOT/PSS Composites for Removal of Toxic Metals. Adv. Sustain. Syst. 2017, 2, 1700114. [Google Scholar] [CrossRef]

- Jarvis, J.M.; Guzinski, M.; Perez, F.; Pendley, B.D.; Lindner, E. Differences in electrochemically deposited PEDOT(PSS) films on Au and Pt substrate electrodes: A quartz crystal microbalance study. Electroanalysis 2017, 29, 1–7. [Google Scholar] [CrossRef]

- Savva, A.; Wustoni, S.; Inal, S. Ionic-to-electronic coupling efficiency in PEDOT:PSS films operated in aqueous electrolytes. J. Mater.Chem. C 2018, 6, 12023–12030. [Google Scholar] [CrossRef] [Green Version]

- Kirch, Y.E.; Fedetov, Y.A.; Iudina, N.A.; Artemov, D.Y.; Yanul’, N.A.; Nekrasova, T.N. On polyelectrolyte properties of sulfo-containing polyamides on the base of iso- and terephthalic acids in aqueous solution. Vysokomol. Soedin. Seriya A 1991, 33, 1127–1133. [Google Scholar]

- Chu, E.Y.; Xu, Z.S.; Lee, C.M.; Sek, C.K.F.; Okamoto, Y.; Pearce, E.M.; Kwei, T.K. Aggregation of sulfonated poly (p-phenylene terephthalamide) in dilute solutions. J. Polym. Sci. Part B Polym. Phys. 1995, 33, 71–75. [Google Scholar] [CrossRef]

- Mochizuki, Y.; Horii, T.; Okuzaki, H. Effect of pH on Structure and Conductivity of PEDOT/PSS. Trans. Met. Res. Soc. Jpn. 2012, 37, 307–310. [Google Scholar] [CrossRef] [Green Version]

- Pang, F.-F.; Li, S.; Sun, W.-Q.; Han, G.-Z. Reversible conductivity modulation of PEDOT:PSS based on pH. Mater. Chem. Phys. 2017, 186, 246–250. [Google Scholar] [CrossRef]

- Modarresi, M.; Franco-Gonzalez, J.F.; Zozoulenko, I. Computational microscopy study of the granular structure and pH dependence of PEDOT:PSS. Phys. Chem. Chem. Phys. 2019, 21, 6699–6711. [Google Scholar] [CrossRef] [Green Version]

- Modarresi, M.; Mehandzhiyski, A.; Fahlman, M.; Tybrandt, K.; Zozoulenko, I. Microscopic understanding of the granular Structure and the Swelling of PEDOT:PSS. Macromolecules 2020, 53, 6267–6278. [Google Scholar] [CrossRef]

- Greczynski, G.; Kugler, T.; Salaneck, W.R. Characterization of the PEDOT-PSS system by means of X-ray and ultraviolet photoelectron spectroscopy. Thin Solid Film. 1999, 354, 129–135. [Google Scholar] [CrossRef]

- Greczynski, G.; Kugler, T.; Keil, M.; Osikowicz, W.; Fahlman, M.; Salaneck, W.R. Photoelectron spectroscopy of thin films of PEDOT—PSS conjugated polymer blend: A mini-review and some new results. J. Electron Spectr. Relat. Phenom. 2001, 121, 1–17. [Google Scholar] [CrossRef]

- Zotti, G.; Zecchin, S.; Schiavon, G.; Louwet, F.; Groenendaal, L.; Crispin, X.; Osikowicz, W.; Salaneck, W.; Fahlman, M. Electrochemical and XPS Studies toward the role of monomeric and polymeric sulfonate counterions in the synthesis, composition, and properties of poly(3,4-ethylenedioxythiophene). Macromolecules 2003, 36, 3337–3344. [Google Scholar] [CrossRef]

- Vitoratos, E.; Sakkopoulos, S.; Dalas, E.; Paliatsas, N.; Karageorgopoulos, D.; Petraki, F.; Kennou, S.; Choulis, S.A. Thermal degradation mechanisms of PEDOT:PSS. Org. Electron. 2009, 10, 61–66. [Google Scholar] [CrossRef]

- Zotti, G.; Schiavon, G.; Zecchin, S. Irreversible processes in the electrochemical reduction of polythiophenes. Chemical modifications of the polymer and charge-trapping phenomena. Synth. Met. 1995, 72, 275–281. [Google Scholar] [CrossRef]

- Semenikhin, O.; Ovsyannikova, E.; Ehrenburg, M.; Alpatova, N.; Kazarinov, V. Electrochemical and photoelectrochemical behaviour of polythiophenes in non-aqueous solutions. J. Electroanal. Chem. 2000, 494, 1–11. [Google Scholar] [CrossRef]

- Ivanov, V.F.; Gribkova, O.L.; Novikov, S.V.; Nekrasov, A.A.; Isakova, A.A.; Vannikov, A.V.; Meshkov, G.B.; Yaminsky, I.V. Redox heterogeneity in polyaniline films: From molecular to macroscopic scale. Synth. Met. 2005, 152, 153–156. [Google Scholar] [CrossRef]

- O’Neil, K.D.; Semenikhin, O.A. AFM Phase imaging of electropolymerized polybithiophene films at different stages of their growth. J. Phys. Chem. C 2007, 111, 14823–14832. [Google Scholar]

- Lyutov, V.; Kabanova, V.; Gribkova, O.; Nekrasov, A.; Tsakova, V. Electrochemically-obtained polysulfonic-acids doped polyaniline films—A comparative study by electrochemical, microgravimetric and XPS methods. Polymers 2020, 12, 1050. [Google Scholar] [CrossRef]

- Cameron, J.; Skabara, P.J. The damaging effects of the acidity in PEDOT:PSS on semiconductor device performance and solutions based on non-acidic alternatives. Mater. Horiz. 2020, 7, 1759–1772. [Google Scholar] [CrossRef] [Green Version]

| Dopant | −Δf (kHz) | d Δf/dQp (kHz/mC) | Intercept (kHz) | R2 |

|---|---|---|---|---|

| i-PASA | 3.900 | −0.140 | −0.130 | 0.9981 |

| t-PASA | 4.117 | −0.143 | −0.167 | 0.9977 |

| PSSA (LMw) | 17.087 | −0.609 | −0.480 | 0.9996 |

| PSSA (HMw) | 22.784 | −0.904 | −0.286 | 0.9991 |

| i-PASNa | 14.290 | −0.547 | −0.513 | 0.9975 |

| t-PASNa | 18.094 | −0.660 | −0.385 | 0.9994 |

| PSSNa (LMw) | 10.747 | −0.388 | −0.697 | 0.9996 |

| PSSNa (HMw) | 14.624 | −0.546 | −0.902 | 0.9964 |

| S (PEDOT) | S (PEDOT+SO3−) | S (Na+SO3−) | S (H+SO3−) |

|---|---|---|---|

| 164.1 | 165.4 | 167.7 | 168.1 |

| 165.2 | 166.5 | 168.9 | 169.2 |

| Dopant | S (PEDOT) (% of S) | S (PEDOT+SO3−) (% of S) | S (Na+SO3−) (% of S) | S (H+SO3−) (% of S) | OL * (XPS) | y | DL ** S-Based | DL *** N-Based |

|---|---|---|---|---|---|---|---|---|

| i-PASA | 58.6 | 10.8 | - | 30.6 | 0.18 | 0.16 | 0.71 | 0.64 |

| t-PASA | 56.4 | 14.5 | - | 29.1 | 0.26 | 0.17 | 0.77 | 0.77 |

| PSSA (HMw) | 45.0 | 20.2 | - | 34.8 | 0.45 | 0.27 | 1.22 | - |

| i-PASNa | 47.8 | 17.6 | 11.2 | 23.4 | 0.37 | 0.25 | 1.09 | 1.25 |

| t-PASNa | 46.3 | 17.5 | 10.1 | 26.1 | 0.38 | 0.23 | 1.16 | 1.40 |

| PSSNa (HMw) | 47.2 | 16.8 | 8.5 | 27.5 | 0.36 | 0.23 | 1.12 |

| Dopant | M (XPS-Based) * (g/mol) | M (EQCM-Based) ** (g/mol) |

|---|---|---|

| i-PASA | 307.64 | 214.05 |

| t-PASA | 323.41 | 219.31 |

| PSSA (HMw) | 365.09 | 1548.29 |

| i-PASNa | 411.03 | 1020.46 |

| t-PASNa | 427.84 | 1042.83 |

| PSSNa (HMw) | 370.64 | 1297.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyutov, V.; Kabanova, V.; Gribkova, O.; Nekrasov, A.; Tsakova, V. Electrochemically Obtained Polysulfonates Doped Poly(3,4-ethylenedioxythiophene) Films—Effects of the Dopant’s Chain Flexibility and Molecular Weight Studied by Electrochemical, Microgravimetric and XPS Methods. Polymers 2021, 13, 2438. https://doi.org/10.3390/polym13152438

Lyutov V, Kabanova V, Gribkova O, Nekrasov A, Tsakova V. Electrochemically Obtained Polysulfonates Doped Poly(3,4-ethylenedioxythiophene) Films—Effects of the Dopant’s Chain Flexibility and Molecular Weight Studied by Electrochemical, Microgravimetric and XPS Methods. Polymers. 2021; 13(15):2438. https://doi.org/10.3390/polym13152438

Chicago/Turabian StyleLyutov, Vladimir, Varvara Kabanova, Oxana Gribkova, Alexander Nekrasov, and Vessela Tsakova. 2021. "Electrochemically Obtained Polysulfonates Doped Poly(3,4-ethylenedioxythiophene) Films—Effects of the Dopant’s Chain Flexibility and Molecular Weight Studied by Electrochemical, Microgravimetric and XPS Methods" Polymers 13, no. 15: 2438. https://doi.org/10.3390/polym13152438

APA StyleLyutov, V., Kabanova, V., Gribkova, O., Nekrasov, A., & Tsakova, V. (2021). Electrochemically Obtained Polysulfonates Doped Poly(3,4-ethylenedioxythiophene) Films—Effects of the Dopant’s Chain Flexibility and Molecular Weight Studied by Electrochemical, Microgravimetric and XPS Methods. Polymers, 13(15), 2438. https://doi.org/10.3390/polym13152438